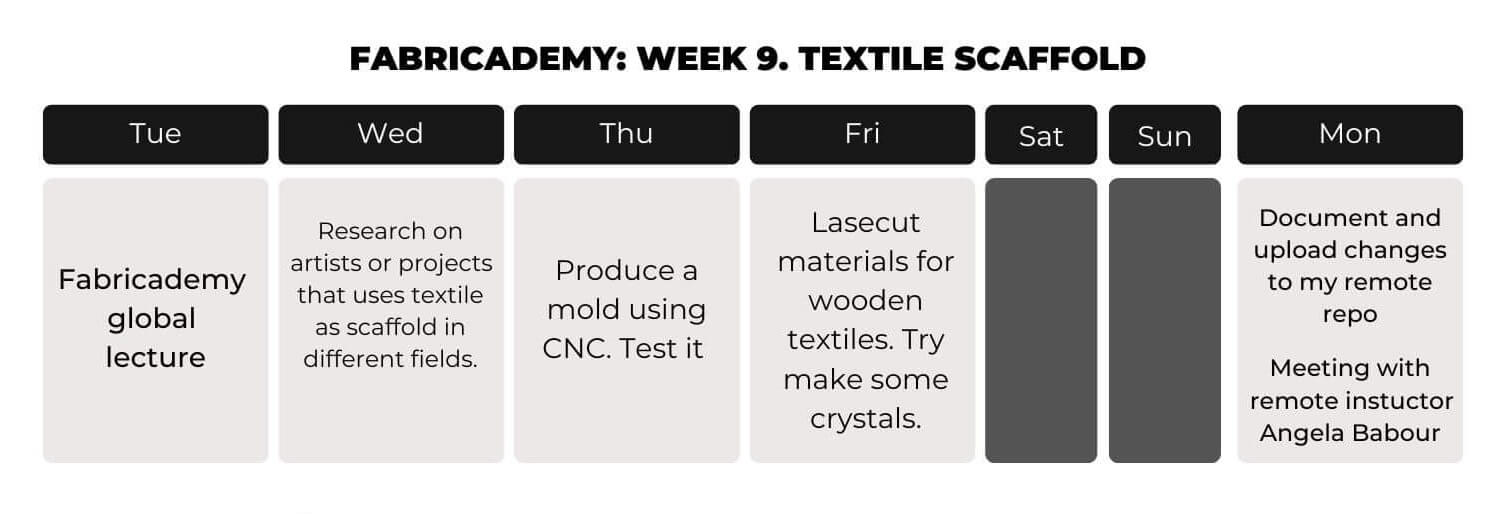

Nov 15, 2022

This class focuses on exploring techniques and applications of technical textiles in the industry. It introduces the concept of designing custom processes that require the design of a set of tools, processes and workflow.

1. Weekly Documentation planning

2.Inspiration and research

3. CNC Mold

I found the work of OTTAN Studio, which is a circular production bussines model that protect natural resources from being depleted and raise awareness about the importance of up-cycling organic wastes in the circular economy. It has a widespread application in architecture and product design.

Another project that I found is Smile Plastics. It is a materials design and manufacturing house creating hand crafted, supersized panels for retail, architecture, interiors and product design.

The research and testing into layering Linoleum flooring, laminating into blocks and shaping through sawing of Laura Jane Atkinson

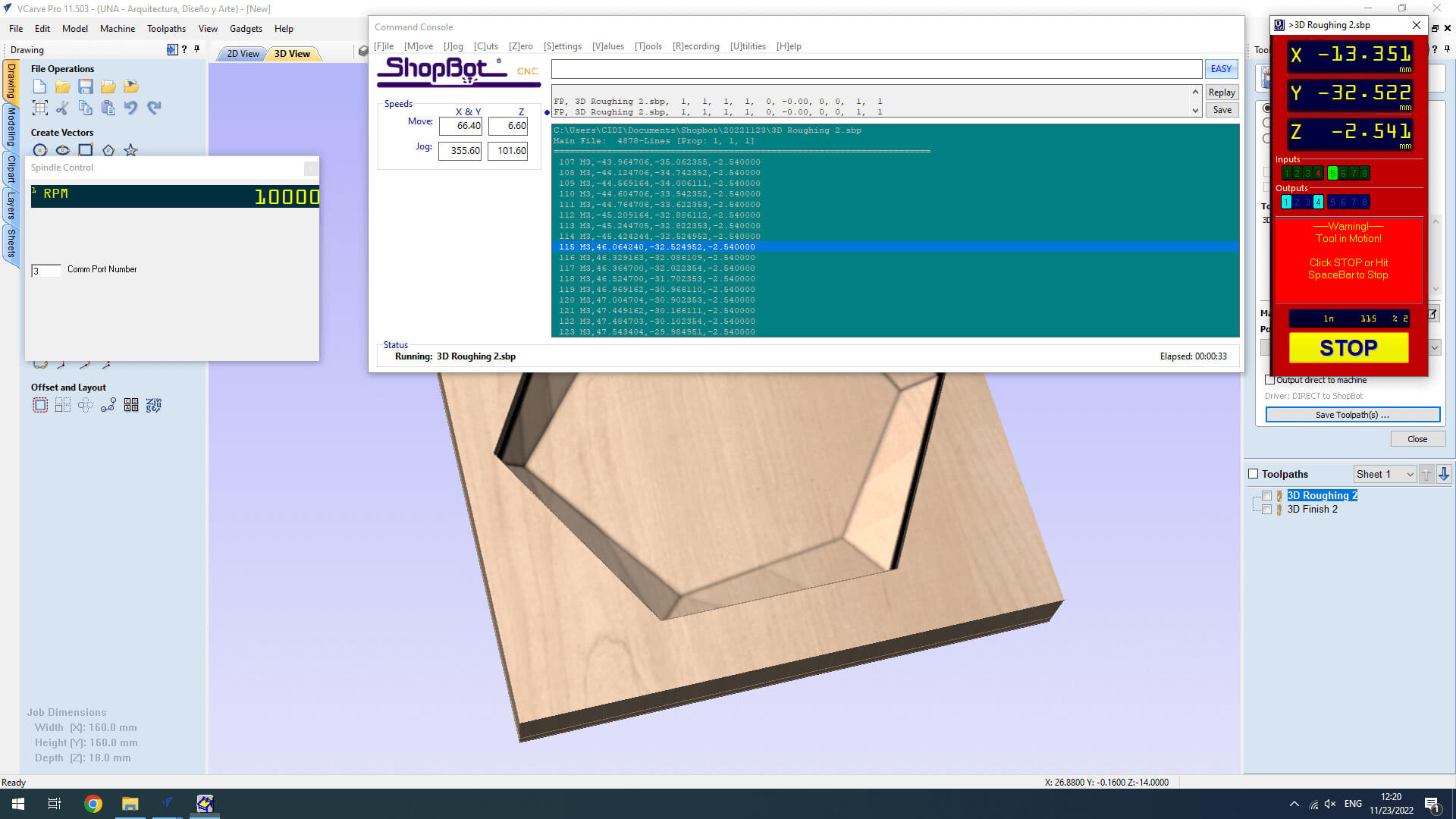

I had experience using the CNC back from Fab Academy. Here's my work during the computer-controlled machining week:

