Oct 31, 2022

In this class we explore computational design methods towards a new reinterpretation of cloths, garments and accessories for fashion design, inspired by a new digital design methodology.

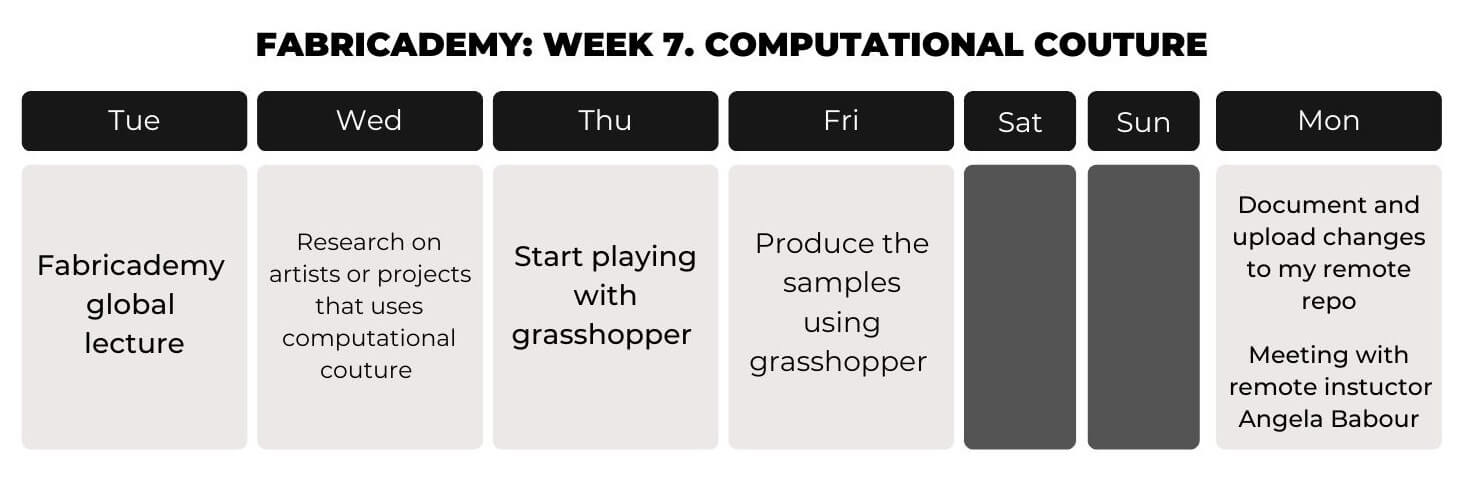

1. Weekly Documentation planning

2. Inspiration and research

