9∙ Textile Scaffold¶

15th to 22th november 2022

Instructor in Lab in Lyon : Lucia Javicoli

Update

- November, 2023

- April, 2023

Assignments

- Produce small samples of textile composite. Compare and document their qualities.

- Design and create a fabric formwork to cast concrete or liquid marble into it.

- Design and create a scaffold of fibers to grow crystals on it

- Design and CNC mill a mold.

- Design and create a fabric composite deriving from a 3D mold.

- Design and create your own textile scaffold with an alternative technique of your choice.

- Participants need to select 2 out of 3 techniques and create their prototypes.

Ressources of the week

Research¶

Objective being focus on 2 subjects:

-

Mycelium

Yes again, two of my favorites subjects to use microbial and animal materials, specifically working with waste and the circle of life of them. I was little bit worried because I some time during this week I was thinking creating again of the biomaterials of the similitudes of elements and going back to my week 6.

References & Inspiration¶

- Blast Studio

They develop a micro-recycling facility called Urban Stomach where the waste from cities can be digested ultra locally to create valuable objects and artefacts. Blast Studio

Source IAAC- Hyper Articulated Mycomorph

Fungi¶

Ingredients & Recipes¶

Links of ressources

I- Process¶

17/11/2022 : The petri dishes are place in polyester box in the "special" room at 24-25° with pot of water for the humidy in the room.

19/11/2022 : The petri dishes start to be slowly white. Happy moment I'm confident for this. We decided to add in the room some test of paper of others partenaires in the lab made. We thinking about will be more easy for dry quickly in this room.

20/11/2022 : We enter in the room, smell bad, all are with moisture... Paper are green, mushroom too. We think they are a combination of mushroom. Mushrooms in carbage and petries dishes going again in cooker for sterilisation.

Old test made with a big of grain buy in la Mycosphère.

- Petri dish

- Ethanol

- Bowl

- Balance

- Jar

- Cooker

- 250ml distilled water

- 5g Malt

- 5g Agar

- oyster mushrooms and beige mushroom (test 1)

- Tramete Versicolor ( waiting of the validation by the pharmacy) found in the forest (test 2)

- Stérée hirsute (test 2)

- Some of the mycelium of the Grown kit (test 2)

* Add the petri dishes in the auto cooking pot.

* Wear a mask and gloves.

* Sterilize the place and the materials.

* Clean with Ethanol equipment and place.

* Mesure Aguar and Malt extract

* Mesure water

* Boiled water

* put water with Agar and Malt

* Mix

* Put it in the jar

* Add in auto cooking pot for sterilization of the preparation

* When it’s starting to be pshhhhhh, baisser le feu.

* Sterilise mixture for 20 minutes

* stop and leave it during 1h

Step 1- Sterilize materials and place¶

Step 2- Making Aguar and add mushrooms.¶

- After putting the mixture inside the petries.

- Wet for having cold and stick

For the test 1 : We used oyster mushrooms and beige mushroom.

- We cut it and take the white part inside them.

Step 3- Keep your eyes on it¶

Mycelium start to grow. Looks nice !

Results¶

The mycelium was contamined and going in trash. I would like to make it again but for the next experience :

-

Taking care of others materials going inside the room. = having a proper space for mycelium.

-

Trying to make liquid culture.

Next objectives :

-

Inoculate a paste for the 3D printer.

-

Arriving to grow mycelium inside knitting.

