5. E-Textiles and Wearables I#

assignment#

- Create your one digital and one analogue soft sensor

- Understand the readings of your sensor and map its values using a microcontroller

- Program a LED o mini vibration interaction with your soft sensor

- Intergate it in a swatch using hard-soft connections

preparation#

conductive fabrics/threads#

I bought some materials for this week.

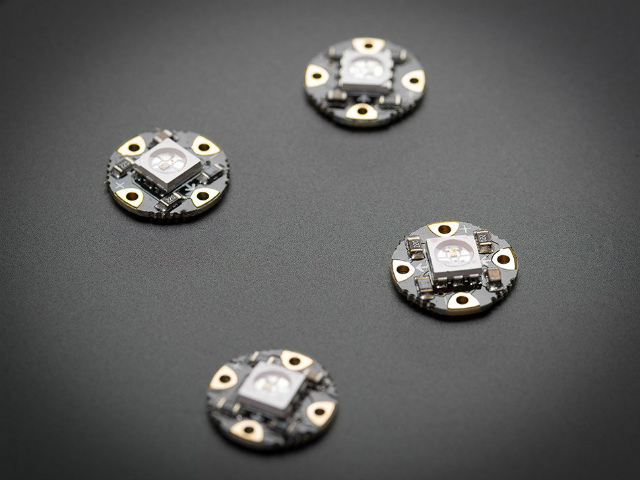

LEDs#

Playing with Neopixels is always fun, so I wanted to use them this time. I found that sewable neopixels are available, but can’t get them soon and they are expensive.

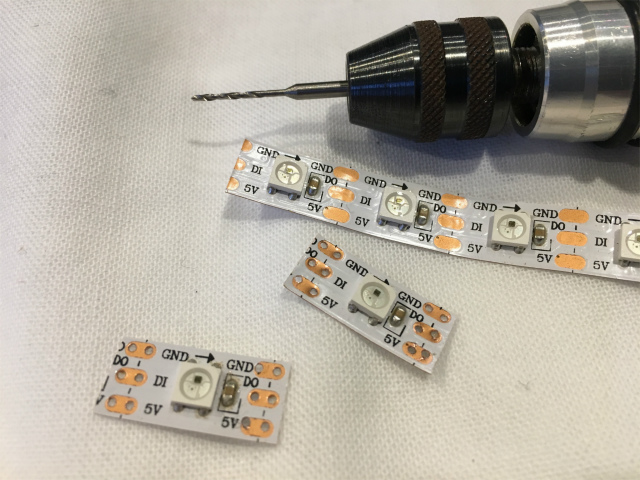

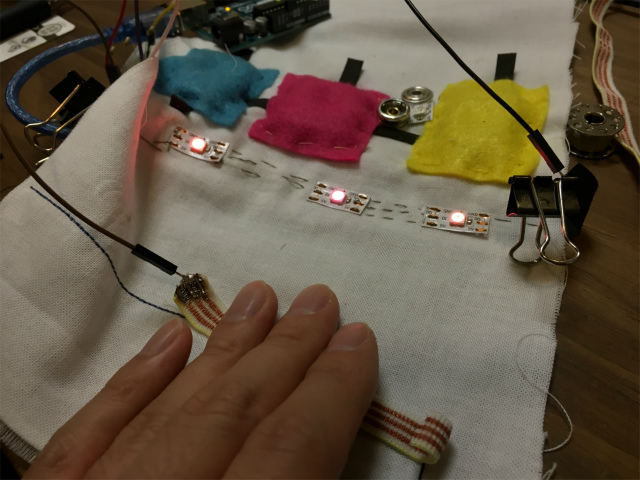

I tired to DIY sewable Neopixel because I have a long reel of them. I cut a reel and drilled holes through an electrode. I connected them with conductive threads and tried a sample sketch of Neopixel. I got a successful result, so used them in this week assignment.

