10. OPEN SOURCE HARDWARE¶

DIY FELTING GUN¶

FELTING PROCESS BASICS¶

- FELTING - process that involves tangling and compacting fibers together to create felt.

-

FELT - a textile material that is produced by matting, condensing, and pressing fibers together. It is typically made from wool or other natural fibers, but synthetic fibers can also be used. Felt is known for its soft and fuzzy texture and is often used in crafts, as well as for industrial purposes.

-

Needle felting involves using a long, thin needle that has notches at its tip. As you repeatedly poke this needle into and out of the wool, the notches tangle the wool fibers together. This process results in the wool becoming firmer and shrinking in size.

-

Felting Mat: foam or rubber mat to place under your work surface. This helps protect your work surface and allows the needles to penetrate the fibers.

FELTING GUN¶

A Felting Gun is a mechanical device that is used to fuse fibers together, much like felting by hand. However, using a felting machine decreases the time-consuming process exponentially compared to felting by hand. It is designed to sew through thick fabrics, and is usually equipped with a heavier-duty needle and a more powerful motor, which helps it to penetrate through thicker fabrics without skipping stitches. Needle felting machines use barbed needles to interlock fibers and create felted fabric.

Research & Ideation¶

Alumni's pages as an inspiration

SOURCES / REFERENCES¶

FELTING MACHINES¶

| DIFFERENT TYPES OF FELTING MACHINES | REFERENCE | DESCRIPTION |

|---|---|---|

|

Needle felting adapter for sewing machine | How to make felting adapter at home |

|

Orange Fly felting machine | Pro-level Felting machine. Active cooling. For NON-STOP wool felting. - All Needles types used. Needles are not need modify, Motor - DC 12V,Bearings - High Speed Precision. Product dimensions - 13х12х3,6 cm, Weight - 148 g, Felting Machine materials: plastic \ metal \ rubber \ polymers |

|

Needle Felting Machine for Quick Felting | SPEED CONTROL: Adjust the felting machine to the speed you want, make your work go by faster to save your time. ADJUSTABLE HANDLE, This needle felting kit comes with a machine, a power, 1 pair finger protector and 3 types of needle. |

|

Simplicity Deluxe Felting Machine | Features built-in lint drawer, accessory drawer, carrying handle, electronic foot control, and universal power supply. Customize the embellishing area by removing needles. Requires no threading or sewing; fibers mesh to create new color and texture combinations. Uses 12 barbed needles to mesh fabrics together. |

|

Hand needle felting tool | Felting tool with eight needles. |

|

Industrial needle felting machine | FELTLOOM® NEEDLE-FELTING MACHINE - Two motors independently control needles and rollers which allows for variable roller/needling speeds. 36″, 48″, 60″, 66″ and 72″ feed widths. |

|

Automatic felting machine | Automatic felting machine with four needles and speed adjustment. |

DIY FELTING MACHINES¶

| DIY TYPES OF FELTING MACHINES | REFERENCE | DESCRIPTION |

|---|---|---|

|

NEEDLE FELTING TOOL FROM A WINE CORK | DIY CRAFT |

|

3D printed Felting tool | This is a felting tool for embroidering on felt. The handle are med for six needles. You need a 4 mm screw and nut hidden in the handle. |

|

Felting Needle Tool - 3D print | A tool for felting. Holds six felting needles firmly in place, so your felting job is much easier and comfortable. |

CRANK MECHANISM¶

- The mechanism is called a "crank mechanism." It's commonly used to convert rotary motion into linear reciprocating motion, as seen in various machines, including felting machines.

-

To regulate the speed, we have incorporated a potentiometer.

-

In felting machines, the crank mechanism typically consists of a crankshaft and a connecting rod. The rotary motion from the crankshaft is converted into linear reciprocating motion through the connecting rod. This motion is crucial for the functioning of the machine, facilitating the necessary movements for the felting process. The reciprocating motion is often used to control the position of needles or other components involved in the felting operation.

