8. Open source hardware: from fibers to fabric#

Weekly task#

In this week we have group assignment of open source hardware. we have to select anyone from the following;

-

Hack or modify an existing machine

-

Build a toolhead for an existing machine

-

Build a new machine

-

Restore an old machine

What I have done?#

We have decided to modify our old brother knitting machine. Nishtha and mahavir have same knitting machine with same model BROTHER KH840.

-

Repair machine

-

Assemble and Restore machine

Amazing knitting machines#

About Knitting machine#

Knitting is the process where we can create fabric from fiber like yarn or tread. It can be made from needles or knitting machines. There are many types of knitting machine with different mechanism which controlled by electronics. In this machine we can also create pattern stitching. knitting machine allow producing clothing much faster than you’d do knitting in traditional formal way of knitting.

Workflow#

As a group

-

We have old brother knitting machine

-

So, we discuss and note down all the problem or difficulties in knitting process.

Individual work#

Restore knitting machine

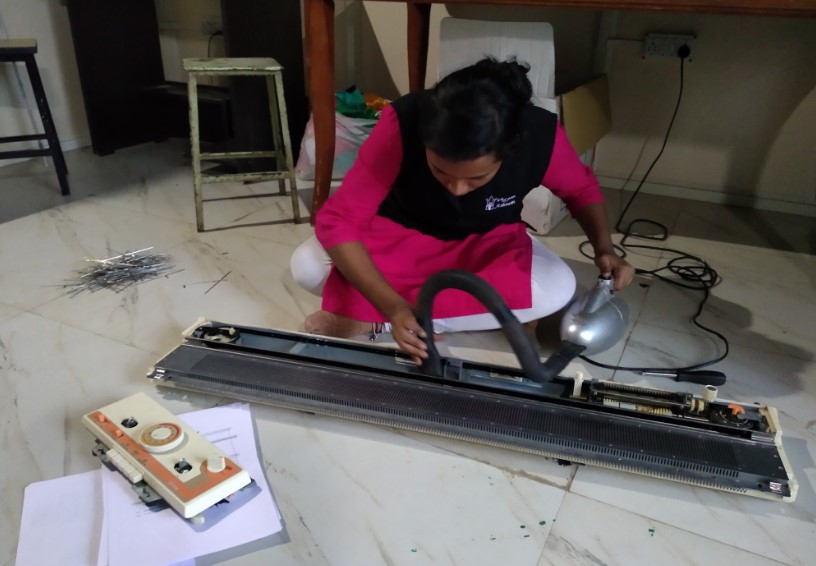

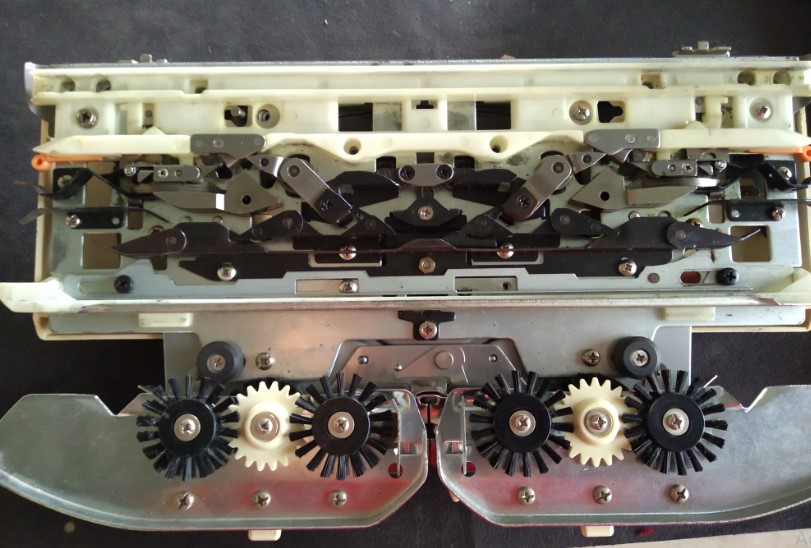

In vigyan Ashram, we have old knitting machine in scrap which is not in working process. So, I decided to repair or restore it. I saw there is so many dust in the internal part of knitting machine. So, firstly I opened all machine and cleaned. There was many corrosion in needles . I removed all the needles and cleaned them. I clean mahine with vaccum cleaner and set all parts with the help of manual.