digital and analogue soft sensor#

digital sensor / button#

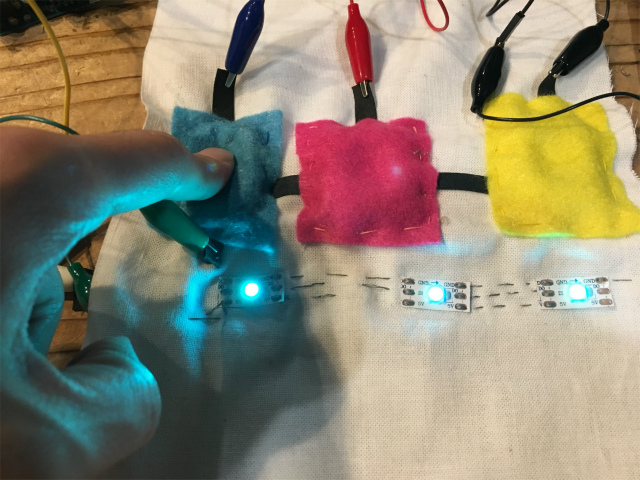

First, watch what I made.

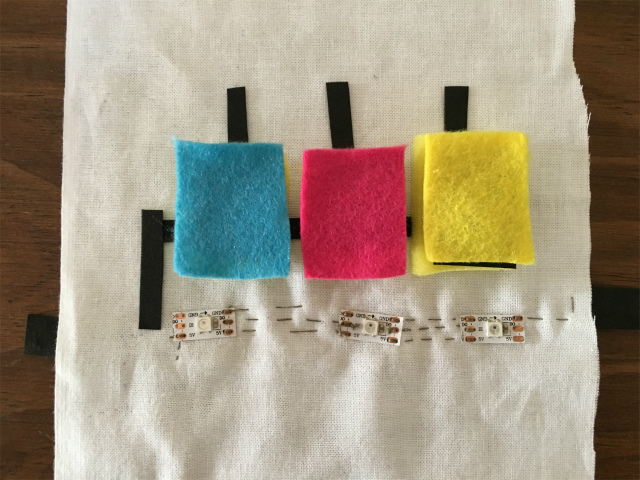

I made buttons with using a conductive fabric, a felt sheet, and a kitchen sponge. I made three color buttons to light up a color LED(Neopixel) corresponding to the color of them.

