2. Digital bodies#

Digital bodies#

The purpose of this week’s assignment is to create a mannequin with using different techniques of digital fabrication. This was very enjoyable assignment for me. I was failed to scan a human body 17 times and every time I was making different mistakes. I tried to scan with different place , different lights, or in different position. Study of human figure is part of design. Human body is studied on the basis of ratio proportion with itself. I saw clara davis work on digital body to understand the process.

What is 3D scanning ?#

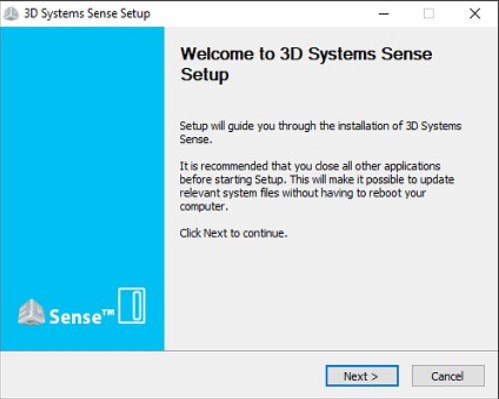

we have “sense 3D scanner” which is very easy to handle. I downloaded and install 3D sense software with one time passcode.

The scanner works only with the sense software provided by 3d system.For scanning connect the scanner USB to your computer machine. In this week we have to scan a human body. And made a mannequin.

Specifications are as follows:

Scan Volume: 0.2m x 0.2m 0.2m (min) (Lower the better) and 2m x 2m x 2m (max) (Higher the better) Depth Resolution at 0.5m: 1mm Spatial X/Y resolution at 0.5m: 0.9mm

I took the following steps;

- Install Software for 3D scanner

- Then connect the scanner to the USB of your machine. If don’t connect then it shows the “device not supported” error. So, connect the scanner and open the software, then follow the instructions.

- In this week have to scan one 3D human body in all direction. This process involves scanning the body with a hand held scanner. The scanner is connected to the PC throughout the process of scanning.

