8. Open Source Hardware - From Fibers to Fabric¶

This week has been

...

In a good way. Just read on and you will understand.

After presentations of Mar Canet & Varvara Guljajeva we had many ideas of what we could work on, but little did we know, our lab already thought that through and suggested making a multipurpose machine which was developed during the first lockdown and who knows when the next one will start, so better be safe than sorry, right?

We really enjoy working together and this time we worked also with our mentors at the FabLabBcn as well as some other students, which made the making process more lively and we were able to share the tips and tricks he to assemble it, since some parts of the design had to be changed, after all, it is a work-in-progress project and not everything can be updated as soon as the changes are made.

SPML a.k.a SixPackMobileLab or SimplePersonalMiniLab¶

Spoiler Alert This is our final (for now) version of the machine!

What is SPML?

--

SPML is a fabbable and open source mini machine,which bode can lasercutted or 3dprinted and with fully Fabable electronics boards. This is a 3 axis machine with a tool work area of 100x100x80mm and exterior footprint of 150x150x200 (almost the same as a pack of six cans) that make it really portable,lightweight and extremely low cost.

What is SPML?

--

SPML is a fabbable and open source mini machine,which bode can lasercutted or 3dprinted and with fully Fabable electronics boards. This is a 3 axis machine with a tool work area of 100x100x80mm and exterior footprint of 150x150x200 (almost the same as a pack of six cans) that make it really portable,lightweight and extremely low cost.

The story¶

This pico machine started as a project to make a fab academy kit machine to help the students develope their FabAcademy assignments during the COVID-19 confinement.

This machine was inspired by the pico dvdroom recycled motor based machine DIY projects but translated to a fablab environment was designed by Eduardo Chamorro Martin, Oscar Gonzalez and Josep Marti in Fab Lab Barcelona 2020.

It is a 1.0 version with 3 different models (3mm closed case, 5mm closed case,5mm open case)

Closed Case on the left - OpenCase on the right

There is two options for fabrication: lasercutted/3dprinted.

Closed Case on the left - OpenCase on the right

There is two options for fabrication: lasercutted/3dprinted.

Main features of this version are:

- Low material usage,body can be fabricated with a 600x400x3 board

- Uses low current motors so could be driven with 5v

- 100% compatible with default Arduino IDE

- Fabbable electronics (fablab inventory components)

- ESP32 control board with usb-wifi-bluetooth control

- Modular tool head (laser and cnc)

- Standart GCODE control

- Accurate upto 0.1mm

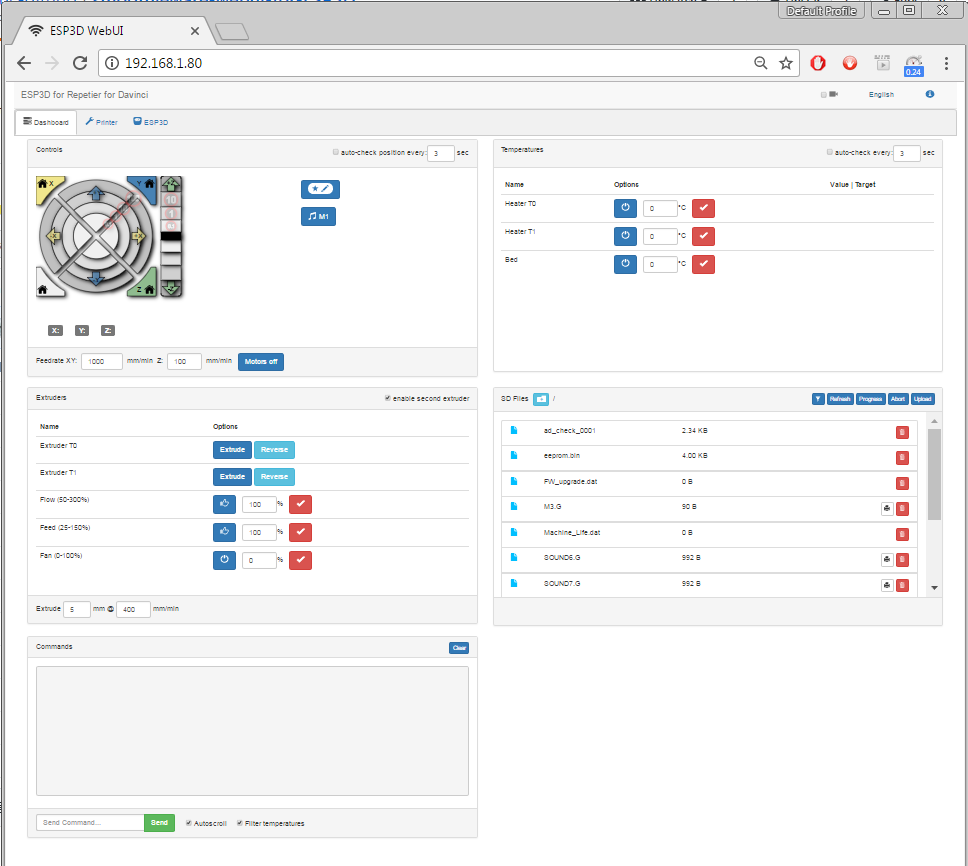

- Self Publish Web Control interface,no need to install a control software

- Compact(can be carried in a backpack) and lightweight <2kg

- Tiny linear motion system that reduces the total cost to <60 euros.