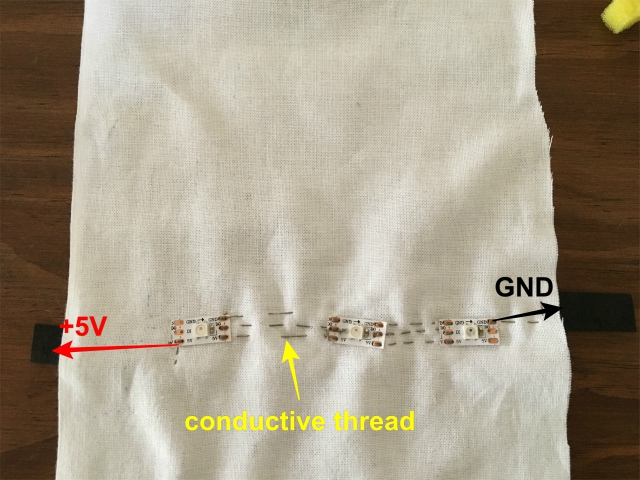

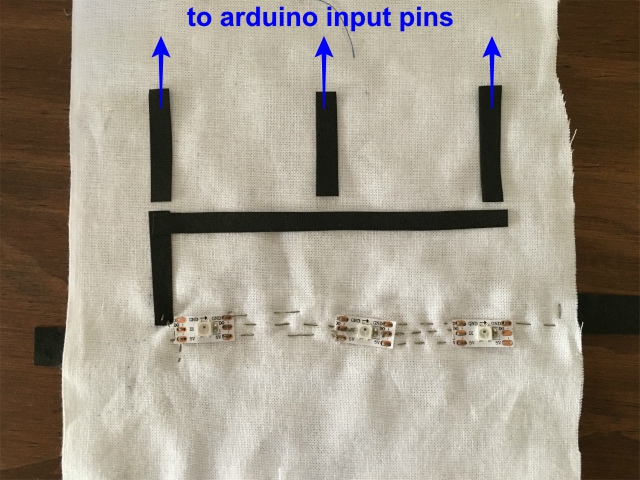

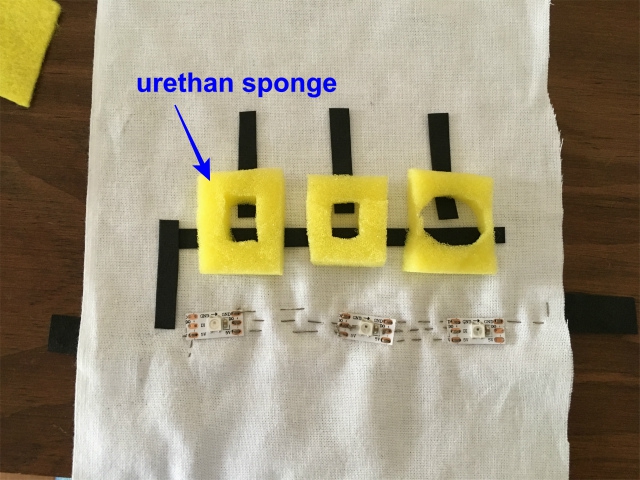

The fabrication process is as follows. I sewed three neopixels on cotton fabric as insulator with a silver-coated nylon thread. Black fabrics of left and right side are EeonTex Conductive Fabric as power supply and ground electrodes respectively.

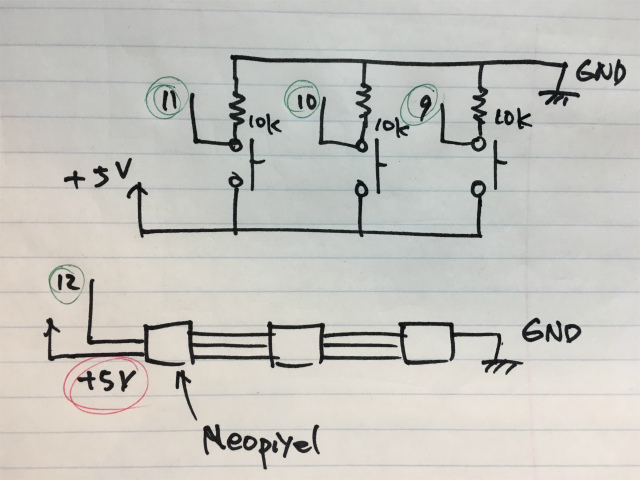

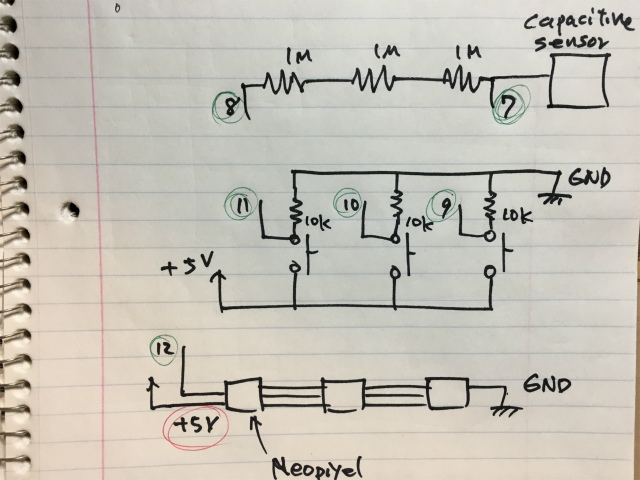

I placed conductive lines from + 5V to arduino inputs pins via buttons. I made a gap of conductive lines where a button will be placed.

I put urethan sponges(cookware scrub sponge) as a spacer for fabric button.

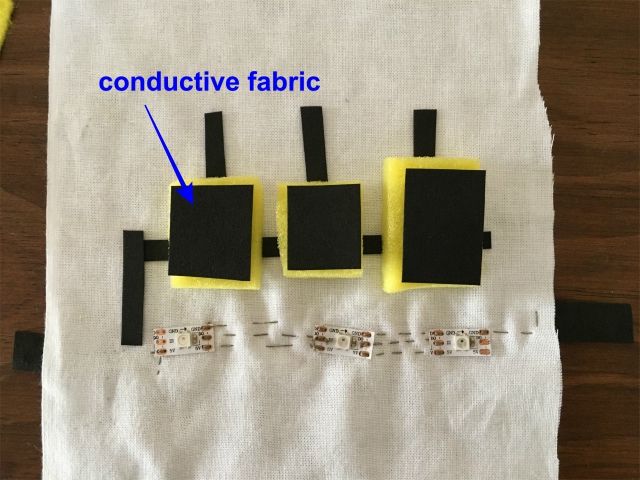

I placed conductive fabric to bridge a gap.

