6. Biofabricating¶

As my project is focused on footwear, I have found in the bio materials many new development opportunities. This week I worked on creating a foamy bioplastics for the insole of a shoe and some biocomposites for the sole.

As my project is focused on footwear, I have found in the bio materials many new development opportunities. This week I worked on creating a foamy bioplastics for the insole of a shoe and some biocomposites for the sole.

What are the differents between biofabricating and biomaterials?¶

Biofabricated materials: Are created by microorganisms such as yeast, bacteria, and mycelium, or by live cells. The only "natural" and "synthetic" polymer building blocks that are biofabricated are those that are created by microbes, such as nylon and silk, respectively.

On the other hand,¨the word “biomaterial” masks differing technology approaches, inputs and impacts. A key takeaway is that blanket assumptions or statements cannot be made about any biomaterial. Each biomaterial must be considered on a case by case basis regarding its manufacturing process, function and impactFrom the fashion industry point, biobased materials have the potential to change industry standards and longer-term obligations with climate change.¨ by Fashion for Good.

Useful links¶

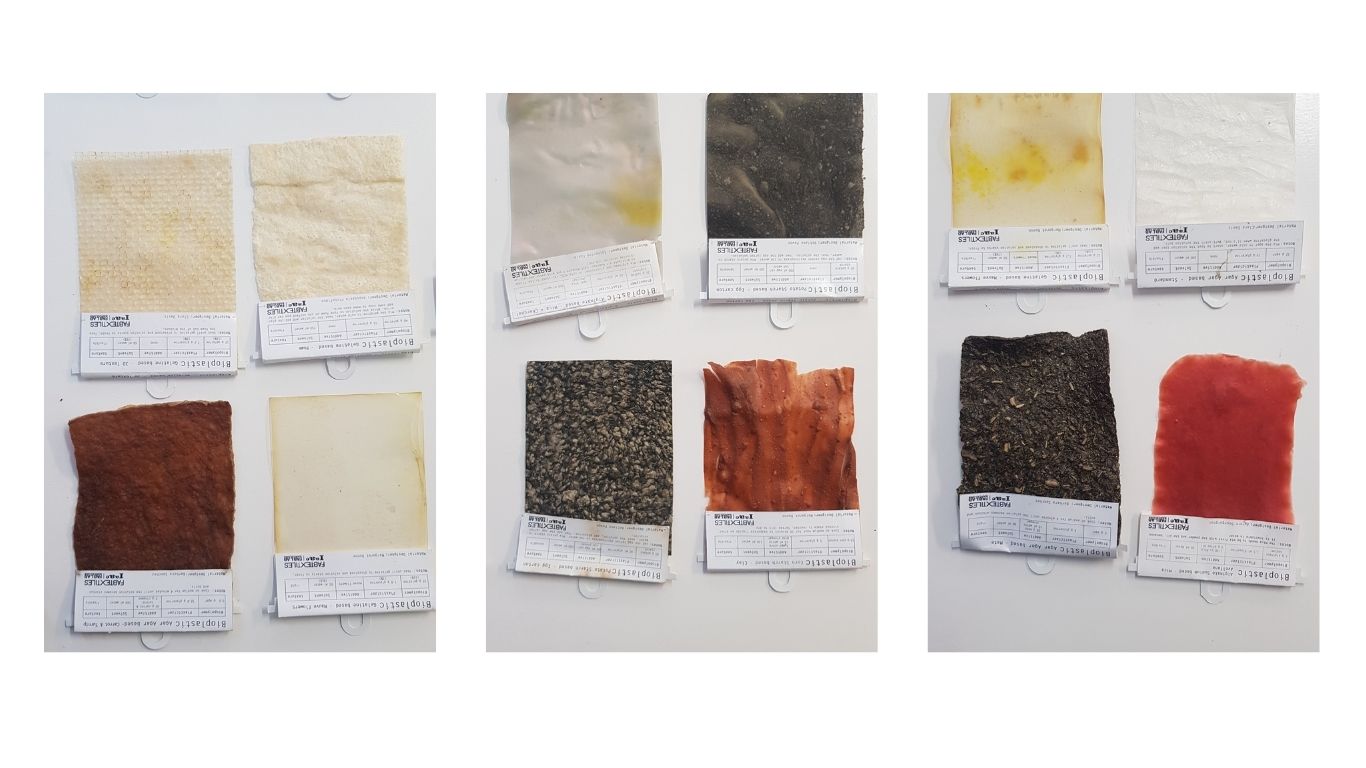

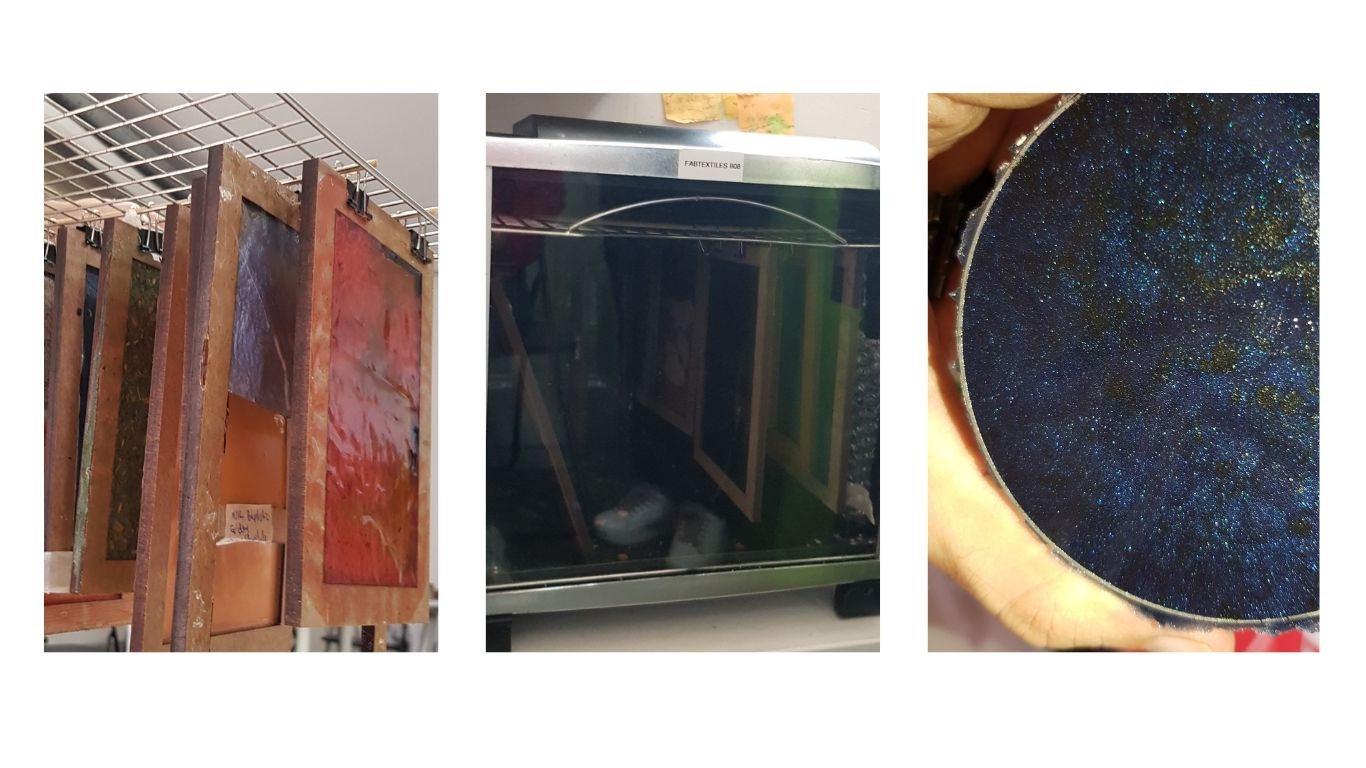

Process and samples¶

This week we are going to biofabricate different materials, from crafted materials to grown materials such as bio-plastics, silicones and resins. And others like: Gelatine, agar agar, alginate, bacterial and mushroom leather.

