Nov 22, 2022

The class explores the open source hardware field in general and focuses on its potential in the area of textile.

1. Weekly Documentation planning

2. Inspiration and research

3. Computational Couture

Laboratory centrifuges spin a sample at high speeds in order to separate particles in suspension. Centrifuges are found in many types of labs including biological, environmental, pharmaceutical, and clinical labs. Microcentrifgues differ from standard laboratory centrifuges in the size of the tubes used.

Microcentrifuge tubes are much smaller than standard tubes, generally in the 1.5-mL to 2-mL range, though models that support larger or smaller tubes can be purchased. When purchasing a microcentrifuge, it is important to consider temperature range, equipment size, speed, and size of centrifuge tubes accepted.Source.

I found a lot of great examples about this centrifuges, here's a recap of some of them:

In this next example I like the simplicity of the product, simplicity when it comes to design and also electronics. I think I'll use the same system.

p

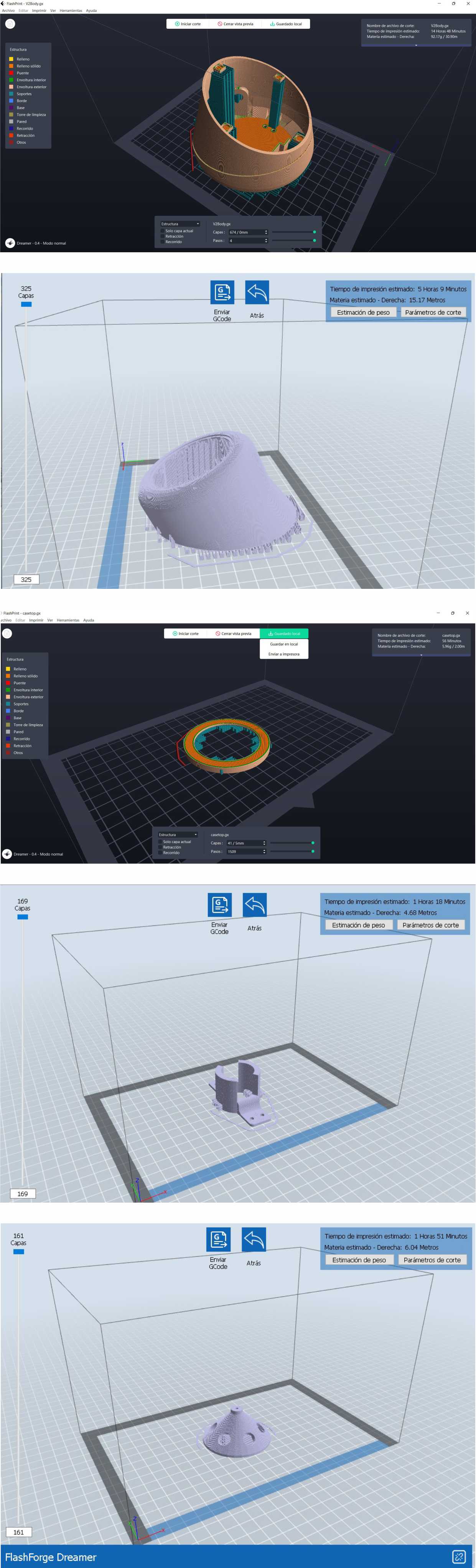

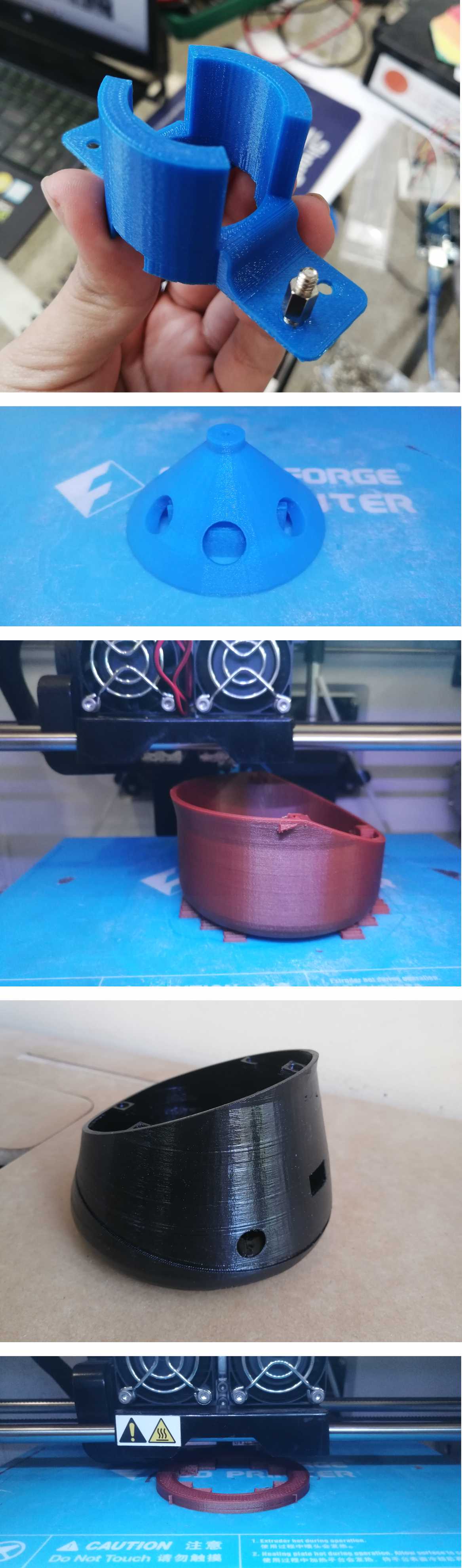

For some parts of the project, specifically the Rotor and the motor mount, I use the design of 3D Printed DIYbio Centrifuge.(V3) However, I made minimal changes to adapt to the electronic componets I bought.

