8. Soft robotics¶

Research¶

Introduction

At first, I didn’t really know what soft robotics was or how it worked. When I heard the topic, I thought it would be very complex and hard to understand. But while working on this week’s assignment, I actually found it easier than I expected — and even exciting.

What I Learned

Soft robotics is all about creating robots using flexible and soft materials that can bend or stretch, almost like something alive. These materials can be silicone, rubber, or fabric. Unlike the usual metal robots, soft robots can safely interact with people, adapt to different shapes, and handle delicate objects.

The part that really caught my attention was the inflation system, where air is pumped inside the robot to make it move or expand. I found it simple but very powerful — and I realized I had already seen similar ideas in things like inflatable toys or cushions without knowing it was related to robotics.

Research Process

After understanding the basics, I did more research to make sure anyone who reads my documentation can also get the main concept. Soft robotics is a branch of robotics focused on making flexible and adaptive machines inspired by nature and soft materials. It connects creativity, design, and motion in a very interesting way.

I mainly used these resources for my research:

• Soft Robotics Toolkit — Harvard University

• Frontiers in Robotics and AI – Soft Robots Manufacturing Review (2018)

• EPFL Review on Soft Robotics (2023)

These sources helped me understand the science and design methods behind soft robotics and how it’s used in real-world applications like soft grippers, wearables, and medical tools.

Reflection

Learning about soft robotics made me realize it’s not as complicated as I first thought. It’s actually creative and fun to explore — especially the idea of using air and soft materials to create movement.

This week’s assignment showed me that innovation doesn’t always have to be rigid or mechanical. Sometimes it’s soft, flexible, and inspired by everyday things we already know.

References & Inspiration¶

Before starting my experiments, I explored different examples and research projects related to soft robotics to understand how flexible materials can be used to create movement. I was really inspired by how air pressure and soft structures can act like living systems — bending, inflating, or expanding in response to force.

The Soft Robotics Toolkit by Harvard University was one of my main inspirations. It shows how soft robots can be made using air chambers, silicone molds, and digital fabrication tools. I also looked at other projects from Fabricademy and different design labs that combine soft materials, laser cutting, and inflation to create movement.

Another source of inspiration came from nature — especially the way muscles, plants, and soft creatures move. These natural systems show how softness and flexibility can create strength and motion without using hard mechanical parts.

- Two images side-by-side

Tools¶

• Thermal vinyl sheets

• Baking paper

• Air pump

• Silicone (Jianghe and NIUB)

• Hardener

• Laser-cut acrylic molds

Tools and Machines:

• Heat press machine: used to seal the thermal vinyl layers together with heat and pressure.

• Laser cutter: used to cut the molds I designed in CorelDRAW (connected through LightBurn software).

• Air pump: to inflate and test the shapes created from both vinyl and silicone molds.

• CorelDRAW & LightBurn: CorelDRAW was for designing my shapes and molds, while LightBurn handled the laser-cutting process since it’s linked directly to the machine.

Process and workflow¶

For my first experiment, I wanted to see how air could create movement in a flat material. I used thermal vinyl sheets and baking paper to make an inflatable shape using the heat press.

Step 1¶

- I first drew a heart shape that I wanted to inflate.

- Then I cut the shape out of vinyl.

- I placed baking paper between the vinyl layers to prevent them from fully sticking together — only the edges needed to be sealed.

- Using the heat press machine, I carefully pressed the edges to seal the vinyl together.

- After sealing, I left a small opening to connect the air pump.

- Finally, I pumped air into the heart shape, and it inflated just as I expected.