Materials needed¶

- Bio -plastics -resins -silicones

- Gelatine

- Agar agar

- Alginate

- Calcium chloride

- Starch

- Glycerine

- Water

- Vinegar

- Pigments

- Sodium carbonate

Biomaterials¶

Recipes¶

Gelatine basic recipe¶

- 240ml of wwater

- 48gr gelatine powder

- 12gr glycerol

Alginate basic recipe¶

- 400ml of Water

- 100g glicerine

- 25g alginate

Pour all the ingredients and mix them with the electric mixer. Remember that this recipe is mixed cold so it does not need to be brought to a boil.

Agar agar basic recipe¶

- 400ml water

- 1g glicerine

- 7,5ml vinegar

- 2,5g agar agar powder

Resin basic recipe¶

- 10gr Colofonia / Pin Resin

- 30.7ml Alcohol

- 30gr Cera Carnauba / Beewax

- 10.3gr Glicerina

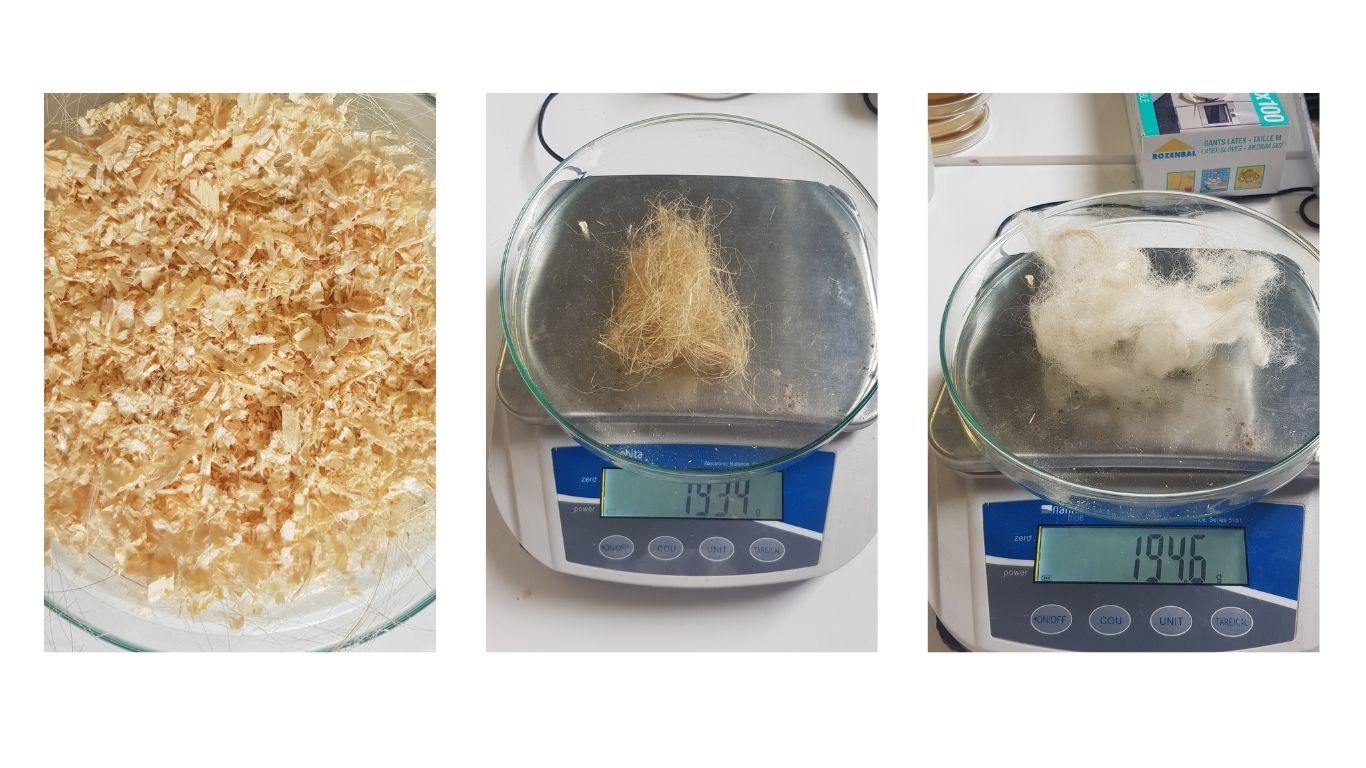

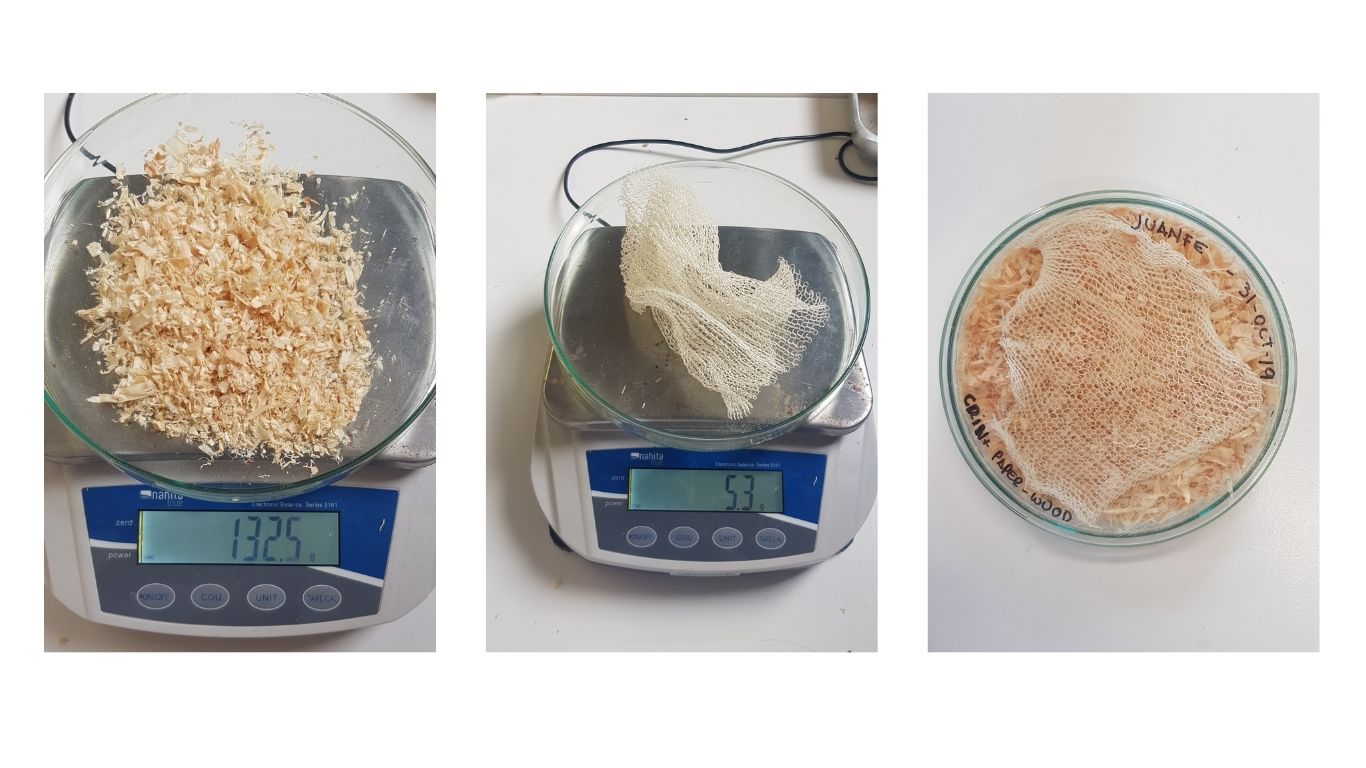

Working with mycelium¶

- 0.2gr Baige paper

- 0.2gr Red paper

- 0.6gr Hemp

- 1gr Alpaca fabric

- 5 spray distilled water

- Mycelium

- Steryl container.

Helful video Important fact: High humidity levels (around 95-100%) helps the mycelium to grow faster.