3. Computational Couture

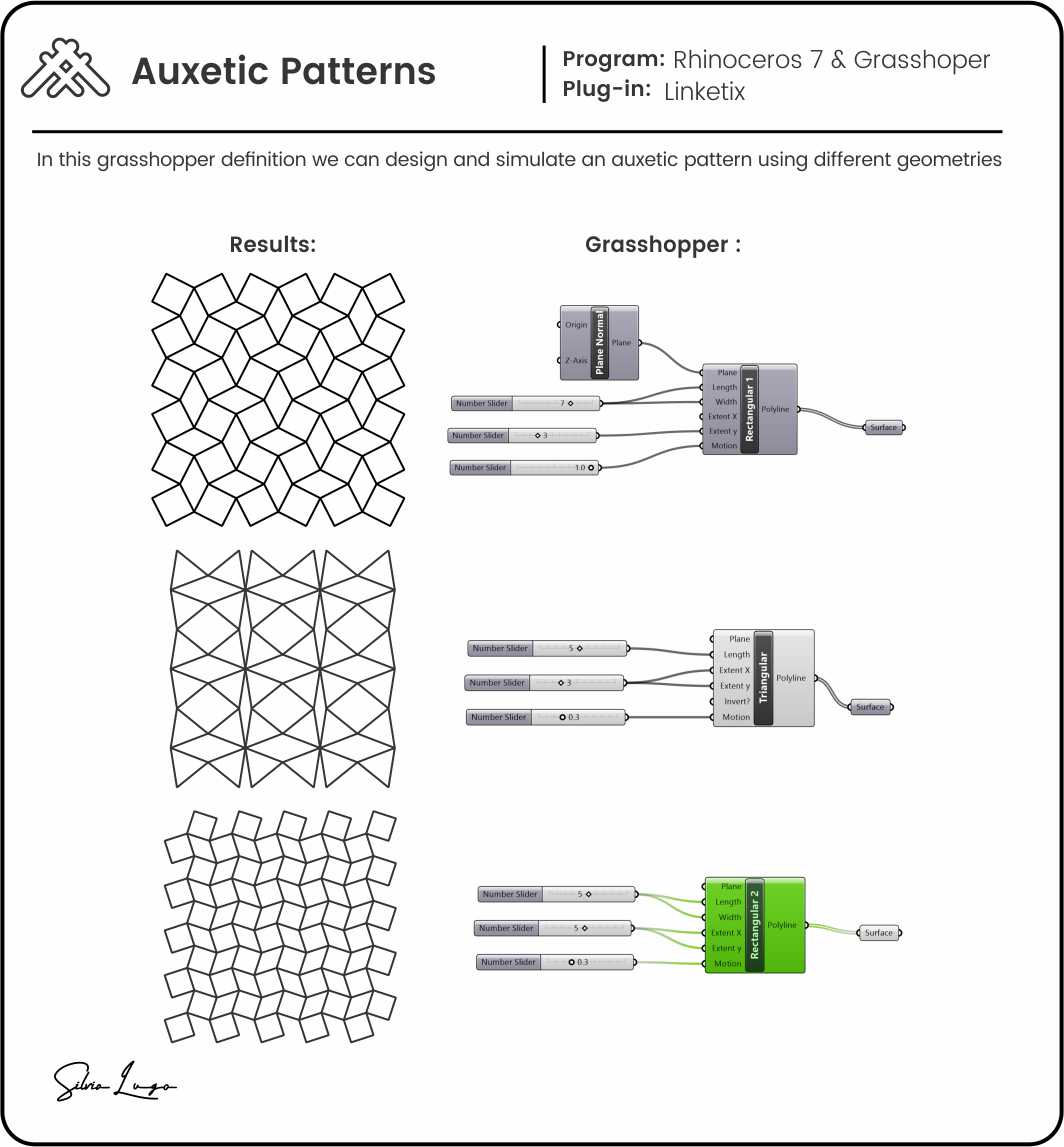

This week I wanted to learn about auxetic patterns and its application to different fields, so I made some reasearch about works related to it. I also write about other techniques and some experiences I had with computational design.

