VI. | BIOFABRICATING MATERIALS

| BIODEGRADABLE POLYMERS |

AGROPOLYMERS

| Polysaccharides |

Proteins, lignins |

Ligno-cellulose |

Plants proteins |

Others |

| Corn |

Casein |

Wood |

Soy |

Pectin |

| Wheat |

Sorbitol |

Straw |

Gluten |

Chitosan / Chitin |

| Potato |

Whey |

Hemp |

Zein |

Gum |

| Cassava |

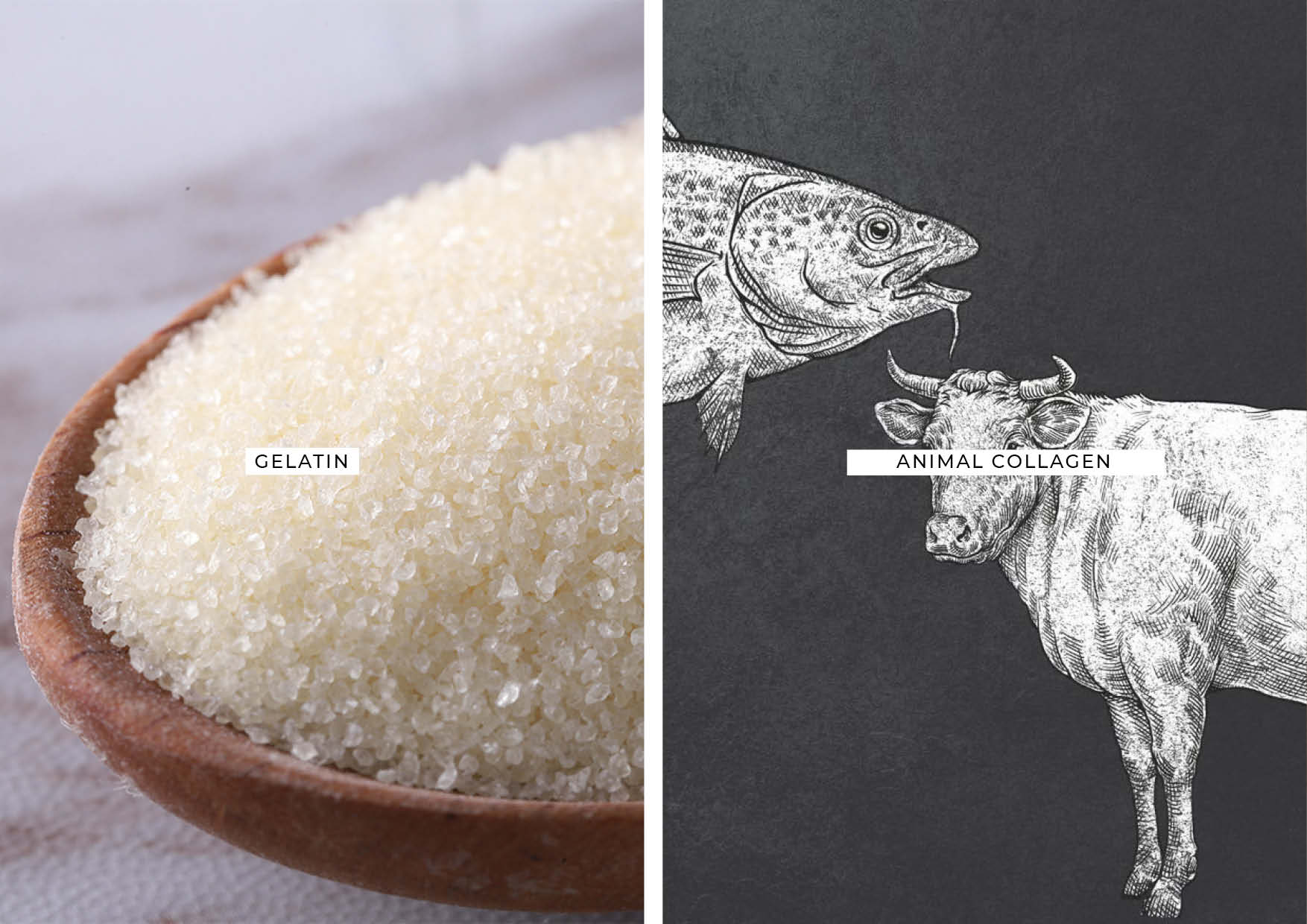

Gelatin |

... |

... |

... |

| Tapioca |

Colagen |

... |

... |

... |

BIOPOLYESTERS

-

FROM MICROORGANISM: PHA, PHB

-

FROM BIOTECHNOLOGY: Polylactides, polylactid acid (PLA)

-

FROM FOSSIL RESOURCES: Polycaprolactones (PCL), other homo-polyesters, aliphatic co-polyesters, aromatic co-polyesters

