Home

ABOUT ME¶

Hey, What's up?

My name is Grecia Bello, I'm from Bolivia, yes that beautiful country in the center of South America, with great food and landscapes.

Hey, What's up?

My name is Grecia Bello, I'm from Bolivia, yes that beautiful country in the center of South America, with great food and landscapes.

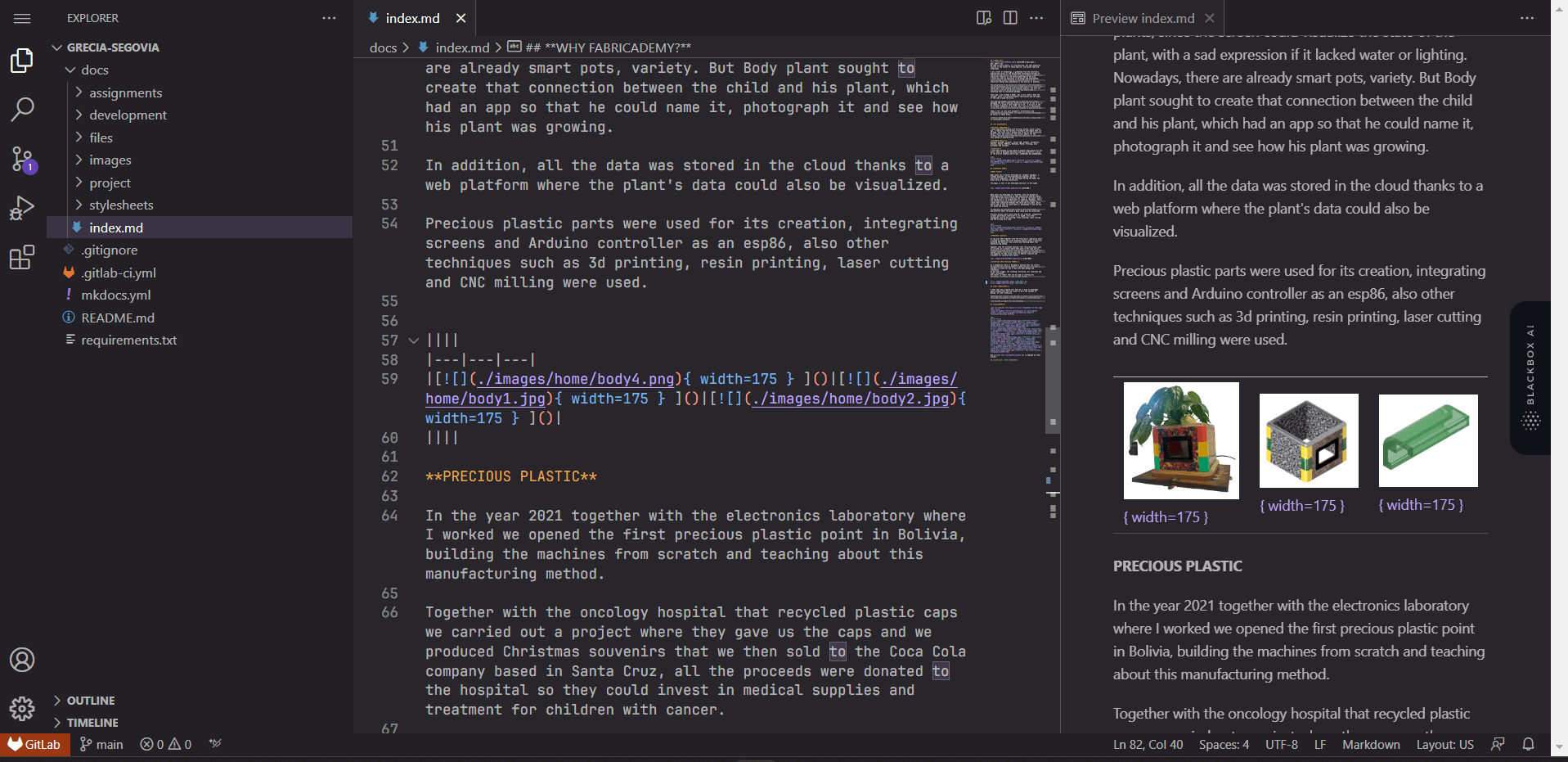

I am a lover of technology. I graduated from the electronic engineering career at the Universidad Tecnologica Privada de Santa Cruz with honors. In order to start a master's degree in industrial robotics at the Universidad Publica del Alto. I would say that my specialty is 3D design and programming. Since college I knew I wanted to dedicate myself to it, industrial design and programming of new devices or machines.