Problem or difficulties🤔#

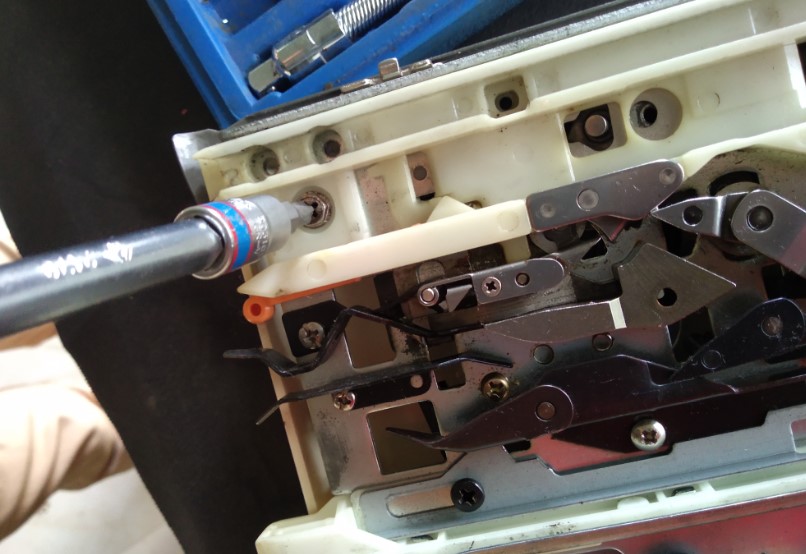

Firstly, I cleaned all parts of machine and oil them and then assemble with the help of this manual. After assembeling machine I observed all Parts were working but some parts got hard to move or some part were not in working process. This srewdriver hand toolkit help me to repair parts.

Cleaning#

I found this machine in the scrap of vigyan sharm. I decided to repair and restore this machine. Zio’s also have same machine then we discuss and distribute some work. So, I start to clean all parts machine and oil them.

Repairing parts#

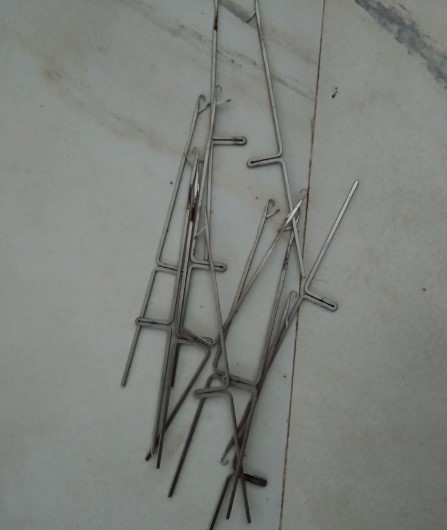

Needles

I saw some needles were not work I changed it. I saw many corrossion in needles. Also i got problem with there positioning when i turned carriage left to right. I observed some needles came to the D or E position From B when i was moving carriage. From this i saw there is problem in the carriage.

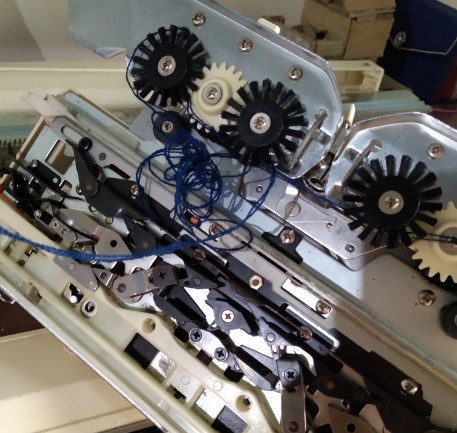

Carriage

I observed machine carriage part was not working beacouse some screw or some part was jam. So, I repair all parts. Now, carriage is good in process. It’s create problem while running on left to right.

