Oct 04, 2022

Hello there! This is a page that documents my third week of Fabricademy. Let's go!

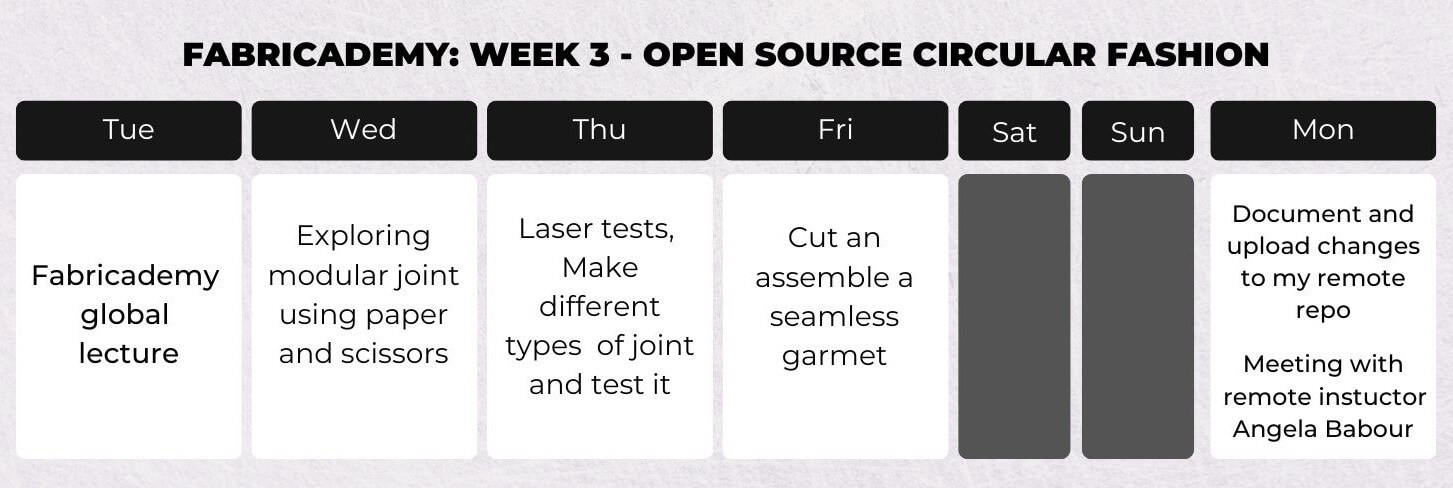

1. Weekly Documentation planning

2.Modular Fashion

3. Creating modular seams

In this week's class the lecture elaborates about the systems behind fashion and the textile industry, focusing on alternative systems such as circular fashion, agile fashion, open value chains.

Our assignment is to create modular elements, structures and connections that allow the user to change the shape of a garment, resize it or replace certain elements.

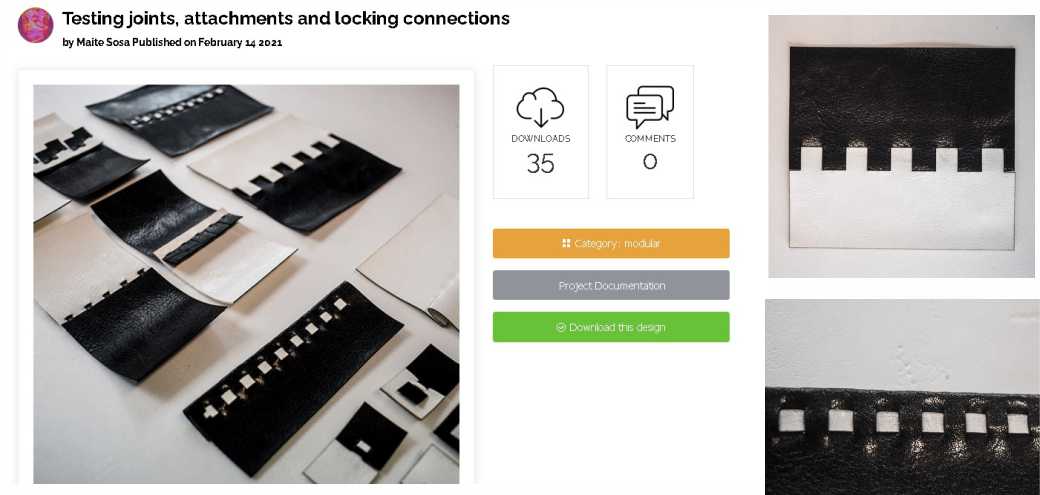

I find inspiration and explore other ideas to do this week in Pinterest and OS Circular fashion page. I find really intesting the explorations of interlocking conections, specially the ones from Maite Sosa and the "Post couture collective" from Martijn van Strien.