| BIOPLASTICS |

| BIOPOLYMERS |

BIOPLASTICIZER |

SOLVENT |

ADDITTIVES (optional) |

| Alginate |

Glycerol |

Destilated water |

Choarcal powder |

| Gelatin |

Sorbitol |

White Vinegar |

Mica |

| Agar Agar |

- |

- |

Eggshells, oyster shells |

| Starch |

- |

- |

Avocado powder, orange peels, coffee grounds, onion |

| Xanhan gum |

- |

- |

Tumeric, black pepper, cinamon, black tea, thyme |

| Guar gum |

- |

- |

Saw dust, paper pulp |

| Pectin |

- |

- |

Spirulina |

| Sugar Cane |

- |

- |

Hemp tow, hemp seeds, canola seeds |

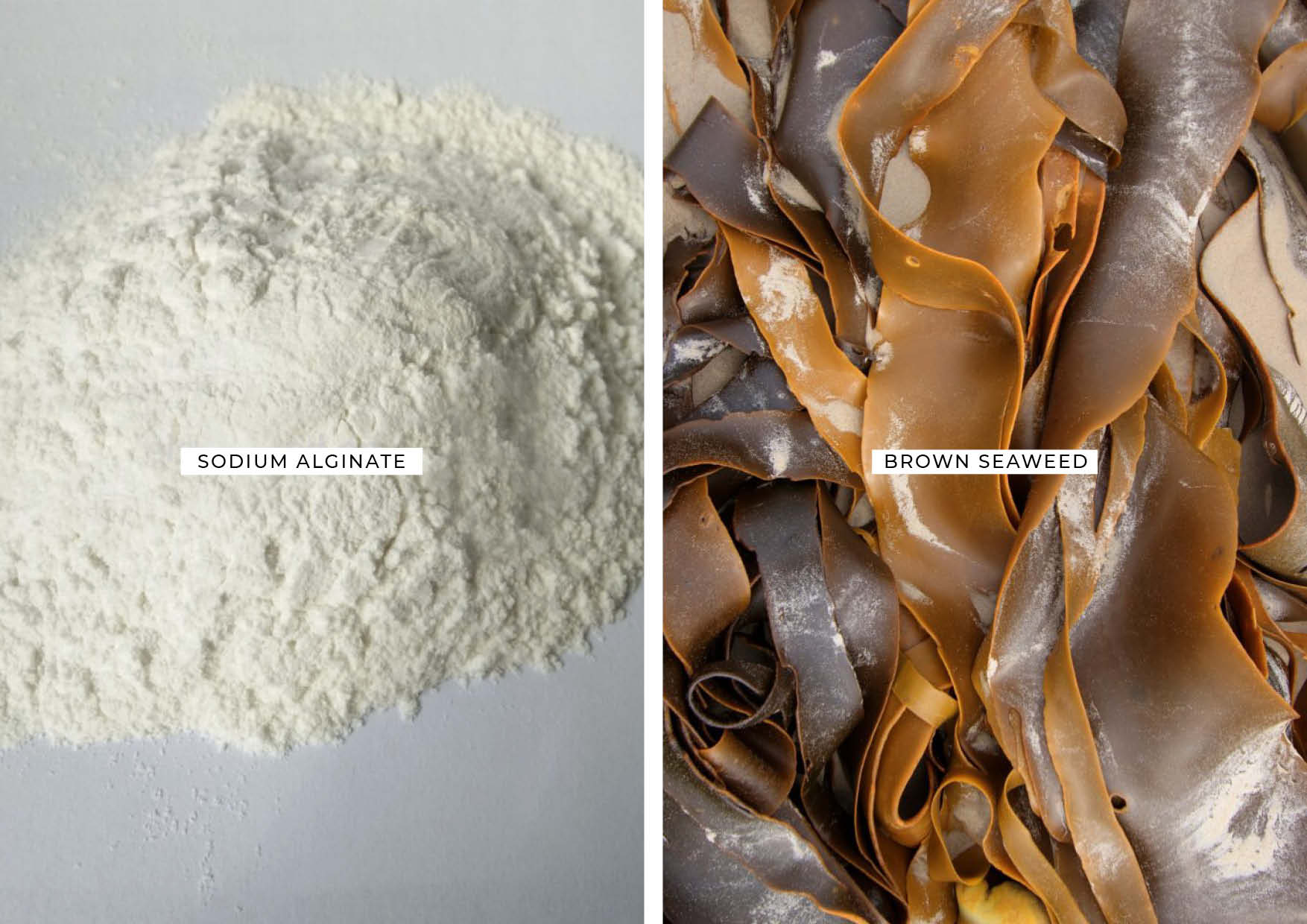

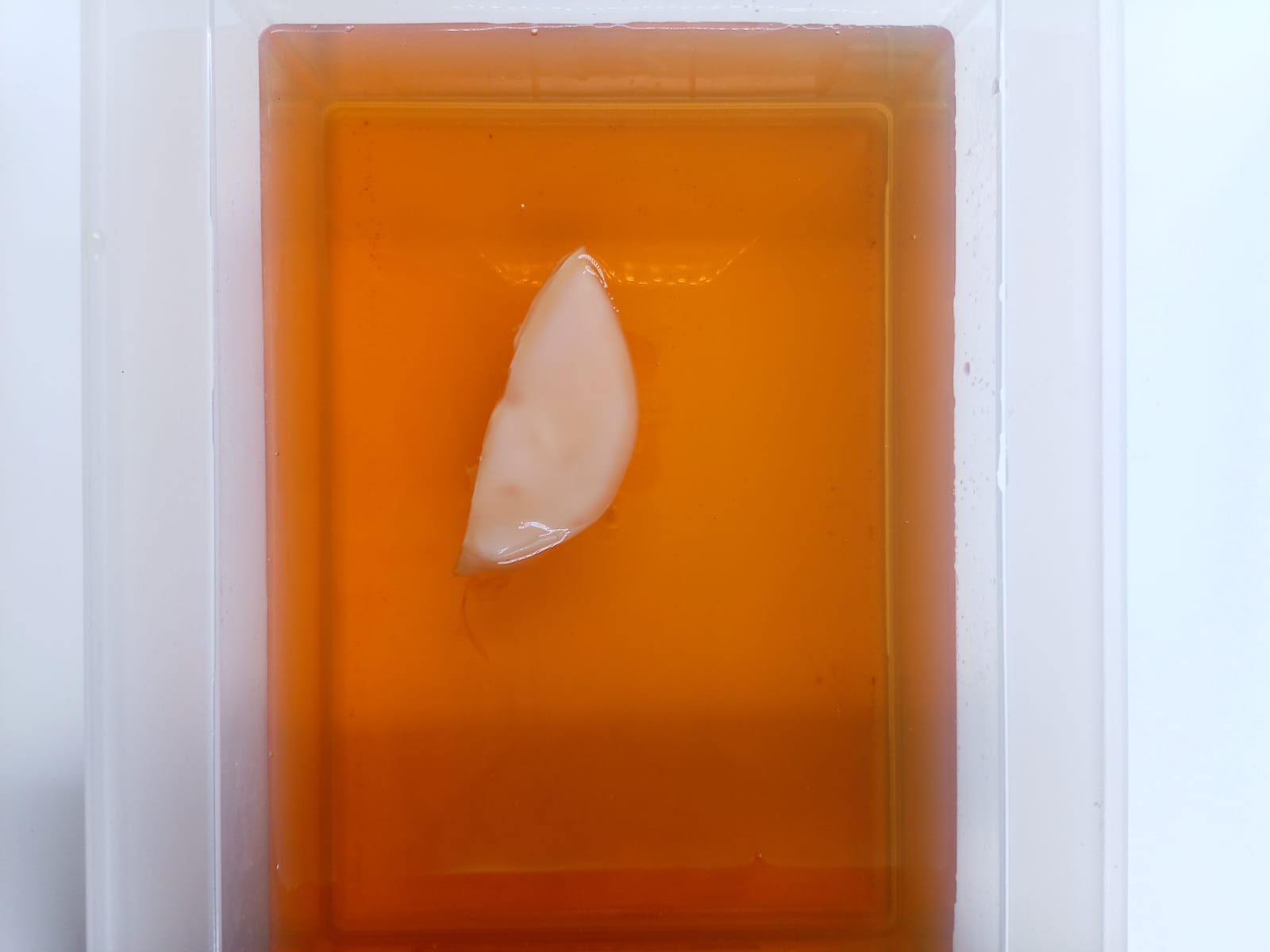

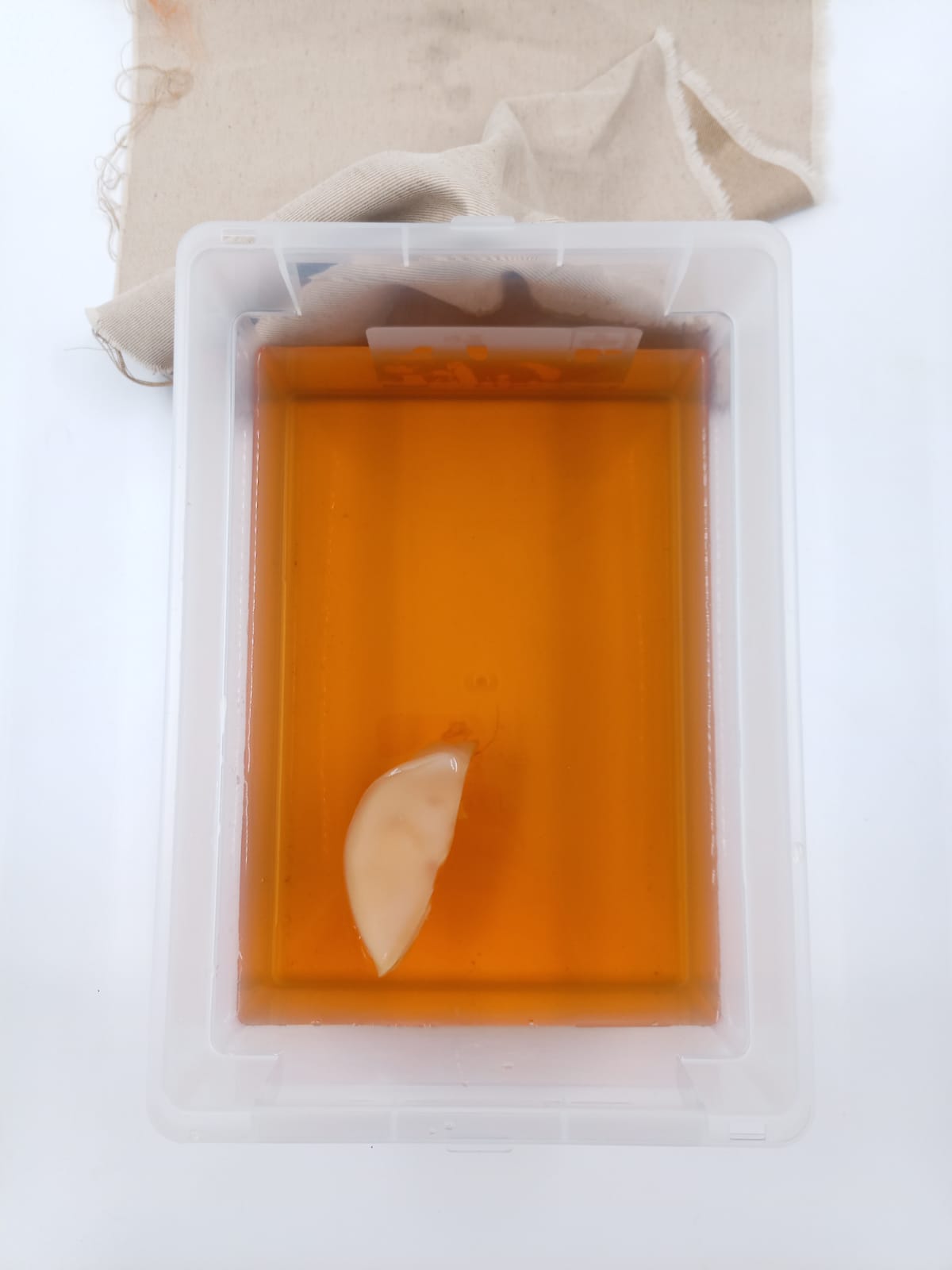

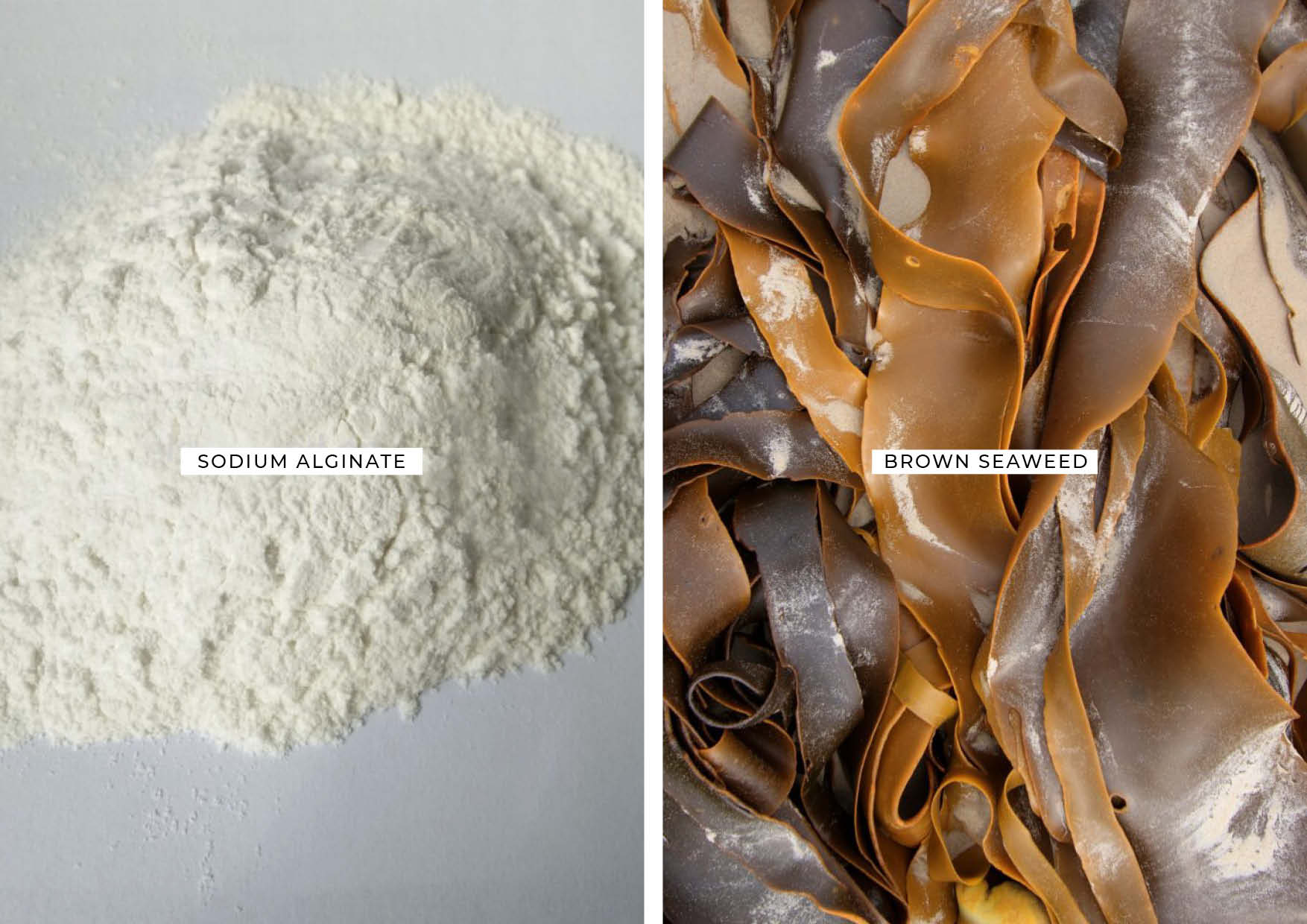

ALGINATE BIOPLASTICS

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

| Alginate |

Glycerol |

Destilated water |

Choarcal |

| 8 g |

flexible: 48 g, normal: 24 g |

400 ml |

5 g |

| a. |

b. |

| Calcium Chloride |

Water |

| 10 g |

100 ml |

- Description: Sodium alginate is a water-insoluble, gelatinous, cream-coloured substance that can be created through the addition of aqueous calcium chloride to aqueous sodium alginate. It has many applications in biology, but primarily known for its healing properties due to the compound's ability to encase enzymes in order to simulate new plant tissue.

