5. Finishes¶

At that point, we already know that we are going to create the bag with the Cellulose leather recipe so this Biomaterial requires some characteristics to be practical for an accessory product:

The most important one is the waterproof resistant to be able to use daily.

So, it's time to start coating to get the characteristics we need for the handbag!

Waterproof¶

Water resistance.💦

In this link, you could read an introduction of various materials to coat with and how: Bio-based materials for barrier coatings on paper packaging.

Carnauba wax and olive oil¶

Mix olive oil and the melted carnauba wax in a pot and then let it cold down, with a fabric coat on the surface of you material.

As a result, the material is still not water resistant, and the oil it's not absorbed.

Tung Oil¶

What's TUNG OIL ?

Is a drying oil that’s extracted from the seed of the tung tree, which is native to China and a few other Asian countries. The oil has been used for centuries as a water-resistant finish for boats and other wooden objects, as well as to finish stone. It's an excellent alternative to other drying oils, such as walnut, linseed, and soy.

This product's most valuable properties are flexible, durable, food-safe, and protective waterproof finish that doesn’t mold, darken or go rancid. Moreover, tung oil dries faster than other oils, making it easier and less time-consuming to apply.

TEST 1:

Coating with the brush on the surface:

- Cellulose leather: It's hard to absorb the oil.

- Paper husks: Have to add more than one layer to get some resistance to water.

- Felt sample: Hard to be waterproof, it has a lot of texture to fill with the Thung Oil.

TEST 2:

Coating with a brush on the surface, pour a thicker layer. Then let the sample dry at over 40ºC to accelerate the process.

After it the sample will get resistance in water, if you let some drops of water on the top.

SHINE FINISH:

Another propriety after coating the Cellulose leather is the shine look.

Tung oil de Emma Picanyol Illa

TEST 3:

To accelerate this process I try to mix the Tung oil in the recipe to dry at one time, so I test 10 and 20% of Tung oil, but it's so hard to completely dry in the 20% sample and all the final tests get an irregular look.

Hemp oil¶

HEMP OIL: Is squeezed from industrial hemp plants with a light nutty aroma. The Hemp Oil wood conditioner provides a non-glossy matte finish and water resistance.

Still need to test it.

Bees wax and olive oil¶

I test in the surface of a Cellulouse leather sample, but the wax doesn't make a uniform surface and you perfectly see where you paint with it or not. Moreover, it's not waterproff.

Furthermore, the paper and felt samples respons much better to the coating, having more resistance in water but not enough for being resistance in a practical way. The drop of water take more time to absorve in the material.

Alginate spray¶

Spray on the top of the Biomaterial to be resistance of water.

Some references:

- Petra Garajová Fabricademy used Keratin and Alginate for textile coating. She used 20g of Alginate mix solved in 150ml of water.

* ALGINATE BASE:

- 100ml Water

- 6g Alginate

- 10ml Glycerin

- SPRAY:

- 150ml Water

- 30g Alginate mix

* Digital scale

* Magnetic stirrer

- Magnet

- Glass jar

- Spray bottle

- Pot

- Spoon

- Blender

* Measure and prepare the Alginate mix.

* Calculate the 20% of Alginate and mix with the blender.

* To get a better dissolution and mixed solution use the magnetic stirrer. 300rpm, 70ºC during 2h.

- The solution is ready to spray on the surface of any fabric, or material to get resistance to water.

In conclusion, if you spray one time on the cellulose leather surface it's not water resistant and if you try to make various layers on the top the layers detach one by one...

Chitosan¶

References:

Beeswax (Apis mellifera) solution was prepared by dissolving beeswax in 2-propanol (Merck, 98% purity). Before use, 2-propanol was preheated for 30 minutes at 75°C. Moreover, chitosan (degree of deacetylation = 79%) solution was prepared to dissolve in 1% (v/v) acetic acid solution (Merck, 98% purity) at room temperature with a stirring speed of 1000 rpm for 1 hour and further heated for 30 minutes at 75°C. Then, beeswax solution and chitosan solution are mixed at 75°C with a stirring speed of 1200 rpm for 2 hours. After that, the whole mixture was homogenized for 30 minutes by Ultrasonic. Last, Carboxymethyl Cellulose (CMC) with high molecular weight (262.19 g mol-1) added in the mixture, and homogenization is continued for 60 min. The mixture was obtained from two experiment models. First, different concentration of beeswax solution (0.25%, 0.5%, 2%, 2,5%) in wt/v were mixed with fixed concentration of chitosan solution (0.5% wt/v). Second, different concentrations of chitosan solution (0.25%, 0.5%, 2%, 2,5%) in wt/v were mixed with a fixed concentration of beeswax solution (0.5% wt/v).

-

Materiom Chitosan 12% - Stiff recipe example to learn how the material reacts and is mixed with.

