13. Implications and applications¶

Who I Am¶

I am a designer, educator, and maker, working across design, art, code, and fabrication.

My practice is all about making things—physically and digitally—and in understanding how materials, processes, tools, and systems shape objects and interactions. I am also interested in bridging the physical–digital gap and creating interactions that use the bridge to become more grounded and realistic.

I work extensively with:

- Digital fabrication

- Computational art and generative design

- Craft processes

- Material experimentation

- Interactive electronics and wearables

Alongside my personal practice, I teach and design learning experiences around tangible products, emerging technologies, creative coding, object histories, product semantics, and data visualization. Education and making are deeply intertwined for me, and many of my projects evolve through teaching, workshops, and collaborative exploration.

Skillsets¶

Design, Code & Computation¶

- Creative coding (p5.js, Processing)

- Generative and algorithmic design (Grasshopper, Blender)

- Parametric modelling (Fusion 360)

- Data visualization

- Web-page-based tools and interfaces

Digital Fabrication¶

- Laser cutting

- 3D printing

- Printing on fabric

- CNC workflows

- 3D scanning and post-processing

- Hybrid digital–physical workflows

Electronics, Interaction & Wearables¶

- Physical computing

- Sensors

- E-textiles and wearables

- Skin-based interfaces

- Machine building

Materials & Craft¶

- Paper as a material (folding, structural exploration)

- Origami and folding systems, paper and beyond paper

- Textile scaffolding and fabric hardening

- Biomaterials and composites

- Molding and casting techniques

Areas of Interest¶

- Making things; hands-on exploration across materials and processes

- Bridging the physical–digital divide

- Digital fabrication (laser cutting, 3D printing, CNC)

- Computational and generative design

- Creative coding and procedural systems

- Craft processes and their contemporary reinterpretation

- Materials, material behavior, and material histories

- Paper as a material

- Origami, folding, and flat-to-structure transformations

- Interactive objects and systems

- Teaching through making and documentation

- Machines and machine-making, specifically drawing and weaving machines

aAdded or strengthened during Fabricademy:

- Skin electronics and on-body interfaces

- Computational couture and printing on fabric

- Biomaterials and biocomposites

- Textile scaffolding and controlled structural systems

- Wearables and body-based artifacts

My Fabricademy Journey¶

Strongest weeks (enjoyment, interest, outcomes)

- Computational Couture — Translating algorithmic logic into printed-on-fabric structures was particularly satisfying.

- Digital Bodies — Enjoyed scanning and laser cutting; strongest interest was in computational manipulation of scans.

- Skin Electronics — Reinforced interest in the body as an interface rather than a data source.

- Textile Scaffold — Folding, hardening, composites, and structure-through-material were key takeaways.

Also

- E-textiles & Wearables — Conceptually strong; soft sensors and expressive outputs mattered more than polish.

- Biomaterials — Interest in material behavior, translucency, fillers, and composites rather than recipes.

- Soft Robotics — Conceptually exciting but practically challenging; ideas remain open.

- Open Source Hardware — Machine ideas were more interesting than outcomes; failures were instructive.

And then

- Open Source Circular Fashion — Material issues limited outcomes, but modular tessellations and volumetric ideas remain compelling.

- Biochromes — Enjoyed digitization and visualization of swatches more than dyeing itself.