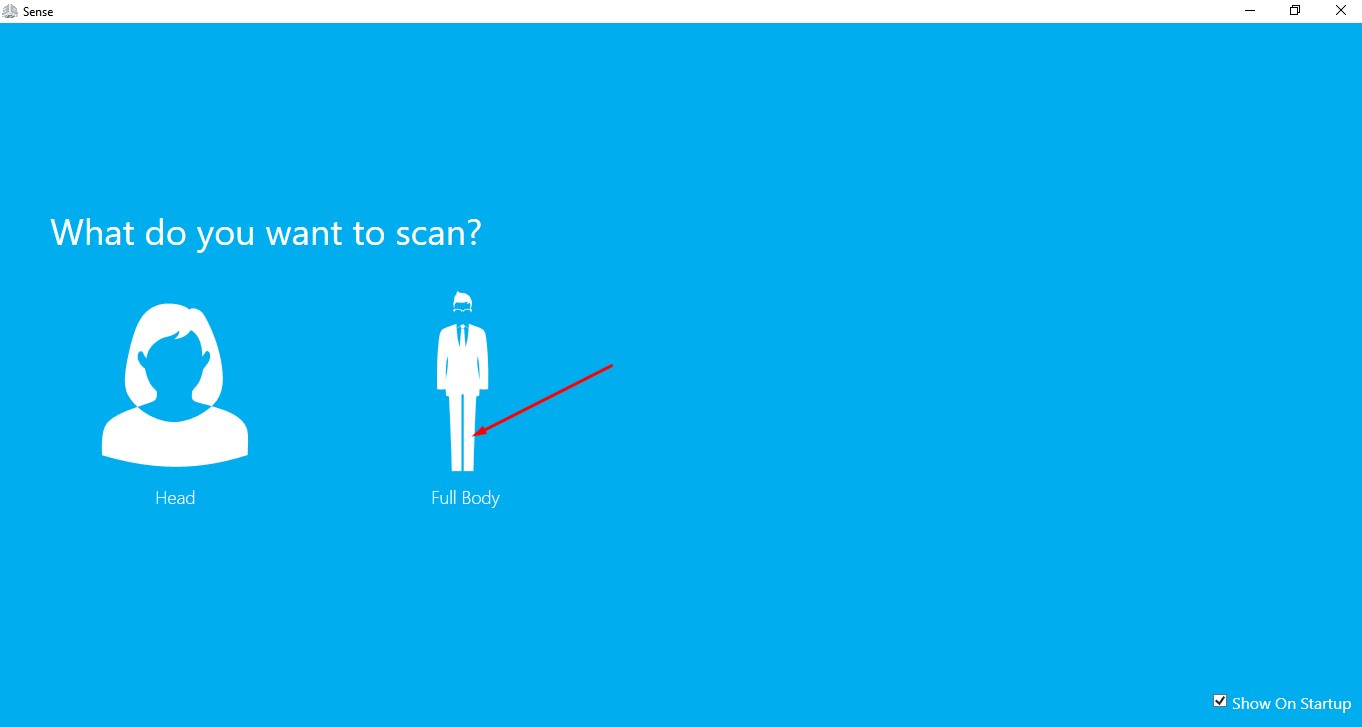

- Select the required option from them i.e if you want to scan human then choose the human and if its any thing then choose the object option.

It is time to scan now, first time I tried with my colleagues and instructor just for understanding the whole scanning process.Select the object and click on the small object. Now adjust (or move) the scanner until a body appears on the object. If you can see your subject properly start scanning. When you done the proper scanning in all directions(X,Y,Z directions) pause the scanning. If you want to erase something there is an option. There is also an option to solidify or keep the object hollow, I choose to solidify the object.I saved the file as .stl file.

Advantages of 3D scanning- Scanner Quickly capture all of the physical measurements of any physical object. It Saves time in design work. We can easily Replace missing or older parts without CAD design.

Limitations of 3D Scanning- For scanning we have take care many things like light, surface of the object, Rotating object or stability of the scanner, etc. Clarity of the image may not be the best.

3D scanning Problems and errors#

Select the option from them i.e if you want to scan human then choose the human and if its any thing then choose the object option. I got two main problems while 3d scanning. The first problem is that a scan of a person contains holes and thousands of unordered points. The second problem is that the shape of human body is changing while 3D scanning as per motions, movement and breathing. I started with describing an approach for finding sparse correspondance between 3D models of human to varing in pose, shape and resolution. Here you will get original file.