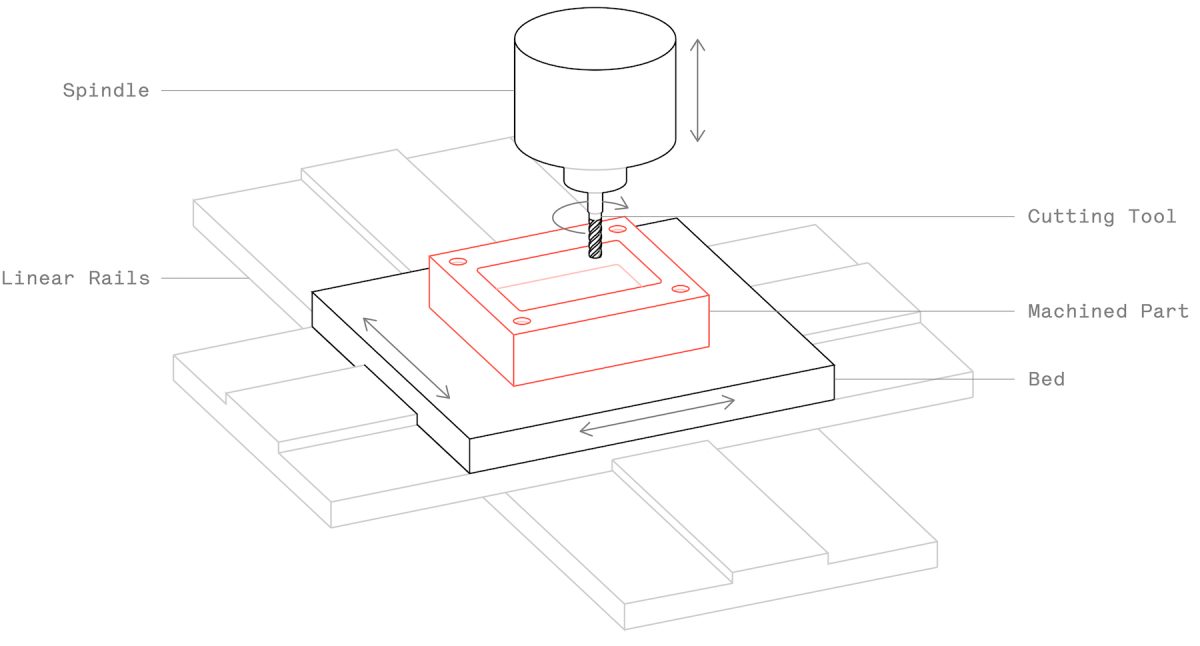

CNC is one of my favorite digital manufacturing technology. It's so complex yet so interesting that I love to be able to document about it. So let's start from the basics: (Huge shout-out to HUBS website. It's not only a manufacturing network, but also a learning platform that I'll be using to explain thing about CNC technology.)

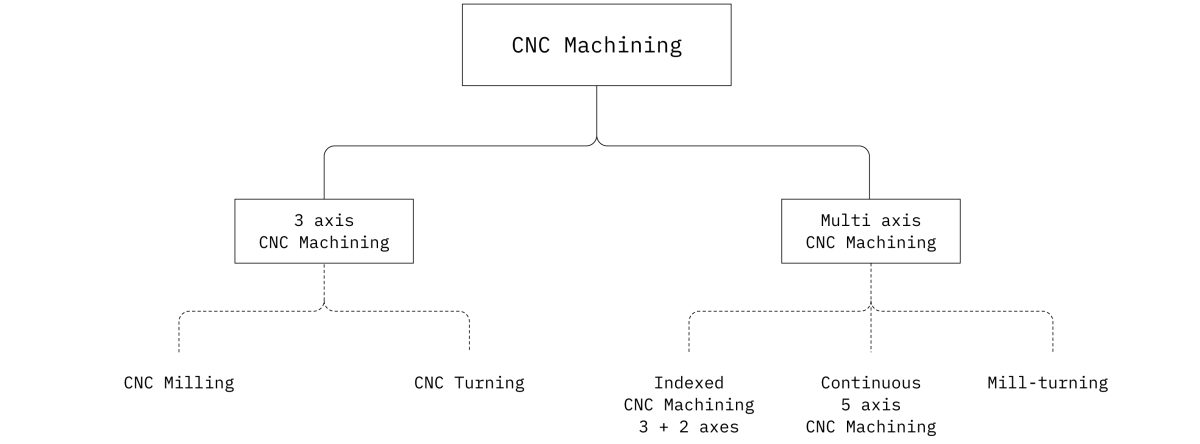

CNC (Computer Numerical Control) machining is a subtractive manufacturing technology: parts are created by removing material from a solid block (called the blank or the workpiece) using a variety of cutting tools.

The two main types of CNC machining systems are milling and turning . Due to the characteristics of each machine type, milling and turning are each uniquely ideal for manufacturing different geometries.

Most CNC milling systems have 3 linear degrees of freedom: the X, Y and Z axes. More advanced systems have 5 degrees of machining freedom via the rotation of the bed and/or the tool head (A and B axes). 5-axis machines can produce parts with high geometric complexity and may eliminate the need for multiple machine steps.

CNC milling and CNC turning machines are examples of 3-axis CNC systems. These “basic” machines allow the movement of the cutting tool in three linear axes relative to the workpiece (left-right, back-forth and up-down).

Currently, we have 2 machines availables at the Fab Lab:

For my crafted material I decide to work with Gelatine. Gelatine is an animal derived ingredient, made from the collagen present in animal parts. it comes in various forms, such as jelly, dry thin flat sheets or powder, in almost all cases it a translucent material, which can be easily coloured.

| ROLAND MDX-540 | Shopbot PRAlpha 120-60 |

|---|---|

|

|

| Dimensions: 500 x 400 x 155 mm from Roland. | Dimensions: 3.28m x 1.55m x .2m from Shopbot. |

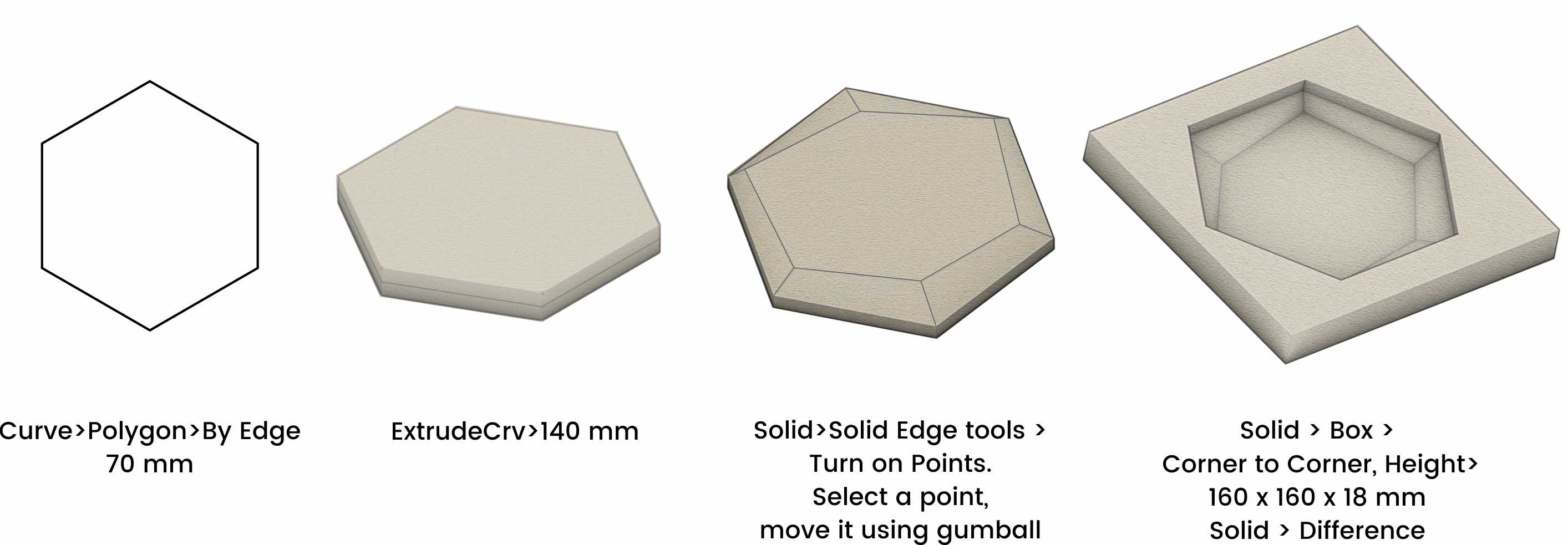

For this week I want to make some some trays for my house.I used Rhinoceros to make a simple design and the Mold. Here are the steps:

I exported the model to .stl.