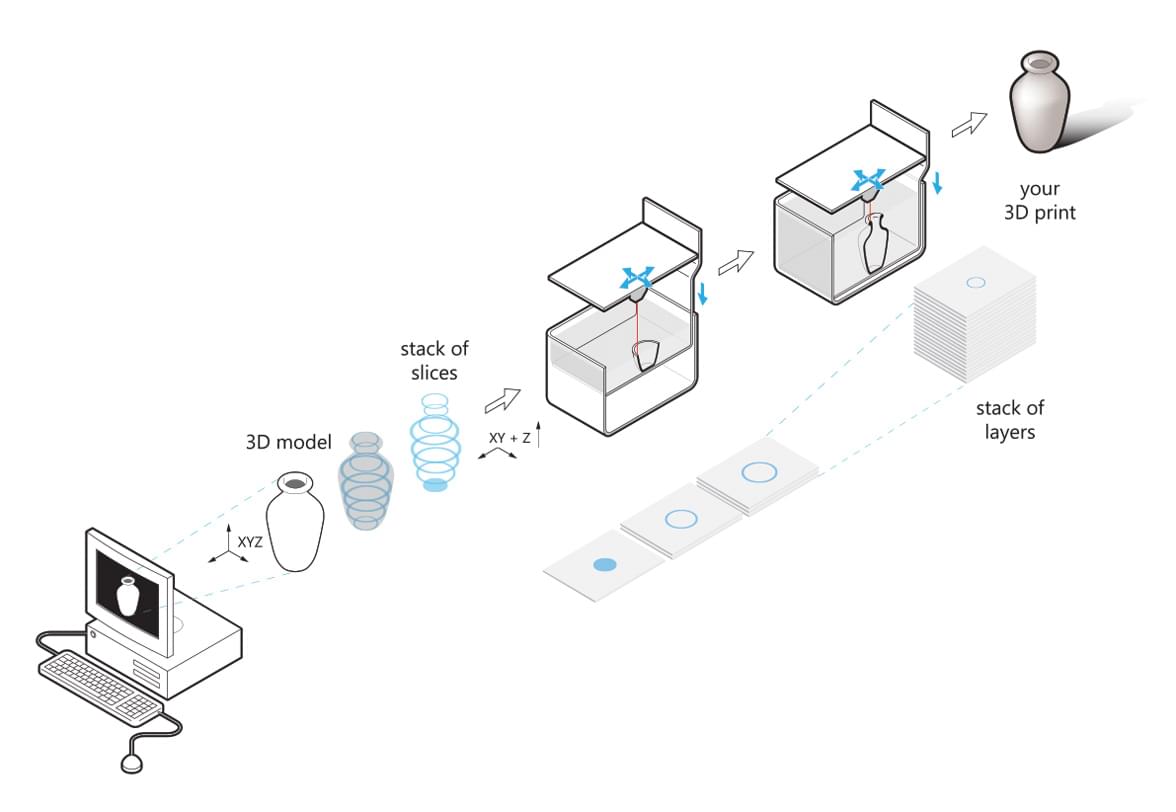

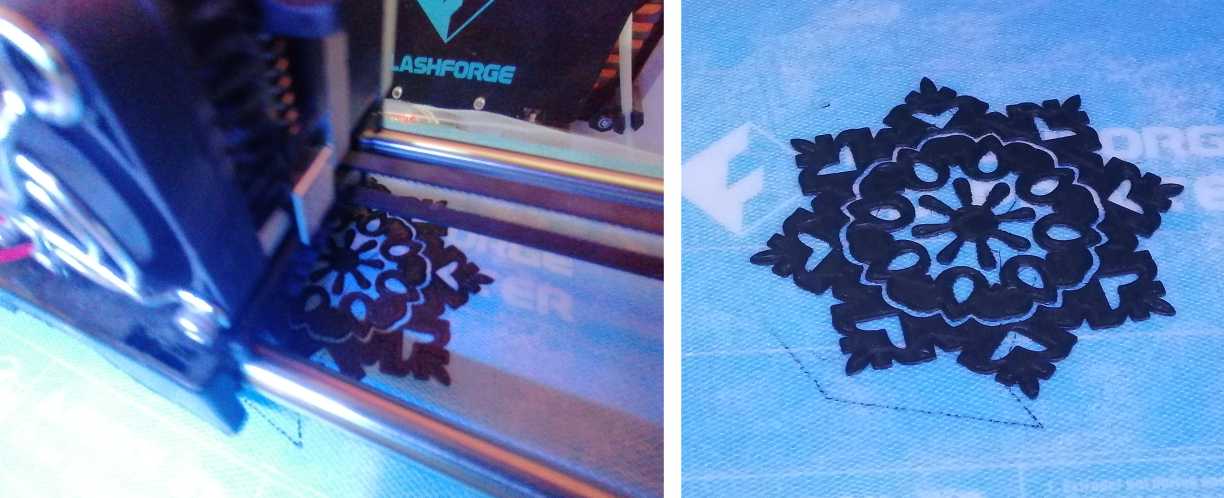

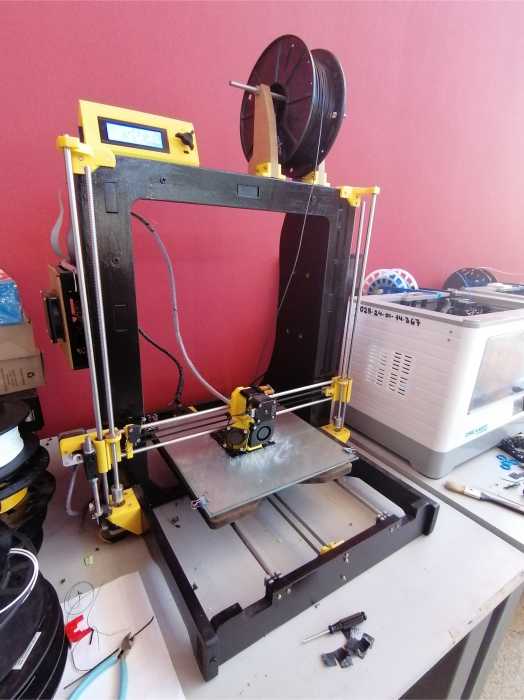

Here's the general workflow of 3D Printing, I'll be going step by step explaining how I worked this week.