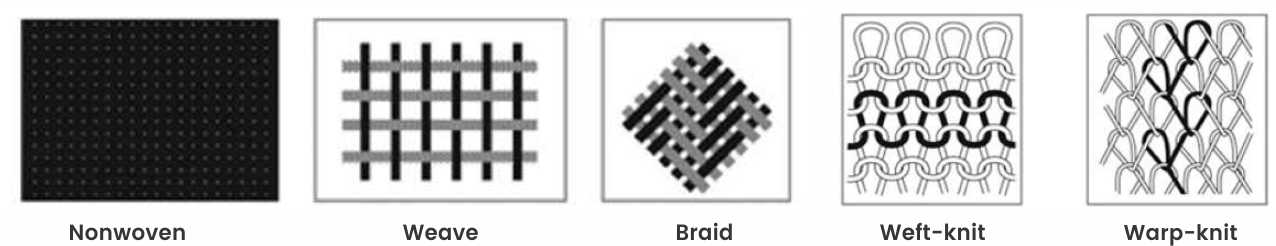

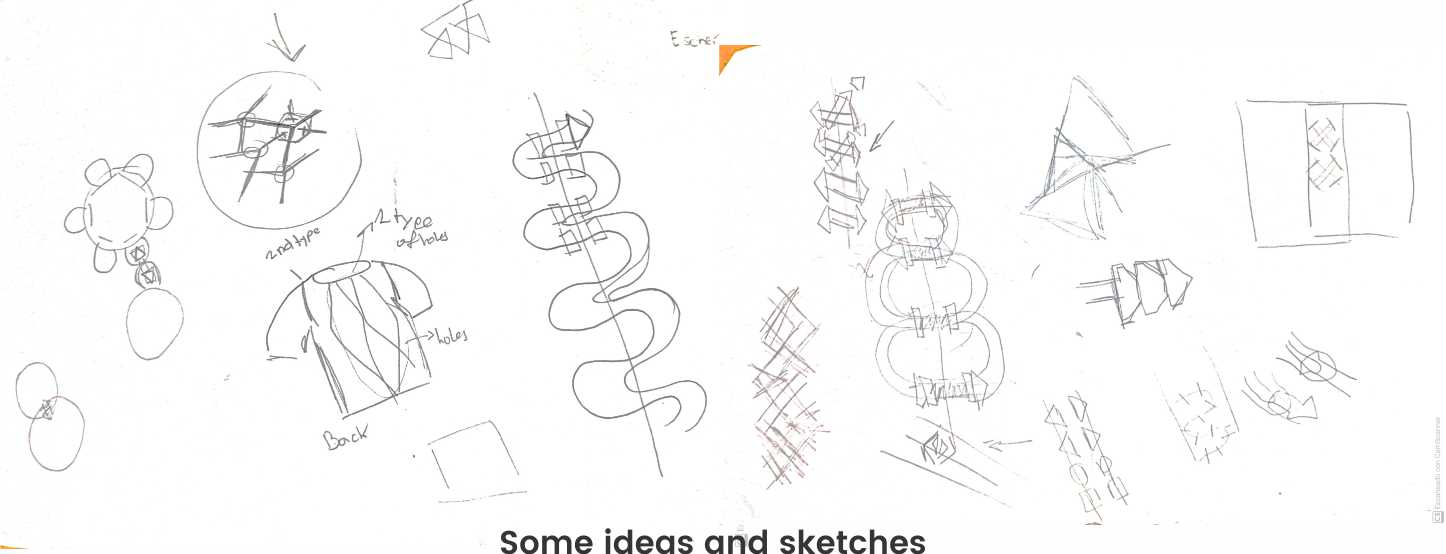

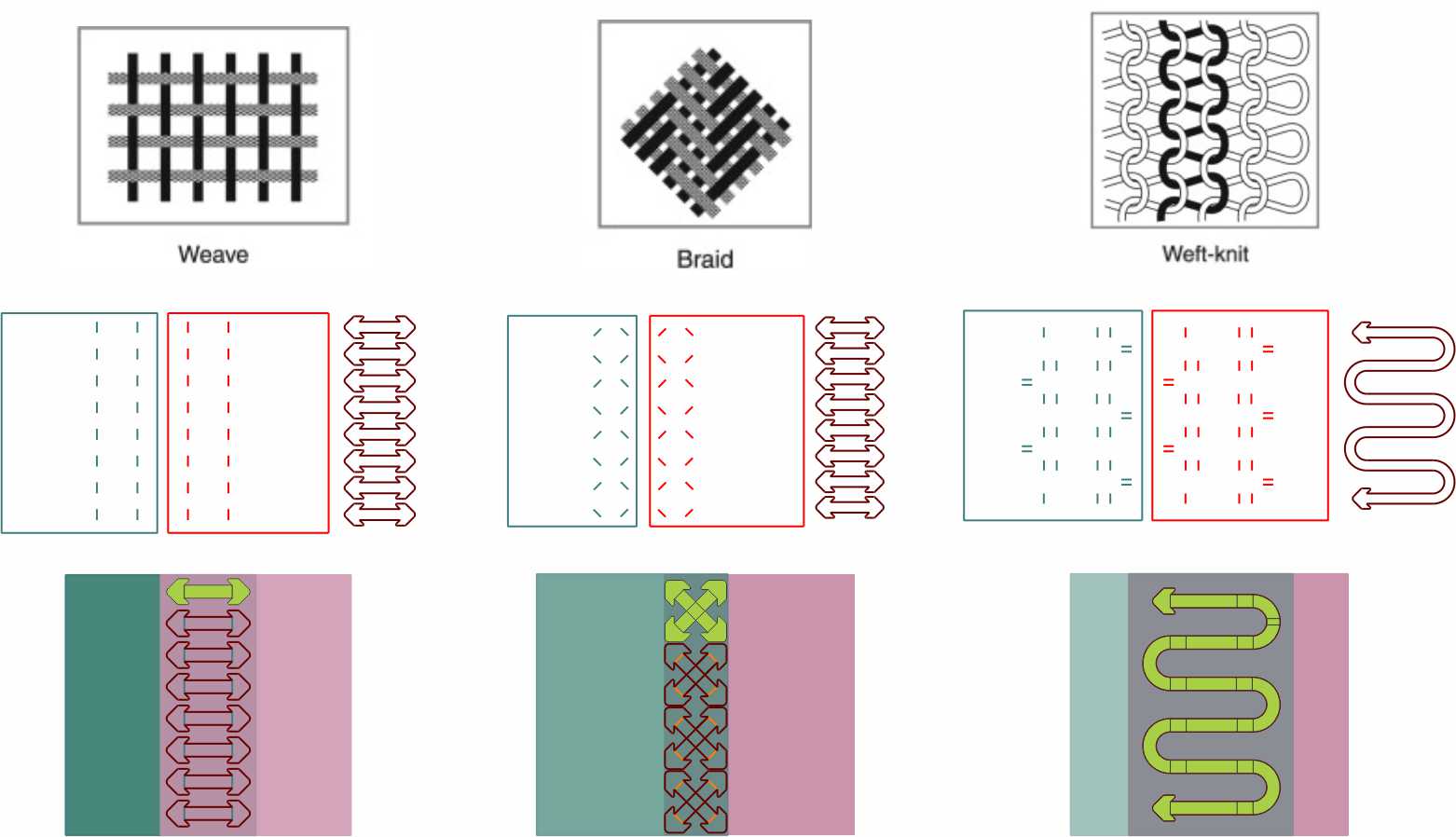

This week I wanted to explore locking connections to create seamless garmets. I started drawing the ideas that I got based on textile structures.