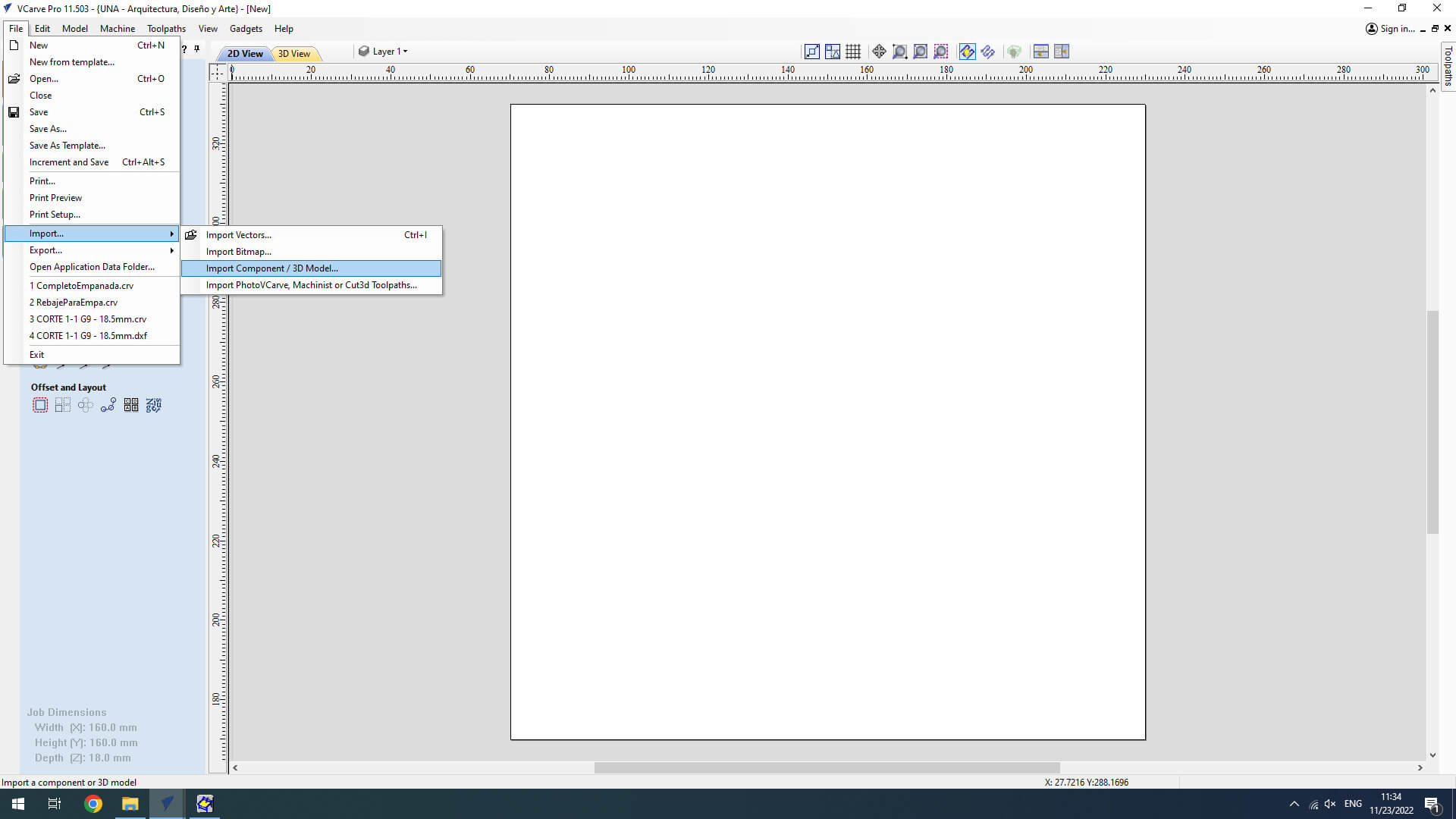

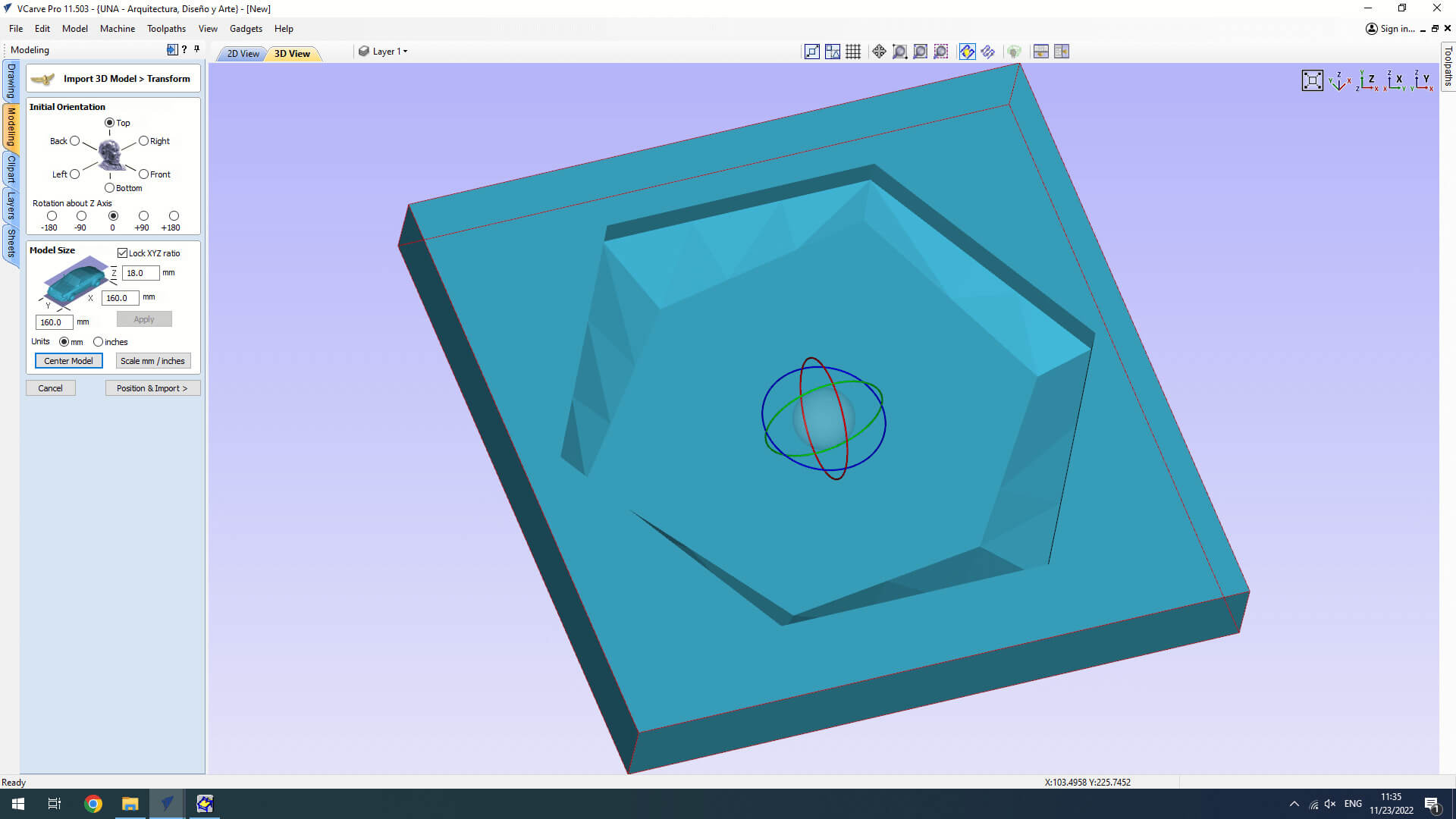

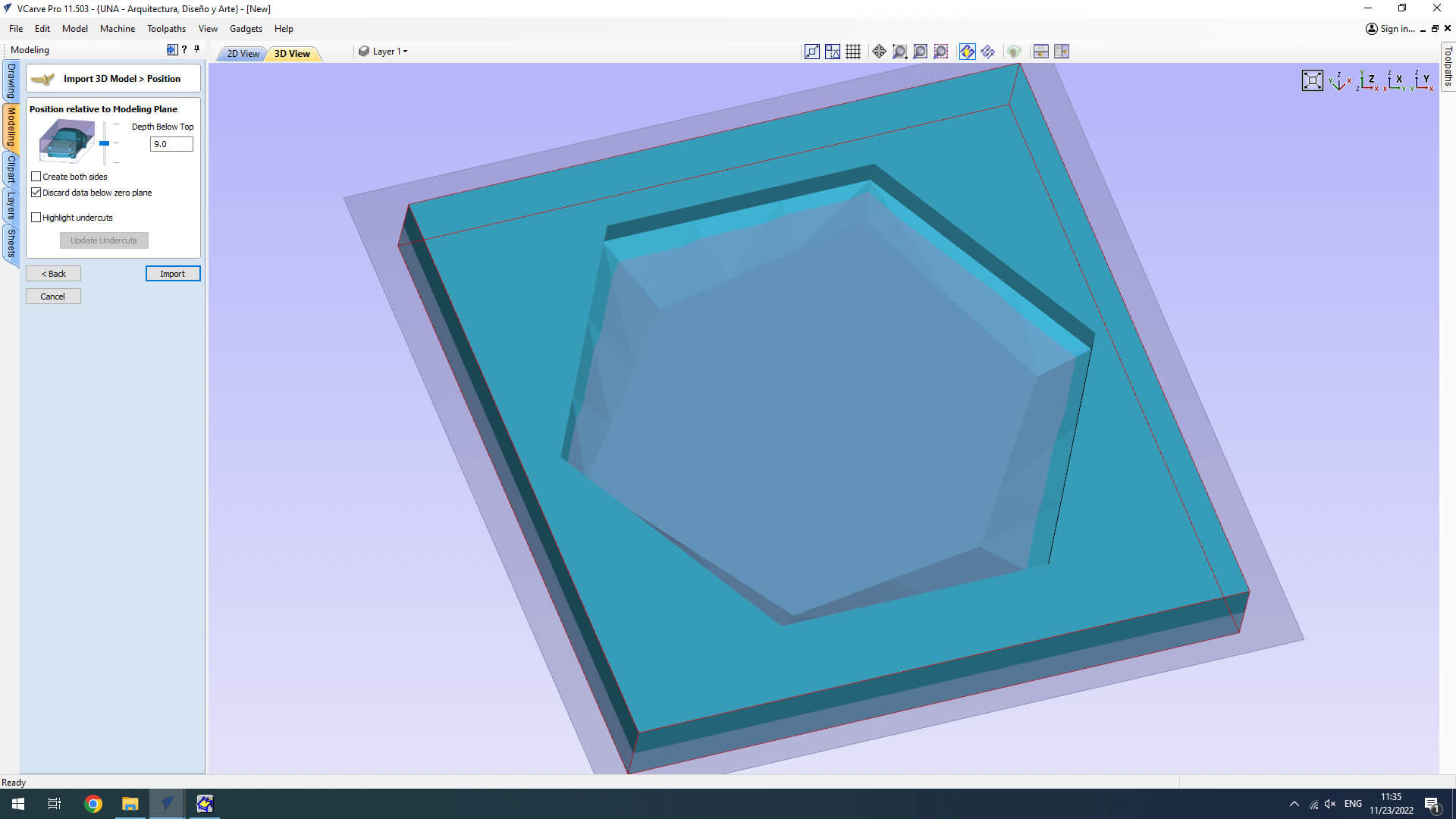

