Week 10 — Textile as Scaffold¶

Research Aim¶

This assignment explores textile structures as scaffolding systems through the design and fabrication of a compact, hand-operated weaving loom using open-source hardware and digital fabrication tools.

The main objective was to reinterpret a traditional textile tool as an accessible, reproducible, and modifiable open-source system, where the textile itself functions as a structural and experimental scaffold.

Rather than aiming for industrial precision, the project prioritizes:

- understanding mechanical and structural logic through hands-on making

- translating traditional textile knowledge into digital workflows

- exploring how textiles can act as scaffolds for material experimentation

This work investigates how open-source hardware, textiles, and digital fabrication can lower the threshold for experimenting with textile-based systems, enabling designers and makers to build, adapt, and modify tools according to their own needs.

Design & Process¶

The project began with online research into various DIY and open-source weaving loom examples. Existing solutions were analyzed through photographs and videos to understand different mechanical approaches and structural configurations.

Based on this research, a new loom design was developed to better support textile experimentation and scaffold-based thinking.

To visualize the structure and clarify the working principles, a preliminary 3D model was created in Blender.

The fundamental mechanics of the weaving process were analyzed, with particular focus on the loom reed (comb) movement, identified as the most critical functional element. Modeling this movement in Blender allowed early evaluation of the mechanism before fabrication.

After finalizing the design, all parts were exported as STL files.

The STL files were imported into Ultimaker Cura for slicing and pre-print checks. All components were printed using PLA filament with standard FDM print settings.

Once printing was completed, all parts were assembled and the loom was tested. Minor adjustments and reprints were made where necessary, resulting in the final working version of the loom.

Tools¶

- Blender (3D modeling)

- Ultimaker Cura (slicing)

- Desktop FDM 3D printer

- Hand tools (screwdriver)