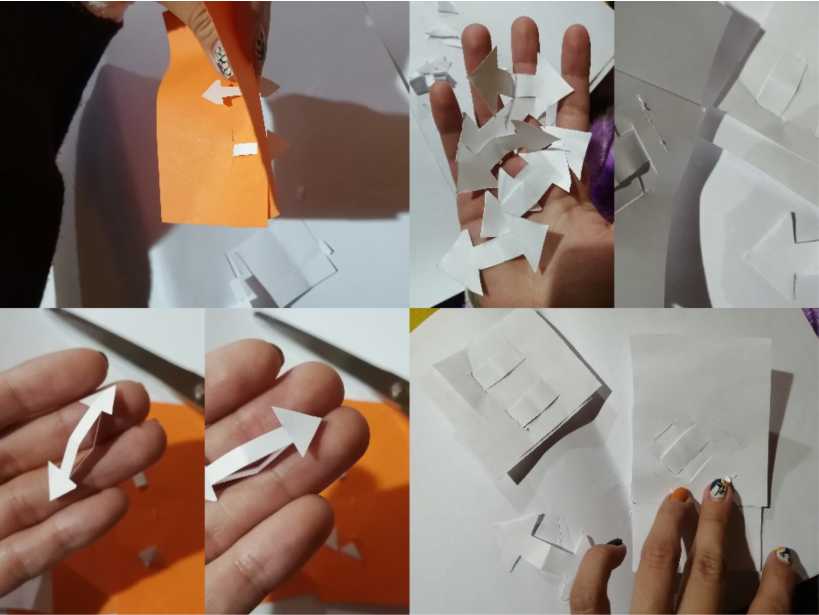

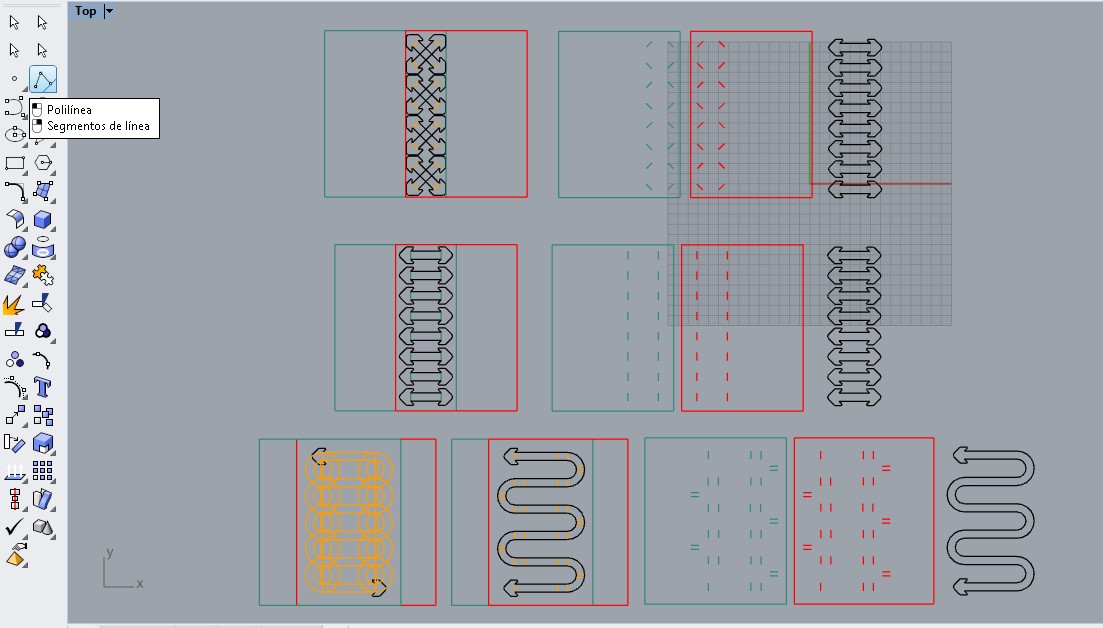

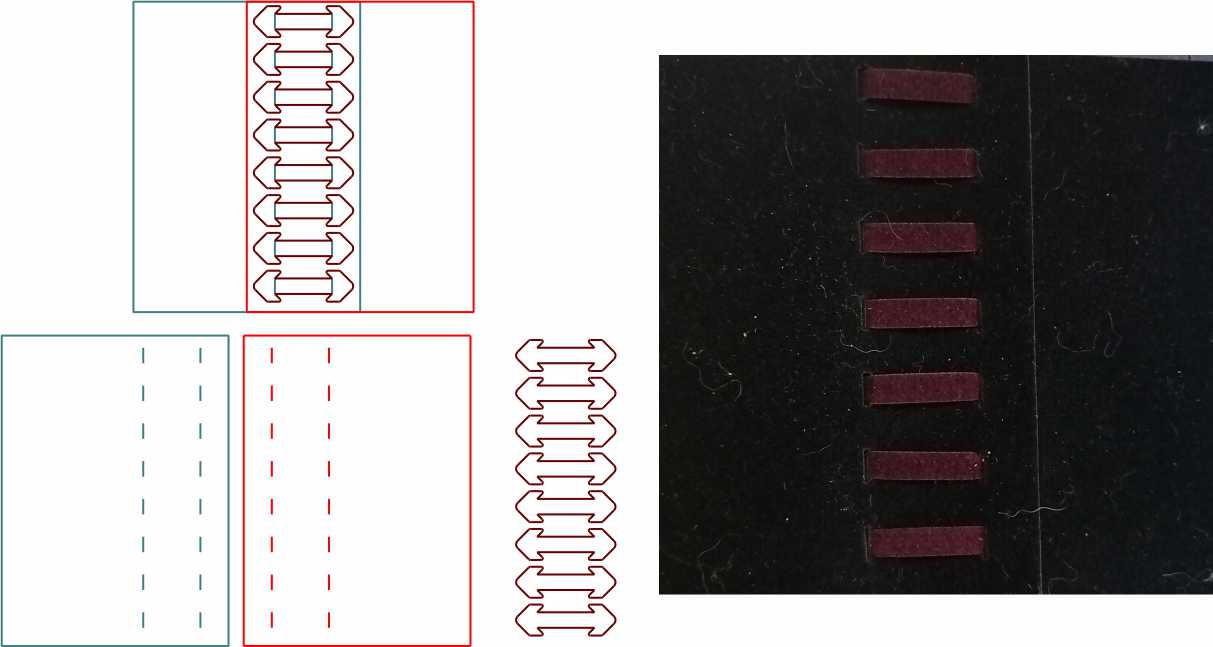

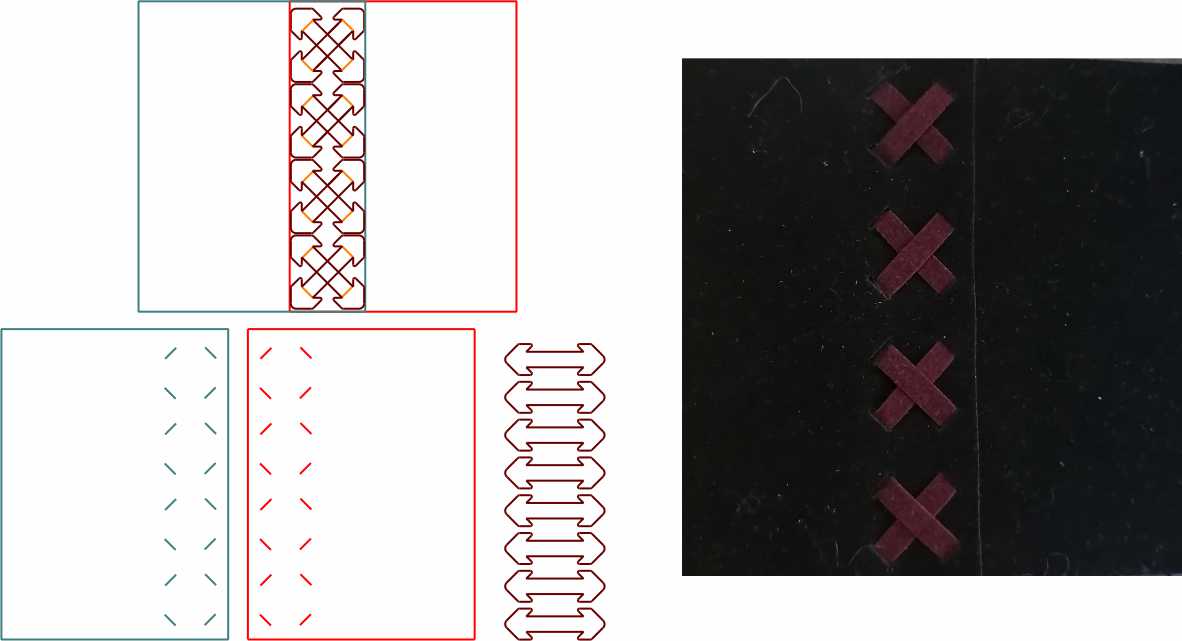

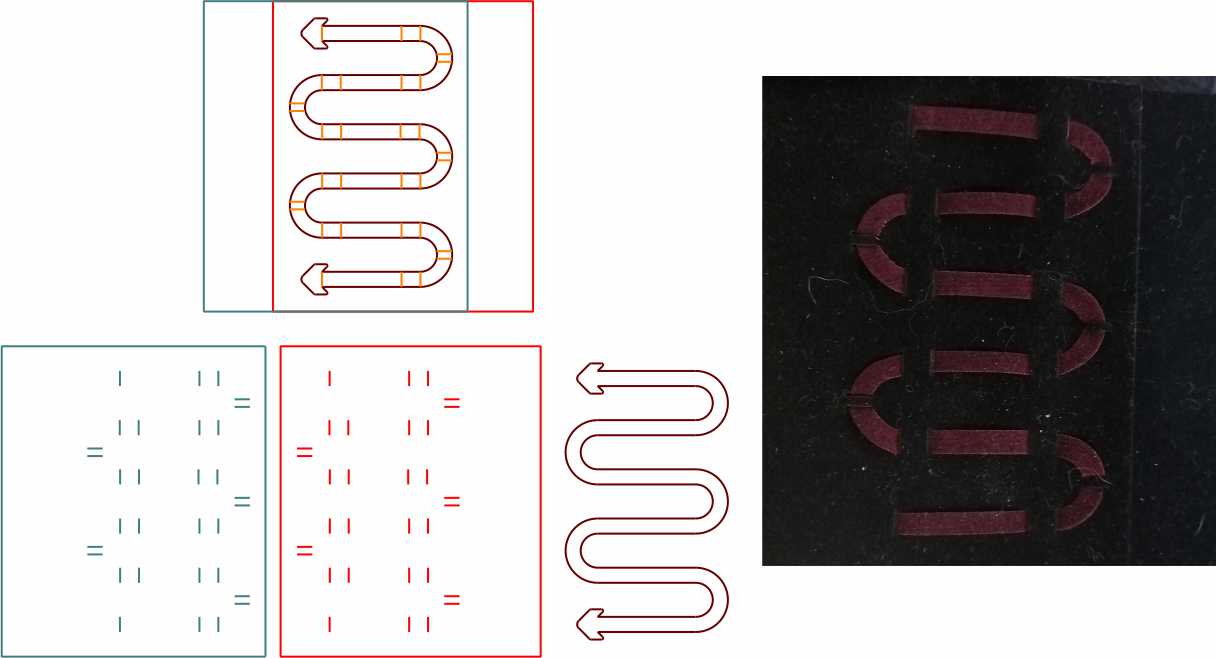

After making these tests I use Rhinoceros to digitally draw my ideas. I use the polyline and fillet tool. Here are my results:

It's important to choose a suitable material for laser cutting. Some material can release dangerous gases or dust. Here's a list of materials that we have to avoid. After reviewing that list I went to a fabric store and pick a material to make the assignment.