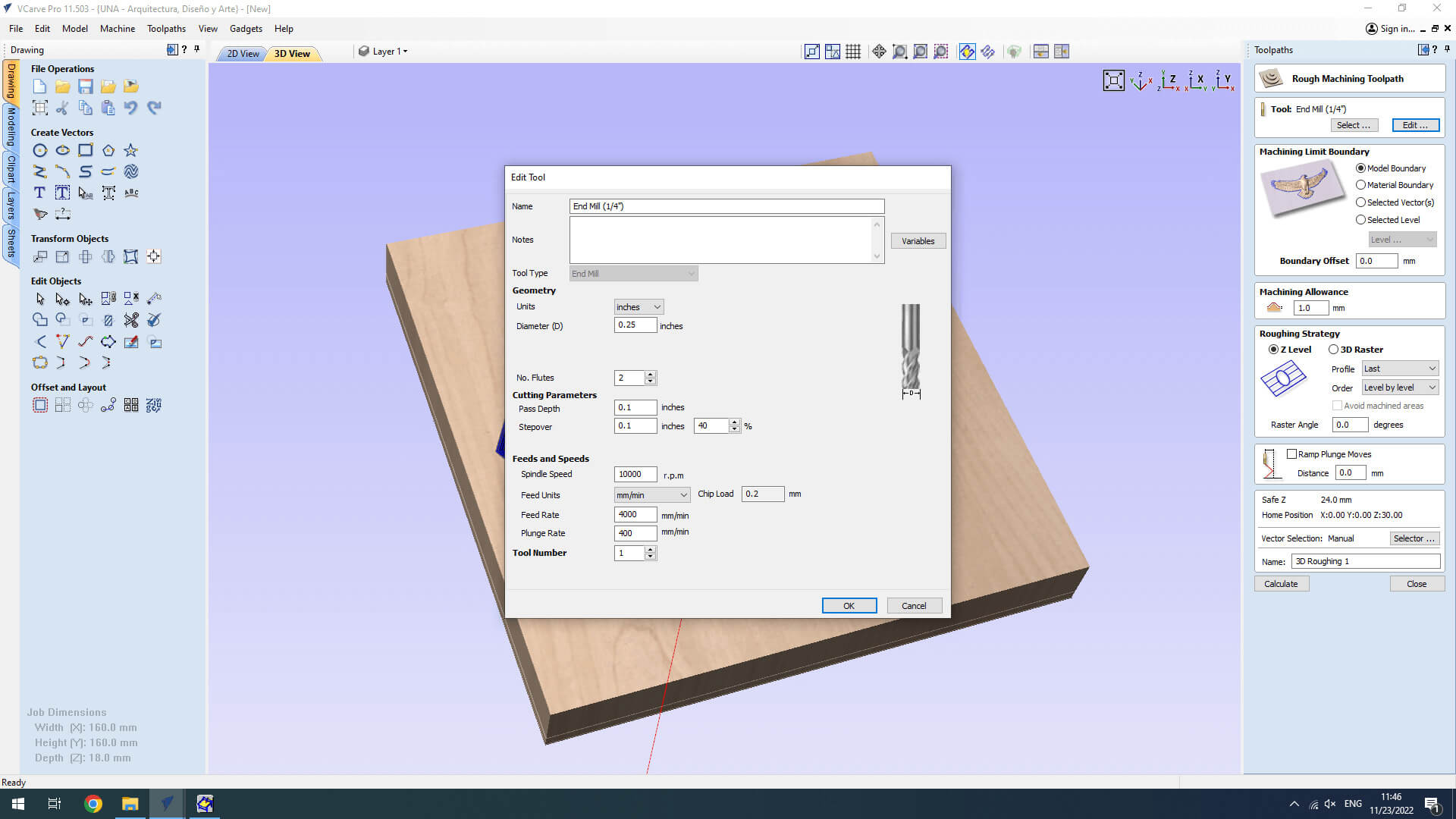

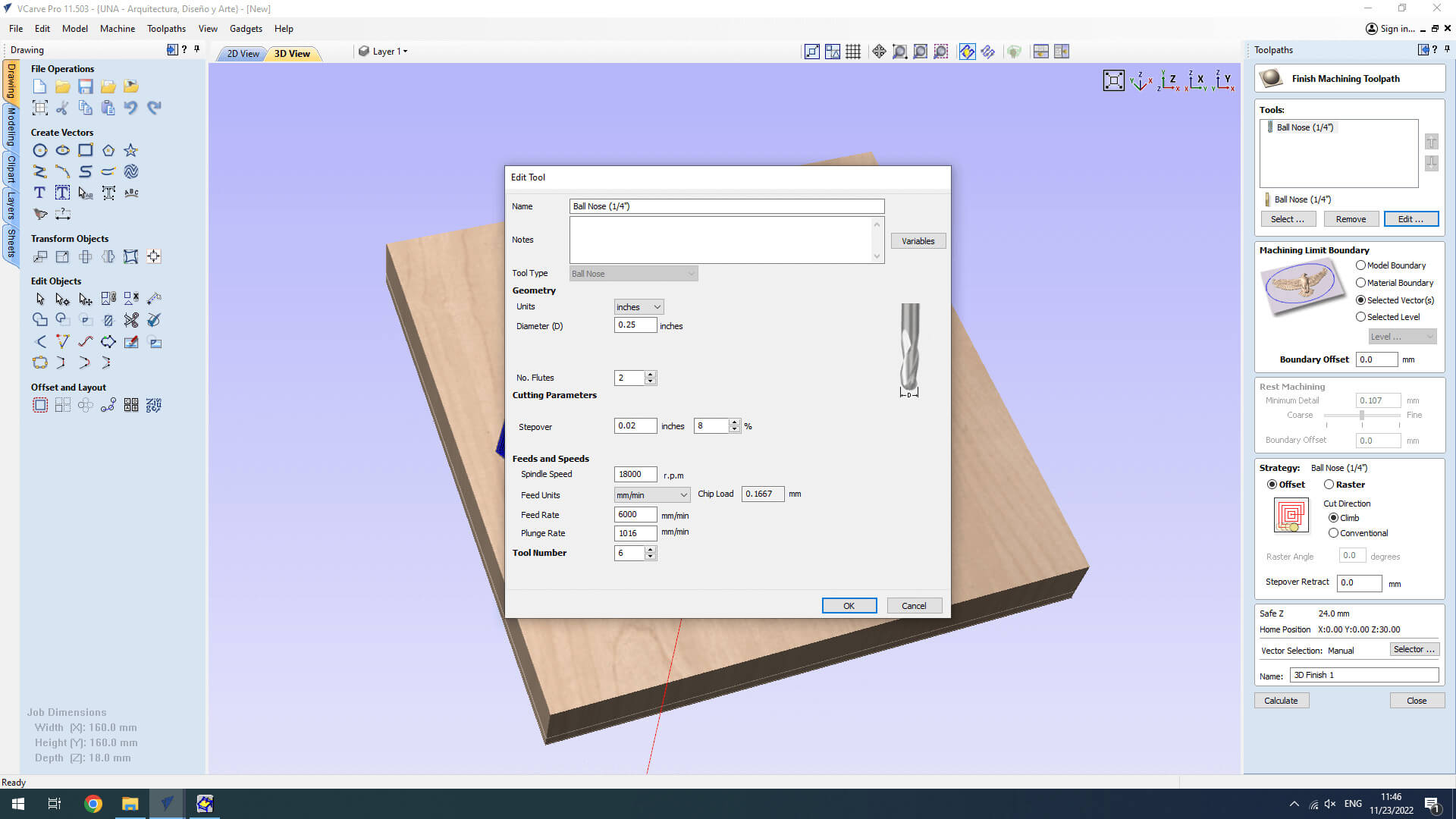

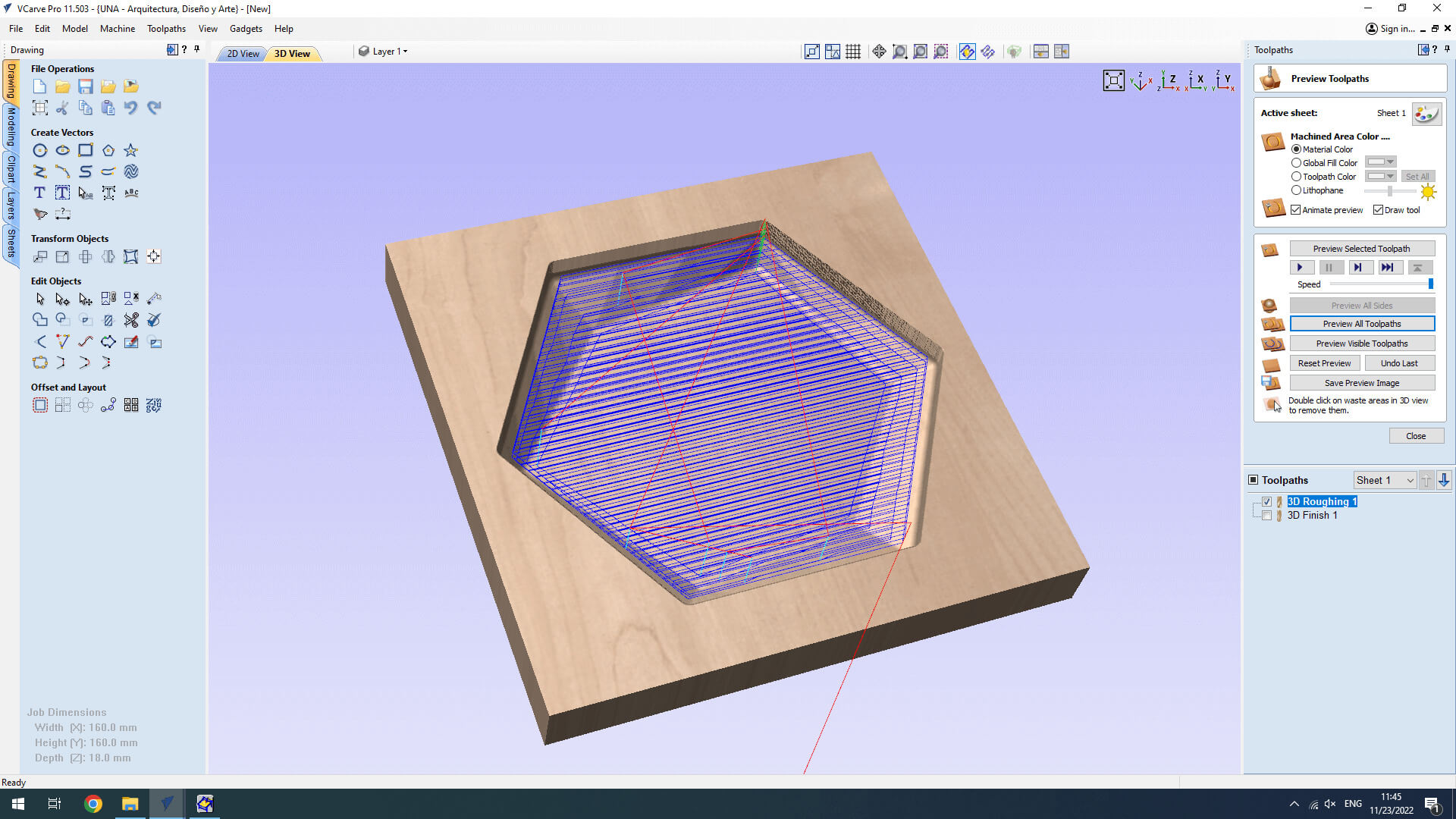