- Alginate is a naturally occurring anionic polymer typically obtained from brown seaweed due to its biocompatibility, low toxicity, relatively low cost, although the addition of divalent Ca2+ (calcium ions) results in mild gelation. Thus, considered a naturally occurring biomaterial.

- Glycerol

- is a simple polyol compound. It is a colorless, odorless, viscous liquid that is sweet-tasting and non-toxic. Glycerol is generally obtained from plant and animal sources where it occurs as tryglycerides. Typical sources include soybeans and palm, and animal-derived tallow.

* Common uses: Food and beverage industries, pharmaceuticals, and metabolism.

- Chemical Formula:

- Activated charcoal

- Description: It’s an odorless black powder composed of carbon-based compounds — such as sawdust, coconut shells, or peat — that have been “activated,” or heated at high temperatures to make them more porous. Processed carbon made of heated Indonesian coconuts.

- Common uses: Nowadays, it continues to be promoted as a potent natural treatment, lowering cholesterol, whitening teeth, curing hangovers.

- stirring spoon, weight, measuring cup, hand blender, glass jar, injection, gloves, dehydrator, breathable textile

Process

- Add the destilated water in the measuring cup, alginate powder, glycerol and blend them with the hand blender. Mix them slowly to avoid any bubbles. If you are not that lucky let it settle down for 2-3h to remove all the bubbles.

- After or before, you can add the activated chaorcal.