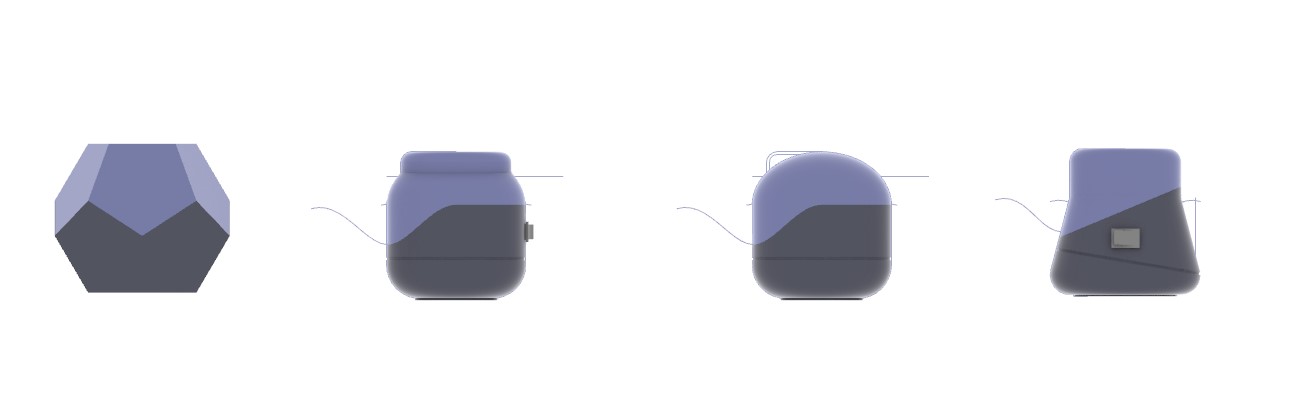

Using Rhinoceros I tried several shapes thinking about aspects like usability, transportability and stability. Also about the types of technologies that'll be using to fabricate my idea.Here are some pictures of the different designs I made:

After some thoguhts, I pick this design:

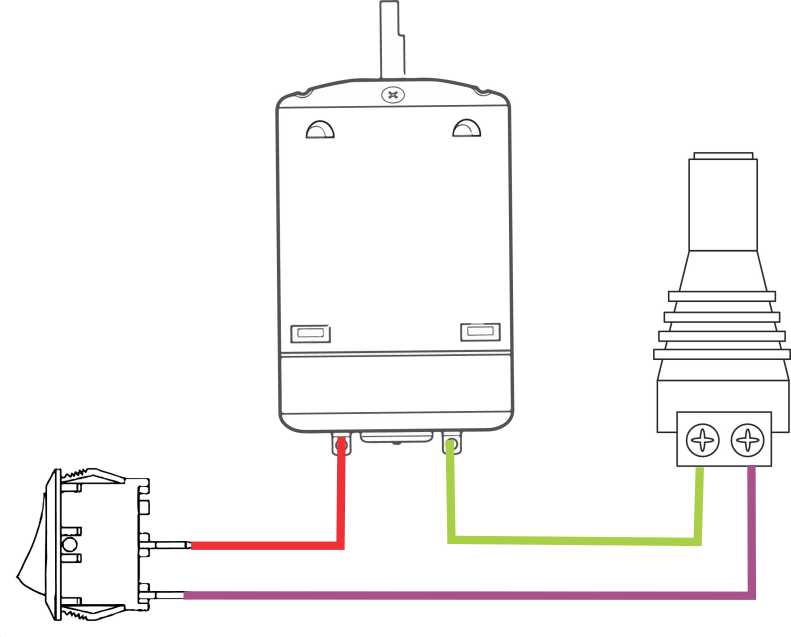

This design has very simple electronics (see diagram and photo of electronics below). It does not need programming, since it is the same system used in this project.

Below is a brief description of the electronic part used according to this documentation page.

To build this prototype I decide not to use a limit switch. Here's the diagram:

All the part that needed to be manufactured were made using 3D printing because I was looking for a great surface finishing, but also to use just one or two lab technologies, to be more easy to replicate.

The stl files can be found at the bottom of this page. All the parts for the electronics were attached and printed with the base, except the motor mount to sold the wires properly.

The prototype has a transparent acrylic lid that allows you to see the machine running and the tubes rotating at high speed. To manufacture this piece I use laser cutting and a sheet of 2mm acrylic .

When all the parts have been printed and the electronics ready, begin the assembly process.

The assembly was done in this order:

To test the prototype, I follow this steps:

Prep and test:

Here are my results:

It was an intense week but I'm happy I could pull out a funtional prototype.