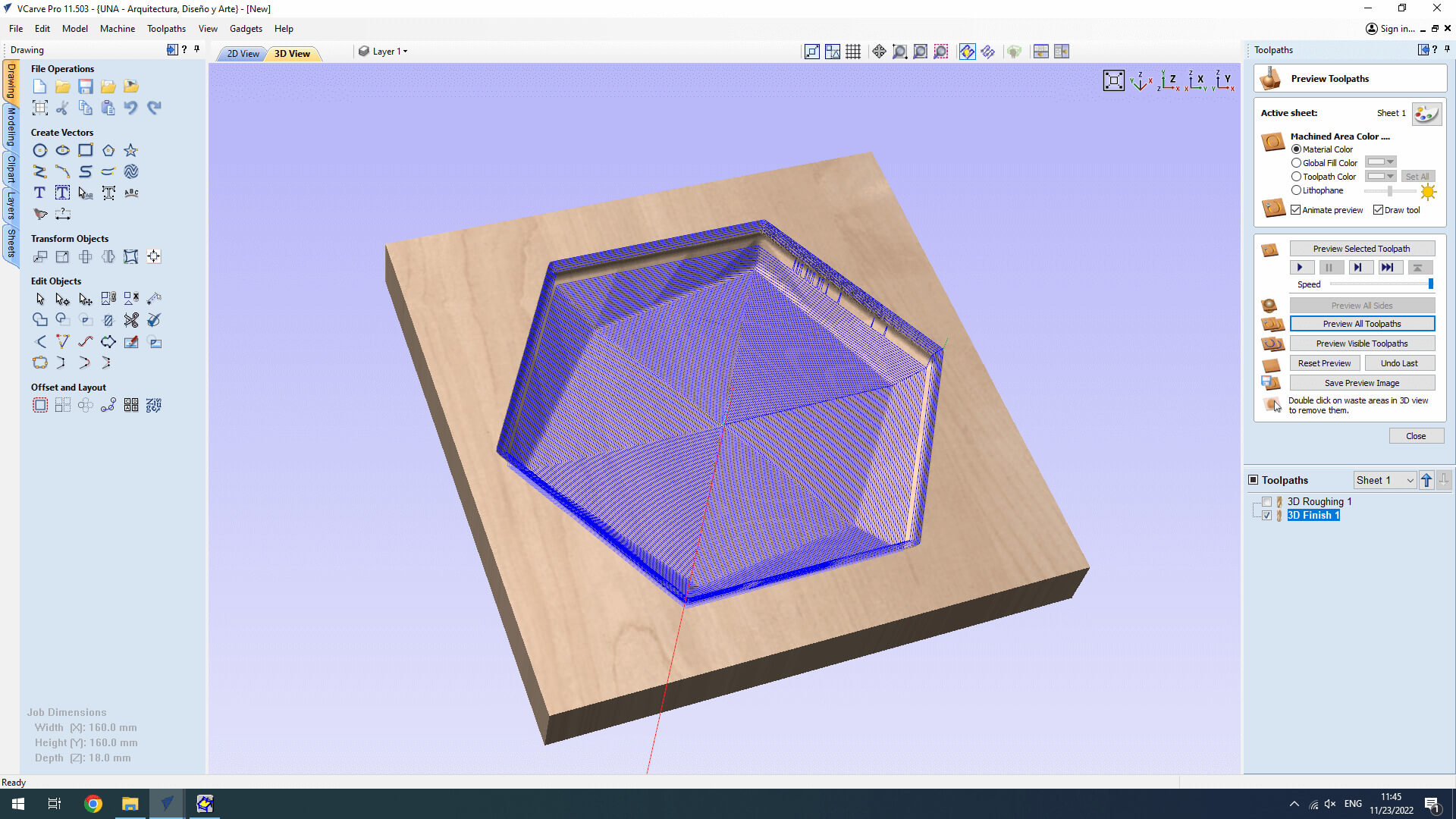

Here are the steps to use V carve pro, which is the software that our CNC use to generate G Code:

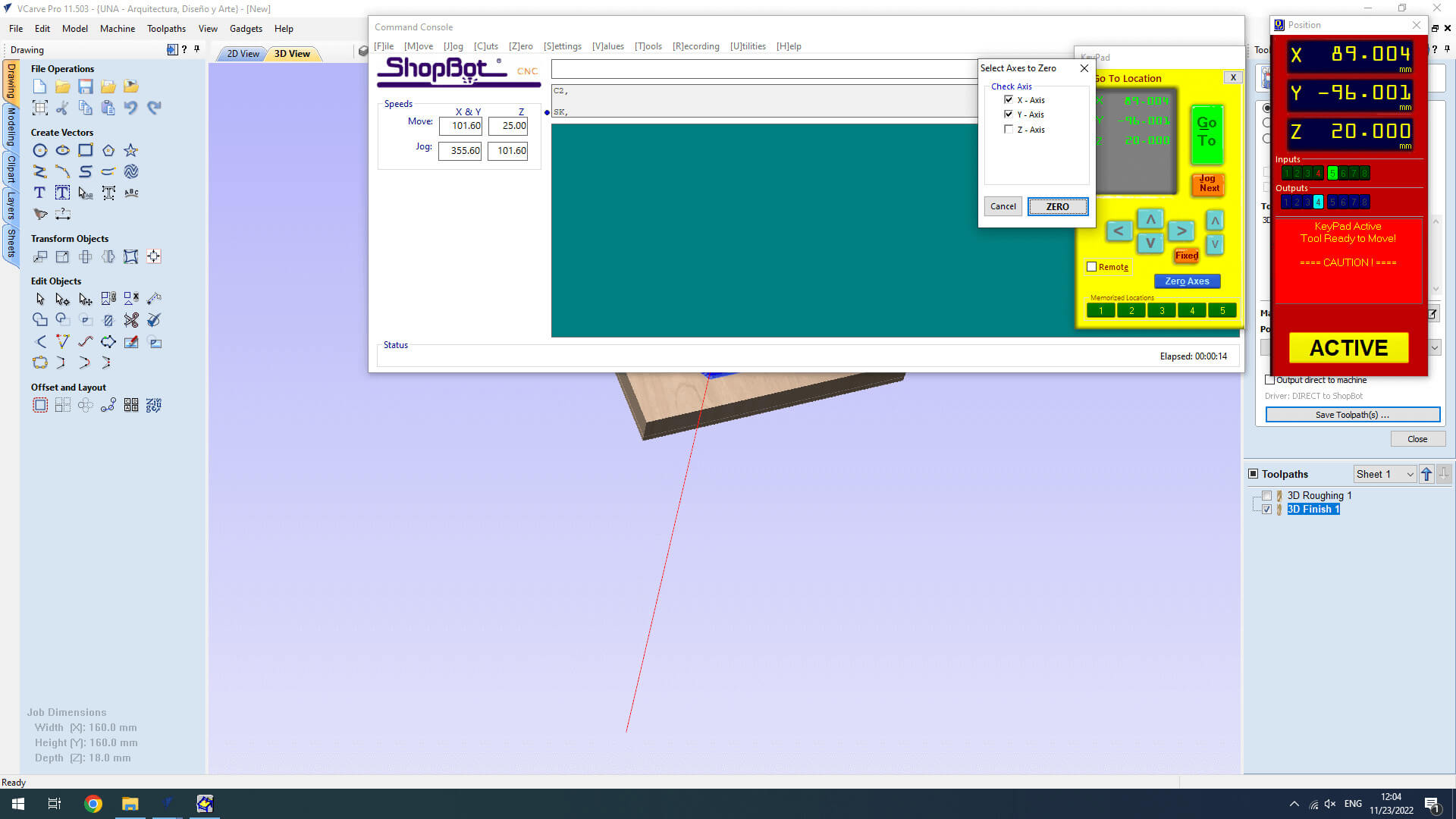

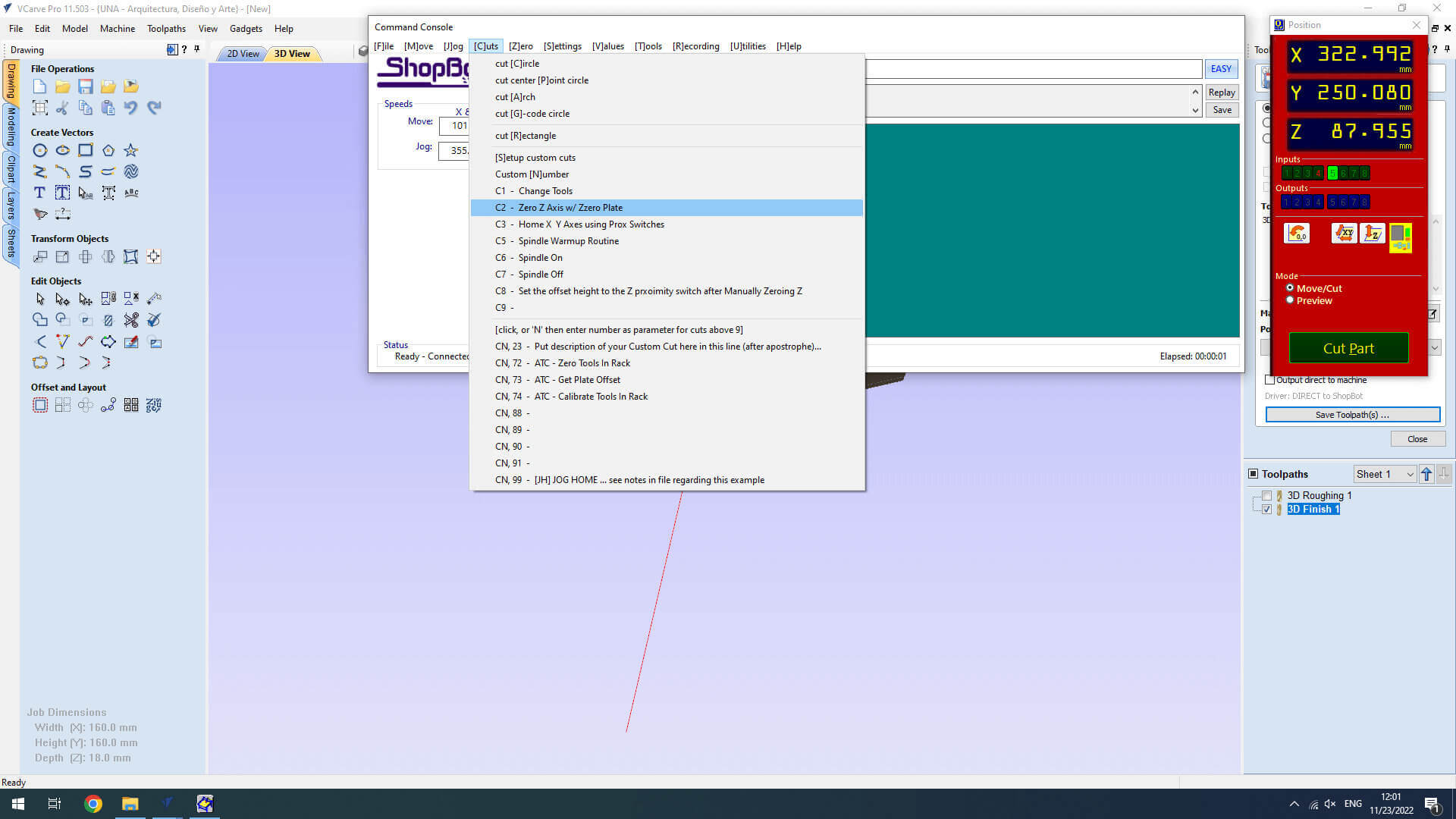

The main steps in order to use the shopbot are:

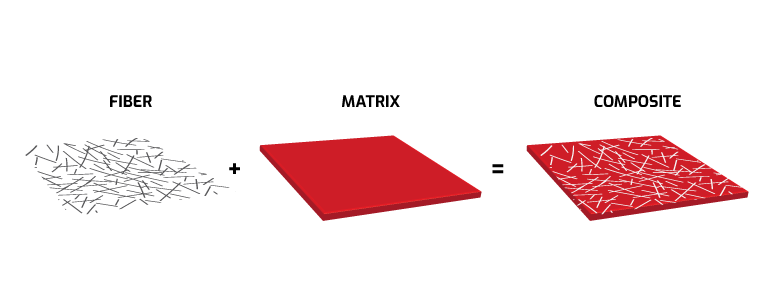

According to TWI Global a composite is "a combination of two materials with different physical and chemical properties. When they are combined they create a material which is specialised to do a certain job, for instance to become stronger, lighter or resistant to electricity. They can also improve strength and stiffness".