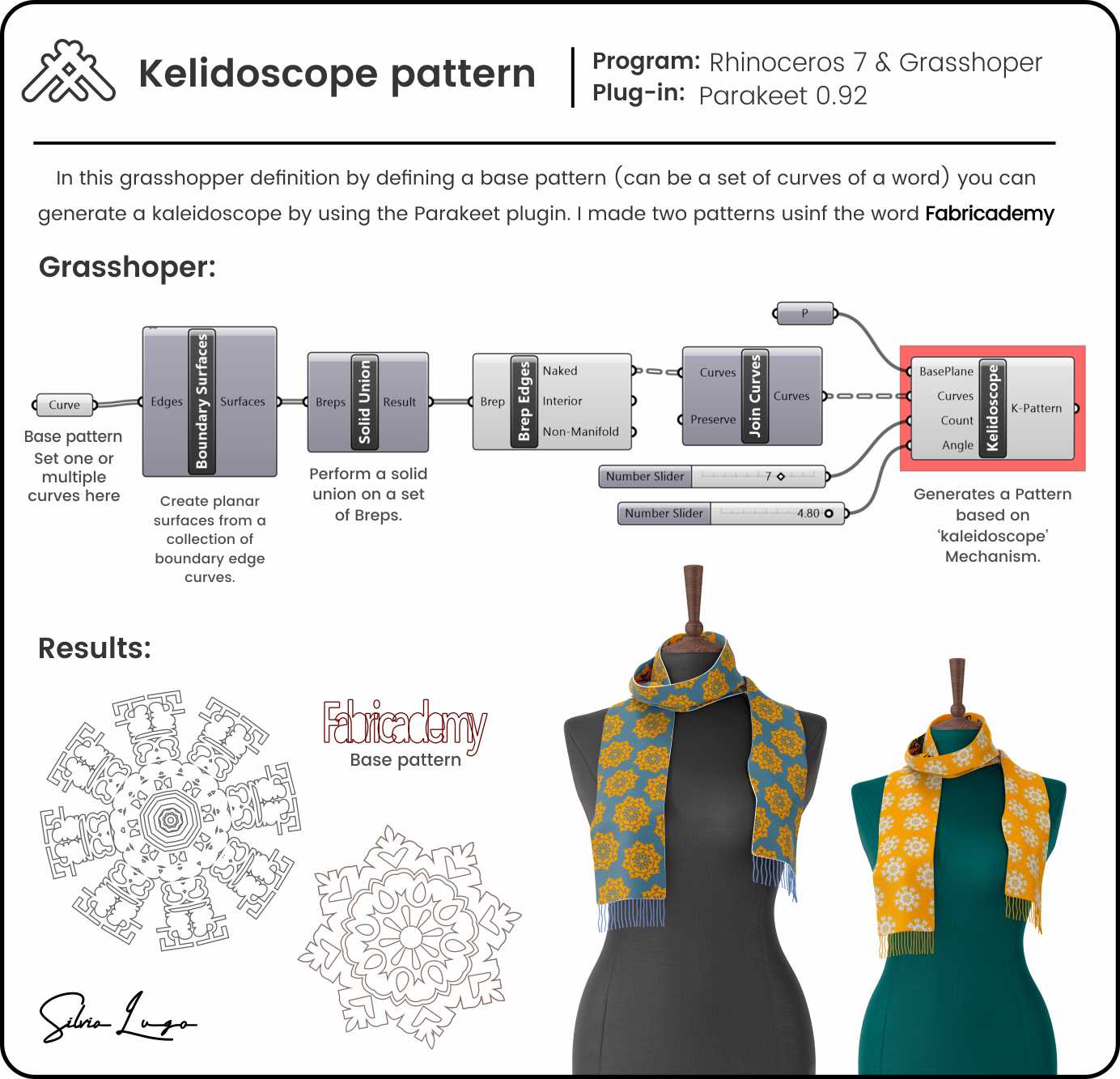

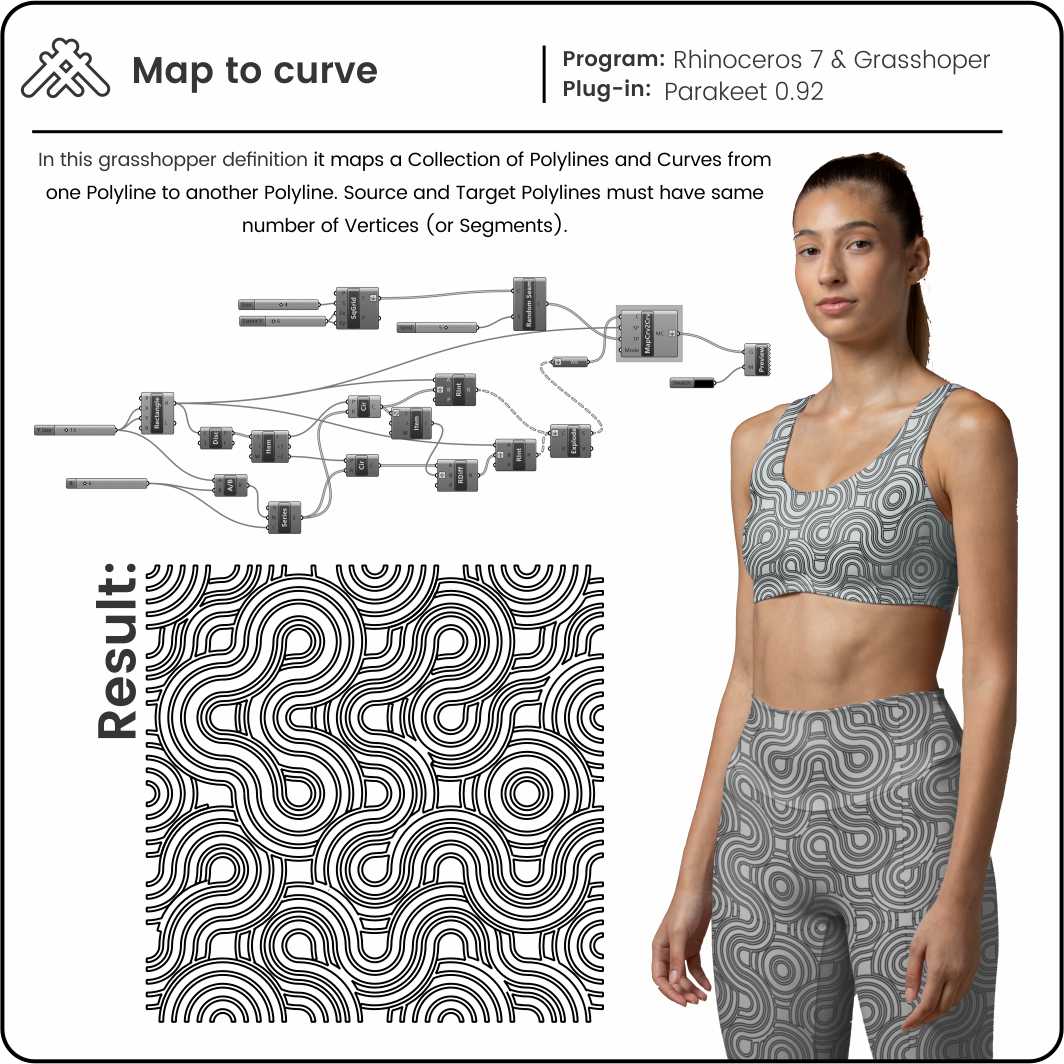

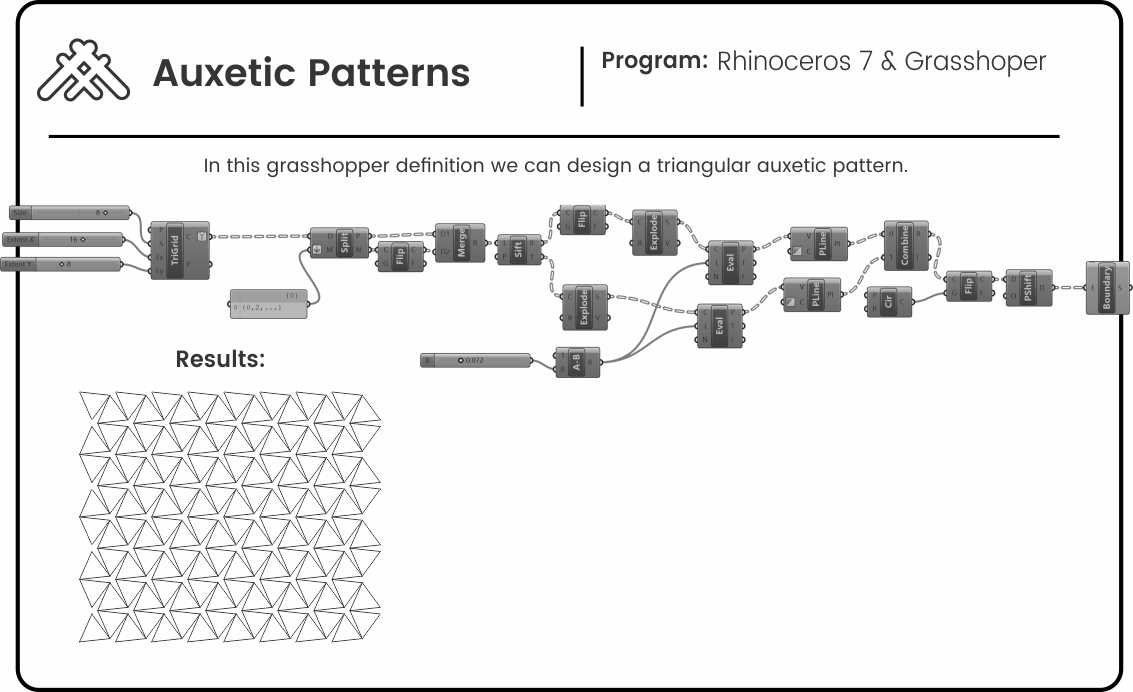

I decide to play a little with Grasshoper. I started testing one of my favorite plugins, which is Parakeet. A collection of components focusing on Algorithmic Pattern Generation; it offers a unique and easy-to-use approach that Generates Geometrical and Natural Patterns/Networks.

I found a Newspaper article called "Auxetics: Don't Pull Me, I'll Get Fatter!" by James N. Grima-Cornish of University of Malta, it's an useful resource that I referenced in this week's documentation a lot. So take your time and read it if you want to.