Project Concepts¶

Anti-Surveillance Skin and Wearable Interface System¶

Concept Description¶

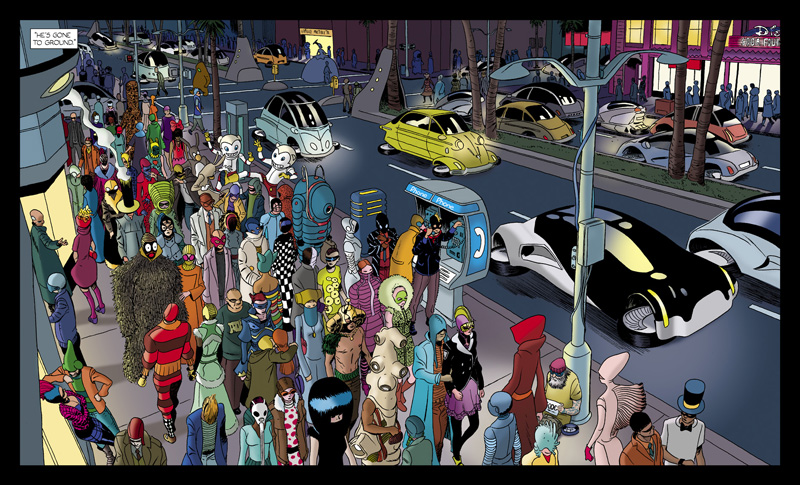

The absurd and bizarre disguises in a futuristic Los Angeles add some serious character to the story.

From : The Private Eye. Source : DigitalAmerica.org

A set of skin interface patches and wearable elements that take inputs from the body and its actions, and convert/transmit them intentionally—by the wearer—into output visualisations and expressions. These may exist partly on the body (light, sound, haptics) and also on a screen, locally or remotely.

This project draws, in part, from speculative worlds such as Private Eye, where pervasive surveillance leads to cultures of masking and selective self-representation.

When being seen and not being seen are both data points, your only option is scramble and noise.

My work from Skin Interfaces

What¶

A modular platform of skin patches and wearables with user-defined input–output mappings, including a software/digital control interface.

I haven't crystallised my story or intent very fully yet; I feel I am circling around it but know it's within this overlap of surveillance, speculation, skin and wearable tech, craft, and art as a political statement.

Inspirations¶

References / Analogous Works¶

Fabri Alumni

Why¶

- Surveillance has gone mainstream, from mandatory apps to mandatory dna profiling, face recognition to gait recognition

- Should one always be available to be read

- Explore anti-surveillance through expression, not encryption - this isn't a faraday cage or a tech solution

- Enable masking and broadcasting emotion, body language, as choice and deliberate action

How¶

- Skin interfaces and e-textile techniques

- Biomaterial “false skins” and textile-scaffold mounts

- Microcontrollers mapping bodily input to expressive output

- Soft-robotics-based kinetic aspects (stretch goals)

Who¶

Designers, performers, educators, and individuals interested in bodily agency.

When¶

The Near Future

Where¶

India/Everywhere

Pros¶

- Modular MVPs in multiple directions

- Low fabrication bottlenecks

Cons & Caveats¶

- Many precedents in wearables and skin interfaces

- Should not become more "Decor"

Fabricademy Criteria¶

- Wearable technology meets fashion

- End-user programming

- Personalization at service level

- Craft × computation

Future Scope¶

Expanded expressive vocabularies, public installations, teaching toolkits.

Phases¶

- Concept locking and definition

- System architecture

- Interface layer (on-body pieces)

- Mapping layer (data → visuals)

- Integration

- Documentation and video

B. Computational Corset¶

Concept Description¶

Images : Amazon.in

Images : Pinterest

A computationally generated structured belt or corset designed to provide support while allowing movement. Originating from a personal, lived need, the project explores how folding patterns, and textile scaffolding can replace rigid, standardized support systems.

an ideation sketch by me showing possible fold lines and rigid sections

What¶

A body-supporting garment component with directional stiffness and flexibility.

References / Analogous Works¶

Elisa Stroyzk

Iris van erpen, Architectonics

- Iris van Herpen

- Julia Körner - the Black Panther movies, but for them managing the balance between the structural engineering of the warrior costumes, and maintaining their aesthetics as well

- The Fabric Formwork Book — Mark West (Taylor & Francis)

- Diego Vencato

- Elisa Strozyk

- Magali Uwimana

Why¶

Comfort and quality of life; rethinking assistive garments through computation. Personal story

How¶

- Parametric pattern generation

- Textile scaffolding and folding

- Paper and fabric prototyping

Who¶

Initially myself; potentially others with similar support needs.