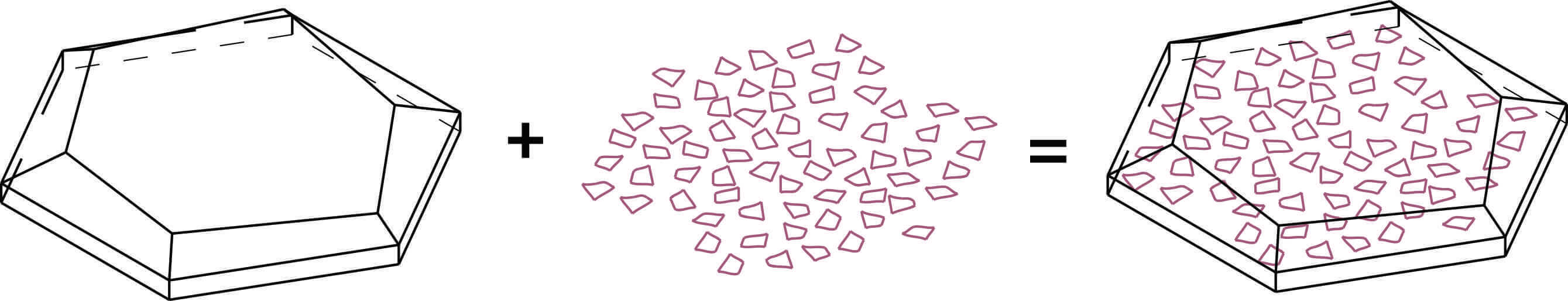

Composites usually has 2 materials. A matrix and a filler. After making the mold I started testing different version of composites combining textile + liquid plastic. Here are some of my test

I cut up a piece of fabric into tiny pieces as the filler. The liquid plastic has two components (A,B) that you have to mix and pour in the mold. It's a fast dry reaction and you can combine it with different colors. I mix the fabric and the reaction and put it in the mold for 30 minutes. Here are pictures of my result:

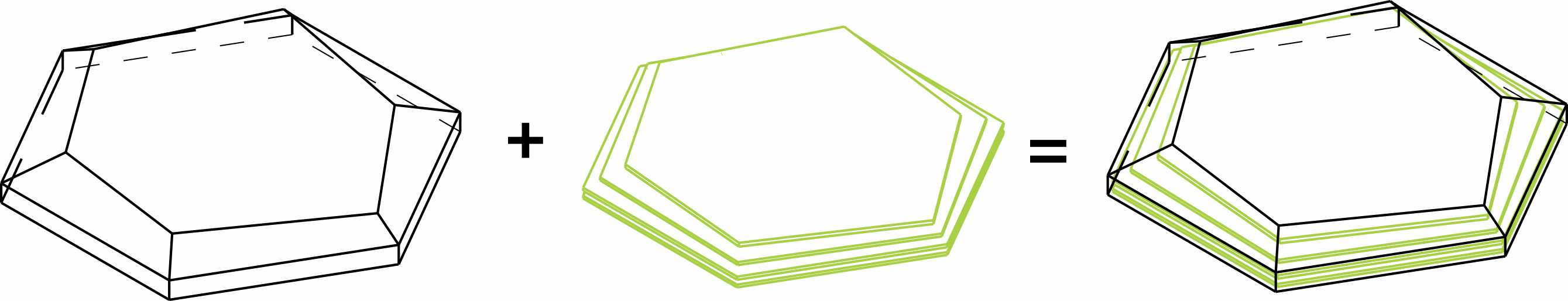

For the second test I wanted to try different colors and add the fabric in layers like a cake. Here are photos of my process and the result:

So that the colors can be appreciated better, I fixed the mold to the CNC and ran a simple program. Heres's the result:

For my thirs test, I decide to use a piece of fabric without cutting it. Here are pictures of my process and my result:

At the end I was really satisfied with my results. I think the combination of Layers and plastic was the best looking of all. It was a fun experiment.

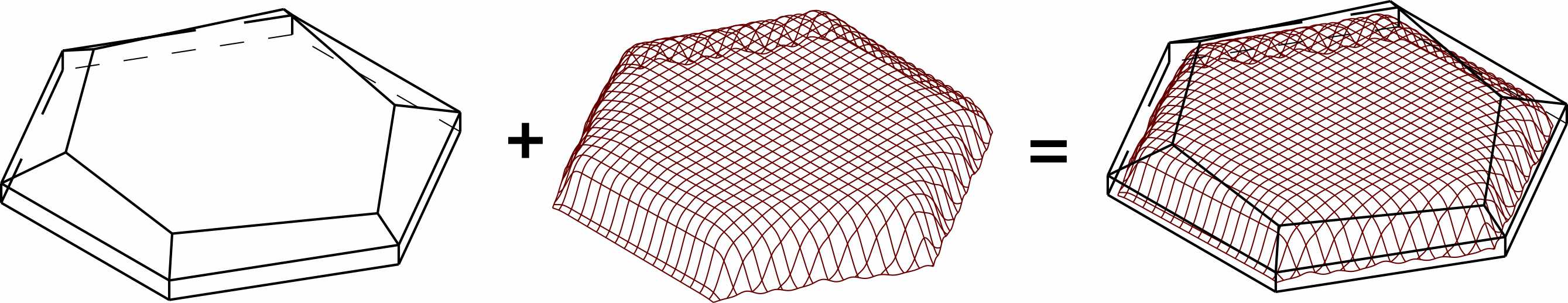

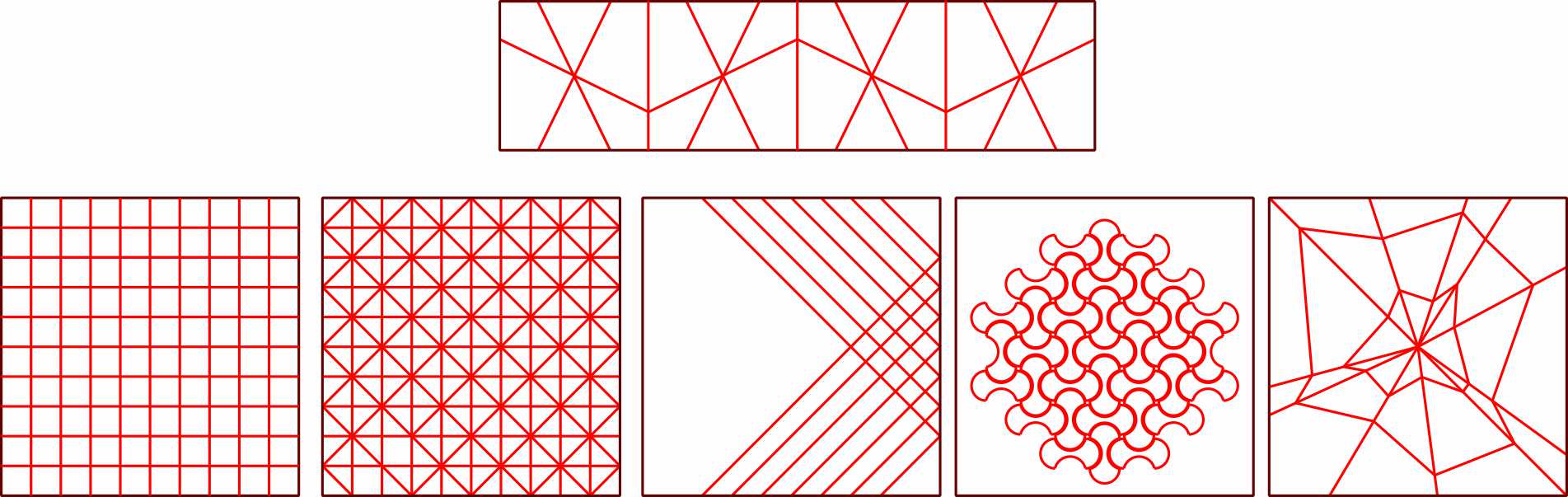

According to Material District wood textiles consists of "a combination of wood veneer and textile. Thanks to the geometric surface finishing of the wood, it becomes flexible, more or less so depending on the size of the shapes. Various combinations of wood and textile combine the hard panel formation of wood with the pliability and folding of textiles."

