10. Implications and applications#

This week I worked on defining my final project idea by using Ultra-personalised product service systems

Concept / Idea#

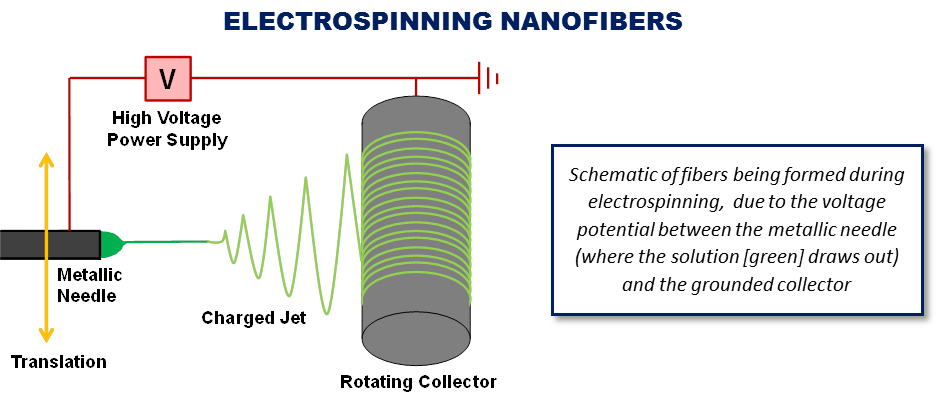

To develop a electrospining, which is a machine able to create fibers out of a polymer solution.

The aim of this project is to electrospun kombucha fibers and fruit leather fibers, biomaterials that are becoming more used in areas such as textiles.

The aim of this project is to electrospun kombucha fibers and fruit leather fibers, biomaterials that are becoming more used in areas such as textiles.

Sketches & Contribution#

-Kombucher propose a vertical diy electrospinning with a turnable collector. Most of the commercial electrospining machines works horizonally, also there are just two types of colector: a plate (static) or a roller like the one below

So i want to kombucher involves a turnable metallic plate

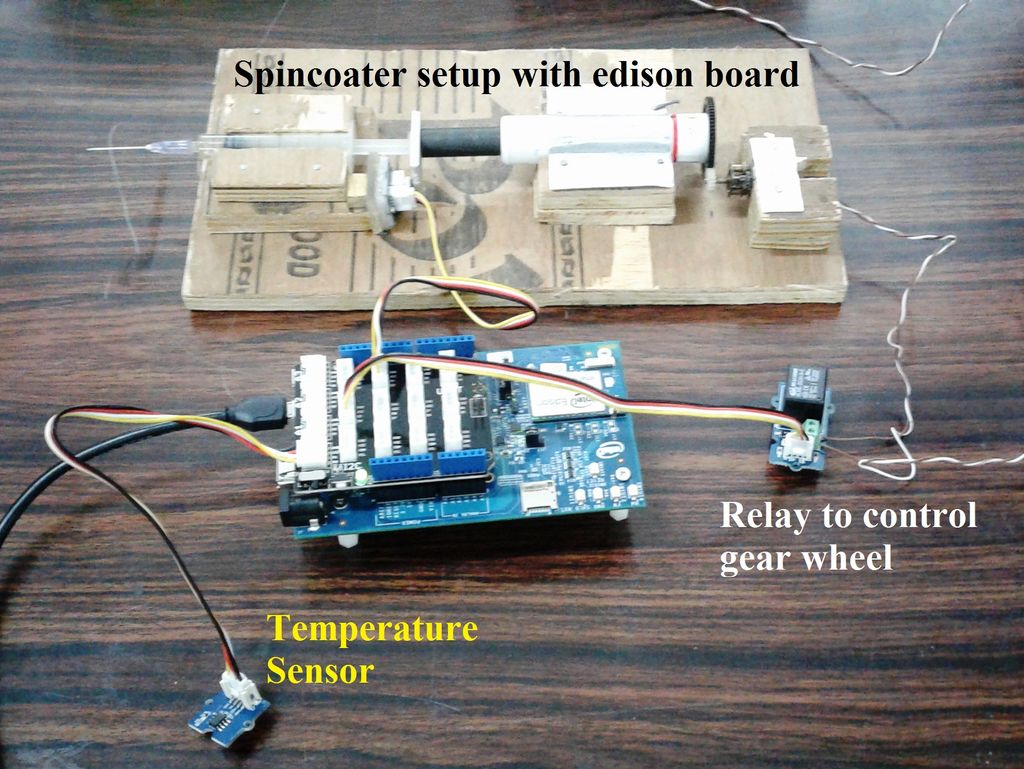

-Cheaper, with recycled components:

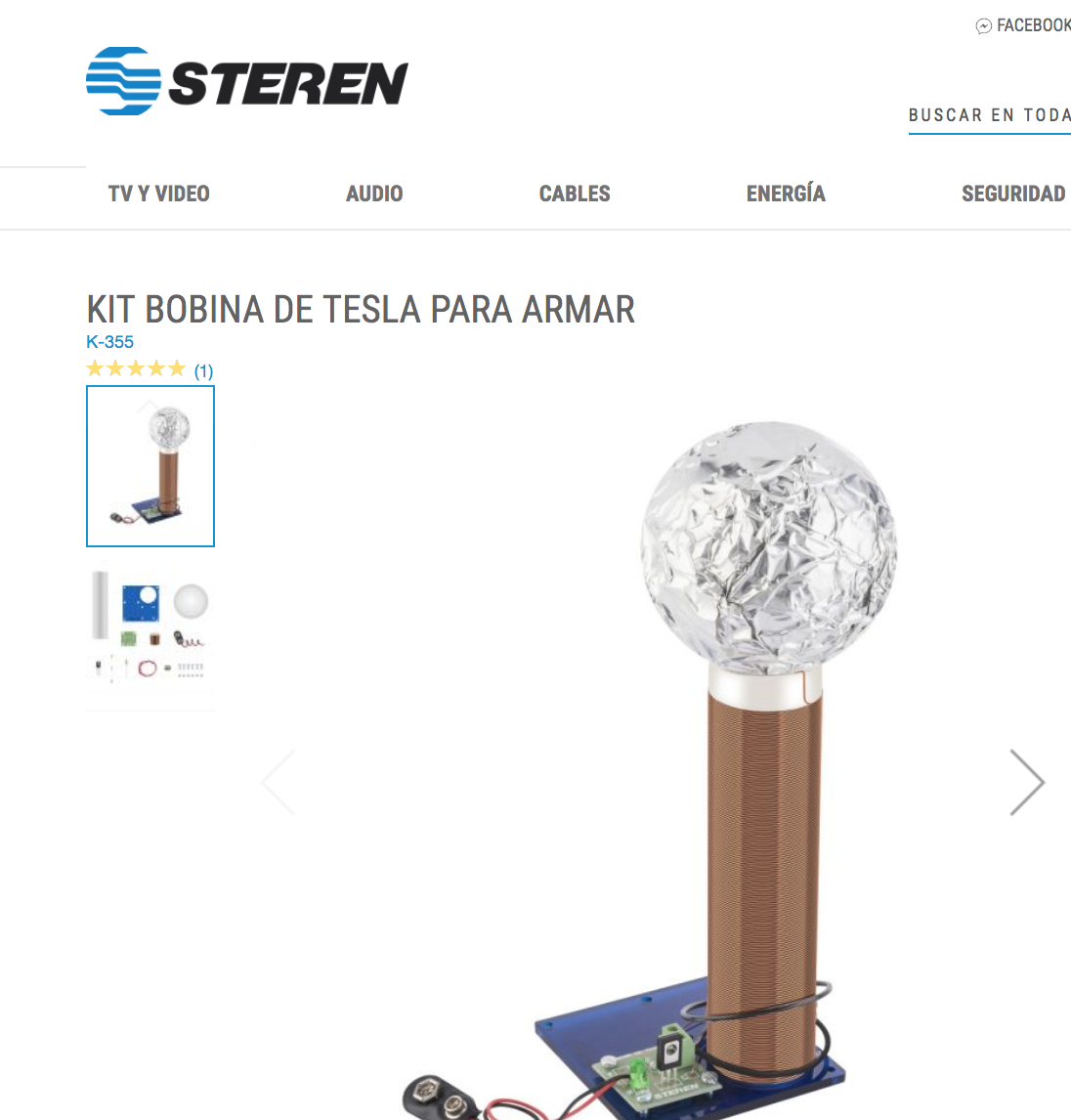

As most of the comercial electrospinners cost above 30,000 USD i would like to create a cheaper one trying to use recycled components, such a Tesla coil kit and a flyback form an old TV

Advantages#

to create a low cost diy electrospinning machine able to electrospun kombucha fibers by using recyclable electronics. Also to create a low cost power source able to produce high voltage (50kv), because most of the commercial electrospinning machines includes a power source which costs around 4000 USD and most of the diy electrospinning only propouse alternatives for the syringe mechanism but no for the power source.

Customers / Target#

Makers textile designers scientists students and universities

Stakeholders#

Scientists, students, universities and fablabs will be benefited from this project since a commercial electrospinning is very expensive but the applications have huge potential on the development of textile and biomedical applications.

Kombucha#

Kombucha is a beverage of probable Manchurian origins obtained from fermented tea by a microbial consortium composed of several bacteria and yeasts(SCOBY). This mixed consortium forms a powerful symbiosis capable of inhibiting the growth of potentially contaminating bacteria. The fermentation process also leads to the formation of a polymeric cellulose pellicle due to the activity of certain strains of Acetobacter sp.

This pellicle or membrane form by bacterial cellulose has proved to be a potential biomaterial on different areas from biomedichal, food ant textile.

References / scientific publications#

“The emergence of nanotechnology, researchers become more interested in studying the unique properties of nanoscale materials. Electrospinning, an electrostatic fiber fabrication technique has evinced more interest and attention in recent years due to its versatility and potential for applications in diverse fields. The notable applications include in tissue engineering, biosensors, filtration, wound dressings, drug delivery, and enzyme immobilization. The nanoscale fibers are generated by the application of strong electric field on polymer solution or melt. The non-wovens nanofibrous mats produced by this technique mimics extracellular matrix components much closely as compared to the conventional techniques. The sub-micron range spun fibers produced by this process, offer various advantages like high surface area to volume ratio, tunable porosity and the ability to manipulate nanofiber composition in order to get desired properties and function. Over the years, more than 200 polymers have been electropun for various applications and the number is still increasing gradually with time.”