Step 2¶

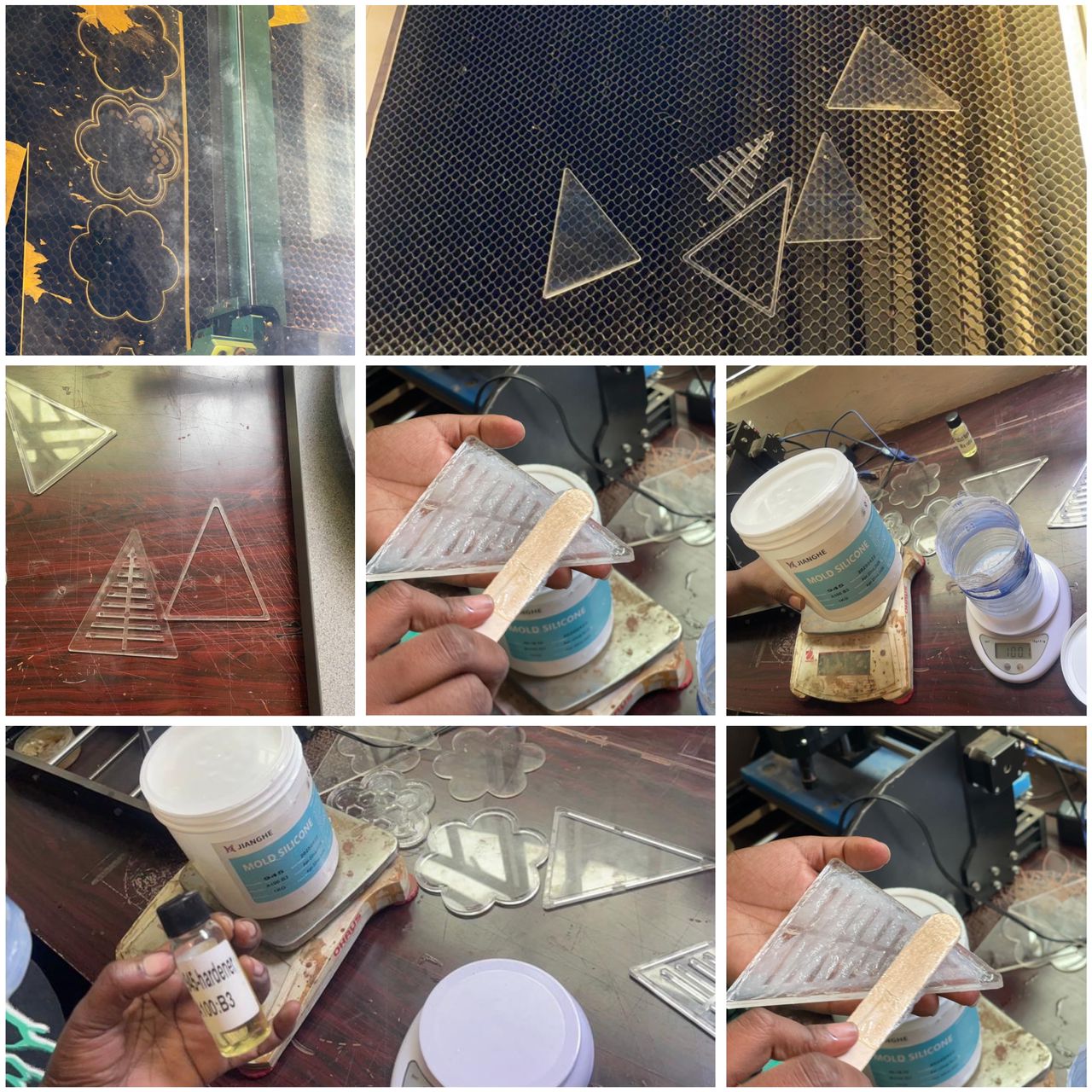

2: Silicone Mold Using Laser Cutting

In the soft robotics module, we learned how to create molds using acrylic sheets and cast them with silicone. The first design was provided by our Fabricademy instructor to help us understand the basic principles of mold making for soft robotics. I followed the given design by laser-cutting acrylic pieces, assembling them to form a mold, and then pouring silicone into it. This step helped me learn the correct mold structure, material handling, and the curing process of silicone.

1. I started by designing molds in CorelDRAW.

2. After finishing the designs, I used LightBurn to send them to the laser cutter, since it’s the software connected to the machine.

3. Once the molds were cut, I prepared the silicone mixture by mixing silicone with its hardener.

4. My first trial used Jianghe silicone, but it dried too fast and became hard before I could finish pouring it into the mold — so that one didn’t work.

Step 3¶

After successfully testing the instructor’s design, I created my own mold design inspired by the same technique. Using the knowledge gained from the first trial, I modified the geometry and structure based on my design reference. I then fabricated the acrylic mold and cast silicone again, applying what I learned to improve accuracy and control in the molding process.

-

I then tried again with NIUB silicone, which took more time to dry but worked perfectly.

-

After pouring the silicone into the molds, I let it dry completely, then attached two silicone layers together to form an air pocket in between.

-

Finally, I connected the air pump, and when I inflated it, the silicone expanded following the shape of my design.

Reflection on Both Experiments

These two experiments gave me a hands-on understanding of how inflation works in soft robotics and how different materials respond to air pressure.

The vinyl experiment was quick and visual — it showed me how heat and air can create instant results. The silicone mold experiment took more time and patience, but it helped me explore the idea of structure and precision.

Through both processes, I realized how creative and fun soft robotics can be — combining digital fabrication, materials, and movement in a way that feels both technical and artistic.