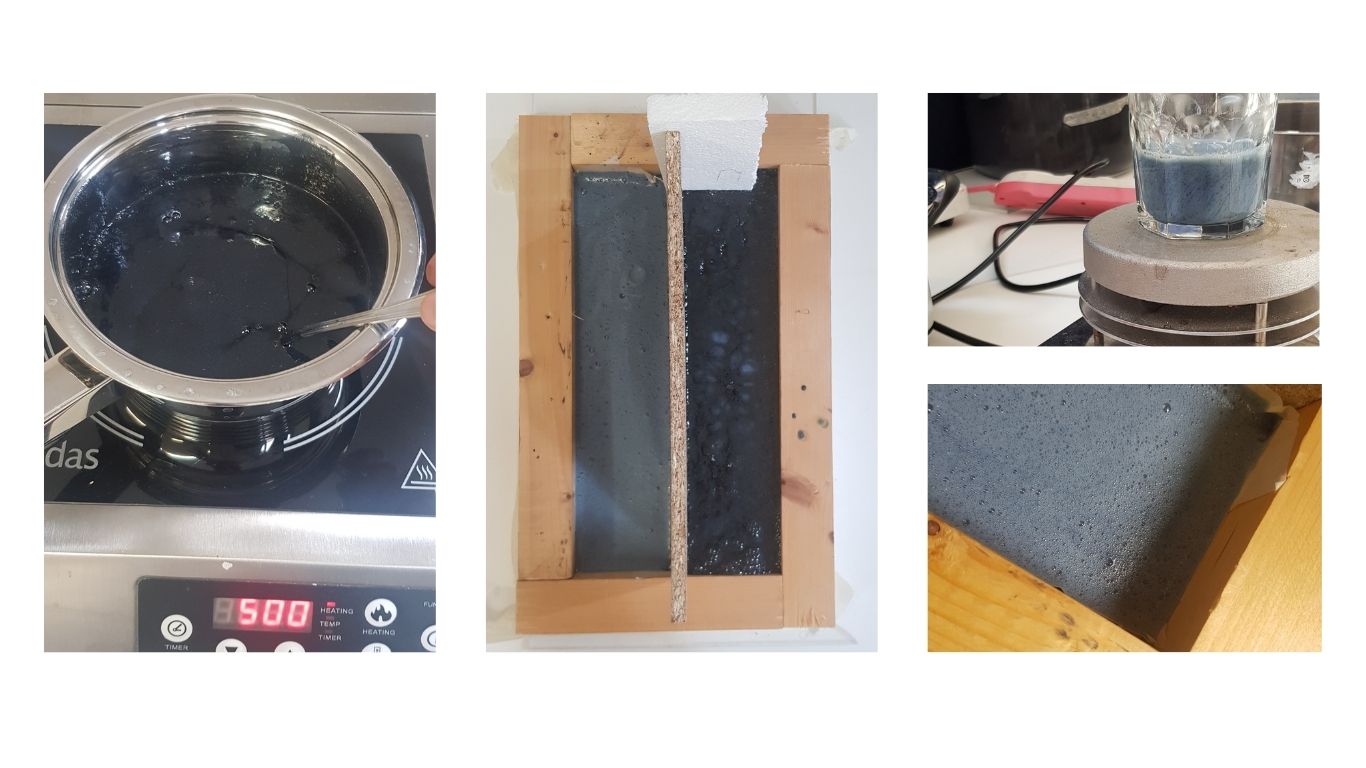

Bioresin¶

Tools: Stove, Pot, moulds (silicon recommended), Scale, Moulds (from silicone like in the photo) and Spoon. emovable base or