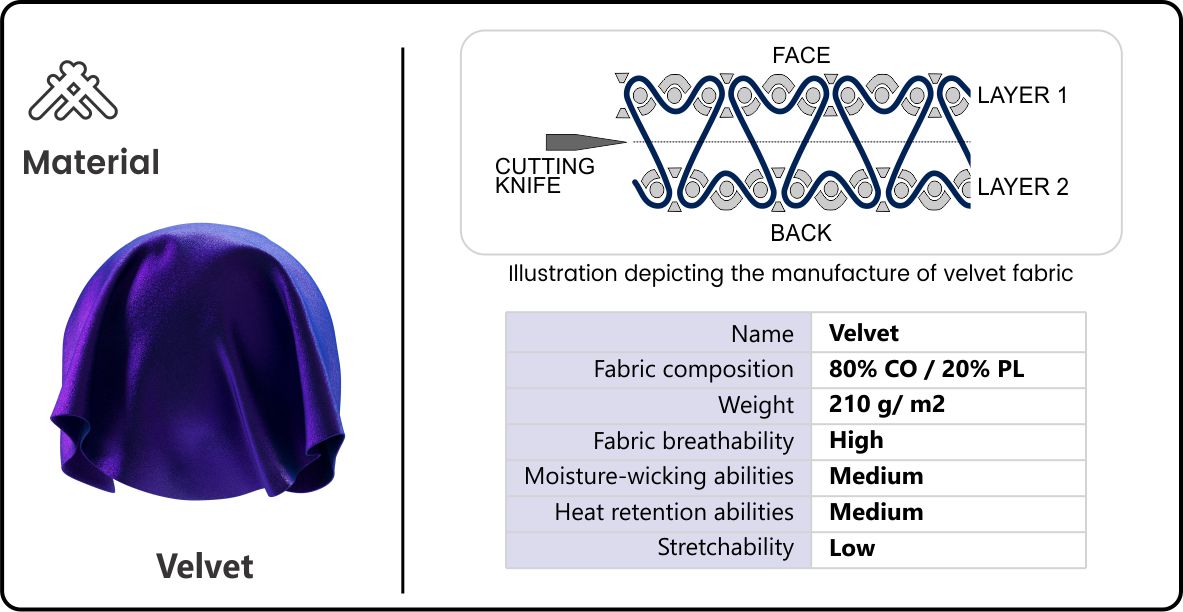

I decided to try velvet, it's a soft fabric and it has fine texture and luxurious look. Here you can check the materiacl specifications:

|

|

|---|

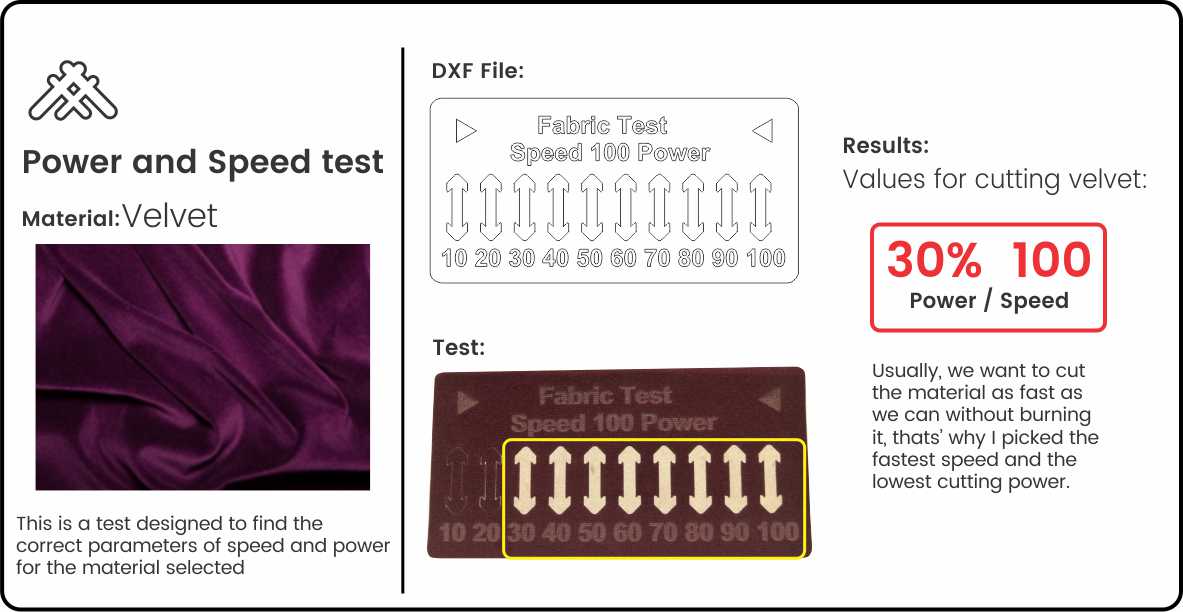

Before cutting a file, it is necessary to carry out tests with the material that we are going to use to ensure a clean job without major problems.

This test will help us find the correct parameters of speed and power for the material selected.