- Problem with carriage

- Open carriage with screwdriver tool

I saw some screw’s are missing. So, I find out screw’s which can be fit to there.

- Now, set carriage to machine

Trials#

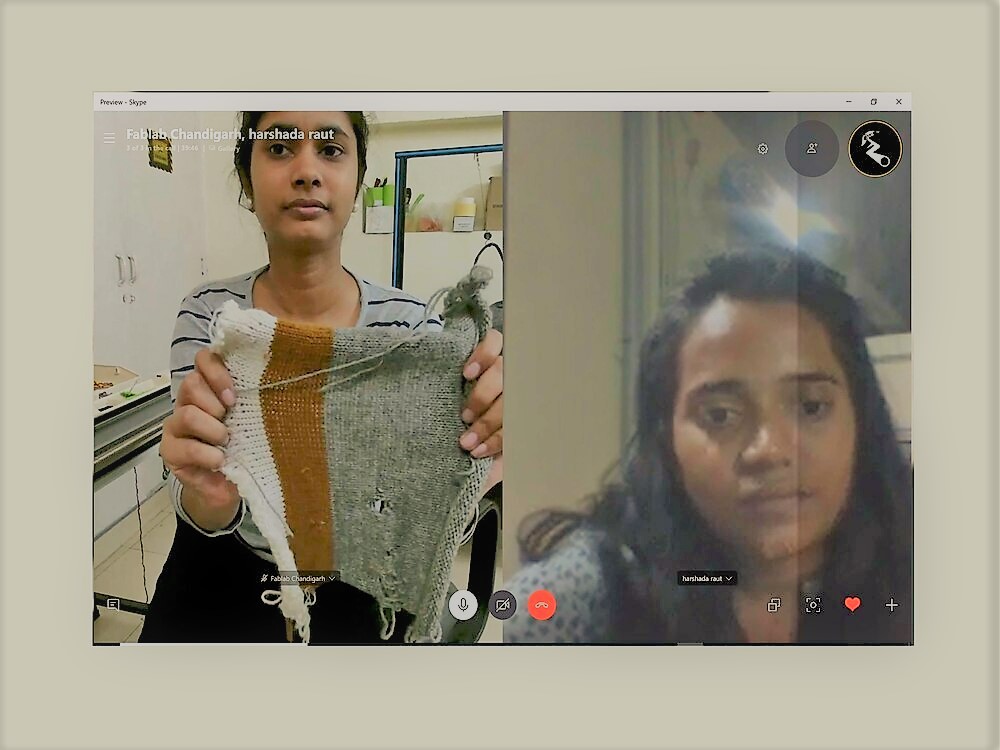

Finally it’s started with help of nishtha and mahavir. We had skype call to start and assemble machine. Nishtha send me manual of machine which was helpful to me.

#knitting #fabricademy from HARSHADA RAUT on Vimeo.

Problem in Knitting Machine#

Because of some parts are missing it didn’t work good😞. But, Nishtha did it sucessfully in our zios makerspace lab in chandigarh. She integrated Handle for easy usage and mahavir designed on the Knitting machine frame integrated the yearn tension unit in the controller.And putting servo motor MG 996R on the guide rail and did basic coding to check if it works. Here is more electronic control or hacked machine example and documentation.