Ingredients¶

- 96 gr Gelatine powder

- 16 gr Glycerine

- Water - 480 ml/gr

- 8 gr waste food porwder

- Coffee filter

- Natural dye

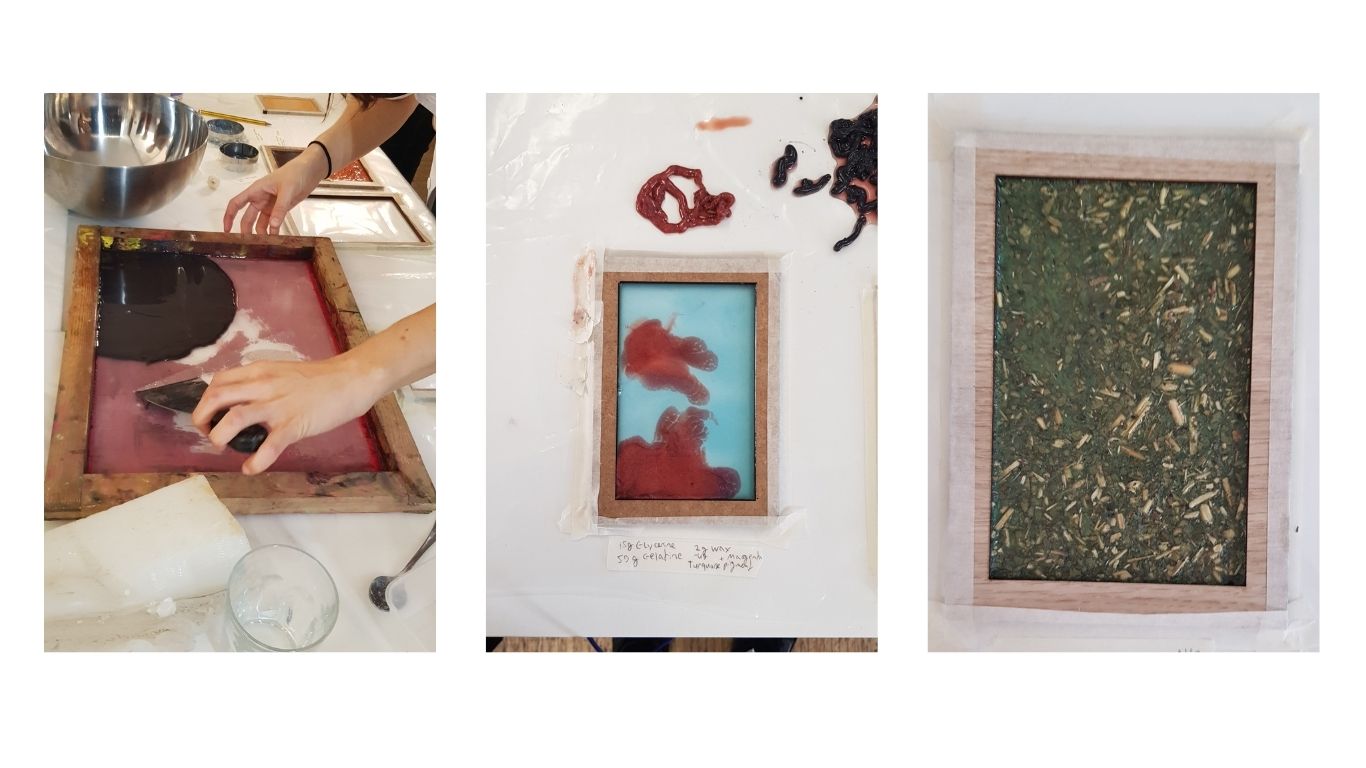

Biofoam¶

Let´s make it fun! After exploring biomaterials in class, I found the biofoam can undoubtedly match with my project of making a collection of sneakers. This material perfectly can be used to make the sole of the final product. That is why immediately I developed a few small samples and after I created two big prototypes to then explore it malleability and hardness.

Let´s make it fun! After exploring biomaterials in class, I found the biofoam can undoubtedly match with my project of making a collection of sneakers. This material perfectly can be used to make the sole of the final product. That is why immediately I developed a few small samples and after I created two big prototypes to then explore it malleability and hardness.

Recipe¶

- 24gr Gelatine

- 1 spoon dish soap

- Water 120ml

- 4gr glycerin

Useful links¶

Mycelium¶

The mycelium, or root system, of fungi, is collected in order to create new materials. The end product is a material that resembles leather and can be used for furniture as well as clothing.

Mycelium is used to manufacture non-toxic, waterproof, fire-resistant, incredibly strong, and flexible fabric. The vegetative portion of a fungus called mycelium usually poses no threat to humans. Even so, certain fungal species might result in allergies or infections, particularly in those with compromised immune systems.

It exist differents strains like Oyster mushroom (Pleurotus Ostreatus), Shiitake and Reishi mushroom (Ganoderma Lucidum). Chosing the best option depends on the material texture final expectations. For example the shiitake mycelium creates a thicker, leather-like skin on the surface comparing to the oyster mushroom where is less dense. For this example we used the Oyster Mushroom (Myco sample from Jessica Dias).