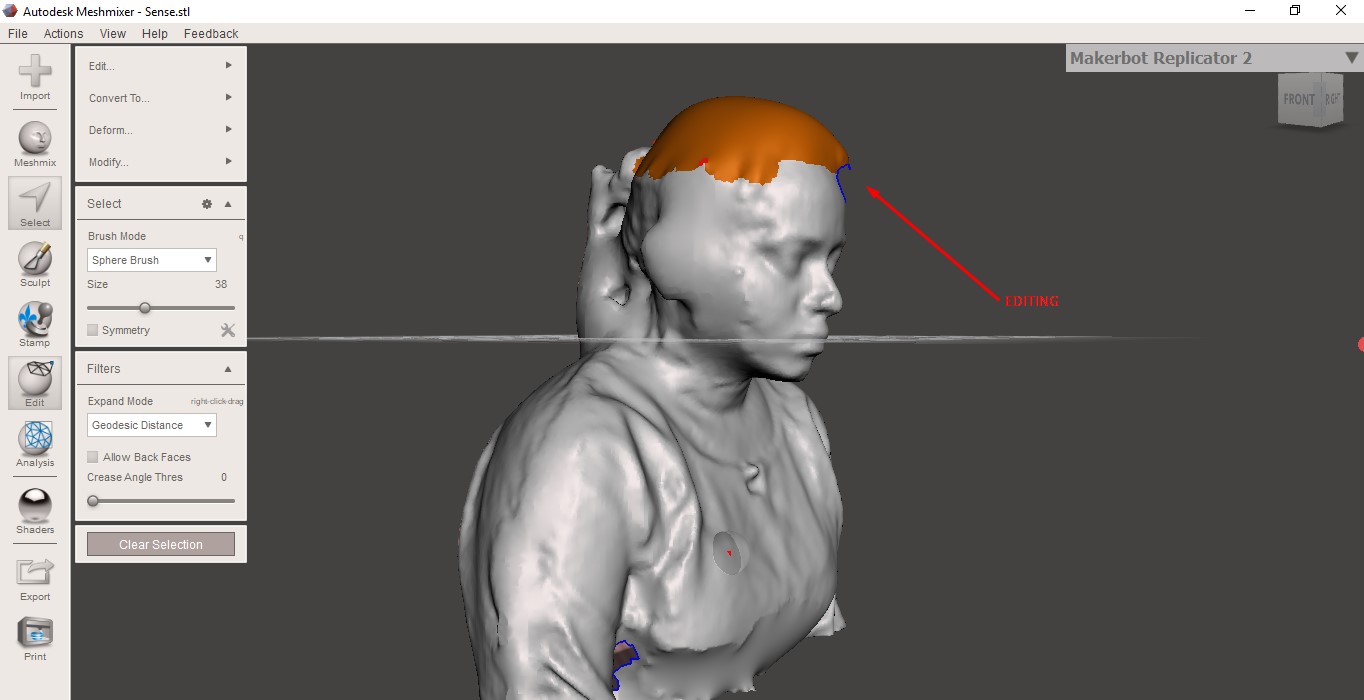

Editing and Repairing in Meshmixer#

I edited my 3D scan model in meshmixer or tried to make it best human body of mine😉 . I imported my 3D model in meshmixer or Mesh there vertices, edges and faces to define a 3D shape. I applied crease, splits and increase level of smothness. Smothness level 0 applies the lowest level of smothning to mesh body object and smothness level 4 applied a high degree of smothness. Mesh resolution refers to the number and distribution of vertices along the surface of an object represented by a mesh.