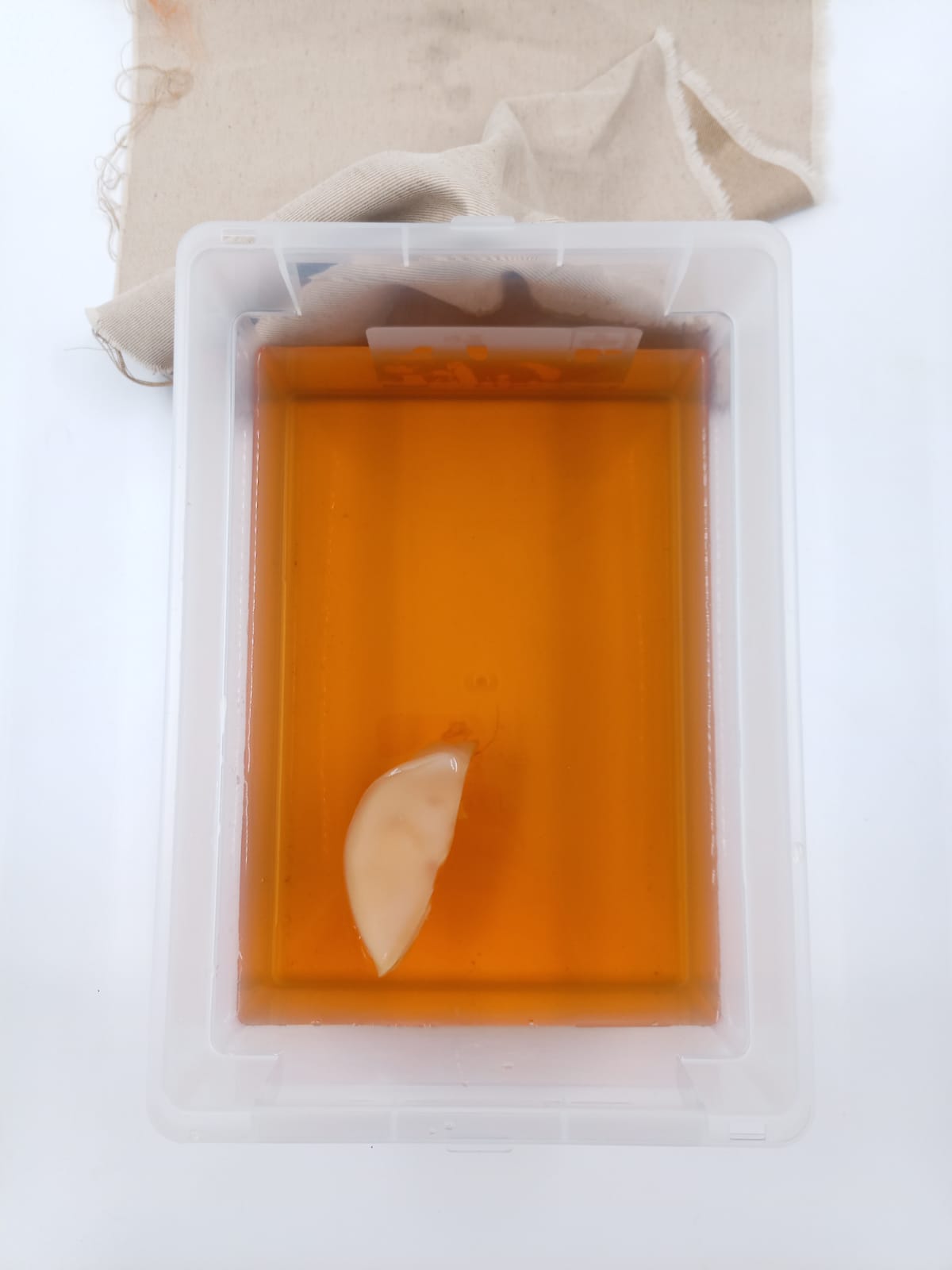

* Place a textile on the bottom and spray calcium chloride solution.

- Pour the alginate mixture onto the fabric. Spray more calcium chloride on the alginate plate and remove the remaining solution with a paper towel.

* You can place your sheet in the dehydrator to let it dry.

Result

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 1 week, Dehydrator: 30 h |

Fireproof >300ºC |

Low |

Flexible |

Opaque |

Water resistant |

Gelatinous |

Resistant |

- Techniques: laser cutting, molding, sewing

STRINGS - TEST 01

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

| Alginate |

Glycerol |

Destilated water |

Choarcal |

| 8 g |

16 g |

400 ml |

5 g |

| a. |

b. |

| Calcium Chloride |

Water |

| 10 g |

100 ml |

Process

- Add the destilated water in the measuring cup, alginate powder, glycerol and blend them with the hand blender. Mix them slowly to avoid any bubbles. If you are not that lucky let it settle down for 2-3h to remove all the bubbles.

- After or before, you can add the activated chaorcal.

- Measure the water and calcium chloride and mix them properly in a transparent measuring cup.

- Fill the injection with the paste and extrude it the solution of calcium chloride.

- Put them out of the calcium chloride and wash them in clean water.

- Hang them to dry naturally and separetely from each other.

Allginate Strings with Activated Chaorcal from PETRA GARAJOVÁ on Vimeo.

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

- Conclusion: Add more bioplasticizer.

- Techniques: knitting, weaving

STRINGS - TEST 02

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

Additives |

| Alginate |

Glycerol |

Destilated water |

Olive oil |

Carbbage pigment |

| 4 g |

8 g |

200 ml |

2 g |

3 g |

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

STRINGS - TEST 03

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

Additives |

| Alginate |

Glycerol |

Destilated water |

Lanolin |

Onion pigment + Mica |

| 4 g |

12 g |

200 ml |

2 g |

3 g + 2 g |

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

STRINGS - TEST 04

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

Additives |

| Alginate |

Glycerol |

Destilated water |

Lanolin |

Mica |

| 4 g |

12 g |

200 ml |

2 g |

3 g + 2 g |

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

STRINGS - TEST 05

| Biopolymers |

Bioplasticizer |

Solvent |

| Alginate |

Guar gum |

Destilated water |

| 4 g |

4 g |

200 ml |

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

Naturally: 2-3 days |

Fireproof |

Low |

Flexible |

Opaque |

Water resistant |

x |

x |

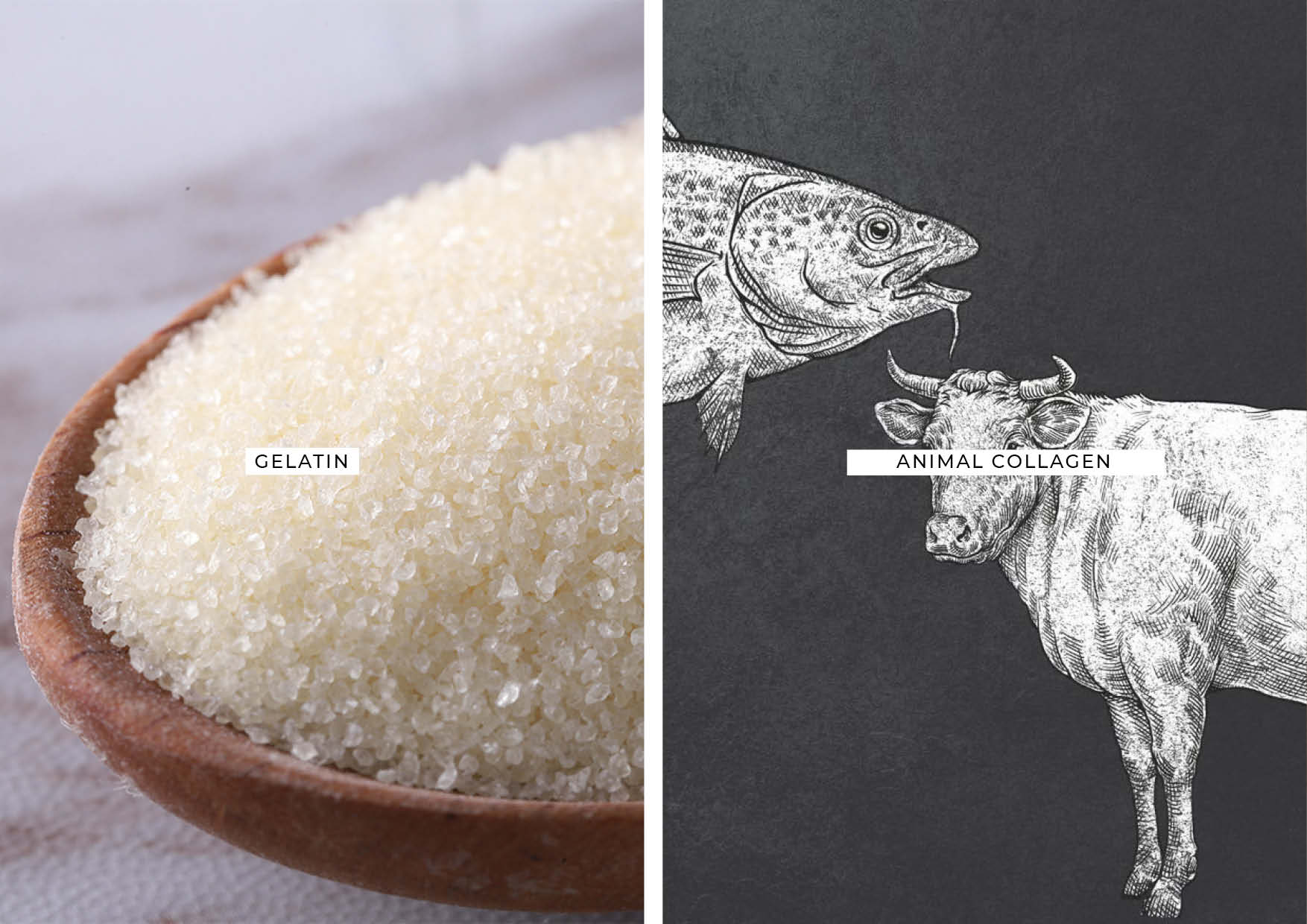

GELATIN BIOPLASTICS

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

| Gelatin |

Glycerol |

Destilated water |

Choarcal, wool |

| 48 g |

elastic: 48 g, normal: 24 g, rigid: 0 g |

240 ml |

5 g |

- Description: Gelatin is a translucent, colorless, flavorless food ingredient, commonly derived from collagen taken from animal body parts. It is brittle when dry and rubbery when moist. It may also be referred to as hydrolyzed collagen, collagen hydrolysate, gelatine hydrolysate, hydrolyzed gelatine, and collagen peptides after it has undergone hydrolysis.