Instructions¶

- First step, you need to gather all the materials that will feed the mushroom into a sterylized container.

- Second step, wet the mixed with distilled water (5 sprays-bottle) for finishing to create the fungi house.

- Third step, sterilyzing the the petri dishes.

- Final step, apply the Myco (Pre-incubated Mycellium) into the petri dish.

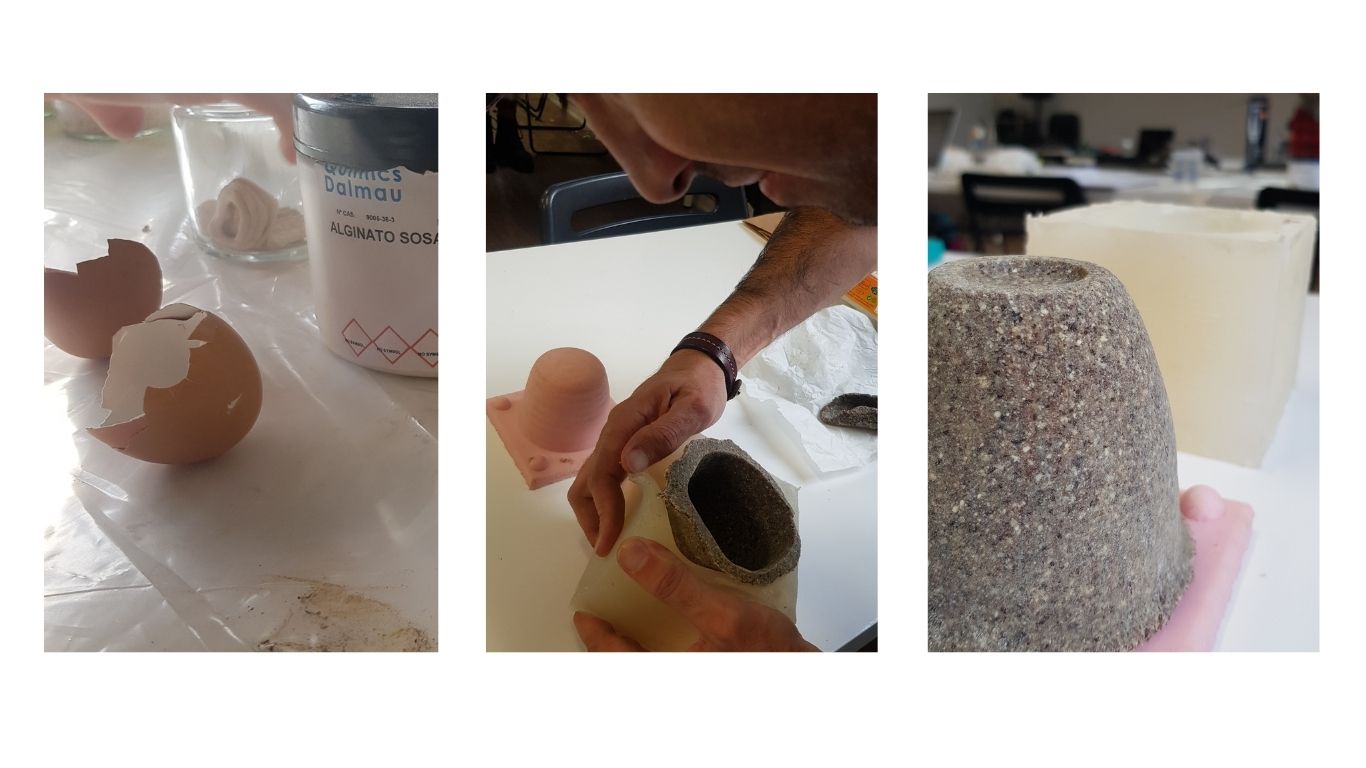

Waste food - Egg shells¶

Source: Potential use of waste eggshells in cement-based materials

Source: Potential use of waste eggshells in cement-based materials

Recipe¶

- 70% eggs powder

- 30% blinder - alginato (2%) + water (98%)