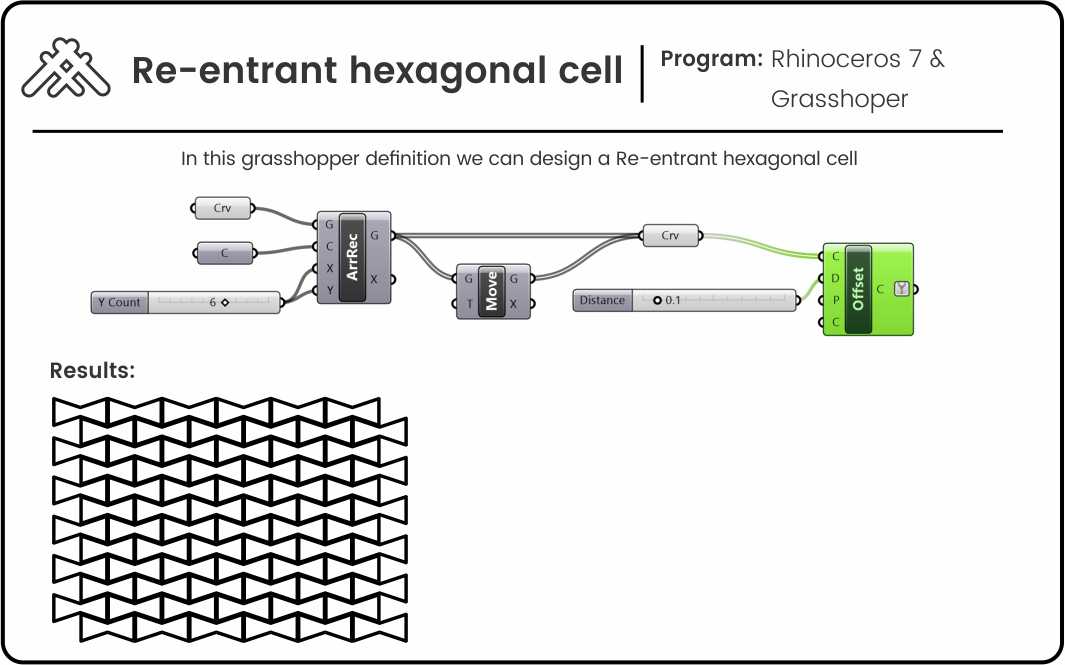

Auxeticity, a term coined by K. E. Evans and coworkers in 1991 (Evans et al., 1991), can be defined as the material property of

having a negative Poisson’s ratio. A visual example of auxeticity is given in Figure 1, which shows how auxetic materials become “fatter” when uniaxially stretched and “thinner” when uniaxially compressed

On the macroscale, applications of auxetic materials and structures include sportswear applications, clothing, furniture, yarns, protection and home improvement.

To try some auxetic pattern I download a new plug-in called Linketix (de parametrichouse). A live Physics Engine for simulating Mechanisms & Kinetic design.

