7. Computational Couture¶

This week we learned about computational couture and parametric design. Aldo Solazzo the founder of Noumena,a Barcelona-based company specialized in tech solutions in robotics, 3D printing, and wearables gave us a lecture along with Anna Correa a former Fabricademist. Eugenio Bettuchi gave us tutorials on how to use Grasshopper a plugin of Rhino. - Grasshopper tutorial 1 - Grasshopper tutorial 2 - Grasshopper tutorial 3

Research¶

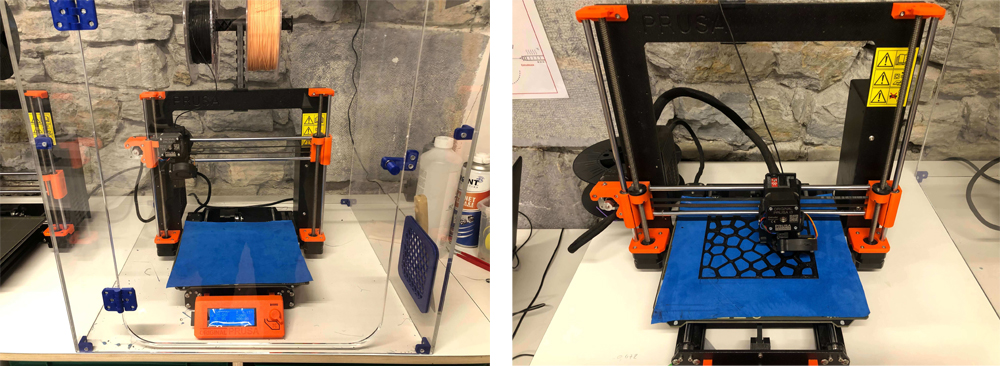

Gaëtan Bobichon, from La Casemate, the Fab Lab in Grenoble where I get to do my assignements gave me an amazing training on Friday on how to use 3D printers.

Turns out he was an intern for Jolan van der Wiel, and worked printing twenty pairs of shoes made for Iris van Herpen. They used a bioplastic loaded with metal. Magnets were used to extrude amazing shapes from the plastic.

Turns out he was an intern for Jolan van der Wiel, and worked printing twenty pairs of shoes made for Iris van Herpen. They used a bioplastic loaded with metal. Magnets were used to extrude amazing shapes from the plastic.

He told me about different initiatives experimenting with bioplastics, such as Francofil, and l'Atelier Luma in Arles. The lab hosts a multidisciplinary network of designers, artists, biologists, engineers, farmers, philosophers, sociologists and activists working together to meet the challenges of transition in the Arles territory.

He told me about different initiatives experimenting with bioplastics, such as Francofil, and l'Atelier Luma in Arles. The lab hosts a multidisciplinary network of designers, artists, biologists, engineers, farmers, philosophers, sociologists and activists working together to meet the challenges of transition in the Arles territory.

- Atelier Luma

Many of these plastics can be used in 3D Printers, such as designers Eric Klarenbeek and Maartje Dros who have developed a bioplastic derived from algae that is said to be a viable alternative for non-biodegradable plastic.

Many of these plastics can be used in 3D Printers, such as designers Eric Klarenbeek and Maartje Dros who have developed a bioplastic derived from algae that is said to be a viable alternative for non-biodegradable plastic.

Designing a parametric model using Grasshopper 3D¶

I was inspired by the Voronoi shape and wanted to try to reproduce the scaled hexagon model Diane Wakim shared with us.

Here you may find the stl file I made:

I started with defining an input, which in this case was rectangle. I populated the design and then used the voronoi pattern as a grid.

Working on Cura¶

3D Printing¶

I printed on Suede fabric, using TPU Filaflex. I had to use double-faced tape on the tablet to hold the fabric in place. This meant that the height of the nozzle needed to be changed. We used Live adjust Z and adjusted the height from -0,655 to -0,455.

Useful links¶

- Adjusting head of nozzle

- Extrude Voronoi tesselation

- [Jolan Van Der Wiel and Iris Van Herpen]https://www.dezeen.com/2013/07/30/magnetic-grown-dresses-by-iris-van-herpen-and-jolan-van-der-wiel/