-

Making leather

-

Adding dying bacteries

-

Making a structure

-

Making sole for shoes

II- Process with Kit.¶

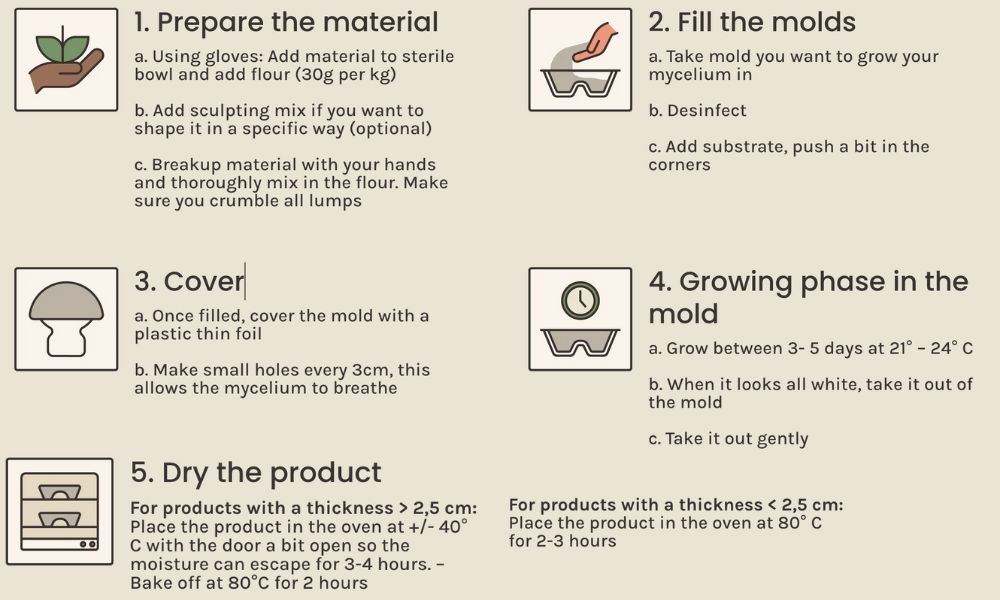

We receive at the lab a kit for molding mycelium. There a bag of mycelium and sculting pouder. The company didn't want to give us of what there are inside, aswell we don't know of which mycelium is it.

Results¶

Video by Lauriane Beaumont

We received a lot of mycelium in the lab. During the first day, Wednesday during which one made somes test in group. But was still having a lot in the fridge. Melanie Abel has a good idea to make the haybox. We used the upper part of an old coal stove as a mold, founding in the garden of the lab.

Finally the haybox will be transform for the plant and making a big pot. I burn it when he was in the oven. And with the hat of the haybox, we decide to make a lamp.

Results of the lamp with others research made during the final project.

Results of the lamp with others research made during the final project.

FISH LEATHER¶

I- Process for Fish modeling leather¶

Previously I used leather fish made by Ictyos.

More info here

For this experimentation I use Salmon skins previously scaled, recovered when I was working in a kitchen.

They were salted and stored during 6 months.

For this experimentation I use Salmon skins previously scaled, recovered when I was working in a kitchen.

They were salted and stored during 6 months.

We working in group for this process too but we had some technical problems during this. Camille Barot was really wanted to make a mold with 3D printing, Laora Guillerm the idea of a mold ( it's the body she made during the second week but this time modelised by Camille for having a little one) and she helping for follow the process of the fish too, and me I was really wanted to use my old fish skin but with no idea of what I will do with aswell I'm not really confortable with Rhino and didn't want to use so much my laptop during this week.

Camille Barot had problem during the printing of the mold and we didn't use it finally. There are manys conditions we need for printing it. Like having some holes.

Step 1 - Mordanting¶

-

79g of fish skin

-

24g of tannin

-

Heat the skins at 2 degrees gently until they reach 50°.

The fish stay inside the bath during all the night.

Step 2 - Dying Color¶

Dying Color ( in french for this moment)

- 30g Campeche

- 3L of cold water

- Fish skin

- Start the cold bath

- Raise the temperature to about 50°.

- Then turn off the heat.

- Leave to cool in the bath for a day.

Step 3 - Making leather¶

- Boil water at 80° with tablespoon of bicarbonate.

- Stop the water.

- Add fish inside.

Step 4 - Molding Leather¶

Material needs :

- Vacuum cleaner

- A thermal strippe

- Moulds with holes

- Vacuum box with plastic and big surface in latex

I use this mold for doing fish molding.

Results¶