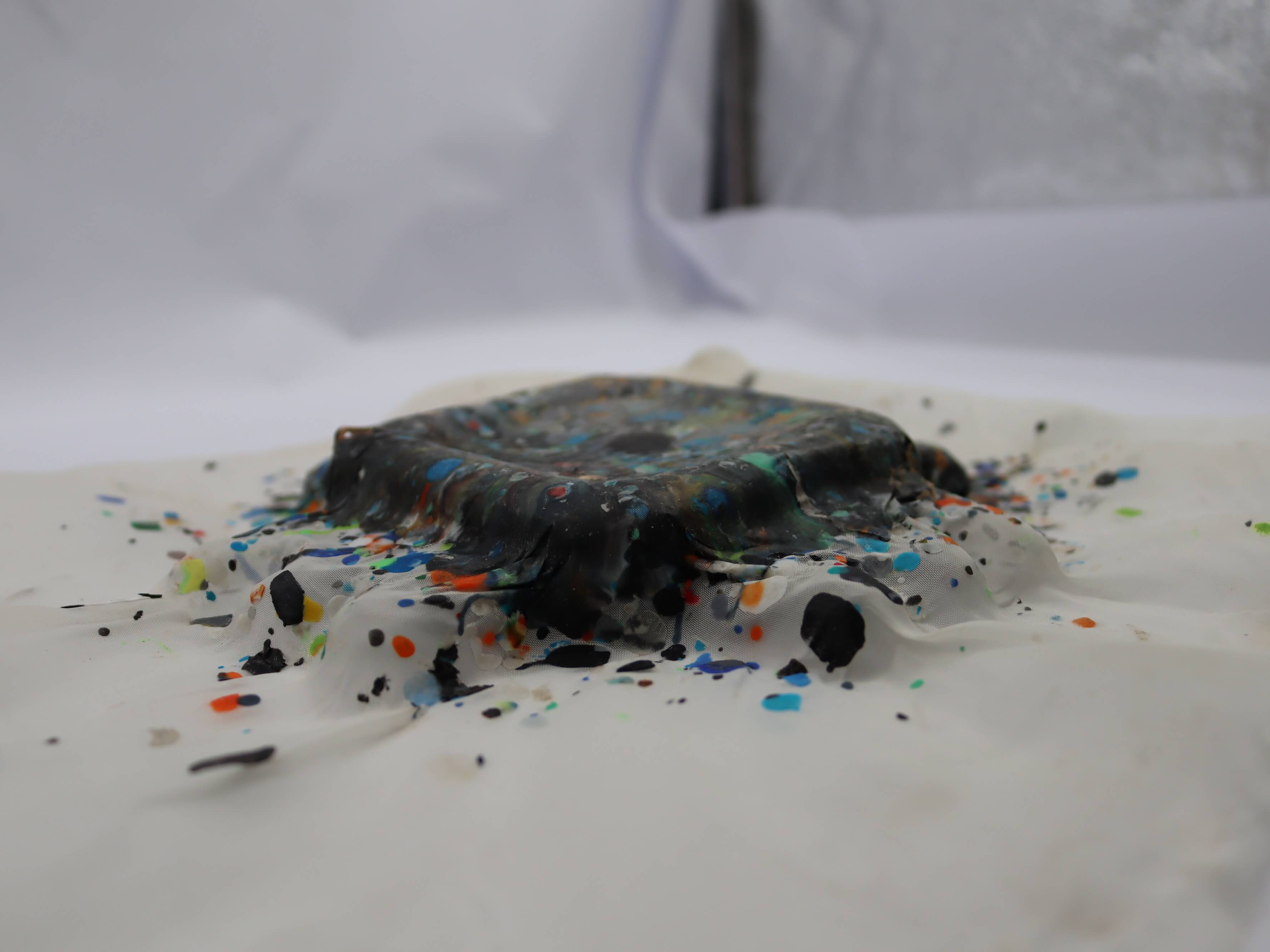

The inspiration of my projects is dedicated to the environment and how technology can be a tool to take care of it. That's the reason why I love working with precious plastic, not only for the colors, but for how we give life and beauty back to something that we considered garbage.

Years ago I was already a Maker, but I still didn't know the concept, until I discovered digital fabrication and the magic of Fab Labs around the world.

This year my biggest challenge was to open the first fully equipped Fab Lab at Unifranz University and one of the first in my country, a project that taught me a lot. I am part of the first Maker community in my city, now I work as a coordinator in the Fab Lab Santa Cruz where we continue to grow day by day.

Today I fell in love with parametric architecture and programming with algorithms, so I want to continue developing my skills in those areas.

I want to learn more about biomaterials and how to apply them in sustainable projects.