Slider crank mechanism - 3D print Slider-crank linkage Slider - Crank Mechanism - geogebra DXF and SVG GEAR DXF GENERATOR

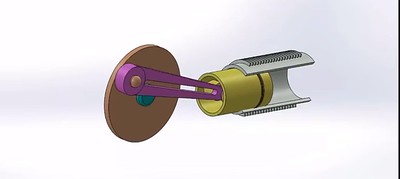

CREATING OUR OWN CRANK MECHANISM¶

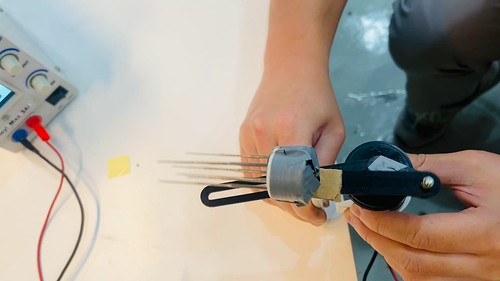

- We attempted to 3D print a test model of the mechanical part that connects to the motor.

- We have conducted tests on various types of motors.

COMPONENTS¶

-

Motor Provides the power for the needle movement.

-

Slider crank mechanism Convert rotary motion into linear reciprocating motion.

-

Felting Needles

Felting needles are specialized needles that are used in the process of needle felting. They are barbed to grab fibers and come in different gauges and shapes. The gauge of the needle determines its thickness, with larger gauges being thinner and better suited for fine, detailed work. Thicker needles like 32-gauge needles are used for bulk shaping work . The barbs on the needles help to interlock the fibers, allowing them to be shaped and molded into any desired form . -

Power switch

To turn on and turn off the machine -

Potentiometer

This is a dial that controls the Speed of the machine. -

Rubber band The rubber band connects the motor with the needles, so that they can move.

3D PRINTED FELTING HEAD with needle exchange system

Electrical circuit¶

MOSFET is a type of transistor. The basic operation of a MOSFET involves controlling the flow of current between the source and drain terminals by applying a voltage to the gate terminal.

- Rotating the knob controls the speed of the motor.

- +ve is connected to D of the MOSFET. The MOSFET should be a N channel Enchancement MOSFET (IRF540, IRF3205,..). Do not short the connections of the power supply. It may lead to damage to power supply and fire/explosion in case of a battery.

- The supply voltage depend on MOSFET and the motor. Example: If the is designed for 12v and MOSFET is capable of 50v.The supply voltage should be 12v.

- We have further tested the circuit using a voltage regulator. A voltage regulator, also known as a step-down converter, is an electronic circuit that reduces the input voltage to a lower output voltage.

MATERIALS¶

| Qty | IMAGE | Price | Link | DESCRIPTION |

|---|---|---|---|---|

| 1 |  |

35€ | MOTOR | 43 x 68 mm, 24V |

| 1 (another option) |  |

~18,50€ | MOTOR | ∅27,9mm, Length 66mm |

| 7 |  |

≈8€ | Felting Needles | 60pcs, S: 3.07 inch, M: 3.39 inch, L: 3.62 inch |

| 1 |  |

0,9583€ | Power switch | SWITCH, SLIDE, SPDT, 200mA, 30V, PANEL |

| 1 |  |

1€ | Potentiometer | Single Linear Rotary Seal Amplifier Potentiometers Type with Switch |

| 1 (another option) |  |

2,5€ | Potentiometer | Rotary Encoder Code Switch Digital Potentiometer with Caps |

| ?kg |  |

€12,99 / kg | Filament | PLA Filament 1.75mm Colored 1KG |

| 1 |  |

6€ | Rewireable Plug | 2 pieces, Ø4.8mm, Can be easily opened en up to connect with wire |

| 1 |  |

?€ | Rubber band | Polyester / Neoprene |

| 1-2 |  |

?€ | Bearing |

CONCLUSION¶

Through this assignment, we gained a deep understanding of the principles of the crank mechanism and created a rapid prototype. However, it is evident that there are still many areas and details that require further optimization. This serves as a reference for our future designs, clearly indicating the positions of the mechanisms.