I placed a felt(polypropylene) as an insulator on a conductive fabric.

Circuit schematic and a code.

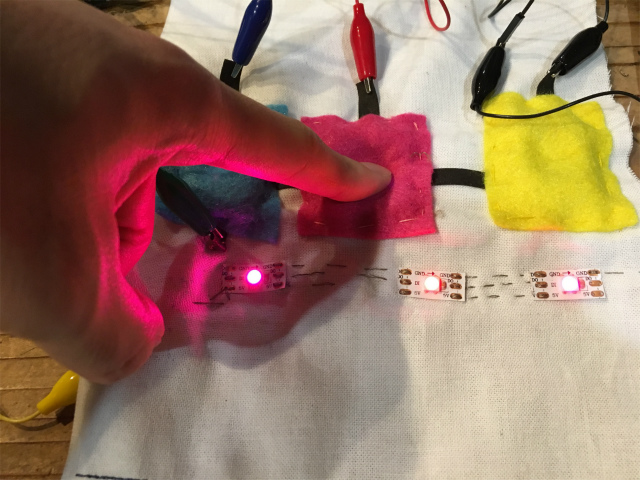

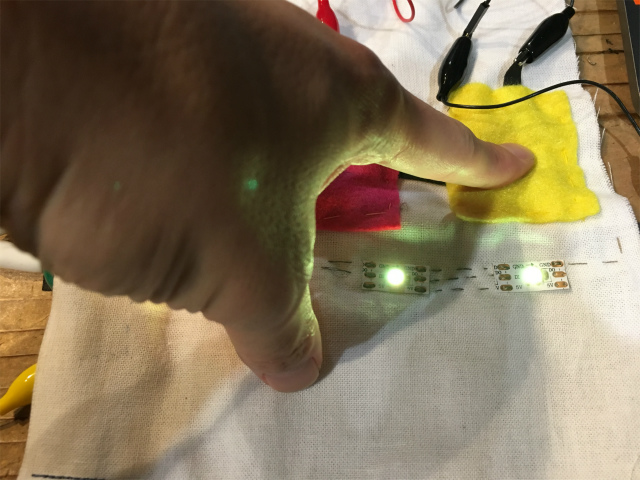

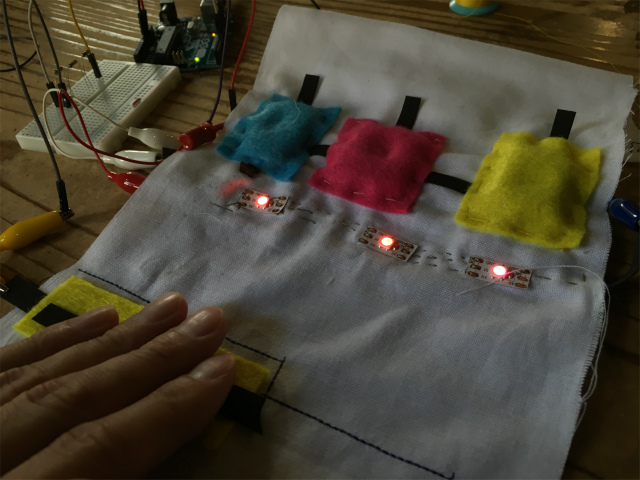

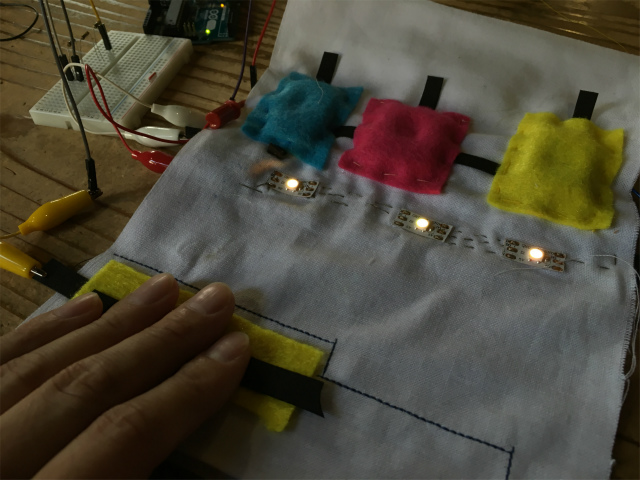

Colorful LEDs emits the color of light corresonding to a button color,

cyan,

magenta,

and yellow.

analog sensor / capacitive sensor#

readin analog sensor#

Here is what I made.