MY BACKGROUND¶

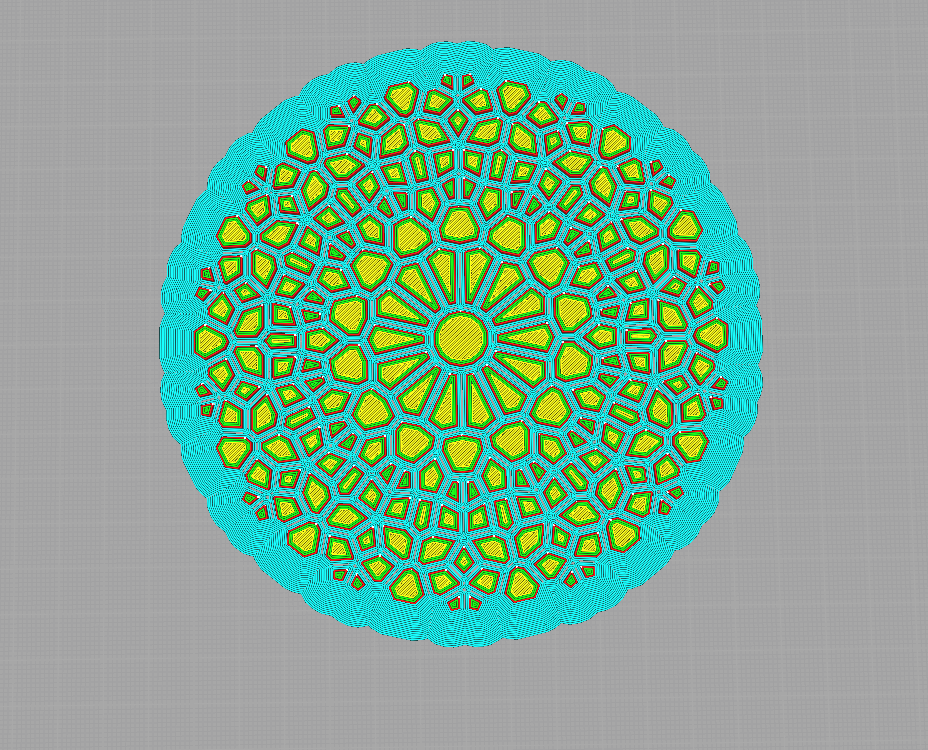

MATERIAL KNOWLEDGE: I have experience working with Precious plastic since 3 years ago, I really like the variety of products and shapes that can be made, the first time I worked with it was at the university where I built the electrical and control panels for the crusher, extruder and furnace that are necessary to work with this method of manufacturing.

SOFTWARE SKILLS: Autodesk AutoCAD, Inventor, Fusion 360, Blender, Solidworks, Arduino, Aspire, RdWorks, NCStudio, Mach3, Fritzing, Cura Ultimaker and Chitubox.

PRACTICE: I have been working in the field of digital fabrication for two years, where I designed machinery and also worked for a while in the area of imaging with X-rays, tomography and mammography.

|

|

|

PREVIOUS WORK¶

BODY PLANT | 2023¶

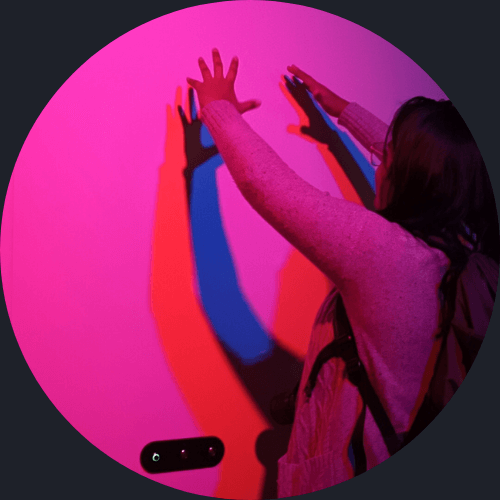

Body plant was a project developed by a graphic designer, a systems engineer, an electromechanical engineer and two electronics engineers. It was developed during the Maker Hub event held at Unifranz University.

The magic is that it was developed and built in one night.

Body plant was developed for children, with the purpose of encouraging and instilling in them sensitivity towards plants, since the screen could visualize the state of the plant, with a sad expression if it lacked water or lighting. Nowadays, there are already smart pots, variety. But Body plant sought to create that connection between the child and his plant, which had an app so that he could name it, photograph it and see how his plant was growing.

In addition, all the data was stored in the cloud thanks to a web platform where the plant's data could also be visualized.