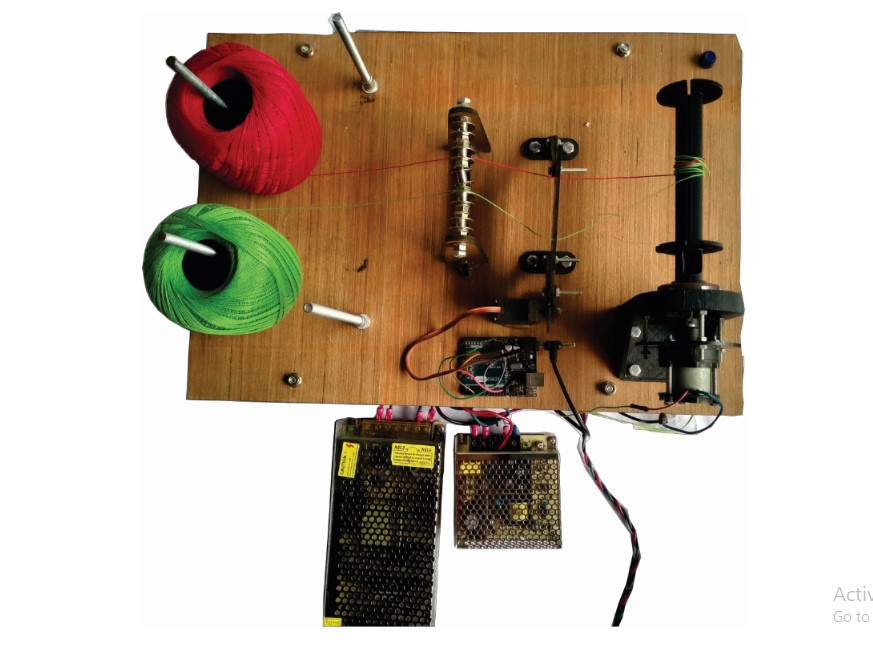

Project no.2 - POM POM Making Machine#

In this assigment, I have started to thinking about my future project on machine design. I wanted to make a machine and wanted to learn machine design. So, after complting my group assignment I have started to thinking on what kind of machine to make..what need..? And many things.. I saw small handloom machine from this but, I wanted to make somethink differnt. One day my student was doing pom pom for her dress designing and she told me I don’t like this work of making pompom by hand. So, I was thinking to make small tool for this. But, Shubham show me some big machines for pom pom on you tube. I decided to make a small version of pom pom.