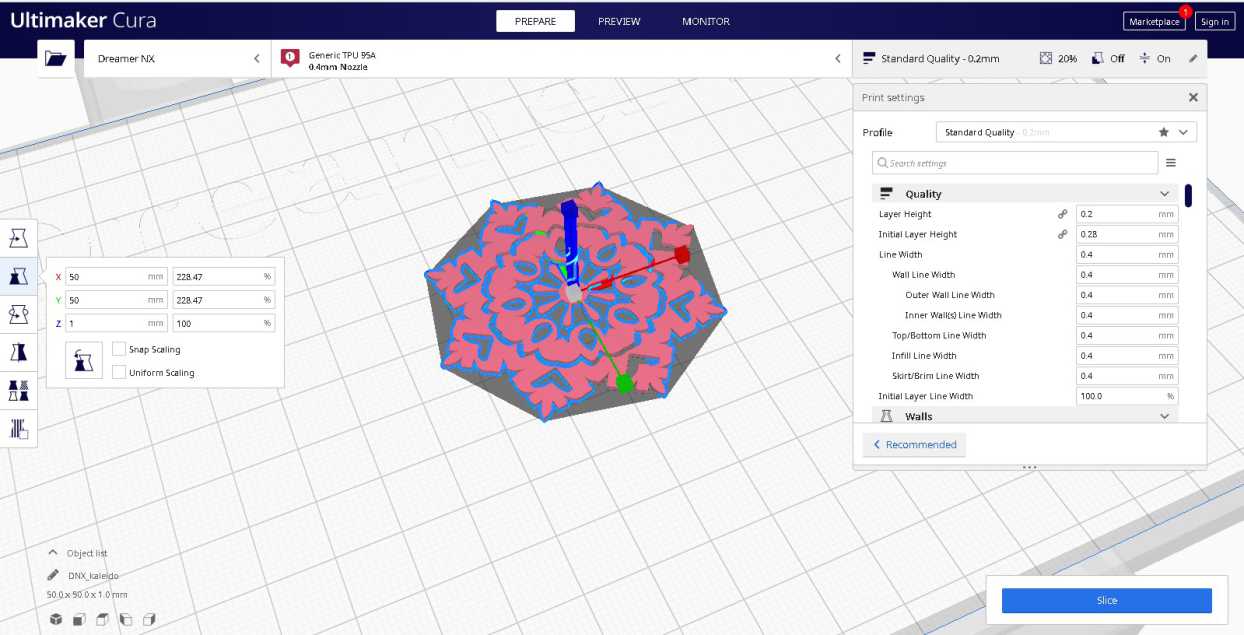

The STL (Standard Triangle Language) is the industry standard file type for 3D Printing. It uses a series of triangles to represent the surfaces of a solid model. All modern CAD (Computer Aided Design) software allow you to export their native file format into STL. The 3D model is then converted into machine language (G-code) through a process called “slicing” and is ready to print.

All my files were exported to stl and have a similar size of 80x80x1 mm.

| Software | Description |

|---|---|

Rhino |

File > Save As… In the Save As... box, select Stereolithography [*.stl]. |

Source:HUBS

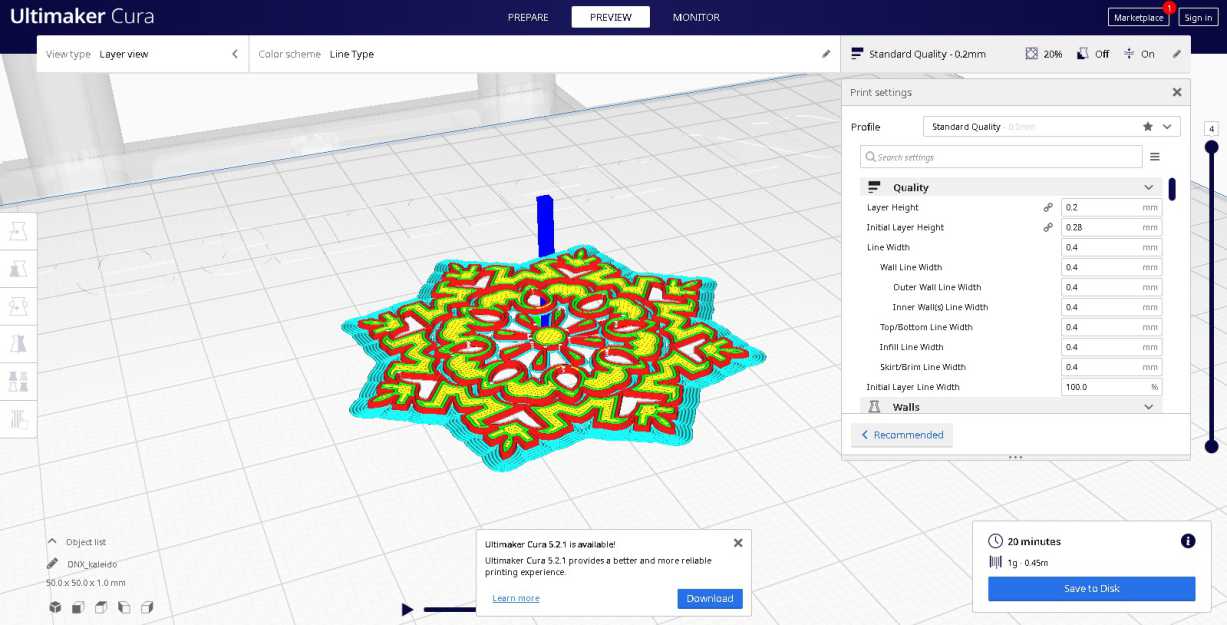

A slicer is a program that converts digital 3D models into printing instructions for a given 3D printer to build an object. In addition to the model itself, the instructions contain user-entered 3D printing parameters, such as layer height, speed, and support structure settings. I use Ultimaker Cura as my slicer. Here are some settings I use to print the samples:

For these works, I'll use TPU, which is a flexible filament. Here you can see a list of the most common filaments.

| 3D Printing | Material | Physical Properties |

| FDM | ABS | The right intensity and temperature resistance; Easier to warp |

| PLA | Low impact strength | |

| TPU | Difficult to print accurately | |

| PA | High impact strength and mechanical | |

| PEI | Excellent fire protection | |

| PETG | Excellent automatic and safe food material | |

|

|

|---|

|

|

|---|