Bill of Materials (BoM)¶

| Qty | Material | Notes |

|---|---|---|

| 1 | PLA filament | Loom components |

| 1 | Yarn (warp) | Warp threads |

| 1 | Yarn (weft) | Weft yarn |

| 6–8 | Screws | Frame assembly |

| 2 | 5 × 5 mm cube magnets | Reed positioning (if used in this version) |

Visual Documentation¶

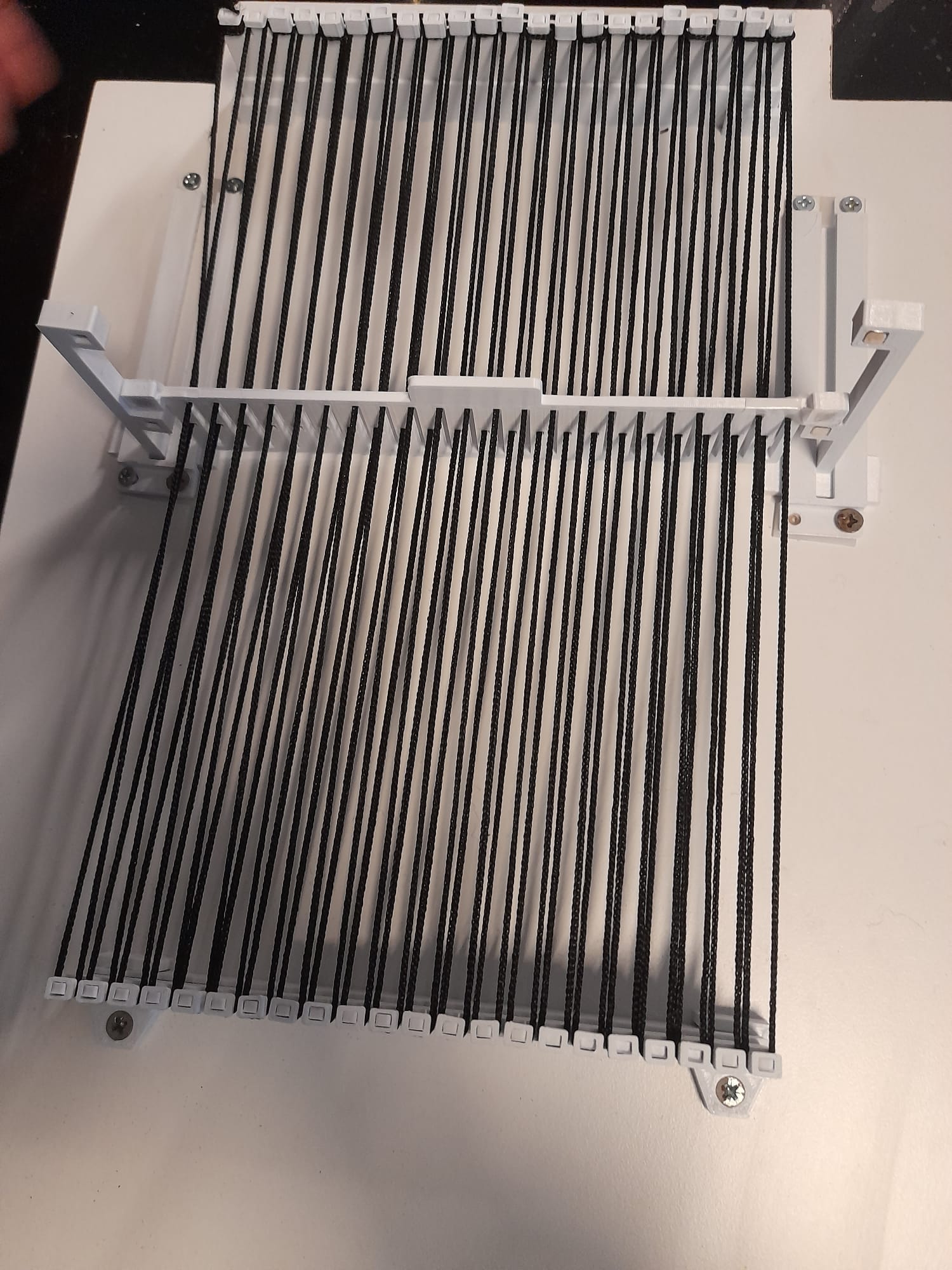

Figure 1 – Overview of the assembled 3D printed weaving loom.

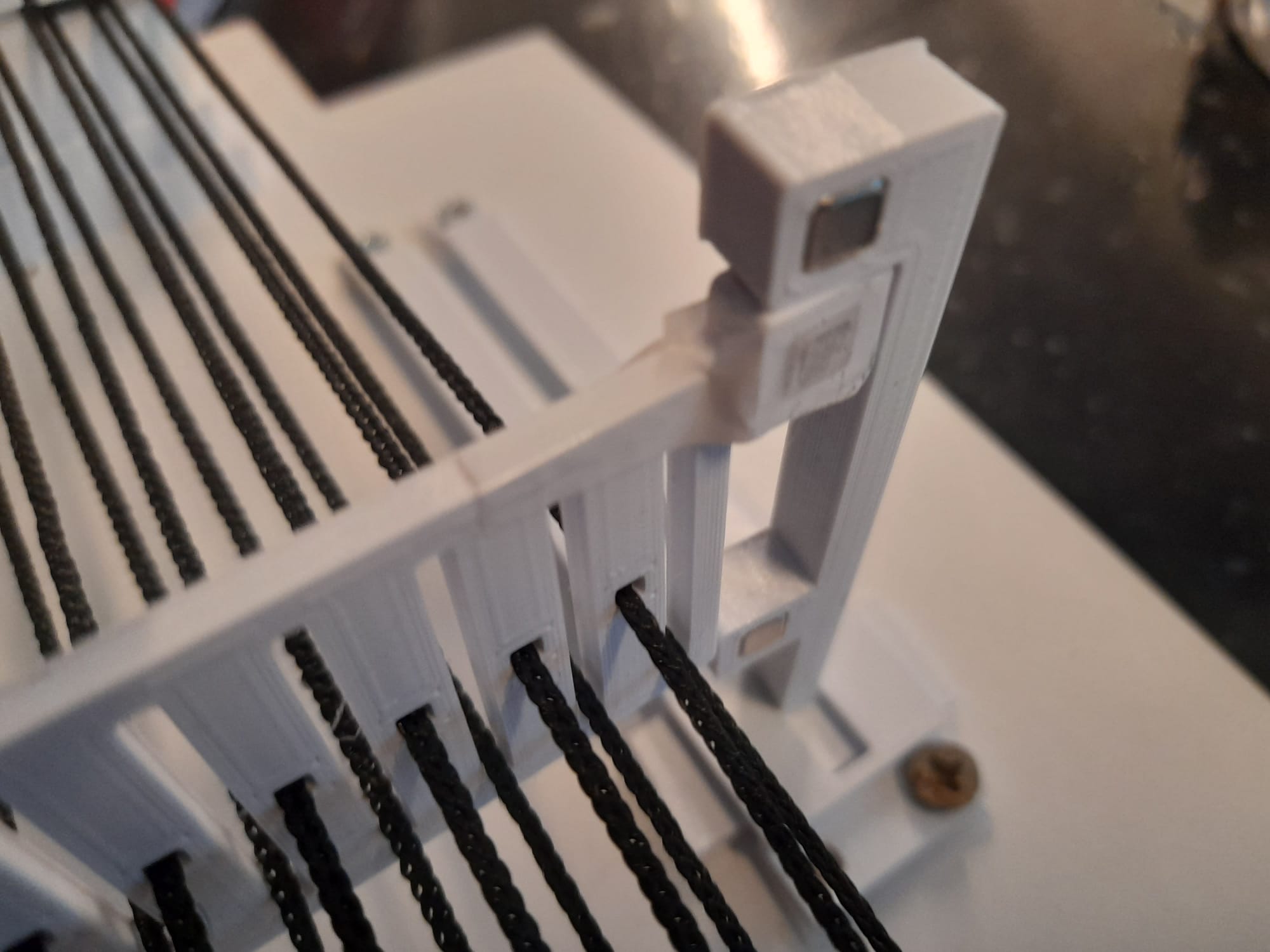

Figure 2 – Detail of the loom mechanism and key functional parts.

Figure 3 – Close-up view showing structural details of the printed components.

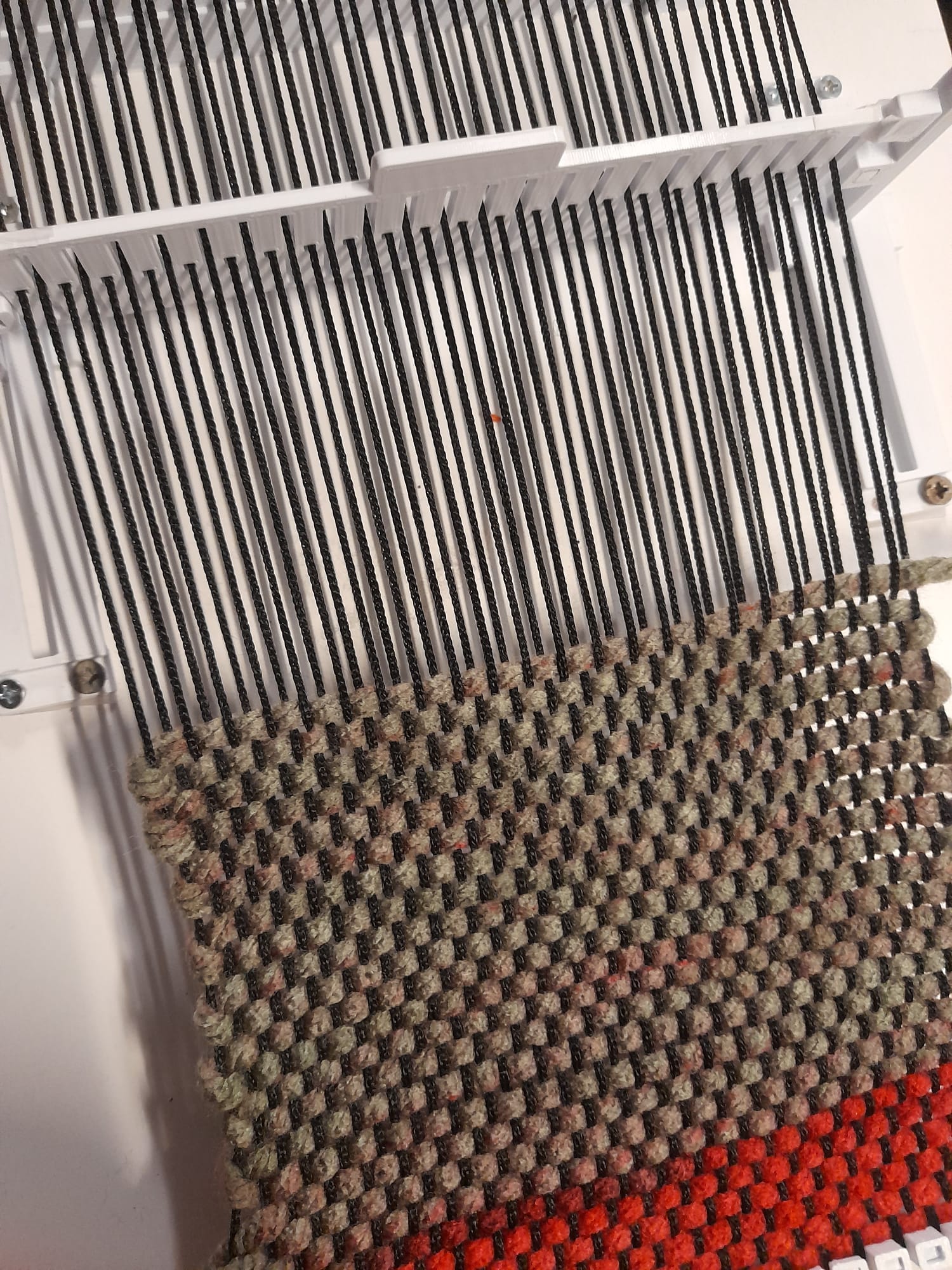

Figure 4 – Additional view of the loom structure and assembly.

Figure 5 – Detail view from the testing stage.

Video Documentation¶

Video 1 – Testing and demonstration of the weaving loom.

Results¶

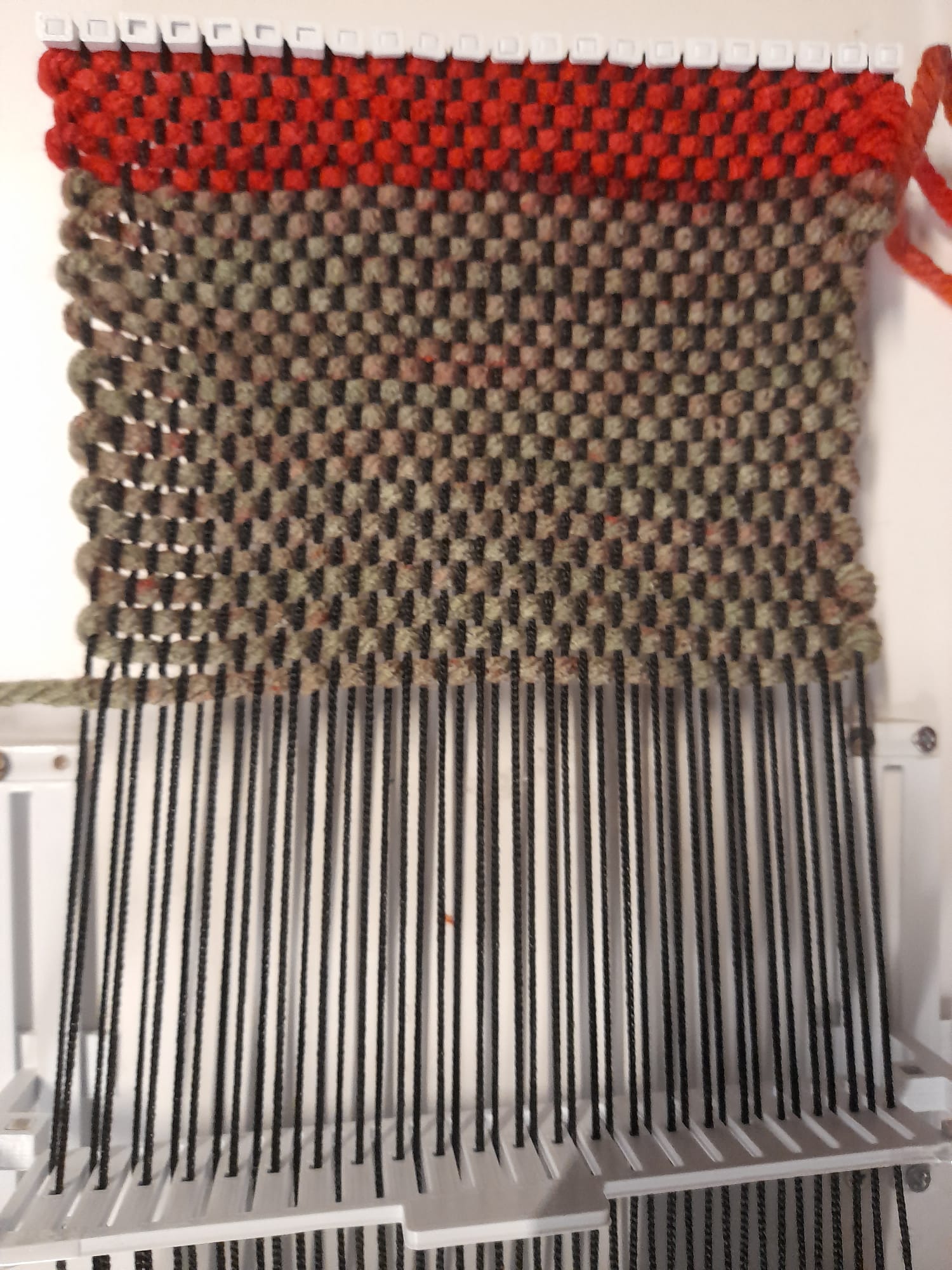

The final outcome is a compact and functional hand-operated weaving loom fabricated using a desktop 3D printer.

Through iterative design and testing, the loom proved capable of supporting basic hand-weaving operations and functioning as a textile-based scaffold for further material and structural experimentation.

Reflection¶

This assignment highlighted the value of open documentation and iterative prototyping when working with open-source hardware and textile systems.

Modeling the mechanism in Blender before printing significantly reduced fabrication errors and enabled early identification of mechanical issues. The final assembled loom demonstrates how traditional textile tools can be reinterpreted as scaffold systems through digital fabrication.

Fabrication Files¶

- Loom components modeled in Blender

- STL files prepared and sliced in Cura

(STL files can be shared as open-source resources.)