Inspiration#

Process and workflow to make Pom Pom Making machine.#

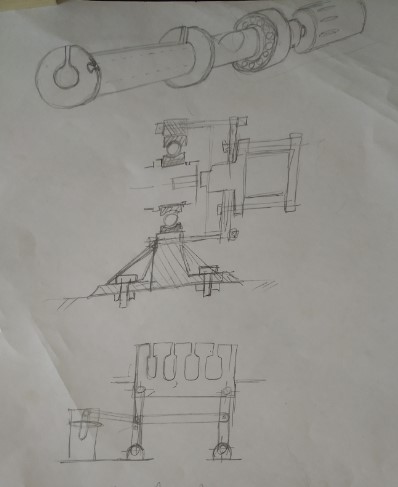

Sketches#

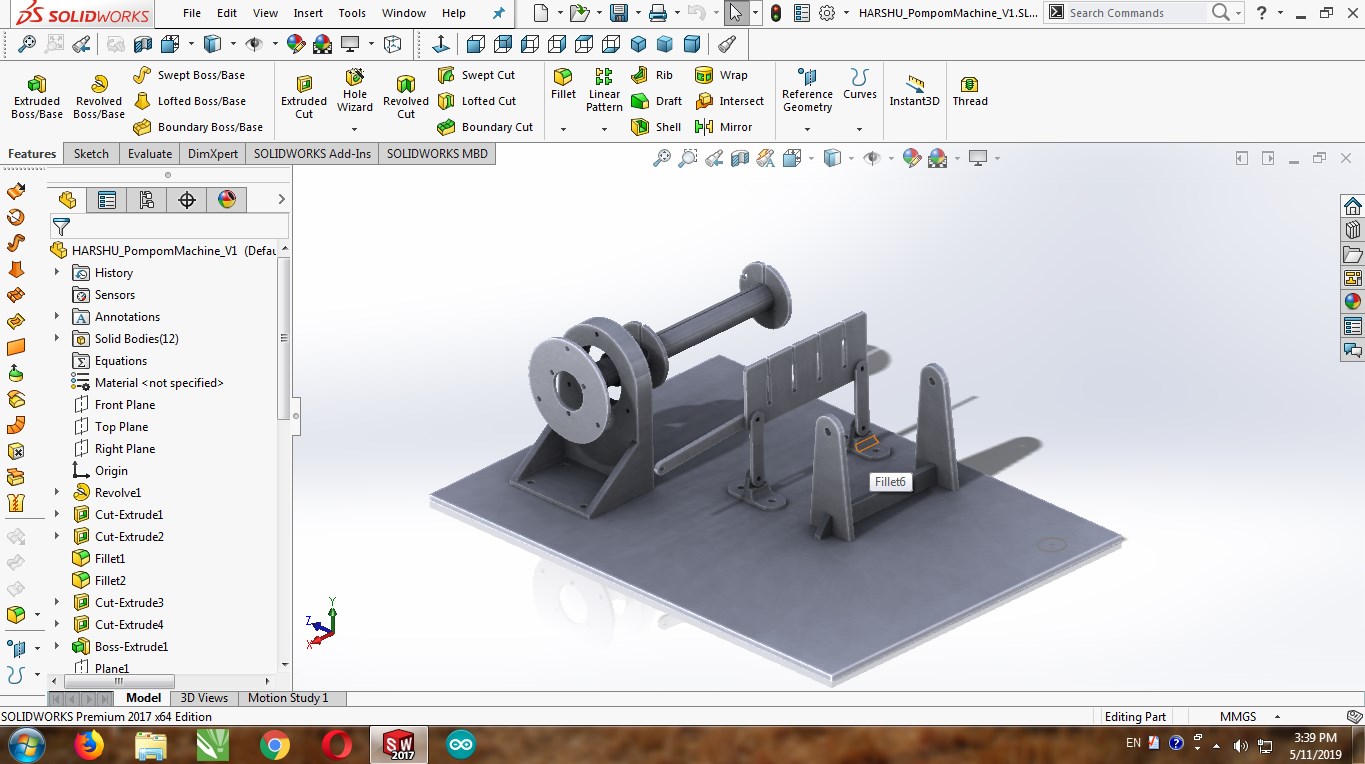

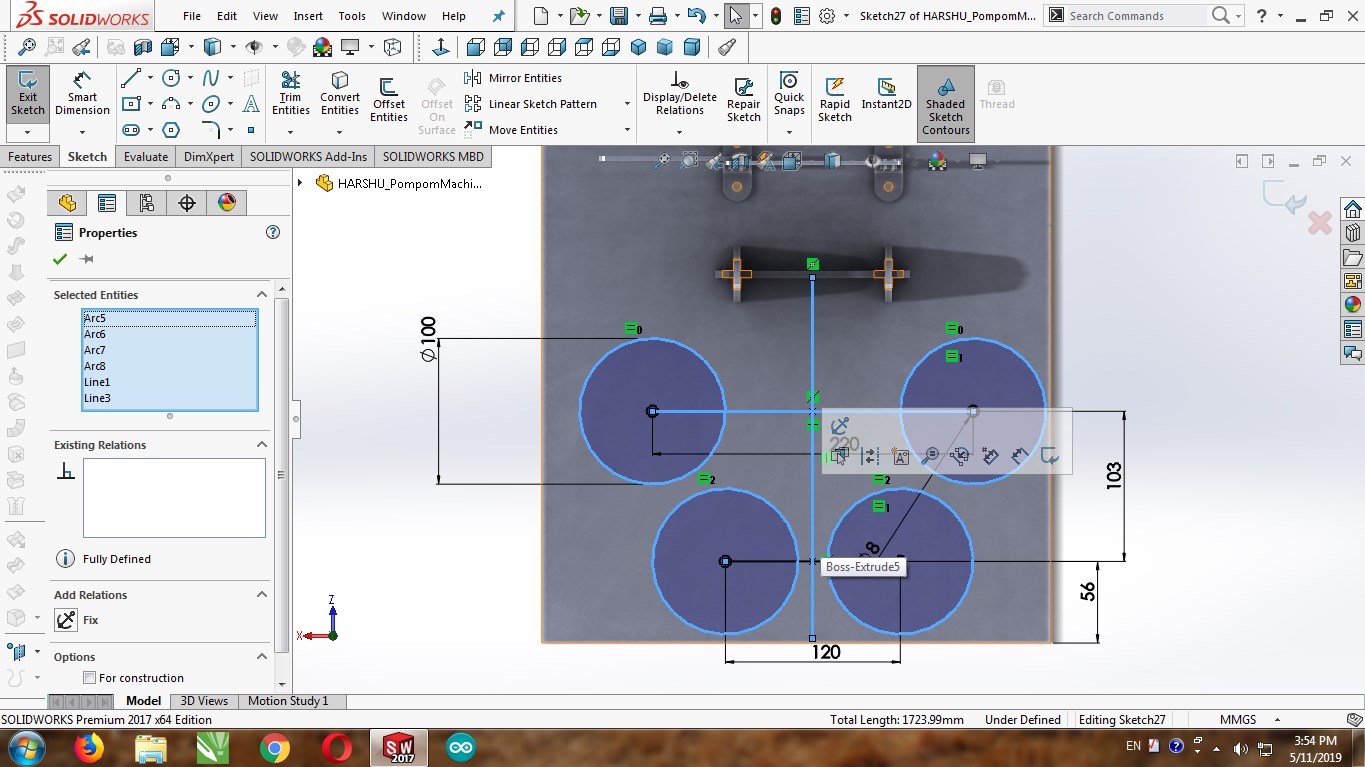