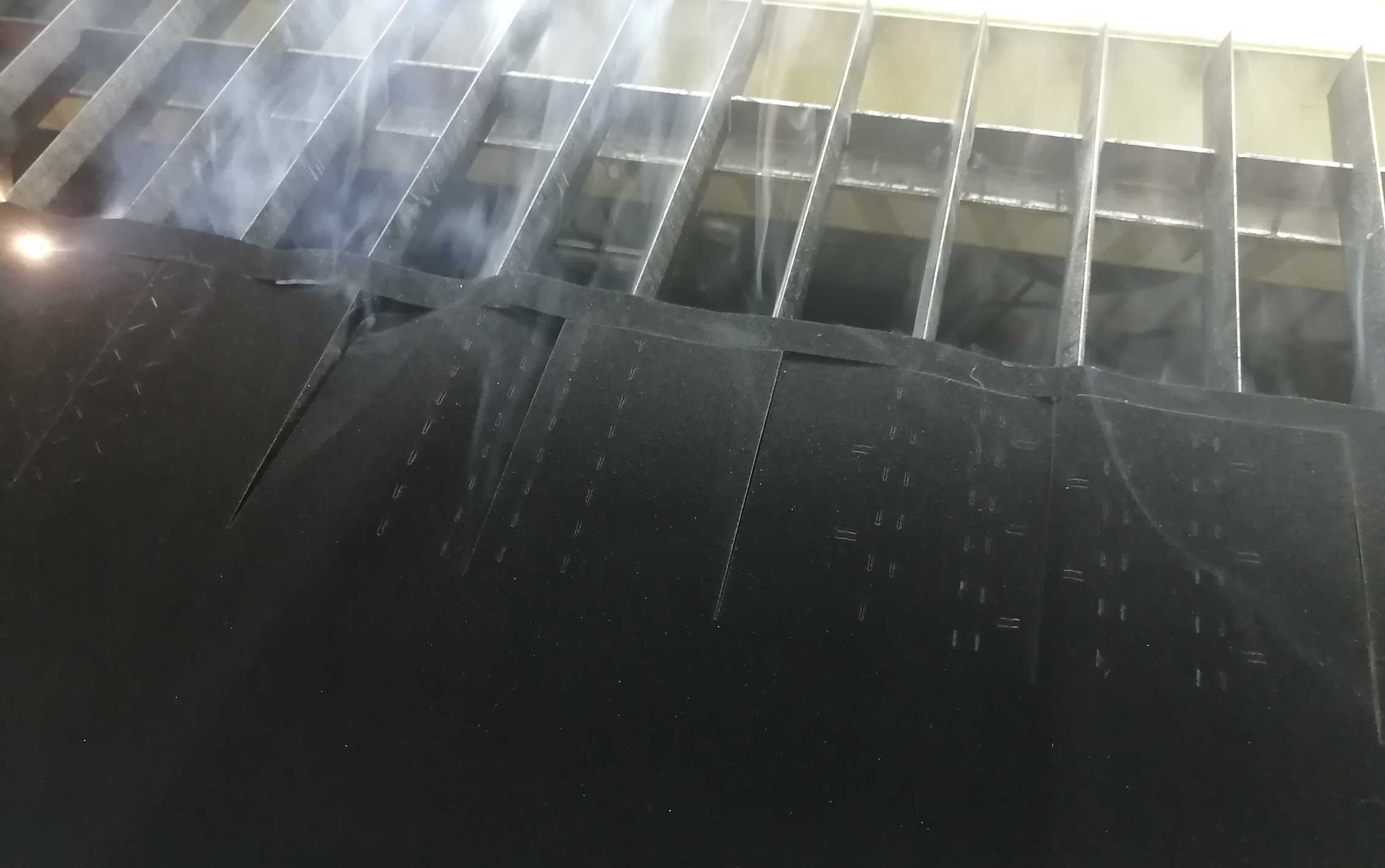

Now, I can start cutting my joints.

I made a detailed list about all the steps required to operate the laser cutting machine in my second week of fabricademy.

I follow the same path for this week's assignments and these were my results:

I tested the joints pulling the fabrics away from each other. All joints worked well, but the second type was stroger and harder to dissamble. That's why I decided to pick that one and designed a seamless garmet using it.