- Common use: It is commonly used as a gelling agent in food, beverages, medications, drug and vitamin capsules, photographic films and papers, and cosmetics.

- Glycerol

- is a simple polyol compound. It is a colorless, odorless, viscous liquid that is sweet-tasting and non-toxic. Glycerol is generally obtained from plant and animal sources where it occurs as tryglycerides. Typical sources include soybeans and palm, and animal-derived tallow.

* Common uses: Food and beverage industries, pharmaceuticals, and metabolism.

- Chemical Formula:

- stirring spoon, weight, measuring cup, hand blender, glass jar, injection, gloves, dehydrator, waterproofplastic textile

Process

- Measure calcium alginate and water.

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| Low |

Naturally: 4 days (fridge - 5 h) |

25°C |

High |

Elastic |

Opaque |

NOT waterproof |

Gelatinous |

Low-resistant |

- Techniques: laser cutting, molding, sewing

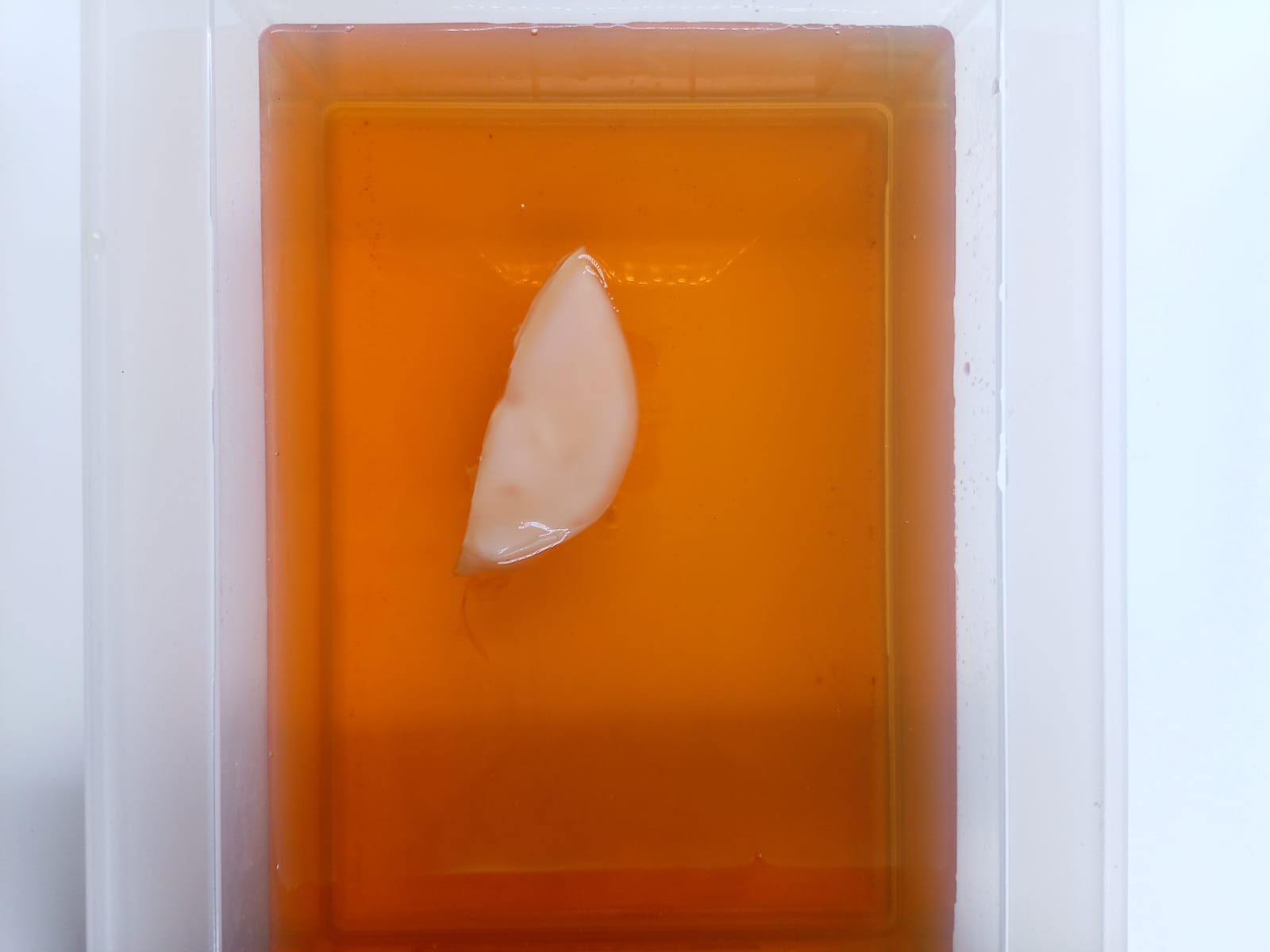

AGAR AGAR BIOPLASTICS

| Biopolymers |

Bioplasticizer |

Solvent |

Additives |

| Agar Agar |

Glycerol |

Destilated water |

- |

| 10 g |

elastic: 32 g, normal: 16 g, rigid: 4 g |

300 ml |

- |

- Description: Agar-agar is a jelly-like substance, obtained from algae. Agar forms the supporting structure in the cell walls of certain species of algae. These algae are known as agarophytes, and belong to the Rhodophyta (red algae) phylum.

- Commoon uses: A substrate for microbiological work, a vegetarian substitute for gelatin, a thickener for soups, in fruit preserves, ice cream, and other desserts, as a clarifying agent in brewing, and for sizing paper and fabrics.

- Chemical Formula:

- picture

- Glycerol

- is a simple polyol compound. It is a colorless, odorless, viscous liquid that is sweet-tasting and non-toxic. Glycerol is generally obtained from plant and animal sources where it occurs as tryglycerides. Typical sources include soybeans and palm, and animal-derived tallow.

* Common uses: Food and beverage industries, pharmaceuticals, and metabolism.

- Chemical Formula:

- stirring spoon, weight, measuring cup, hand blender, glass jar, injection, gloves, dehydrator

Process

- Measure calcium alginate and water.

Material Parametres

| Viscosity |

Curing time |

Solidifying, Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| Low |

Naturally: 1 week (fridge - 5 h) |

32–40 °C, 85 °C |

Medium |

Flexible |

Transparent |

NOT waterproof |

Gelatinous |

Low-resistant |

- Techniques: laser cutting, sewing

PINE RESIN

| a. |

b. |

c. |

d. |

| Pine resin |

Carnaubax wax |

Alcohol |

Avocado powder |

| 45 g |

5 g |

20 ml |

120 g |

- Description: Obtained from the bark of Pinus species. Resins are often mixtures of organic compounds, principally terpenes. Many plants, particularly woody plants, produce resin in response to injury. The resin acts like a botanical bandage protecting the plant from invasion by insects or pathogens.

- Common uses: Sealent, glue, varnish.

- Carnaubax wax

- Description: Carnauba also called Brazil wax and palm wax, is a wax of the leaves of the carnauba palm Copernicia prunifera (Synonym: Copernicia cerifera), a plant native to and grown only in the northeastern Brazilian states of Pernambuco, etc. It is known as "queen of waxes"[2] and in its pure state usually comes in the form of hard yellow-brown flakes. It is obtained from the leaves of the carnauba palm by collecting and drying them, beating them to loosen the wax, and then refining and bleaching the wax.

* Common uses: As a food additive, its E number is E903.

- stirring spoon, weight, measuring cup, cooking pot, mold, baking paper

Process

- Melt the pine resin in the cooking pot, add carnaubax wax and alcohol.

- Mix them properly and add as much avocado powder as you need to create a consitent paste.

* Cover your laser cutted mold with baking paper. You need to work fast. Place the past on the top of the baking paper and press it with a wooden cover.

- It will be dry and ready in 15 min.