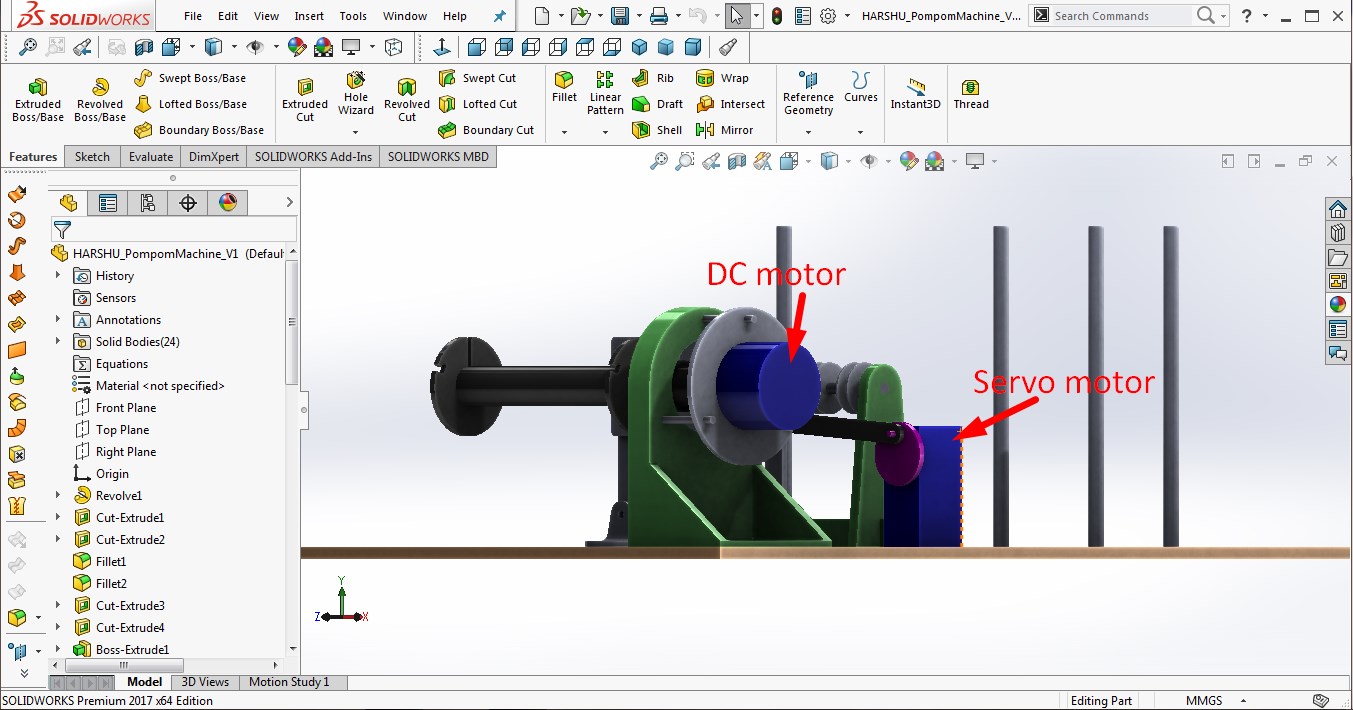

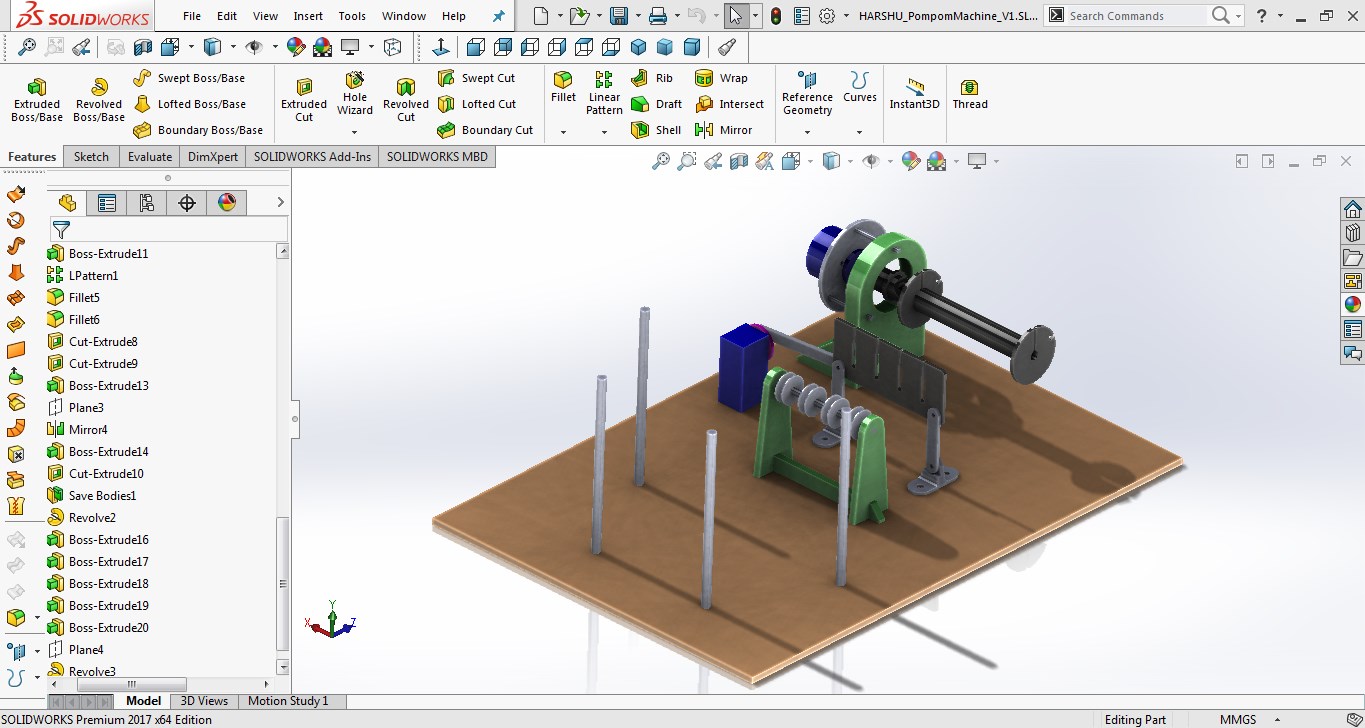