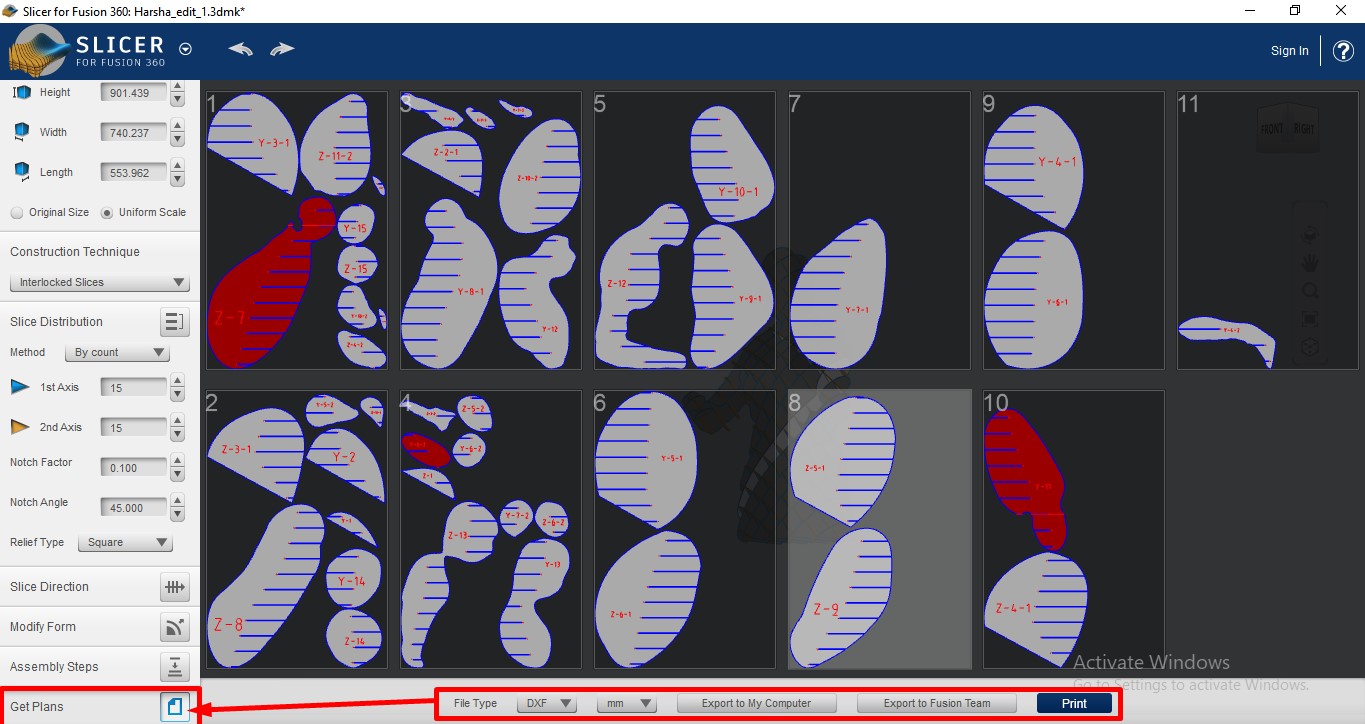

slicer for fusion360#

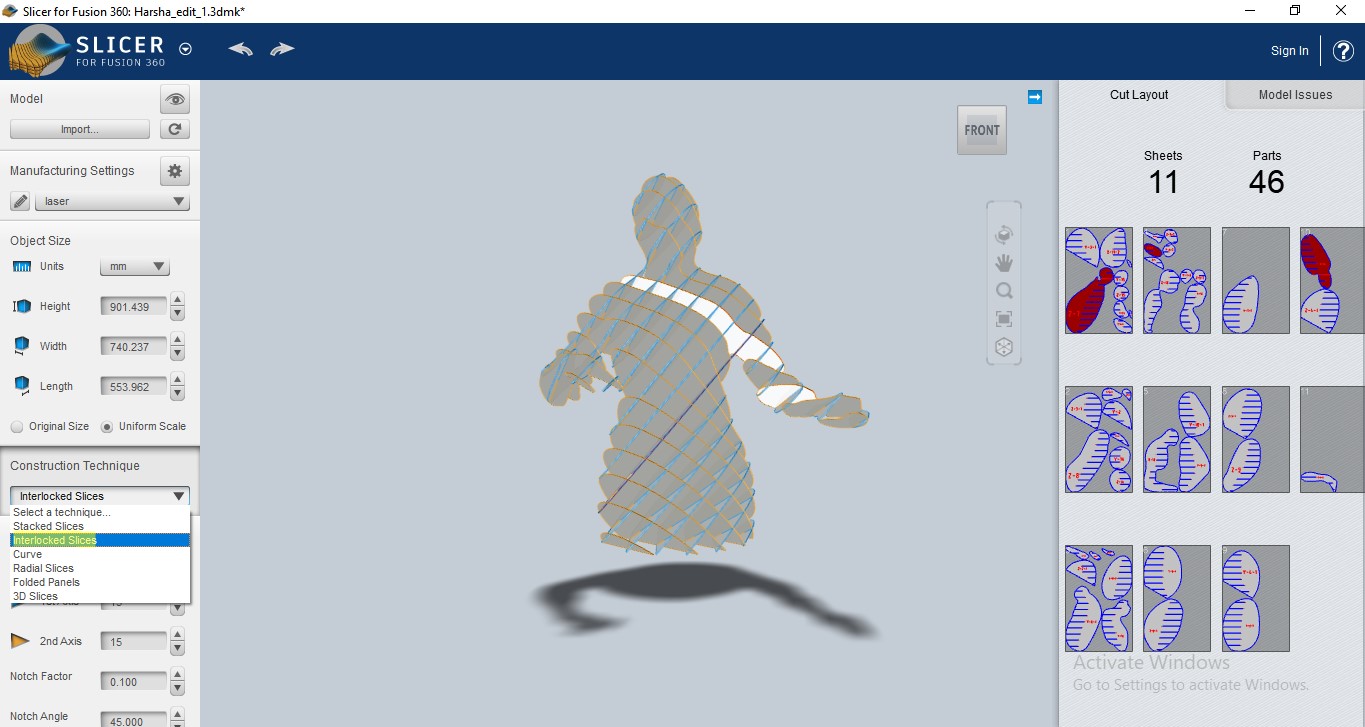

Slicing is the process of turning 3d model into a file in which Machines like laser cutter , 3d printer etc can understand. First, I dowunloaded the Autodesk software Slicer for fushion 360 from Fushion 360. Once install slicer restart Fushion 360. With this software , we can explore different construction techniques to capture design intent, limit material use or explore stock selection and finish. This link help me to learn fushion 360.