Still searching for a working recepie...

Shellac¶

In Spanish called "Goma laca".

Still need to test.

Heat¶

Fire resistance.🔥

Test the cellulouse leather samples with the heat gun and let them in the oven 140ºC during 10' and the sample doesn't deform, it make some cook smell and lost a little flexibility and thickness.

On the other hand, I test with a lighter and the sample was turned off by itself the flame.

Dye¶

After working with beige and green colors it's time to get some new colors in the palette!

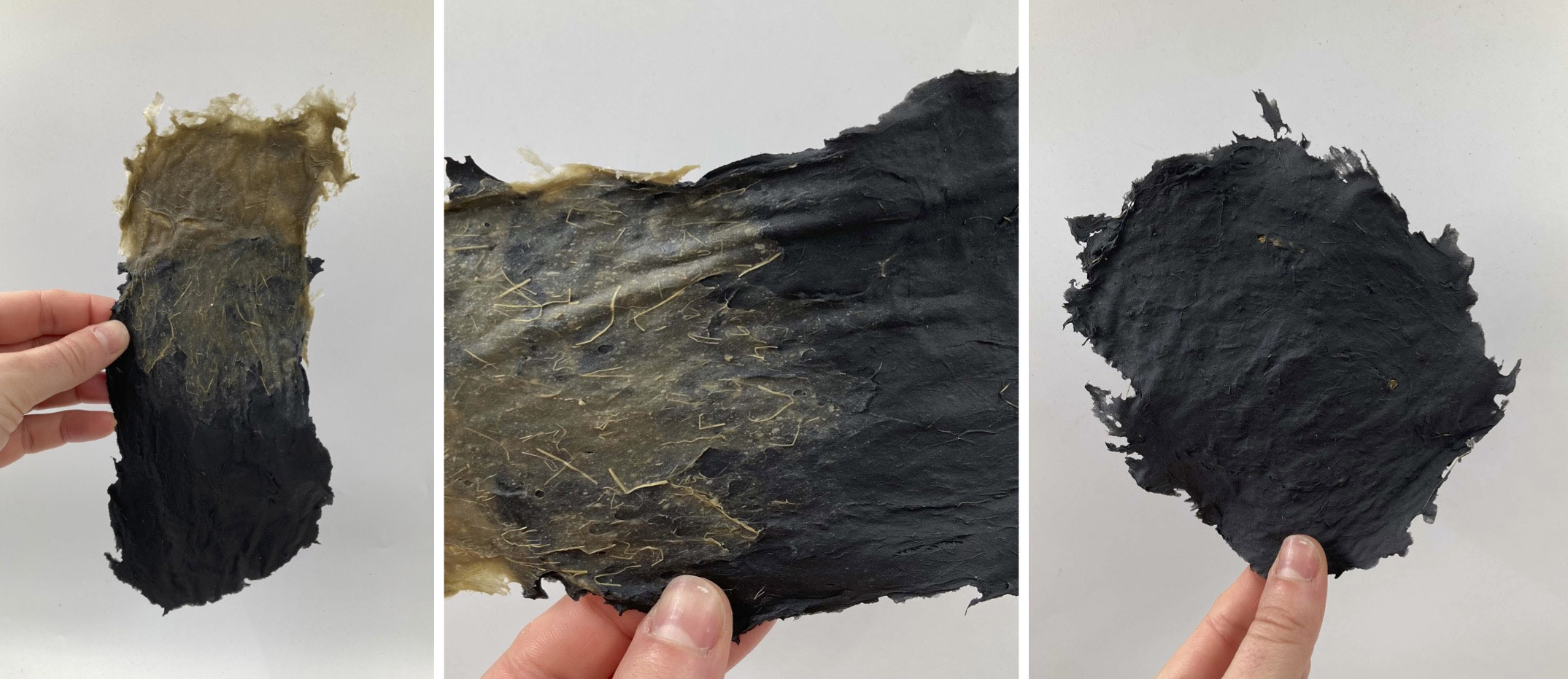

I decided to dye my samples in black because my purpose is to cook a ready-to-wear accessory so one of the most common colors is: BLACK.

It's time to add some Carbon to the mixture of the Cellulouse Leather.

First of all, where to buy Carbon? In Drogueria Dalmau, Barcelona.

Now, let's go to cook! I start testing 2%, 5%, and 8% of Carbon solved in water. The better result was 5% of Carbon (Carbon Activo).

Playing a degradation like painting or get a complete black sample to coat on the last layer of my final shapes to convert and turn it black.

Amazing result in the last minutes before I start molding my final handbags.

Because of the time I couldn't test more pigments but the spirulina, Curcuma, and Índigo could be the following ones!

Could you imagine some handbags in these colors? 😝

So excited!!