Material Parametres

| Viscosity |

Curing time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| Very High |

Naturally: 15 min |

DOES NOT melt |

Low |

Rigid |

Opaque |

Waterproof |

Consistent |

Highly durable |

REFERENCES - craft materials

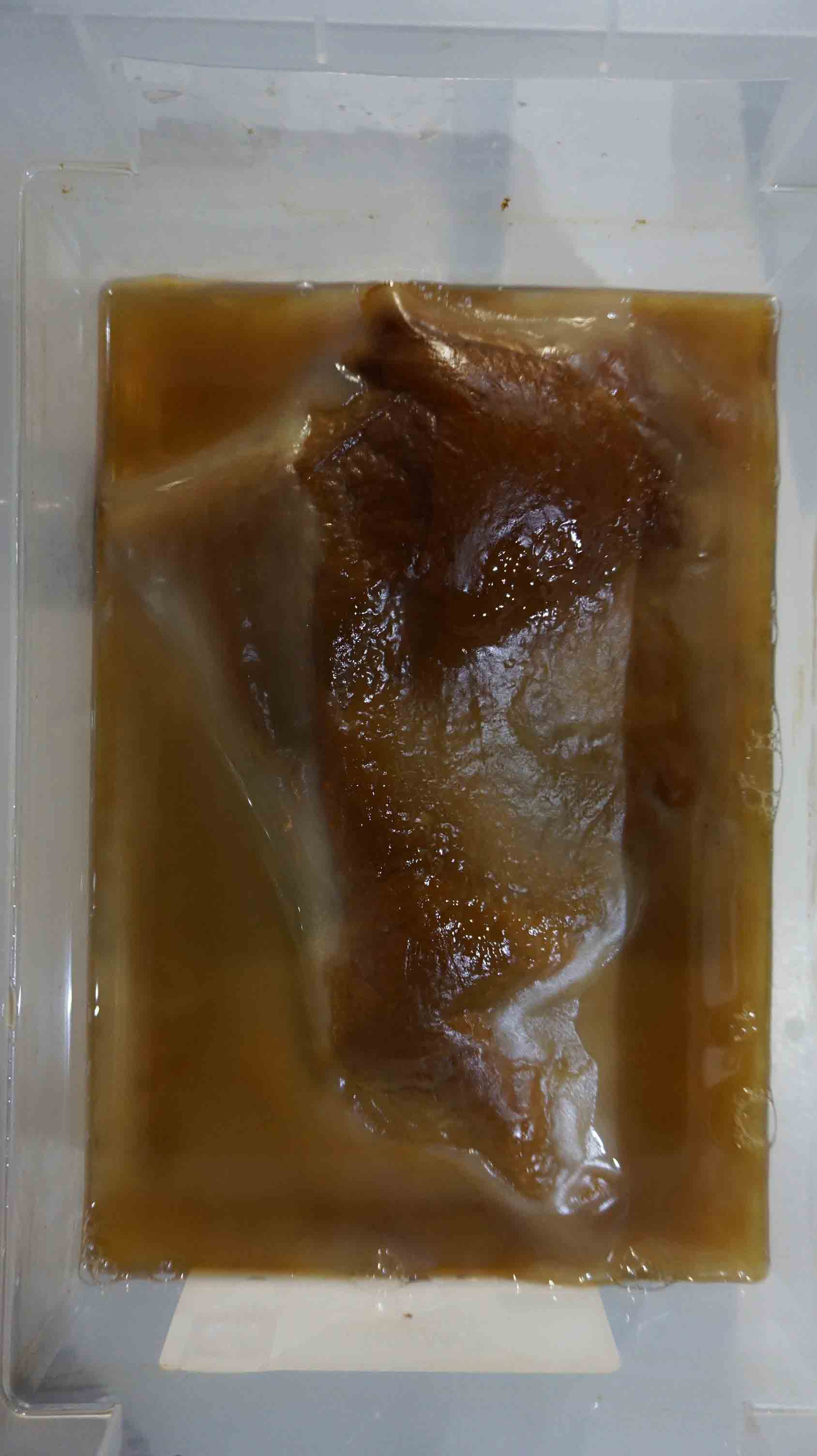

| KOMBUCHA |

| a. |

b. |

c. |

d. |

e. |

| Scoby |

Black tea |

Water |

Sugar |

Cider Vinegar |

| 30 g |

8 tea bags |

8 l |

800 g |

800 ml |

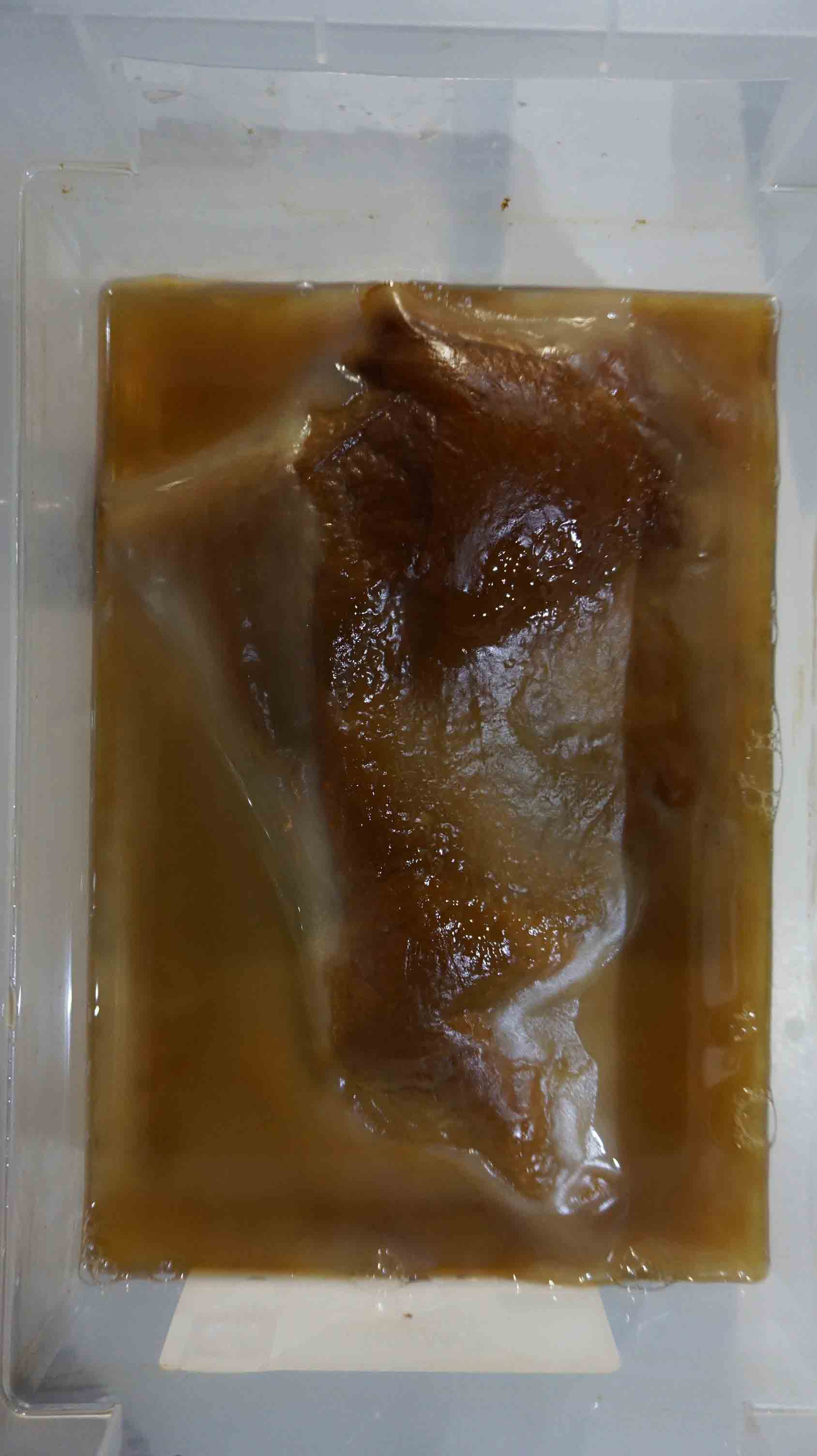

- Description: Kombucha starter culture or Mother (also known as Manchurian fungus, tea fungus or Chinese fungus) is a gelatinous microorganism colony obtained from wild fermented sweetened tea.

- This colony can also be found in the apple fermentation (vinegar) and it can also act as an starter for the kombucha culture.

FABRICATION

- stirring spoon, weight, measuring cup, cooking pot (15 l), plastic box, kettle

Process

- Boil the water. Add the tea and sugar, and infuse for 5 min. Let it cool to below 30° celsius, do not use hot tea in the preparation, as it can kill the starter bacterial culture.