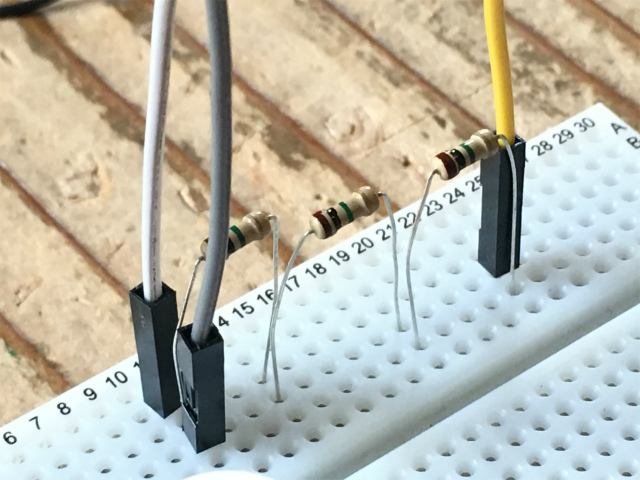

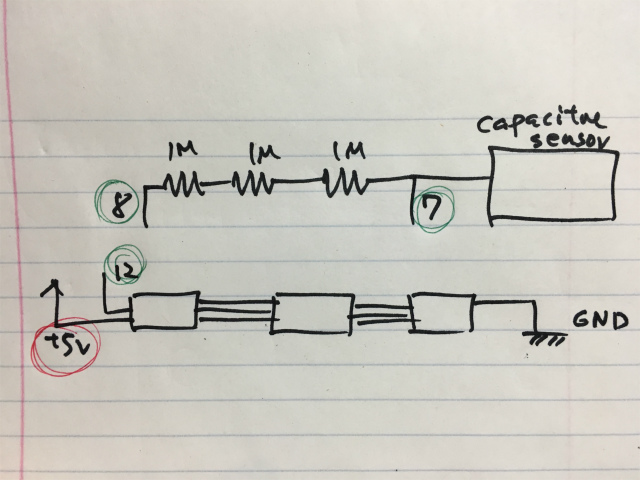

I made a cavacitive sensor as analog sensor to contorol the color of LEDs. There are a lot of references for capacitiv sensors, I referred here mainly.. I placed three 1 mega ohm resistors (3 megohm) between the send pin and the receive (sensor) pin to make a sensor sensitive.

I made a wrong choice of a capacitor, a conductive knit, which is lack of reliability and reproducibility.

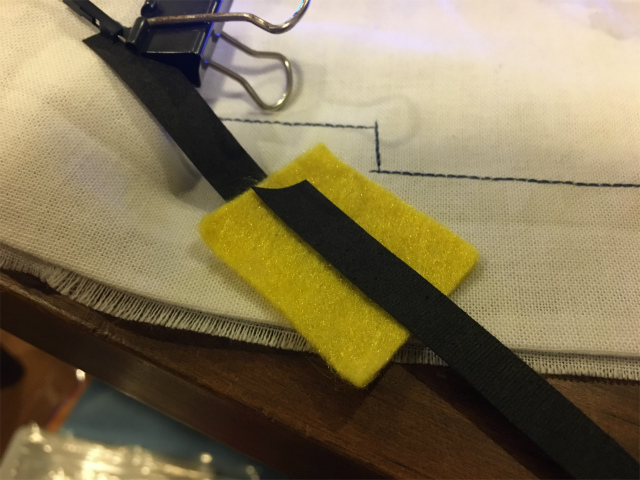

Eventually, I used EeonTex Conductive Fabric covered with felt sheet.