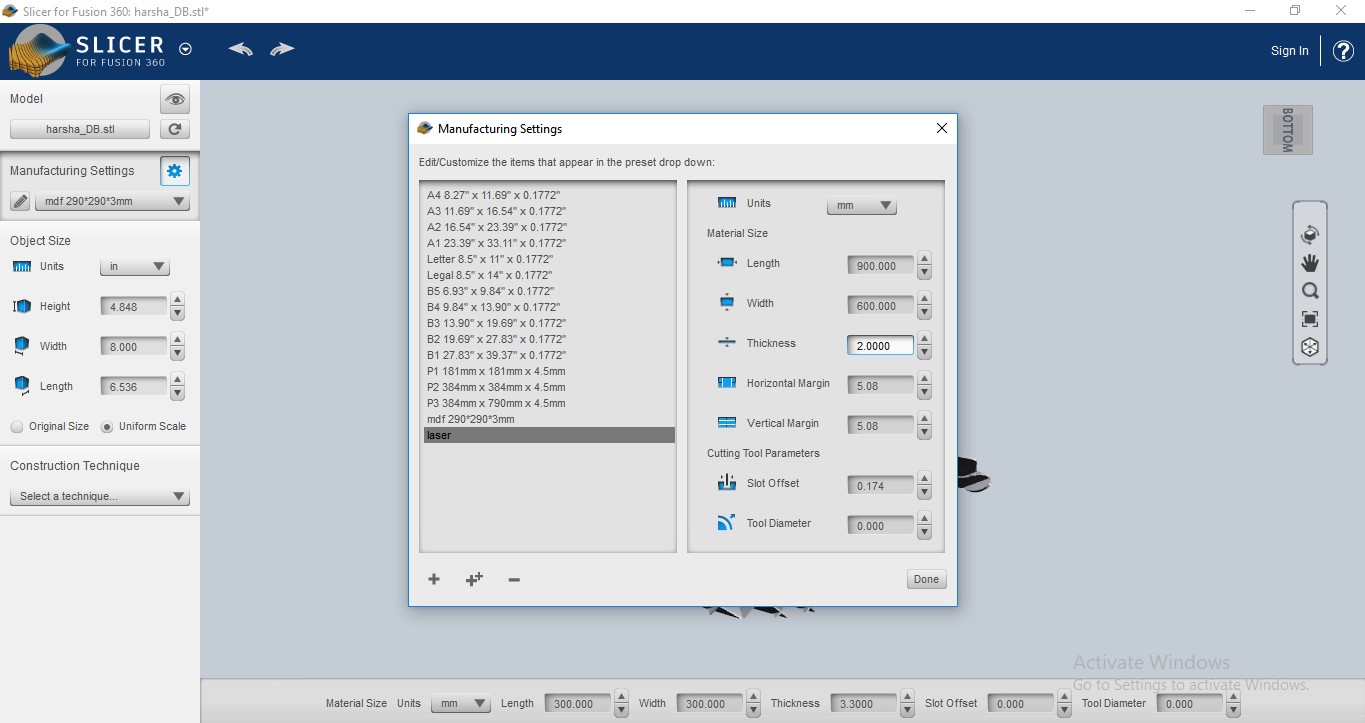

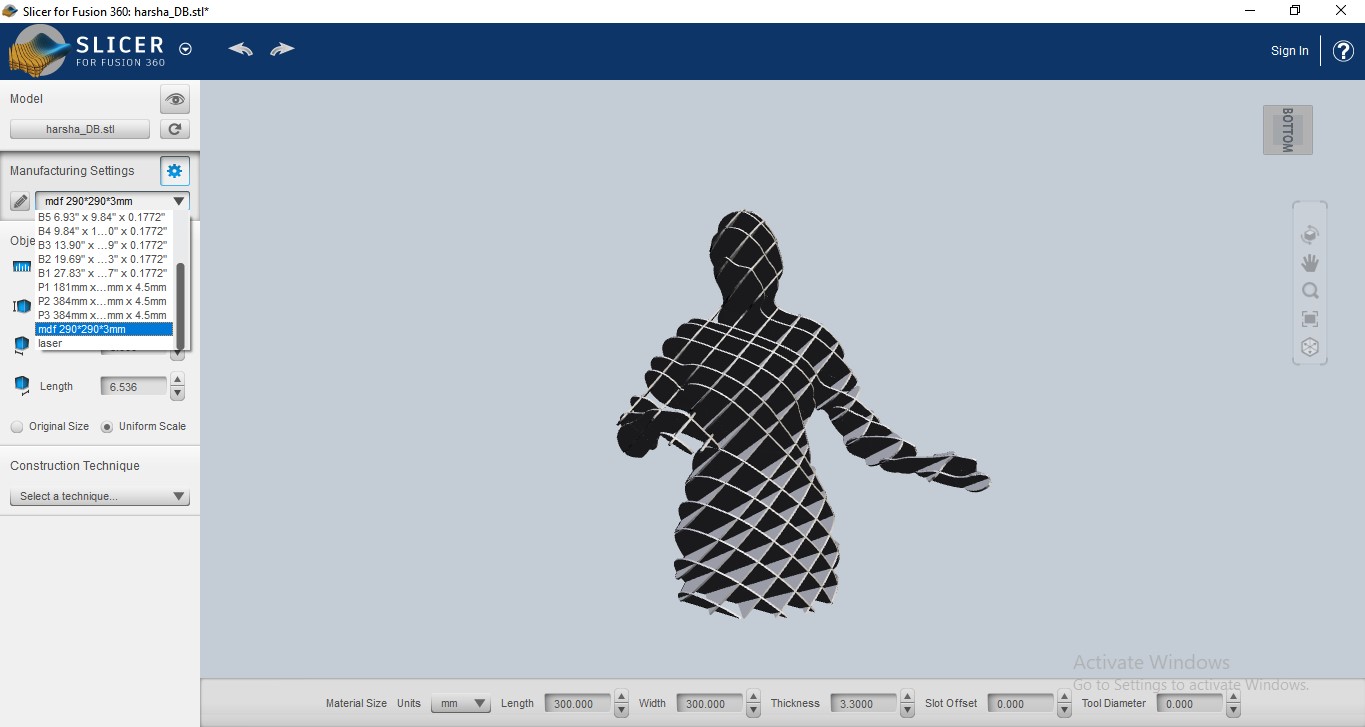

I exported .stl and open in Slicer, the first step is to set up the Manufactures settings. First I saved my open file.The average laser cut width is about .012mm.