* When the tea mixture is below 30 degrees celsius in temperature, pour into a sterilized canning jar. Do not use a ceramic or metallic container (if you want to drink the Kombucha).

-

Add the starter culture, this can be another kombucha drink, the kombucha pellicle, organic apple vinegar, or just try wild fermentation.

-

Cover with cloth or a paper towel, it's important to let the gaseous exchange happen but we need to avoid culture contamination. Leave to ferment at a temperature of 25 degrees celsius avoiding light.

-

The growth of the kombucha mother, or 'scoby', is a process of growth spanning seven to fourteen days depending on environmental conditions, reaching a thickness of seven to twelve millimeters.

3 MONTHS AFTER..

SHEETS

Process

- Remove the kombucha skin from the plastic container and rinse thoroughly under water. Add a lot of soap - so that the kombucha is not sticky.

- Clean the plastic container and fill it again with water and soap. Leave the kombucha there for a while.

- You can use the water from growing kombucha again, you just have to add more sugar and vinegar. Do not forget to filter it first using a mesh strainer.

- Straighten kombucha on a wooden board. Remove all water from the surface and fold it in half. You can remove the last remnants of water with your hands.

- You have to fold it in half because it may remain too thin after drying.

Material Parametres

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

12 weeks |

20-23°C |

High |

Elastic |

Opaque |

Waterproof |

Cellulose leather |

Resistant |

- Techniques: laser cutting, sewing

Wine colors

INFLATABLES

Process

Result

Material Parametres

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

12 weeks |

20-23°C |

High |

Elastic |

Opaque |

Waterproof |

Cellulose leather |

Resistant |

3D PRINTED KOMBUCHA

- Plastic cup, hand blender, spoon, weight, syringe

Recipes

| a. |

b. |

c. |

| Total weight |

Alginate |

Glycerol |

| 20 g |

0,75 g |

3 g |

| a. |

b. |

c. |

| Total weight |

Alginate |

Glycerol |

| 20 g |

0,5 g |

2,0 g |

| a. |

b. |

c. |

| Total weight |

Alginate |

Glycerol |

| 20 g |

1,0 g |

3,0 g |

Process

- Blend the leftovers from kombucha mother with a hand blender.

- Add alginate and glycerol and blend it all together with a blender again.

- Fill half the injection with the prepared paste using a spoon.

- Print it on a wooden board and try to keep the syringe in vertical position close to the surface otherwise the layers will not stick together.