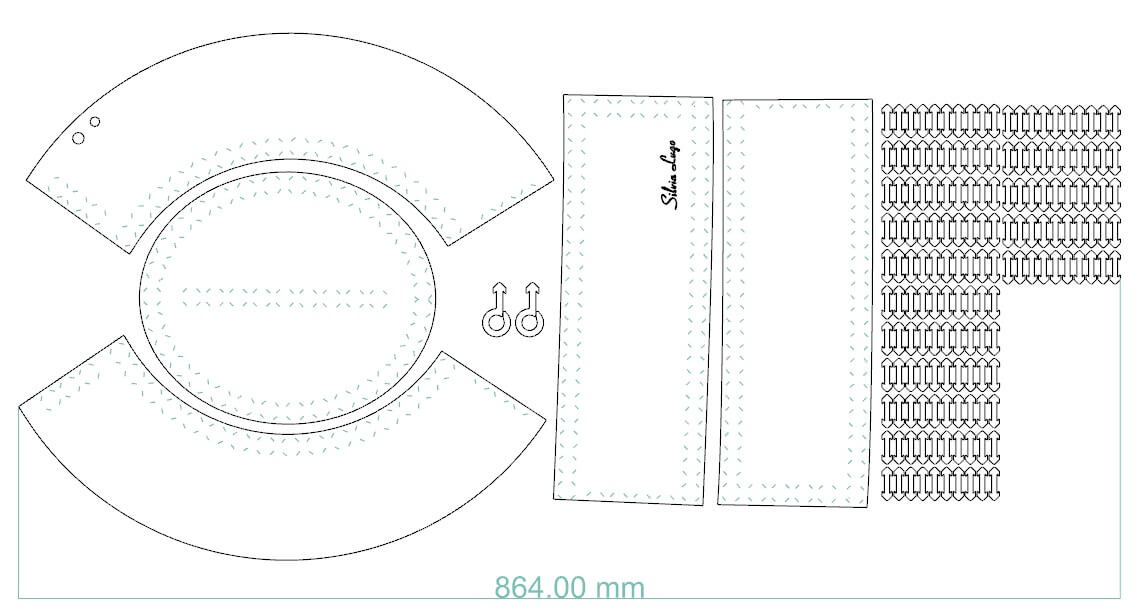

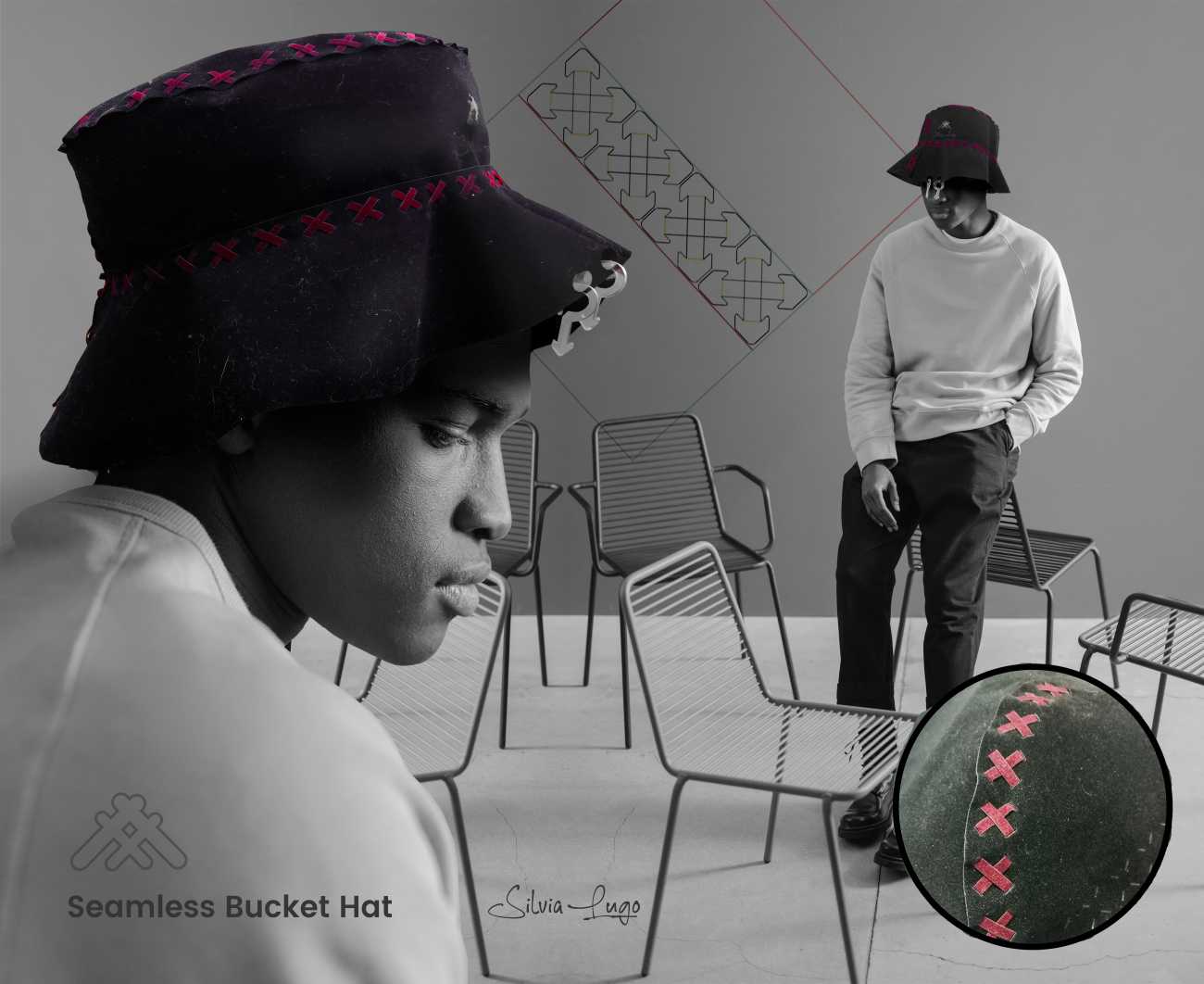

I design a Bucket hat using this free template. I edited the file in Rhino and add the joint pattern making sure each "X cut" was equidistant from each other and following the seam path.

The assembly process was pretty slow at the beginning but it quickly became easier and faster. The result was great and I'm excited to try this interlocking connection with more garmets. (You can find the file at the bottom of the page).

I upload my design files the Fabricademy Open Source Circular fashion catalogue. You can check it here.