12| Soft robotics¶

Research¶

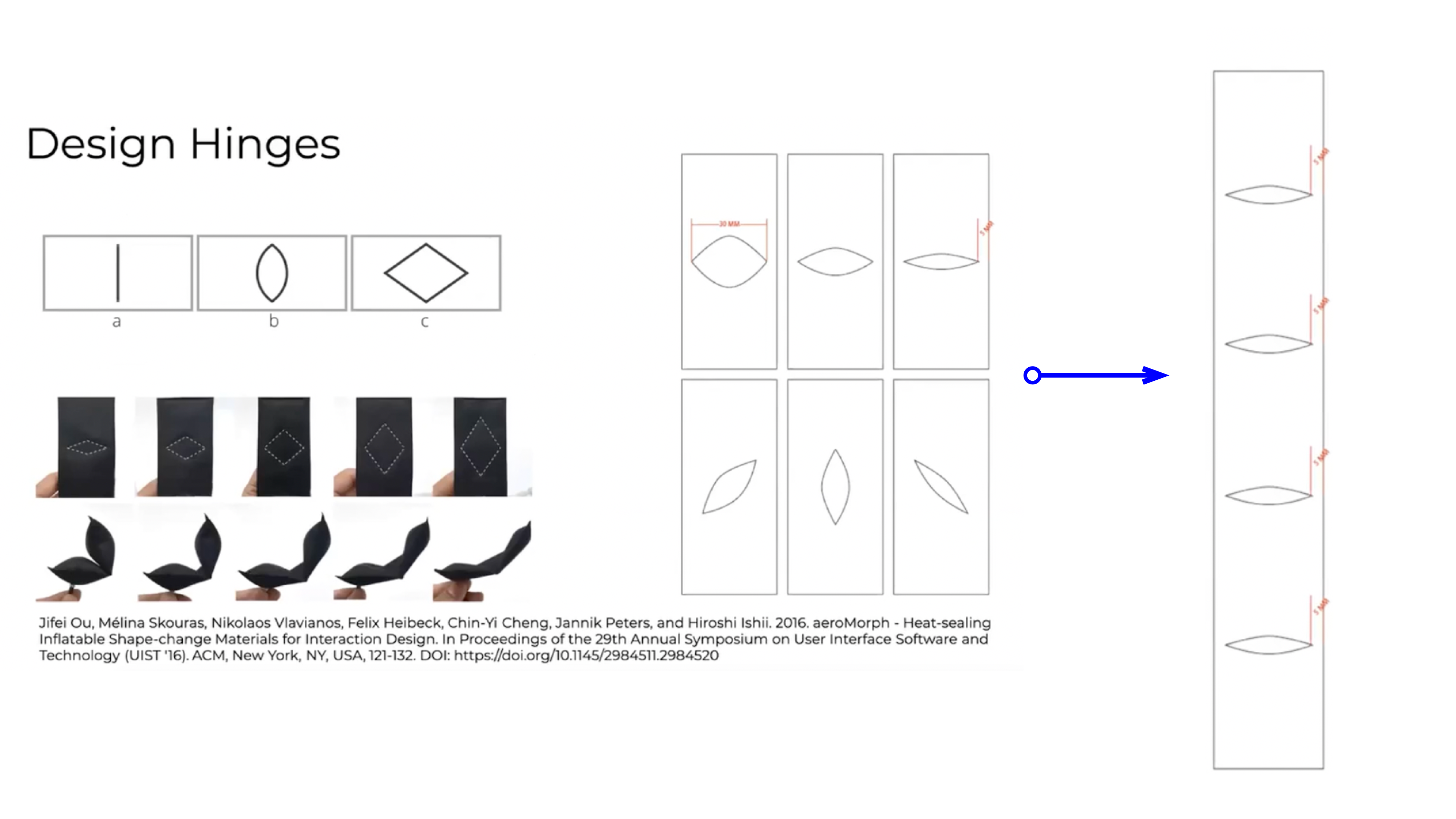

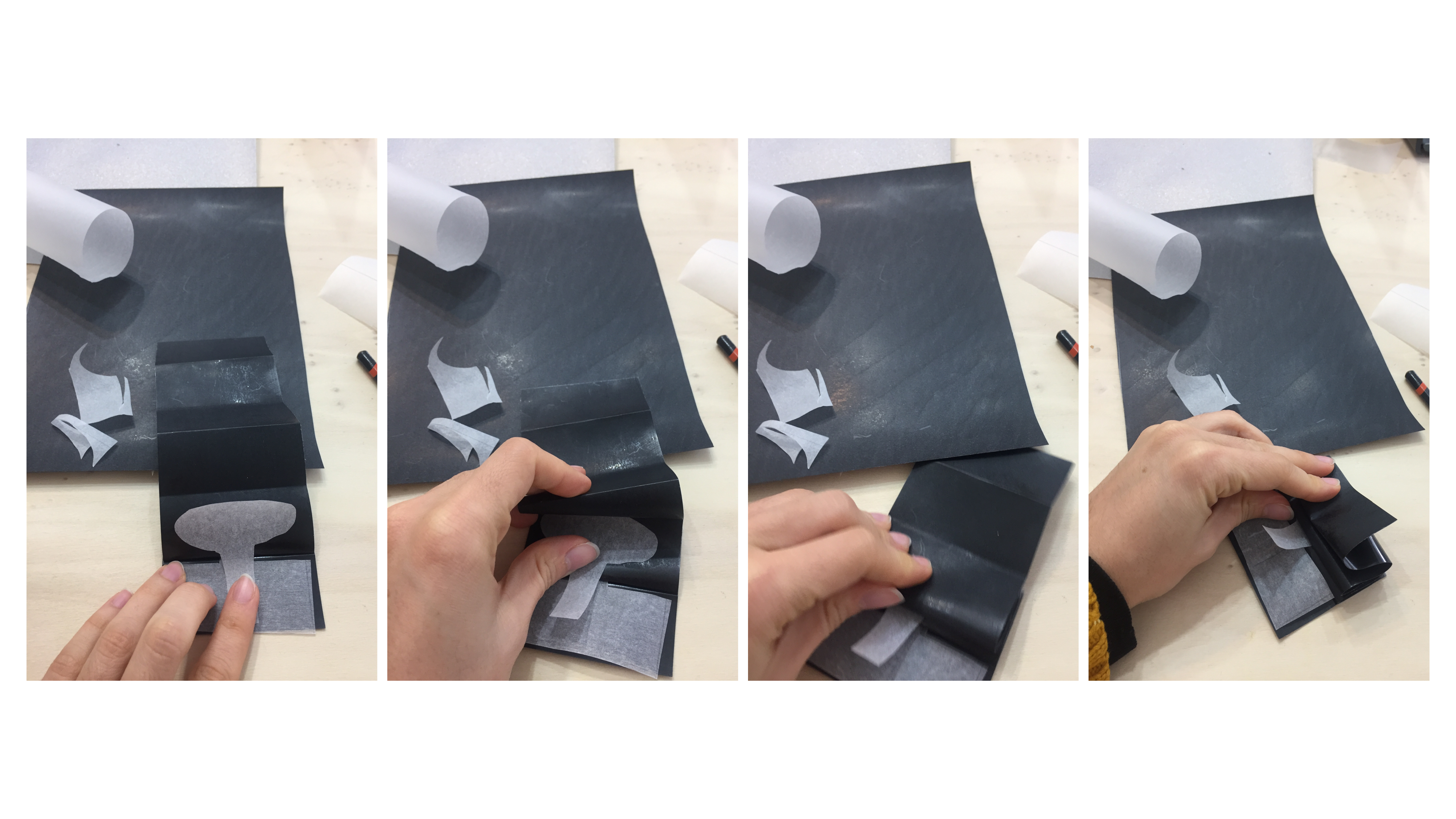

Heat sealing¶

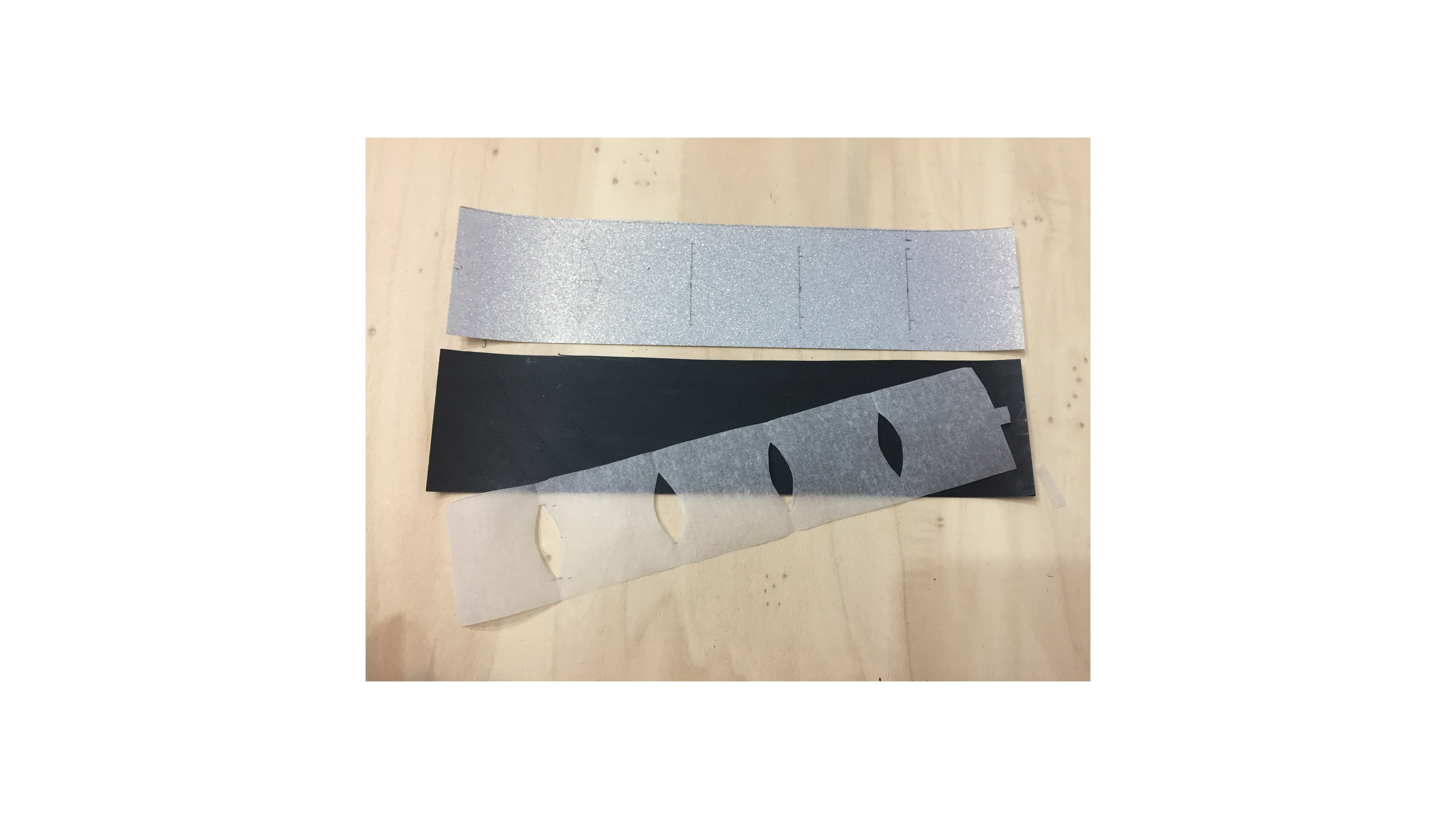

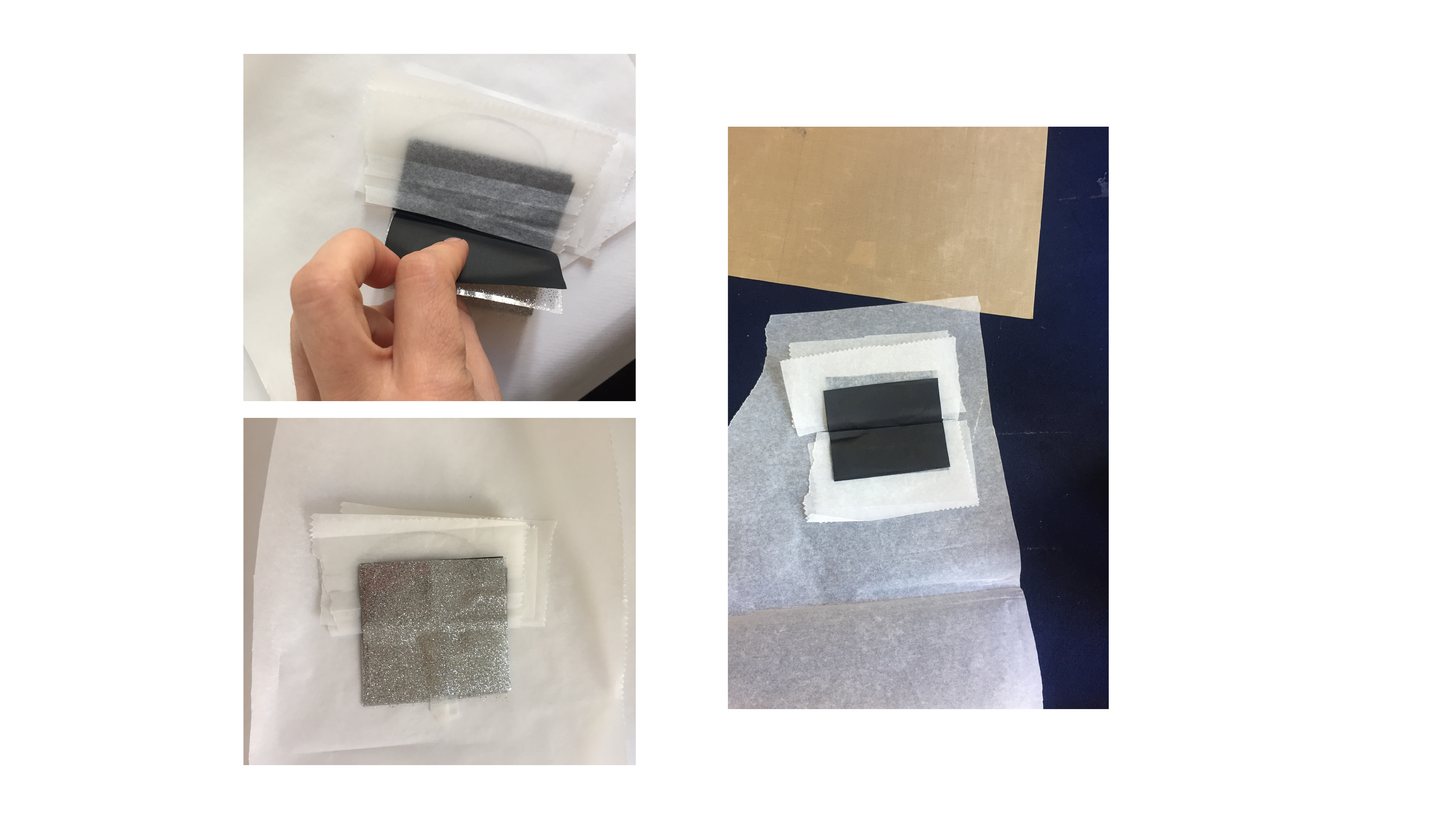

For this prototypes I used heat sealing material - sheet of polyurethane that have one side that stick when heated

To heat and seal the patterns we used an iron and some parchment papers to proptect the iron and table so that the material do not stick to other things.

Note: do not heat it too much or it could make holes in the material - (put the iron on "synthetic" and heat for approximately 1min...)

The parchment paper is used to prevent the material to stick in between - this is where air compartments will be inflated.

The more compartiments the more air you will need to inflate it. So a bigger air pump can be necessary in some cases.

I proptotyped 2 different patterns:

Flat 2D pattern¶

I took the pattern shown during the lecture and multiply it to obtain the pattern on the the pattern on the right:

Once sealed, this is the result:

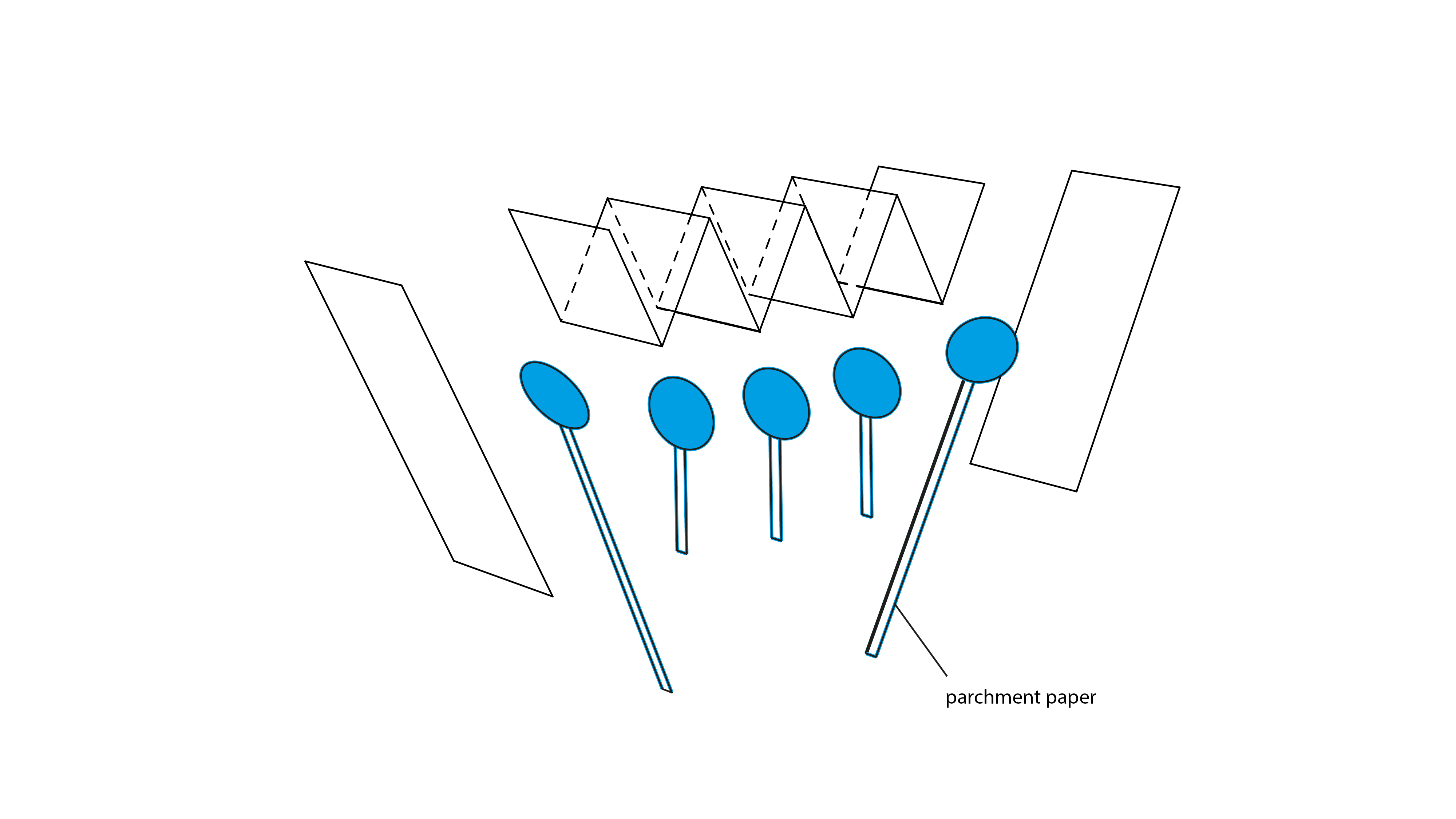

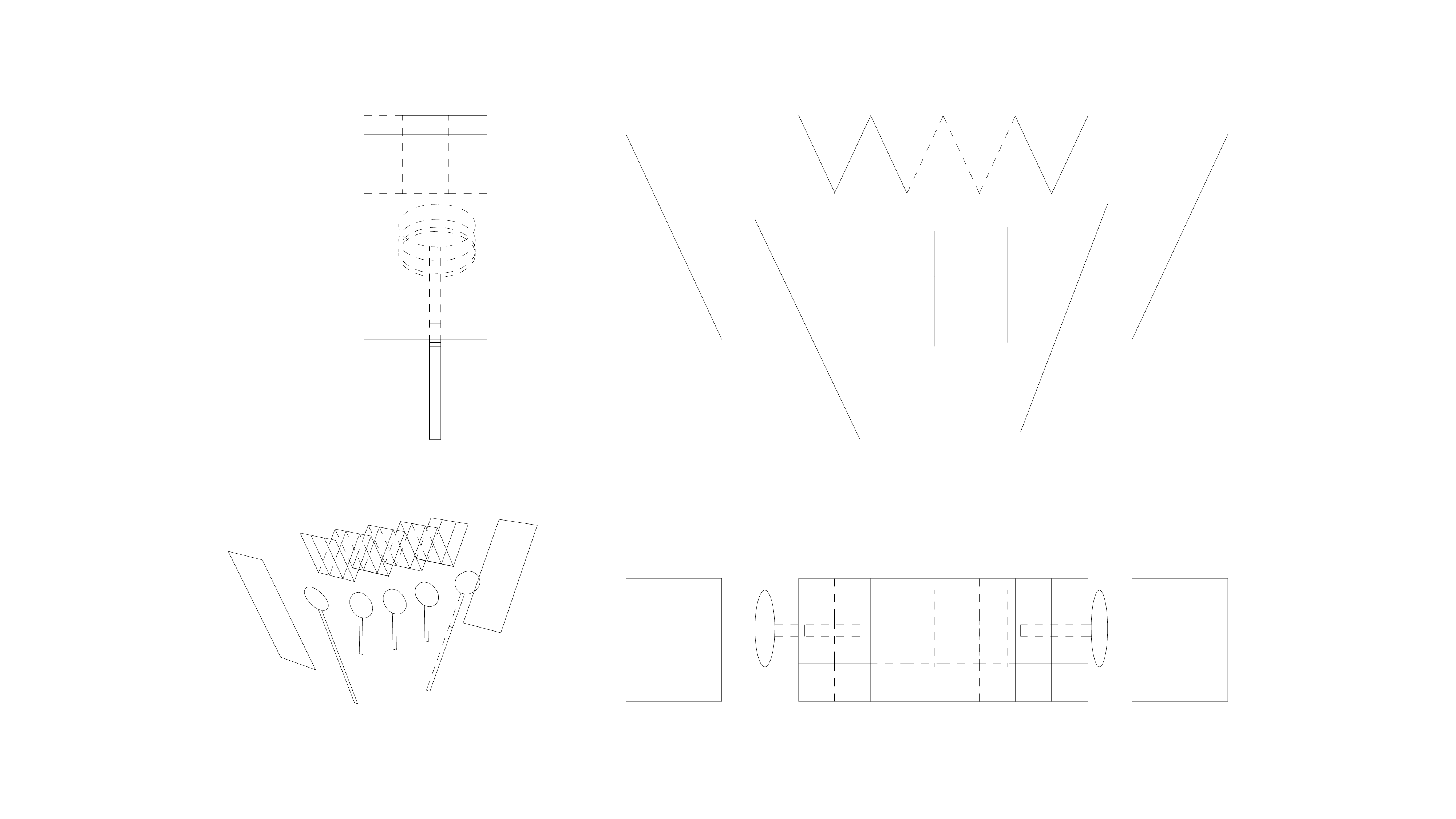

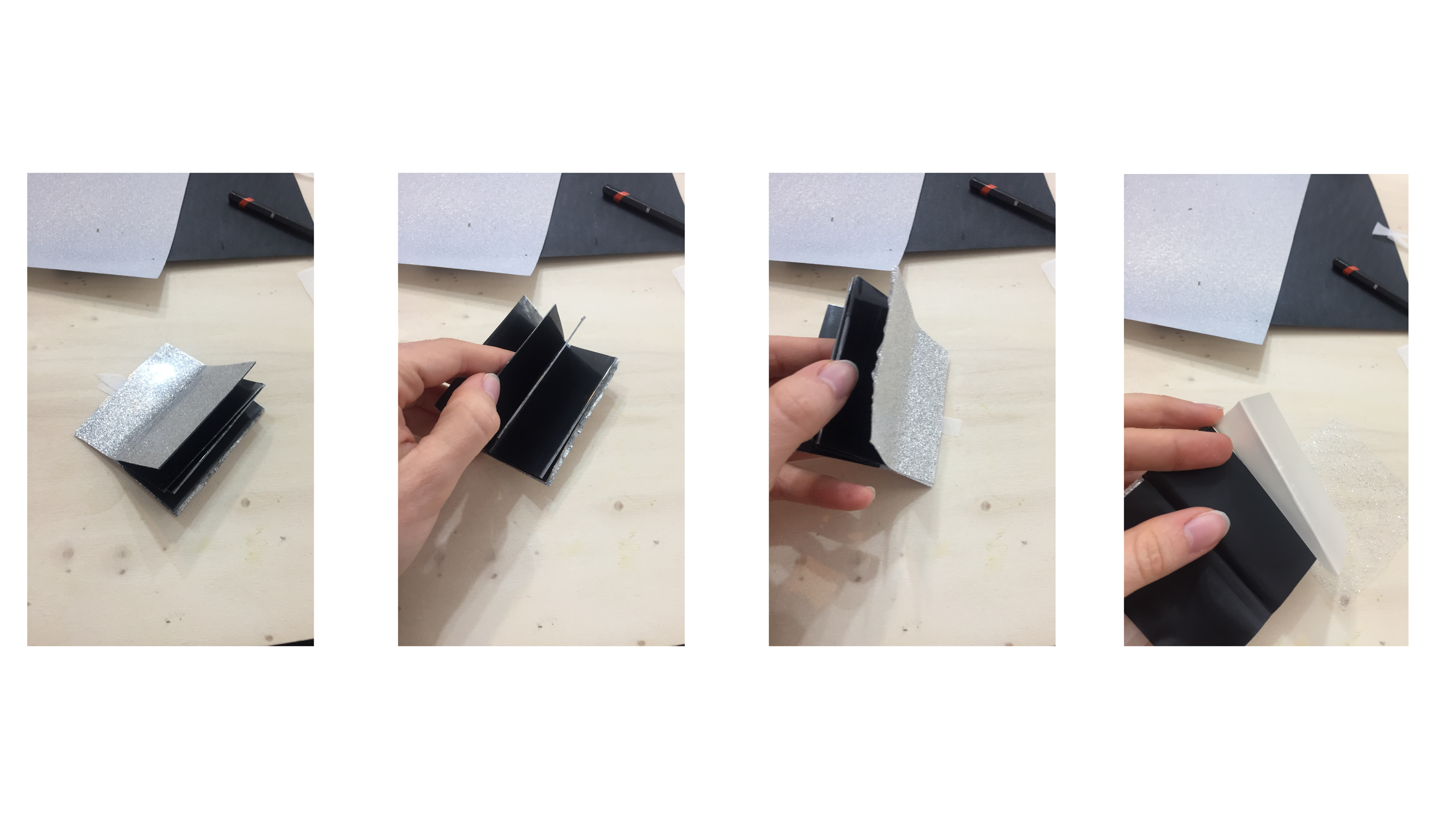

Pleated pattern¶

I experimented a pleated pattern so the design is not made on 2D level but as a superposition-3D

This is a small sketch on how I made it.

Note there is only one side of the sheet that can be sealed when heated - the matt side -

- First fold as an "accordion" the inside of the pattern (- the folding should start and end with a matt side to be able to stick to the two external pieces later.)

- Place the cuted parchments papers in between each fold

- Heat it slowly - but with somme pressure

- peal the protective transparent oustide layer

- now place again 2 parts of parchement on each side and then 2 parts of sealling plastic paper

- heat again

- Peal the protective transparent oustide layer

- with some parchment paper in between each fold heat again to be sure the material is well sealed

Bio-silicon¶

I then produced a bio-silicon form. to make it quick and dirty experimentation:

First I carved a mold on an engraving eraser block - use normally for linocut printing: The mold needs to be wide enough at the edges and the interior compartments which represent the air flow slightly lower than the edges

I then pasted both parts into a flat surface.

Then I made some bio-silicon using the following recipe: - 1 gelatine - 1 glycerin - 2 water

Note to self using gelatin sheets is better as it will avoid bubles in the mixtures - the powder gelatines produces a lot of bubbles.

16g gelatine/ 16gglycerin/32g water

Mix water+gly+gel

Heat slowly for appr. 10/15 mintes - do not boil it will produce bublbs

Once the mixture is well dissolve pour it into the mold and some into a flat surface (plexiglass other)

![]()

![]()

RESULTS ONCE INFLATED to come