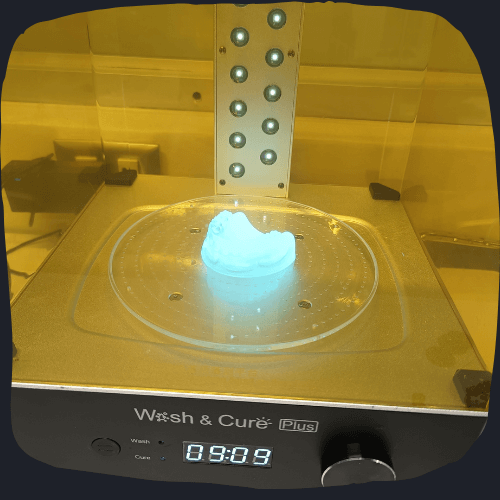

Precious plastic parts were used for its creation, integrating screens and Arduino controller as an esp86, also other techniques such as 3d printing, resin printing, laser cutting and CNC milling were used.

BOOTLE INTO TEXTILES FIBERS | 2022¶

As a graduation thesis I designed a machine that can convert pet bottles into textile fibers, I hope one day to be able to assemble it since for now it has only been design and simulation. It has four stages, the crushing, extrusion, air injection and fiber collection. The result is fibers that can be used as stuffing for mattresses, furniture or also to make clothes.

PRECIOUS PLASTIC | 2021¶

In the year 2021 together with the electronics laboratory where I worked we opened the first precious plastic point in Bolivia, building the machines from scratch and teaching about this manufacturing method.

Together with the oncology hospital that recycled plastic caps we carried out a project where they gave us the caps and we produced Christmas souvenirs that we then sold to the Coca Cola company based in Santa Cruz, all the proceeds were donated to the hospital so they could invest in medical supplies and treatment for children with cancer.

WHY FABRICADEMY?¶

I feel that this program will help me to grow in knowledge about biomaterials and will plant in me a new concept of design, art and creativity.

Something that I know I will be able to share in my country and encourage more people to create and think in a different way.

I am excited to begin this new challenge.

ASSIGNMENTS¶

Project management Project management |

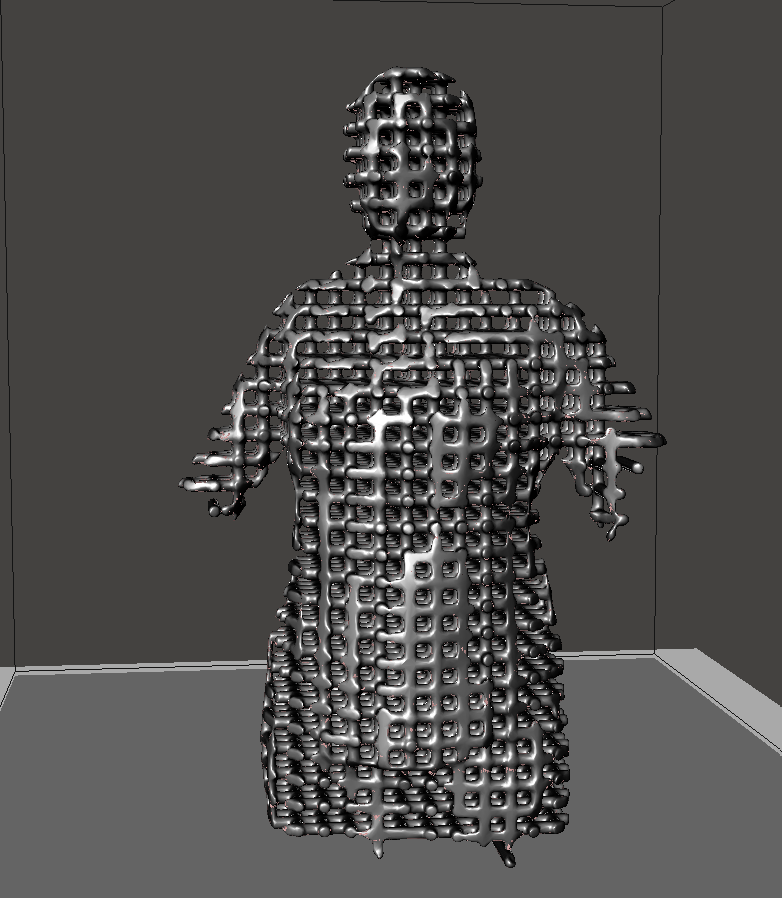

Digital bodies Digital bodies |

Circular fashion Circular fashion |

E-textiles E-textiles |

Biofabricating Biofabricating |

|

Computational couture Computational couture |

Wearables Wearables |

SoftRobotics SoftRobotics |

Textile scaffold Textile scaffold |

Skin electronics Skin electronics |

And in week 13 I proposed my final project.