- Open case version(better for modifications) or closed(better for travelling)

- Modular electronics.Base BARDUINO BOARD + CUSTOM CNC SHIELD

- Integrated one hole in the base to clean up the dust accumulated in the base

- High mobility, ability to be run on batteries.

This has been the evolution of the machine until now:

Main features of this version are:

- Low material usage,body can be fabricated with a 600x400x3 board

- Uses low current motors so could be driven with 5v

- 100% compatible with default Arduino IDE

- Fabbable electronics (fablab inventory components)

- ESP32 control board with usb-wifi-bluetooth control

- Modular tool head (laser and cnc)

- Standart GCODE control

- Accurate upto 0.1mm

- Self Publish Web Control interface,no need to install a control software

- Compact(can be carried in a backpack) and lightweight <2kg

- Tiny linear motion system that reduces the total cost to <60 euros.

- Open case version(better for modifications) or closed(better for travelling)

- Modular electronics.Base BARDUINO BOARD + CUSTOM CNC SHIELD

- Integrated one hole in the base to clean up the dust accumulated in the base

- High mobility, ability to be run on batteries.

This has been the evolution of the machine until now:

Update on ELECTRONIC CONTROLBOARD - Barduino+CNCShield+Casing

OUR EXPERIENCE**

Update on ELECTRONIC CONTROLBOARD - Barduino+CNCShield+Casing

OUR EXPERIENCE**

Making process of the Machine

BALLPEN TEST

MARKER TEST

??? note "Hardware" - 3x motor+rail systems 100mm microsteppers we choose this as the power train due to its small size,power consumption,travel and cost. - 1x dc motor rs555Standart 555 size dc motor up to 17.000rpm at 12v - 1x simple collet 3.175mm to 3.175mm - 3x microendstopAny normal 3d printer endstop will work we choose a small one to make it easier to fit. - 3x stepper drivers a4988 - screw set 3mmWe choose this kit as it contains all the screws needed(in particular we need :30 x m3-20mm screws + 30 x m3nuts) - 1x power supply 12v 6a eu plug - screws flathead m2We choose this kit as it contains all the screws needed(in particular we need :20 x m2-8mm screws) IMPORTANT, THESE SCREWS ARE FLATHEAD!! - nuts screw m2We choose this kit as it contains all the screws needed(in particular we need :20 x m2-nuts) - 600x400x3/5mm material(our choice was acrylic)This material opcion is the most expensive one to look for an alternative you can use mdf boards ??? note "Electronics" All the electronic components are standard fabacademy inventory - 1x WIFI MODULE 32MBITS SPI FLASH - 1x RES 10.0K OHM 1/4W 1% 1206 SMD - 1x SWITCH TACT SMD W-GND 160GF - 2x CAP CER 10UF 35V Y5V 1206 - 1x IC REG LDO 3.3V 1A SOT223-3 - 2x LED RED CLEAR 1206 SMD - 2x RES 100 OHM 1/4W 1% 1206 SMD - 1x SWITCH SLIDE SPDT 12V 100MA GW- - 1x CAP CERAMIC .1UF 250V X7R 1206 ??? note "What you will find in this repo" - Kicad Design Files + fab library + esp32 library + Design Rules - GRBL firmware + WebUi - Png files for producing the boards - Diagrams of connections - Libraries install for arduino - Lasercutter ready files for 3 and 5mm material - 3d stl files in case you want to 3d print the casing(you need a least a 220x220 3d printer) ??? note "ControlBoards" Currently, the control boards are under development. It's based on an Barduino (ESP32) with micro usb. Barduino: - Kicad Barduino sch - Kicad Barduino brd - Kicad Barduinolibraries ESP32 Barduino CNC Shield: - Kicad Barduino Shield Sch - Kicad Barduino Shield brd ??? note "CNC" - Laser Cutter File 5mm version - 3dFile- Backplate - 3dFile- Base - 3dFile- cuttingplate - 3dFile- frontplate - 3dFile- motorholder - 3dFile- sideplate x2 - 3dFile- top

Arduino ESP32 LibrariesRequired¶

http://arduino.esp8266.com/stable/package_esp8266com_index.json

https://raw.githubusercontent.com/espressif/arduino-esp32/gh-pages/package_esp32_index.json

https://dl.espressif.com/dl/package_esp32_index.json

Using GRBLESP32¶

SelfPublish web interface to control the machine through the browser via wifi or bluetooth through a cncgbrl app.

How to generate Gcode from Inkscape

Rhino & Gcode Process¶

We recommend you to use a Gcode visualizer before sending the Files to the machine. We have recompiled this minimalistic version LINK TO Gcode WebVisualizer MORE PHOTOS ON DRIVE

Special Thanks goes to :¶

- eduardo.chamorro@iaac.net

- oscar@fablabbcn.org

- josep@fablabbcn.org