Results

Material Parametres

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

12 weeks |

20-23°C |

High |

Elastic |

Opaque |

Waterproof |

Cellulose leather |

Resistant |

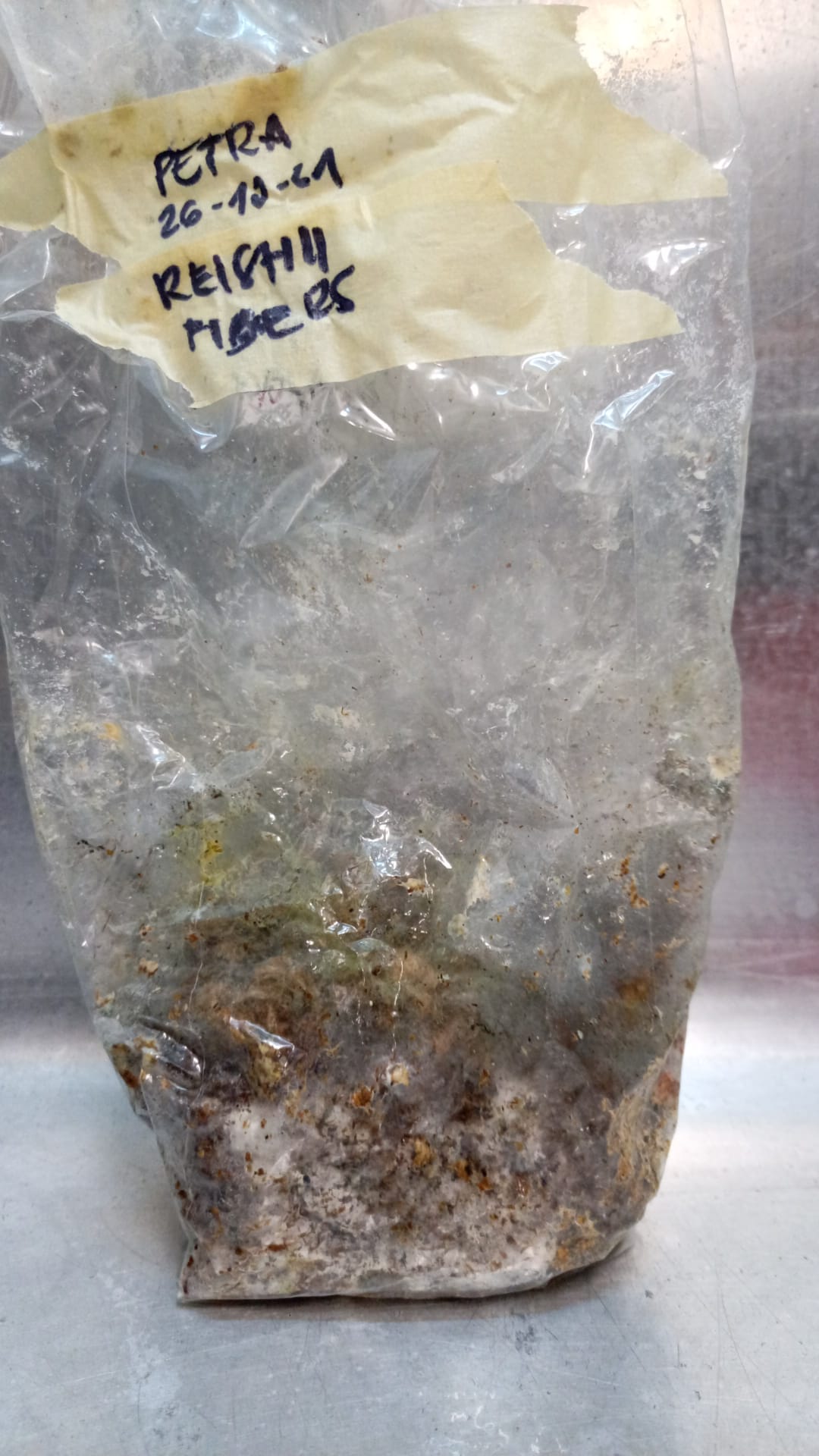

| MYCELIUM |

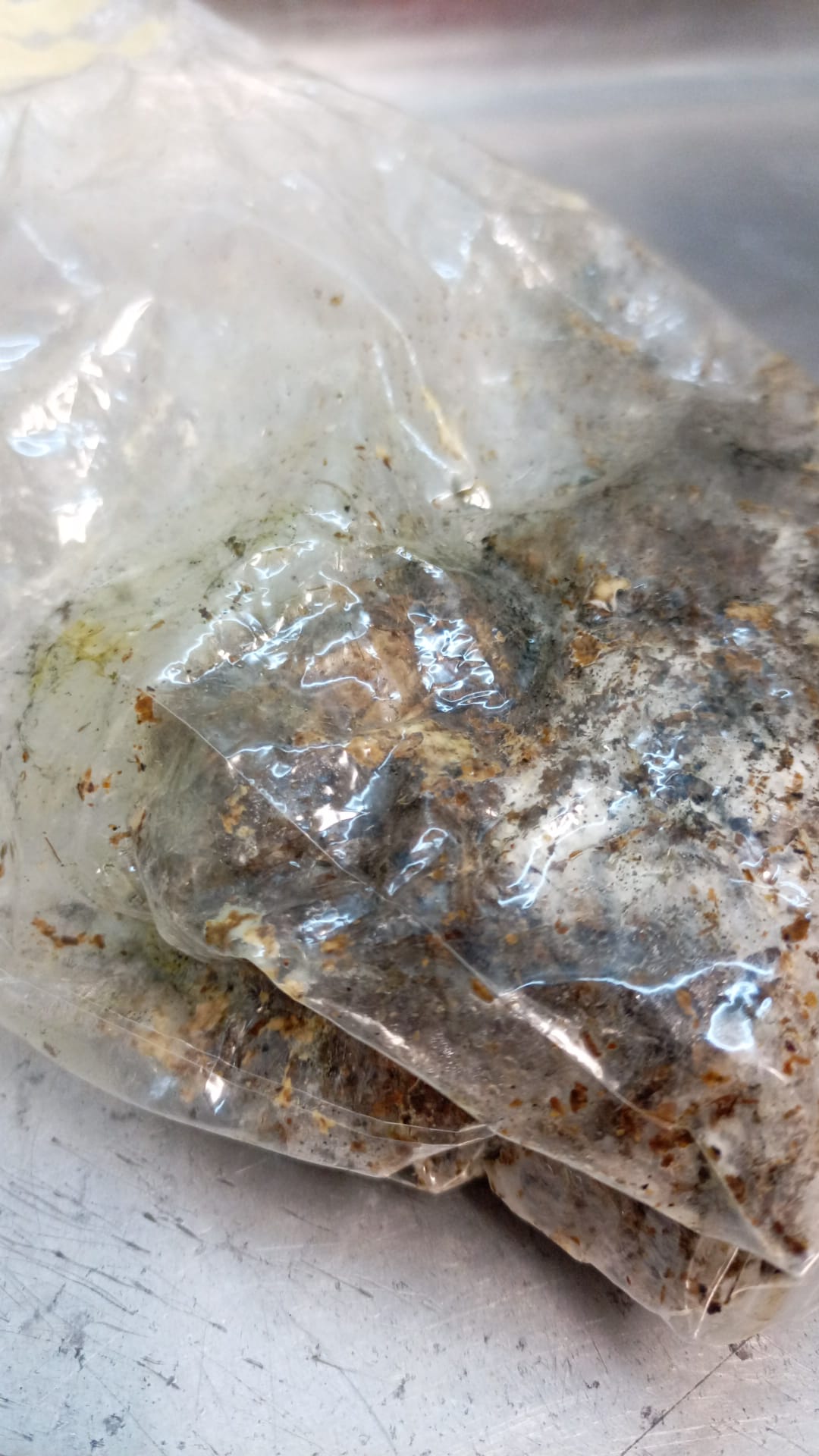

MYCELIUM SPAWN - TEST 01

- Description: Trametes versicolor – also known as Coriolus versicolor and Polyporus versicolor – is a common polypore mushroom found throughout the world. Meaning 'of several colours', versicolor reliably describes this fungus that displays different colors. Mycelium is the vegetative part of a fungus or fungus-like bacterial colony, consisting of a mass of branching, thread-like hyphae. The mass of hyphae is sometimes called shiro, especially within the fairy ring fungi. Fungal colonies composed of mycelium are found in and on soil and many other substrates.

Ingredients

| a. |

b. |

c. |

| Mycelium spawn |

Destilated water |

Straw, hemp, cork, fibers |

- bowl, plastic bag, gloves, alcohol + spray bottle, face mask, lab coat, lovely pressure cooker

Process

- Put your glows and lab coat on and spray alcohol all around you!

- Take one of plastic bags and put the straw, hemp, cork and fibers together and mix them thoroughly with distilled water - try to find a balance between too wet and too dry.

* Close the plastic bag, mark it your name, date and ingredientes you used. Put in a pressure cooker and cook for 40 minutes.

* Close the plastic bag, mark it your name, date and ingredientes you used. Put in a pressure cooker and cook for 40 minutes.

- First prepare a sterile place and put a piece of mycelium in the plastic bag with other materials.

- Properly close it with pins and place in the incubator.

Material Parametres

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

1 week |

Fireproof |

None |

Consistent |

Opaque |

Resistant to moisture |

Light-weight |

Resistant |

MYCELIUM SPAWN - TEST 02

Ingredients

| a. |

b. |

c. |

| Mycelium spawn |

Destilated water |

Hemp - fibers |

- bowl, plastic bag, gloves, alcohol + spray bottle, face mask, lab coat, lovely pressure cooker

PROCESS

- Put your gloves and lab coat on and spray alcohol all around you!

- Take one of plastic bags and put the straw, hemp, cork and fibers together and mix them thoroughly with distilled water - try to find a balance between too wet and too dry.

* Close the plastic bag, mark it your name, date and ingredientes you used. Put in a pressure cooker and cook for 40 minutes.

- First prepare a sterile place and put a piece of mycelium in the plastic bag with other materials.

- Properly close it with pins and place in the incubator.

MATERIAL PARAMETRES

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

1 week |

Fireproof |

None |

Consistent |

Opaque |

Resistant to moisture |

Light-weight |

Resistant |

RESULT

- CONCLUSION: Anastasia threw it out for me.

MOLDS - TEST 01

Ingredients

| a. |

b. |

c. |

d. |

| Micelium Grow Kits |

Destilated water |

Straw, hemp |

Flour |

- Description: Trametes versicolor – also known as Coriolus versicolor and Polyporus versicolor – is a common polypore mushroom found throughout the world. Meaning 'of several colours', versicolor reliably describes this fungus that displays different colors. Mycelium is the vegetative part of a fungus or fungus-like bacterial colony, consisting of a mass of branching, thread-like hyphae. The mass of hyphae is sometimes called shiro, especially within the fairy ring fungi. Fungal colonies composed of mycelium are found in and on soil and many other substrates.

- bowl, plastic bag, gloves, alcohol + spray bottle, face mask, lab coat, lovely pressure cooker, plastic film, pin, tape, flower pot (outside), glass jar (inside)

Process

- Put your gloves and lab coat on and spray alcohol all around you!

- Put a bigger part of your Micelium Grow Kit into the clean and strerilazed bowl and start separating it into small piecies so you can fit into your mold shape. ! If you drop off some pieces out of the bowl DO NOT PUT IT BACK, you will contaminate your mixture!

- Add destilated water and flour to create a wet and sticky mixture. You can check it with your hands if it is strong enough and holds together.

- Take your clean flower pot and wrap it with plastic foil and tape. Clean it with alchol in spray.

* Place a little bit of your micelium mixture on the bottom and press it hard with your fingers (always use gloves and spray alcohol everywhere).

- On the top of it you need to place the glass jar (which radius should be smaller than the flower pot), put more mixture all around the jar and press it properly.

* Cover it with plastic foil, fix it with the tape and make holes with a pin to let mycelium breathe and grow! Mark your name and date.

- Wait approx one week

- Remove the plastic foil and put your creation out of the flower pot. Let it rest for a while and then you can put it in the dehydrator.

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

1 week |

Fireproof |

None |

Consistent |

Opaque |

Resistant to moisture |

Light-weight |

Resistant |

MOLDS - TEST 02

Ingredients

| a. |

b. |

c. |

| Micelium Grow Kits |

Destilated water |

Flour |

- bowl, plastic bag, gloves, alcohol + spray bottle, face mask, lab coat, lovely pressure cooker, plastic film, pin, tape

Process

- Put your gloves and lab coat on and spray alcohol all around you!

- Put a bigger part of your Micelium Grow Kit into the clean and strerilazed bowl and start separating it into small piecies so you can fit into your mold shape. ! If you drop off some pieces out of the bowl DO NOT PUT IT BACK, you will contaminate your mixture!

- Add destilated water and flour to create a wet and sticky mixture. You can check it with your hands if it is strong enough and holds together.

- Wrap your mold with the plastic foil, put the mixture inside and press it properly.

* Cover it all with the plastic foil, fix it with the tape and make holes with a pin to let mycelium breathe and grow! Mark your name and date.

- Wait approx one week.

- Remove the plastic foil and put your creation out of the flower pot. Let it rest for a while and then you can put it in the dehydrator.

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

1 week |

Fireproof |

None |

Consistent |

Opaque |

Resistant to moisture |

Light-weight |

Resistant |

MOLDS - TEST 03

Ingredients

| a. |

b. |

c. |

| Mycelium |

Destilated water |

Tapioca |

- bowl, plastic bag, gloves, alcohol + spray bottle, face mask, lab coat, lovely pressure cooker, plastic film, pin, tape

Process

- Measure calcium alginate and water.

| Viscosity |

Cultivating time |

Melting point |

Stickiness |

Structural properties |

Visual |

Structure |

Texture |

Strengh |

| High |

1 week |

Fireproof |

None |

Consistent |

Opaque |

Resistant to moisture |

Light-weight |

Resistant |

REFERENCES - grown materials

Last update: 2022-01-16

* Close the plastic bag, mark it your name, date and ingredientes you used. Put in a pressure cooker and cook for 40 minutes.

* Close the plastic bag, mark it your name, date and ingredientes you used. Put in a pressure cooker and cook for 40 minutes.