- Download software and sign in

- Import stl file

- Click on manufacturing setting and change all the settings.

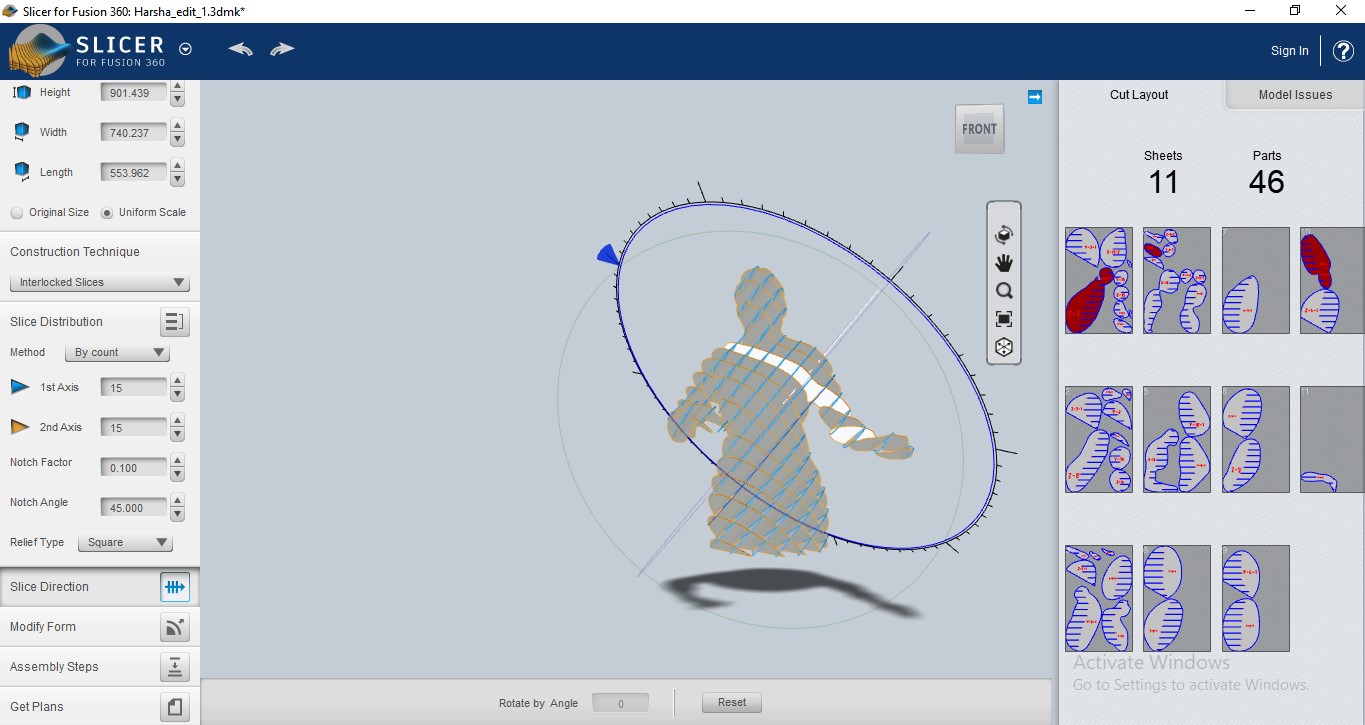

- I select interlock settings and set it’s angles.

- Export file as DXf.

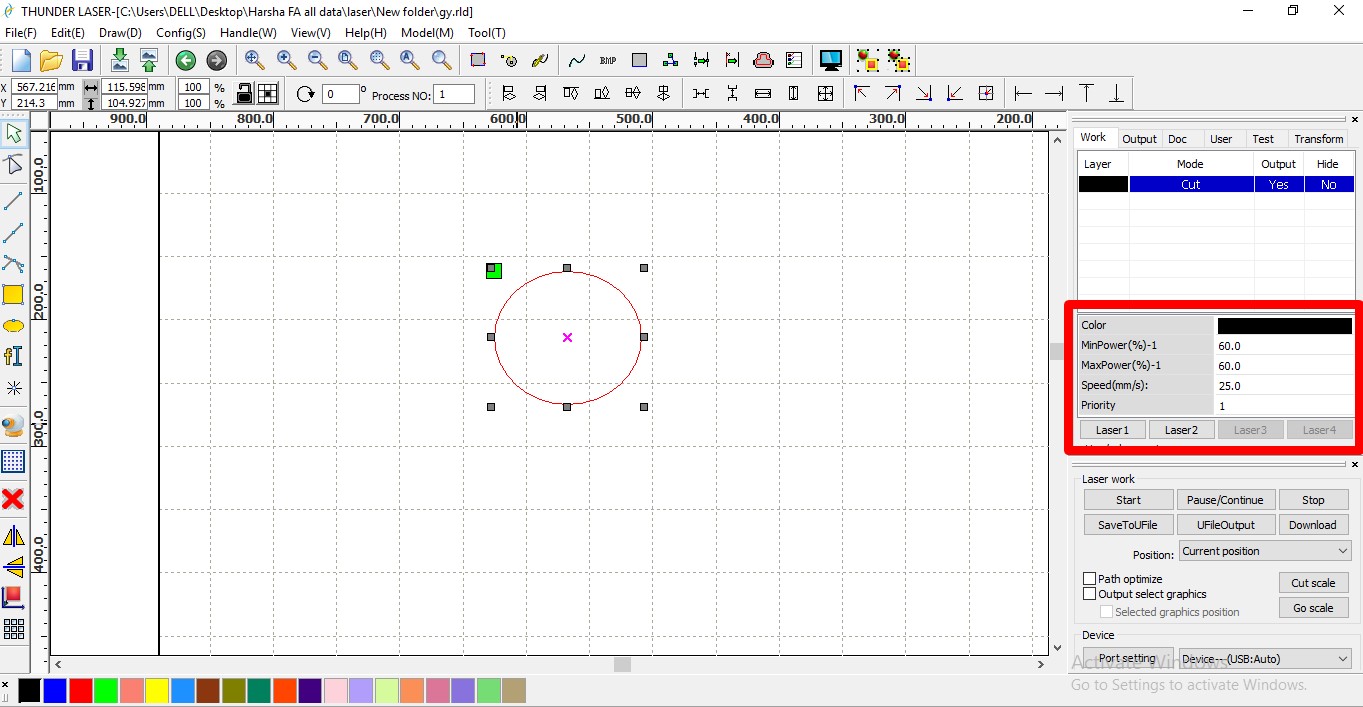

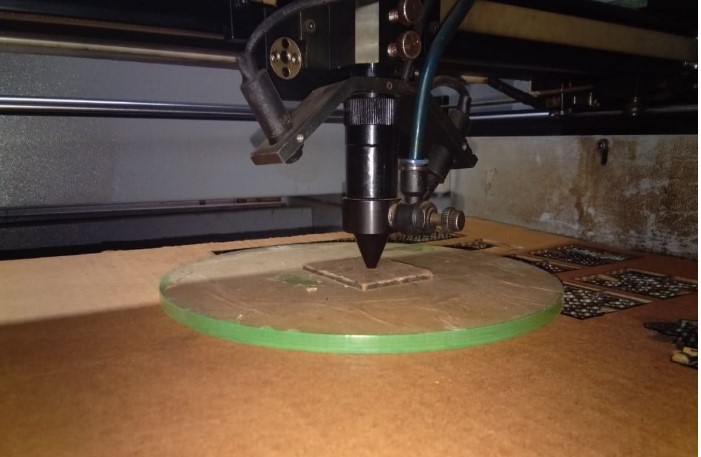

Laser Cutting#

In Vigyan ashram we have two types of laser cutter i.e SIL laser cutter and epilog laser cutter. Generally, we are using SIL laser or CO2 laser cutter which having 600*900mm bed area and can cut material upto 6mm. After slicing the 3d model, I cut them with Laser cutter. For laser cutting I use Cardboards of 3mm. Shubham help me and show me how to do KERF calculation.Here you will get laser cut file.

Settings and kerf calculation

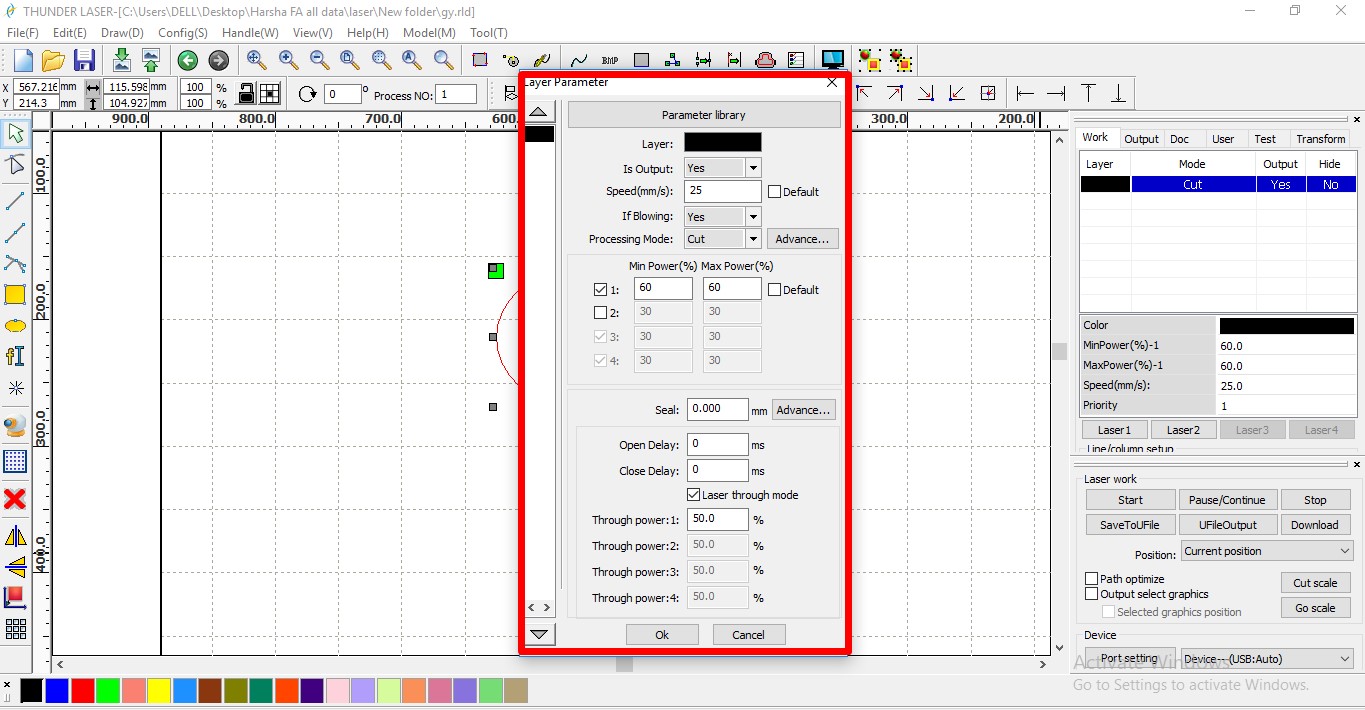

We are using RDworks as a machine software. In this software we can adjust the spacing between the cutting object for minimum wastage of the material.

KERF- Laser burns away the portion of the material when it cuts through is known as Laser kerf. We have to consider kerf everytime if we want perfect dimension or press fit object.

Steps for cutting the object:

- Make object in any software and save as “.dxf” file.

- Import design file i.e. “.dxf” file in RDworks software and adjust the object for minimum wastage of material. We can set different power and speed for different object by using different color.

- Specify the Power and speed according to material.

-

Connect the laptop to laser cutter and download the file.

-

Adjust the focus for minimize the kerf and good cutting. This laser has manual focus adjustment. We want 8.5mm focus so we pasted 2.5mm MDF square shape on 6mm acrylic sheet.

- Downloaded file or recent file is on the top. Select your file press the file and then enter.

- Set the origin, check the frame(Total area of your object) and give “START” command for cutting.

Precaution#

-

Laser cutter is the dangerous machine in Fablab and we have to take care of machine as well as ourself as a operator.

-

In vigyan Ashram, Laser cutter runs on three phase supply and it also has power backup because here frequent power cuts.

-

Our laser cutter has Stabilizer, Isolated Transformer and air Compressor. The machine has Exhaust(duct) to remove the dangerous gases.

-

Machine has Chiller to maintain the temperature of the tube.

Assembled mannequin#

Digital_body_assembly from HARSHADA RAUT on Vimeo.

My experience in this week..!!#

I enjoyed this week’s assignment .It was difficult to obtain a good 360 degree scan of full body parts, due to obstacles in the environment while scanning. To overcome this, the part needs a lot of repairing and smoothing in Meshmixer. I also tried to use differnt softwares for scanning. But it doesn’t work like sense scan so i decided to scan on sense.

3D Models#

Original Files#

Fabricademy by Harshada raut is licensed under a Creative Commons Attribution 4.0 International License.

Based on a work at https://class.textile-academy.org/.

Permissions beyond the scope of this license may be available at http://vigyanashram.com/.