When¶

Now

Where¶

Mumbai / broadly applicable

Pros¶

- Clear MVPs

- Easy iterative testing

- Strong personal motivation

Cons & Caveats¶

- Initial audience of one

- Requires careful generalization

Fabricademy Fit¶

- Fashion × technology

- Personalization at product level

- Digital material production

Future Scope¶

Expanded sizing, alternate materials, hybrid sensing.

Phases¶

- Problem definition and requirements

- Body mapping (static and in motion)

- Pattern development and material experiments

- Finesse to final garment/object

- Documentation and video

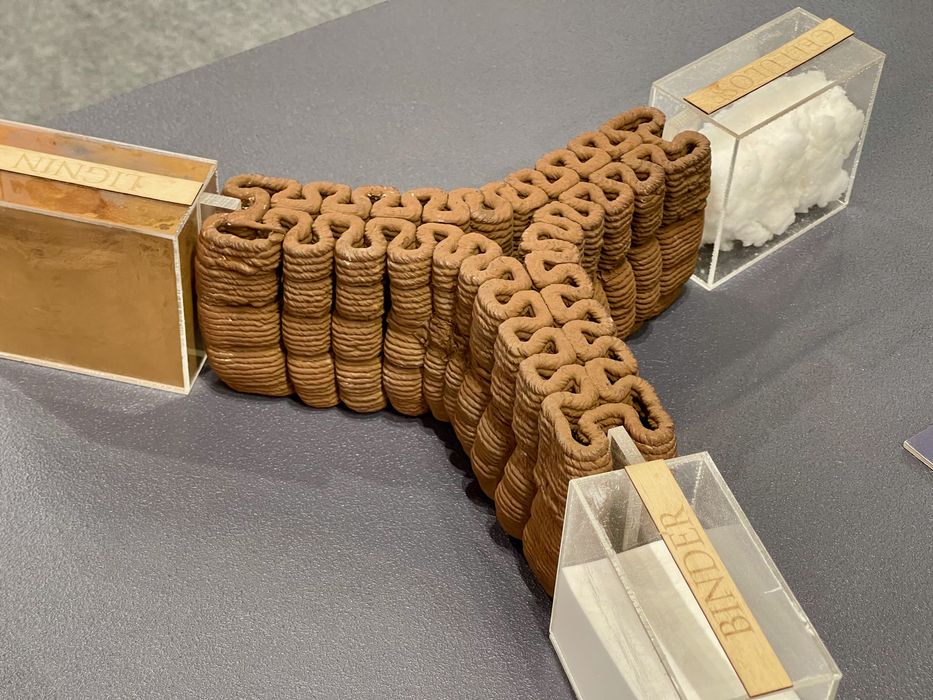

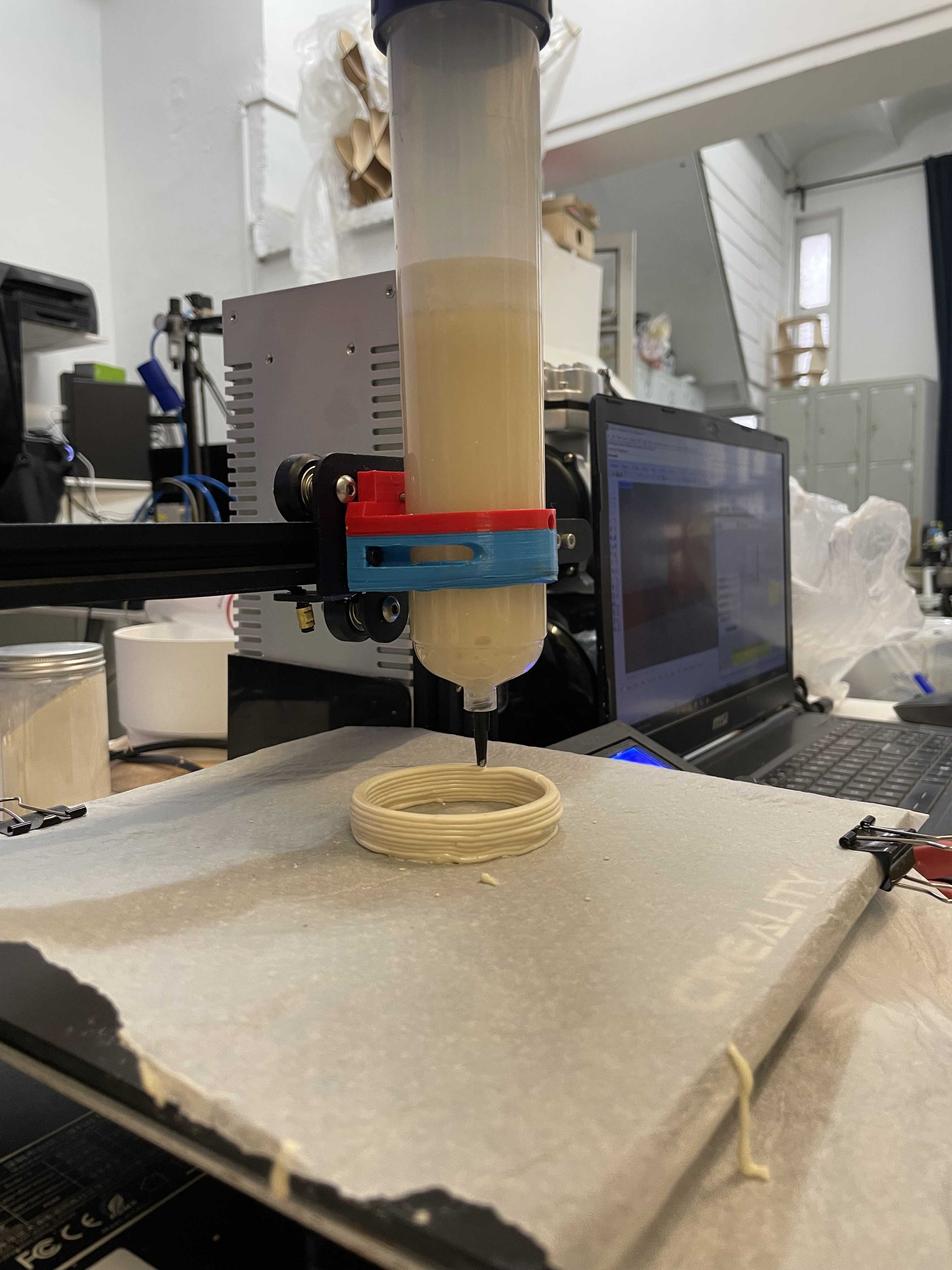

C. Biocomposite / Paper-Based 3D Printer¶

Concept Description¶

A 3D printer/machine that uses paper pulp and biomaterial binders to print three-dimensional objects, exploring alternatives to plastic-based additive manufacturing. With a focus on Bagasse based cellulose as raw material.

What¶

A modified 3D printer capable of depositing paper-based composite material.

References / Analogous Works¶

- MIT — 3D Printing Cellulose

- TU Delft cellulose + lignin printing (Fabbaloo)

- ACM / ResearchGate — 3D Printing Eggshells

- Bagasse Paper

Why¶

PLA remains plastic with concerns around disposal and microplastics; paper and biocomposites are a lot friendlier. I have institutional access to bagasse and bagasse cellulose

How¶

- Adapt existing 3D printer hardware

- Develop printable paper-binder recipes

- Explore drying, curing, and bonding

Who¶

Artists, designers, prototypers, packaging researchers.

When¶

Now

Where¶

Fabrication labs, studios

Pros¶

- Clear sustainability argument

- Concise end goal

- Bagasse access

Cons & Caveats¶

- Many related precedents

- Hardware access - find a spare printer, esp a Delta; one that's working so I'm not solving for repair work

- Three major aspects to solve: hardware, recipe, solidification

- No spiral development initially — it either works or it doesn’t

Fabricademy Fit¶

- Digital material production

- Open-source hardware

- Sustainability

Future Scope¶

Structural composites, packaging, hybrid textile systems.

Phases¶

- Scope and definition

- Material recipe development

- Hardware development

- G-code and controls development (mostly Grasshopper-based)

- Integration and testing

- Samples

- Documentation and video