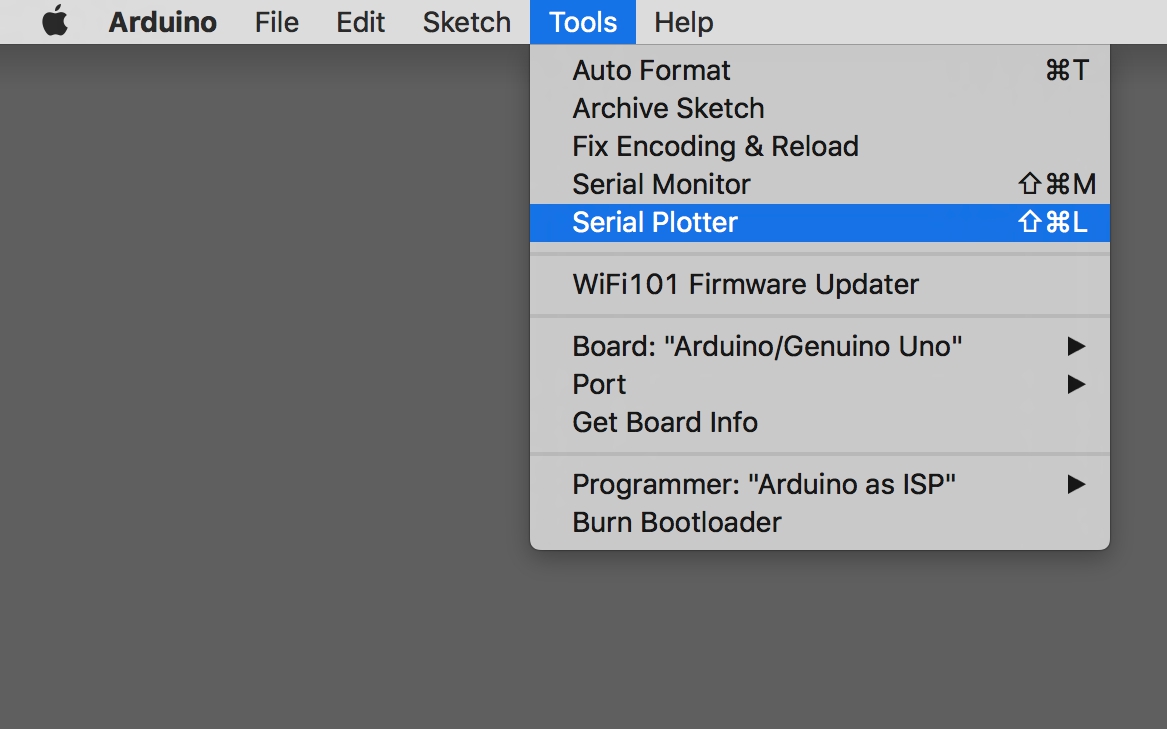

Serial monitor shows only bunch of numbers, but serial plotter shows you a time cource of changes in analog readings.

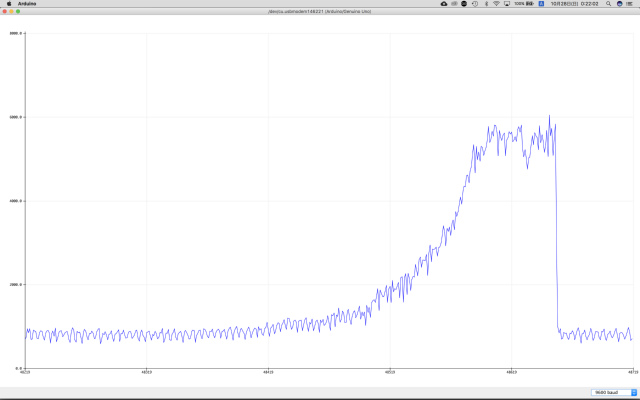

If you bring your hand near a capacitor, analog reading value gradually start increasing and reach plateau.

Circuit schematic and a code.

The color is cyan when the hand kept away from a sensor.

The sensor will start to sense when a hand barely touched, and the color become magenta.

If you touched a capacitor firmly, the color become yellow.

integration#

I integrated button switches and a capacitive sensor.

I couldn’t turn the first led on. It’s not broken. I know it has something to do with my skectch, but I don’t figure it out yet.

Circuit schematic and a code.

At regional review, my mentor, Saverio, pointed out that felt sheet was deformed after pushing many times because it is not elastic enough, which could eventually cause a short circuit. I think polypropylene sheet is going to be a good alternative.

files#

- arduino sketches(.zip)

references#

- WEEK 3: Switches, Sensors, + Swatches - Computational Craft Fall 2018

I made a pushbutton as digital sensor and a capacirive sensor as analog sensor with LEDs

firs push button