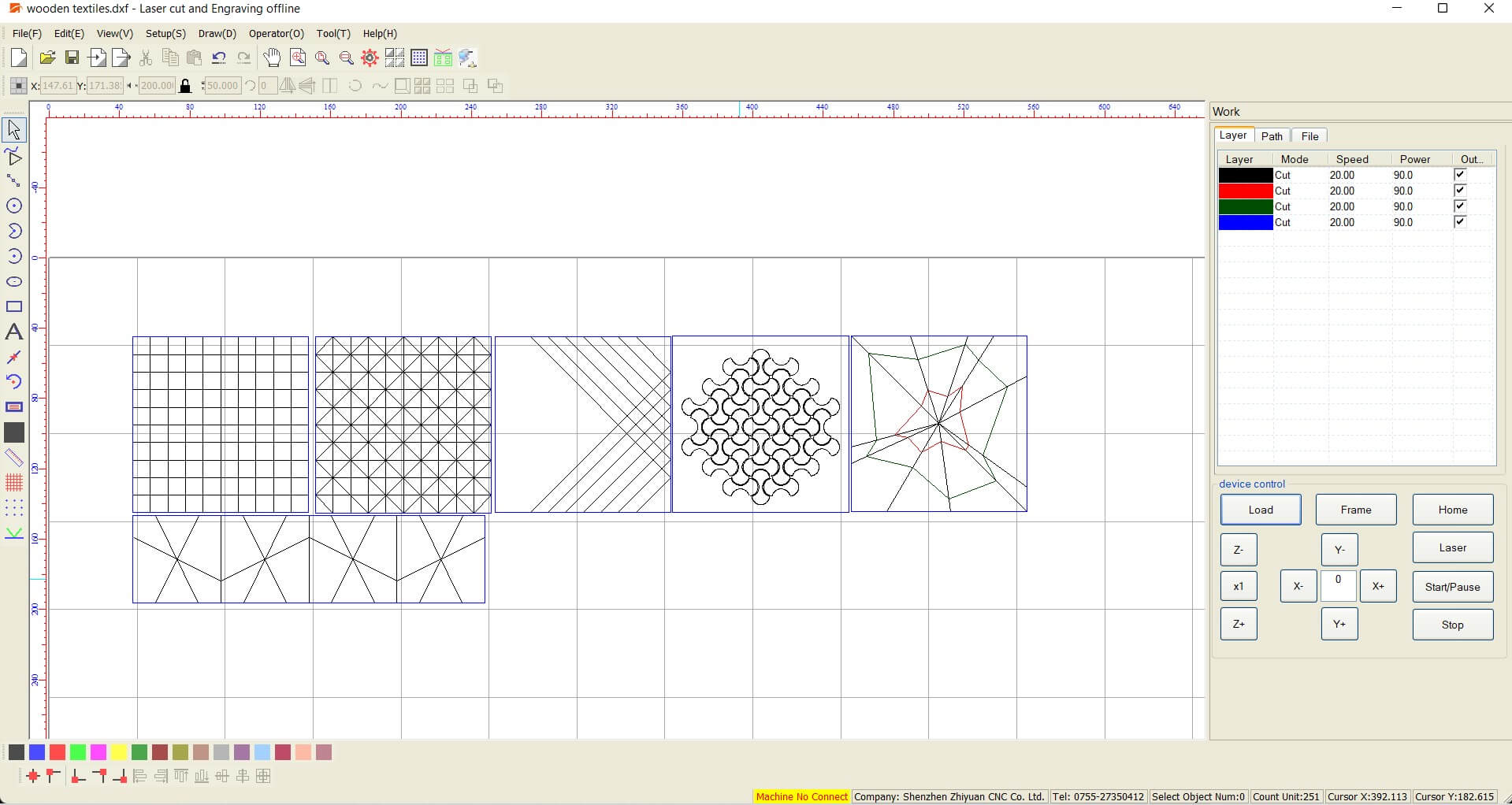

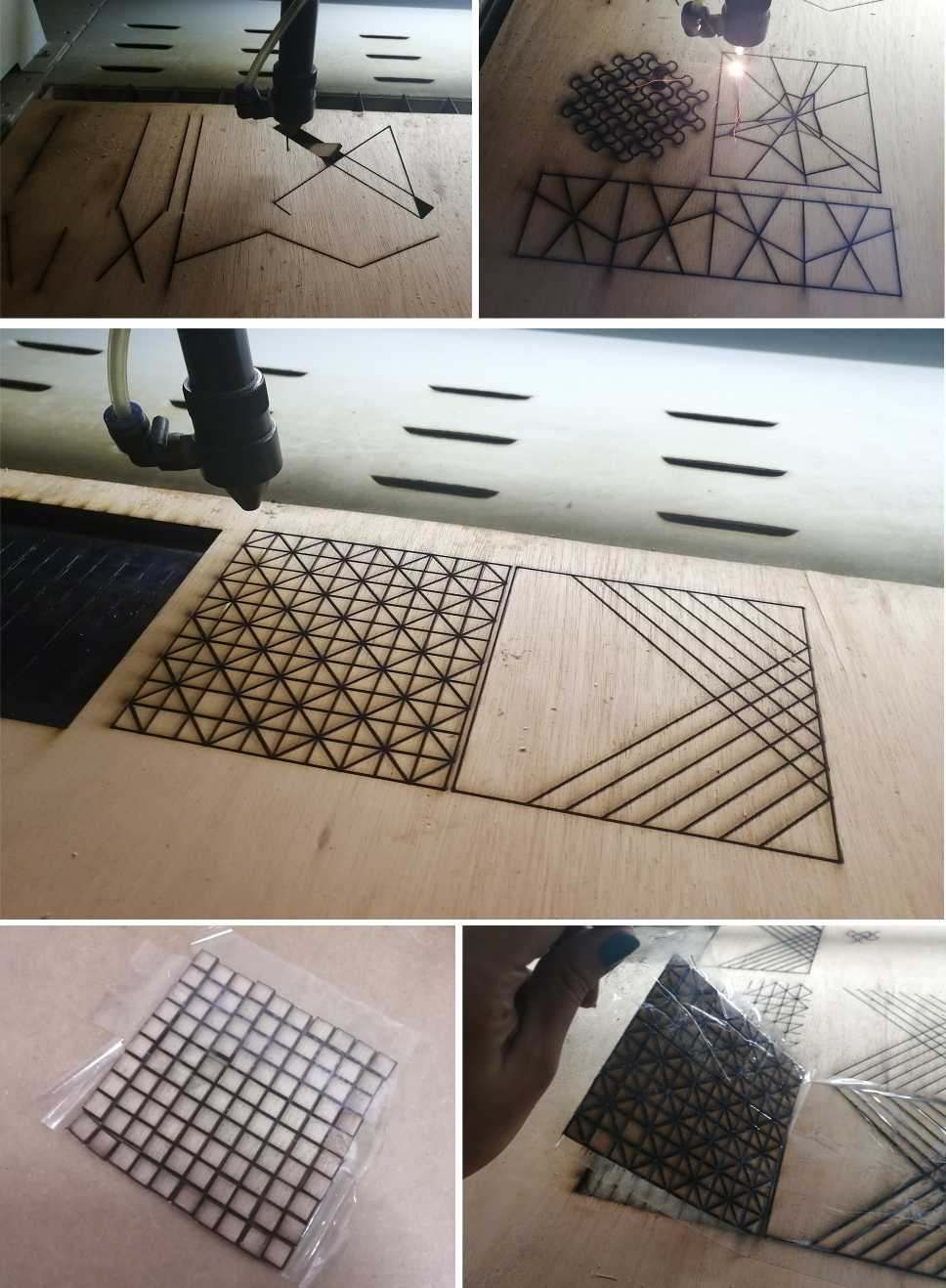

Using Rhinoceros I prepare some designs:

According to this website "Salt crystals form out of a “supersaturated solution”. A supersaturated solution is a solution (or mixture) that contains more solute (salt, in this case) than is capable of being dissolved in the solvent (water).

The water molecules speed up as they are heated, creating space between them for more salt to be absorbed than usual. As the water cools and evaporates, the salt comes out of the solution and forms crystals in a process known as “recrystallization”.

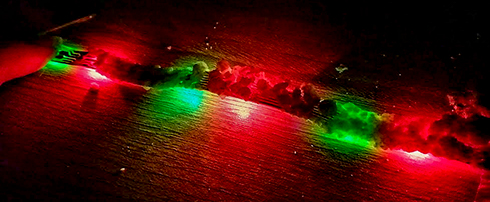

I decide to experiment with crystallization and electronics. I follow this tutorial ans this recipe: