| V. DIY ELECTROSPINNER |¶

Electro-spinning machine is designed to produce nano or micro scaled fibers. The syringe with the solution inside is connected by a needle to a high voltage generator and is able to spin or spray the material onto a metal collector. It creates a soft surface on aluminum foil.

DIY MACHINE - I.¶

Tools¶

- screws, laser cutter, glue, power supply, soldering machine, syringe, needle, aluminium foil, crocodilles (2 p)

Fabrication I. - laser cutting¶

- download FILES here

| Material | Thickness | Speed | Power | Cutting time |

|---|---|---|---|---|

| MDF Polywood | 2 mm | 1 | 60 | 15 min 10 s |

Fabrication II. - electronics¶

- We hide the high voltage generator into a box and solder longer wires to connect it with the metal plate and syringe.

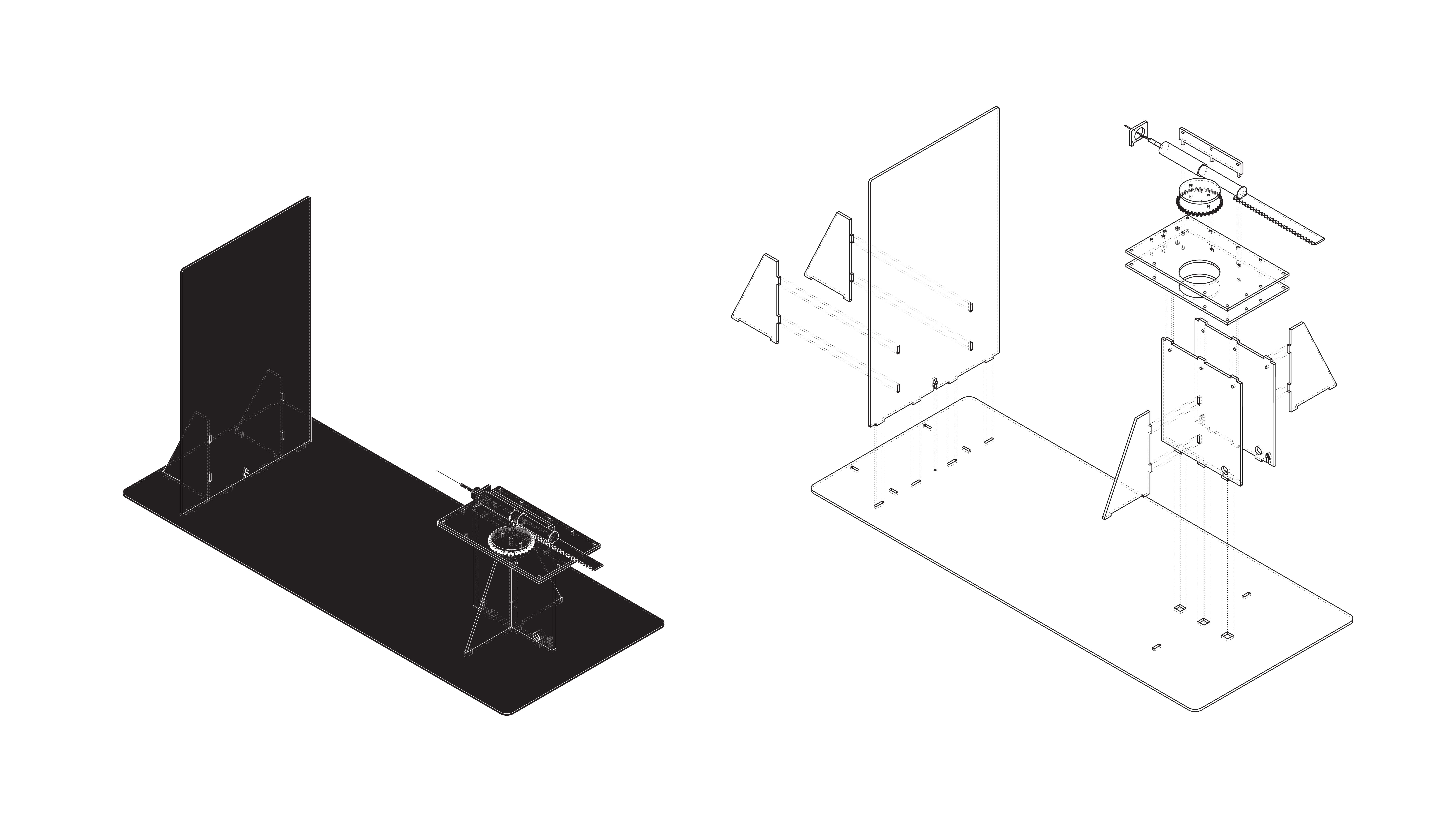

Axonometry view¶

Materials pricing¶

| n. | Name | Price | Amount | Source |

|---|---|---|---|---|

| 01 | Syringe with needle | x € | 1 | Fab Lab BCN |

| 02 | High Voltage Power Supply (3-11kV) | 15 € | 1 | Amazon |

| 03 | Aligator Clip | x € | 2 | Fablab BCN |

| 04 | Polywood board 2 mm | x € | 2 | Fablab BCN |

| 05 | Servo motor (L 28 W13) | x € | 2 | Fablab BCN |

| 06 | Arduino | x € | 2 | Fablab BCN |

| TOTAL | - | x € | - | - |

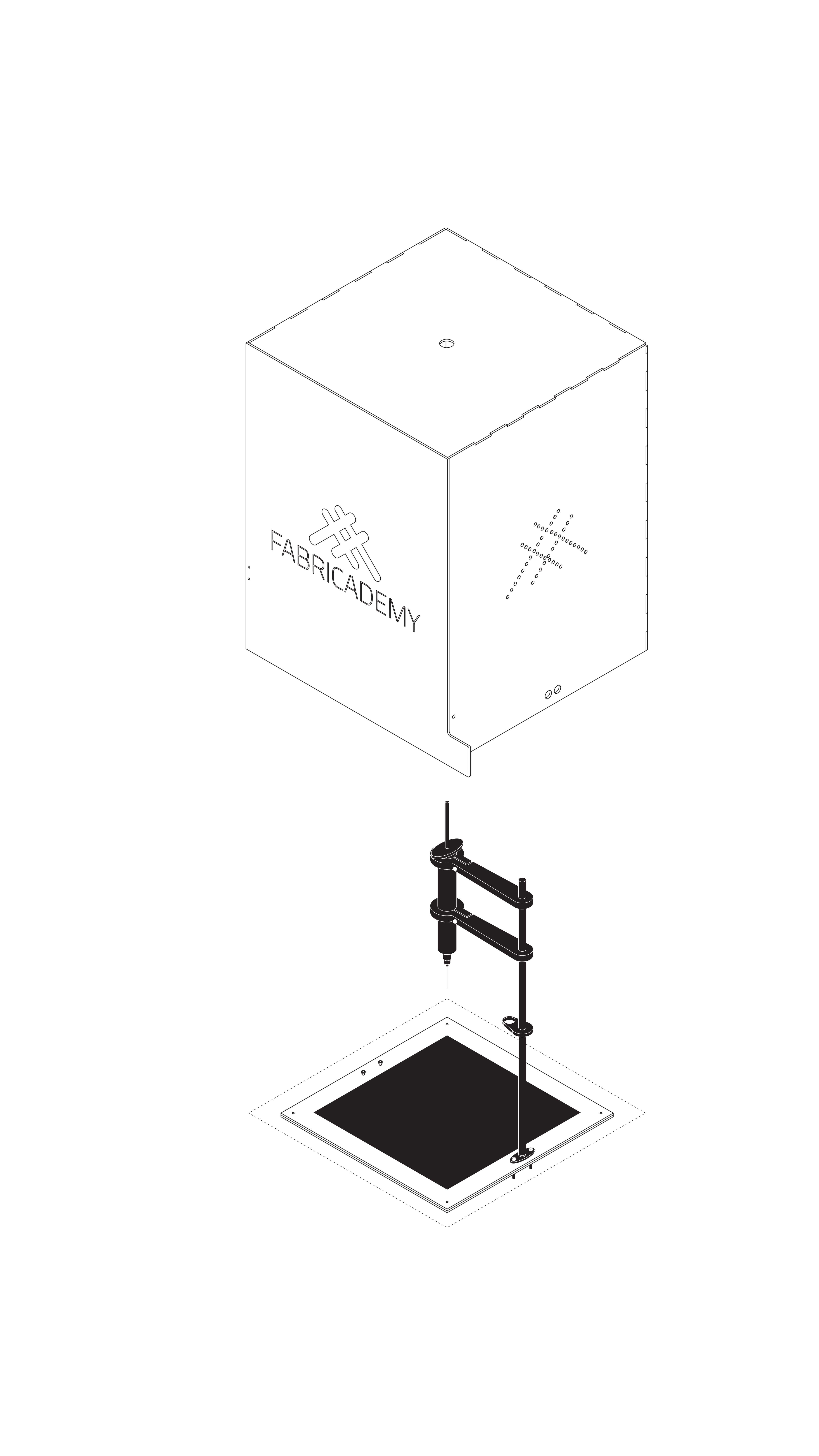

DIY MACHINE - II.¶

Tools¶

- screws (6 p), laser cutter, glue, power supply, soldering machine, syringe (1 p), needle, air compressor, aluminium foil, crocodilles (2 p), metal beam with nuts

Fabrication I. - laser cutting¶

- download FILES here

| Material | Thickness | Speed | Power | Cutting time |

|---|---|---|---|---|

| MDF Polywood | 2 mm | 1 | 60 | 8 min 04 s |

Materials pricing¶

| n. | Name | Price | Amount | Source |

|---|---|---|---|---|

| 01 | Syringe with needle | x € | 1 | Fab Lab BCN |

| 02 | High Voltage Power Supply (3-11kV) | 15 € | 1 | Amazon |

| 03 | Aligator Clip | x € | 2 | Fablab BCN |

| 04 | Polywood board 2 mm | x € | 2 | Fablab BCN |

| TOTAL | - | x € | - | - |

Axonometry view¶

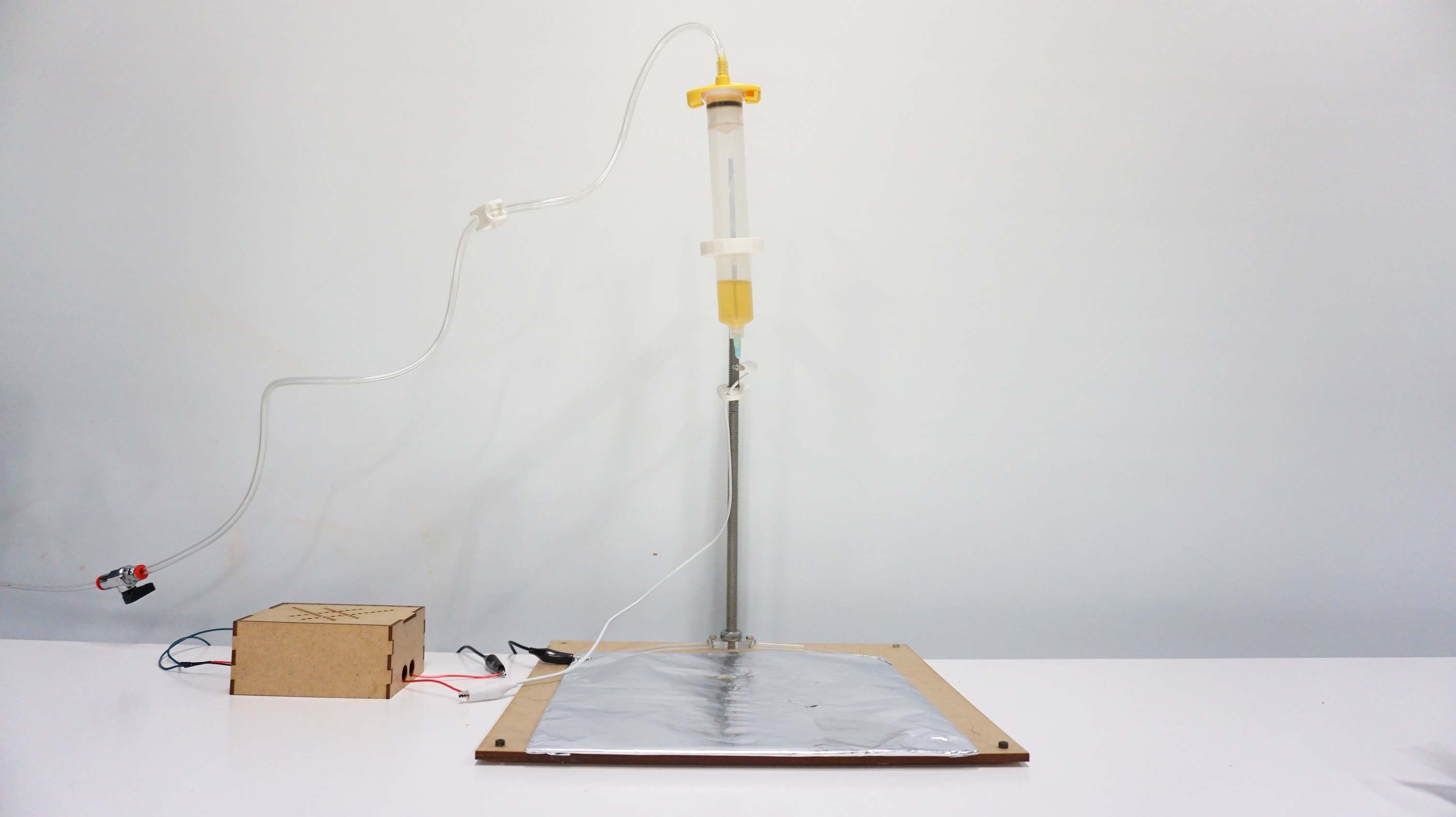

Prototype¶

CONCLUSION¶

- DIY Machine I. - the servomotor was not powerful enough to control the syringe pressure. Also the horizontal position created air bubbles in the syringe. Depending on the distance between the syringe and the metal plate to create a bridg for spinning was not powderfull enough. The material was attached to the aluminium foil but it was not consistent.

- DIY Machine I. - the vertical position of the syringe caused the drops of solution to hit the metal pad. However it was good for the air compressure to push the solution down through the syringe.

SOURCE¶

- Generic Lab Equipement by GaudiLabs

- FILE: DIY Electrospinner by GaudiLabs

- Electrospinning Machine by Douglas Miller

- Easy Electrospinner

- A Simple Homemade Electrospinning for Nanoscale Fibres Production, Ngurah Ayu Ketut Umiati1, V.G.S. Kadarisman1, Agus Subagio, Kunto Wandono, 2019, https://doi.org/10.1051/e3sconf/201912512001

RECIPES¶

Tools¶

- magnetic stirrer, magnet, glass jar, weight, spoon

Recipe I. - Pure Keratin¶

- 20 wt%

Recipe II. - Keratin & Gelatine¶

- 15 wt% - 5 wt%

Recipe III. - Keratin & Cellulose¶

- 15 wt% - 5 wt%

Recipe IV. - Keratin & Alginate¶

- 15 wt% - 2 wt%

Last update: 2022-05-12