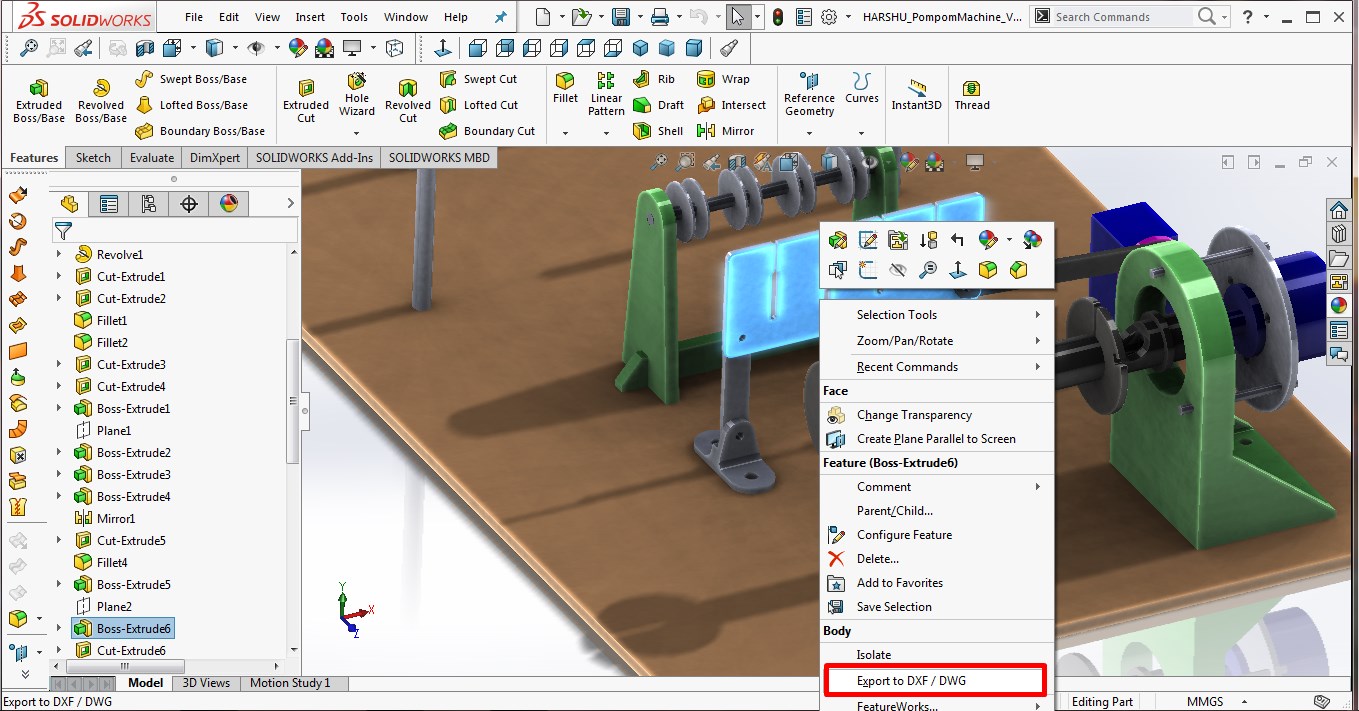

Create model and parts in solid works#

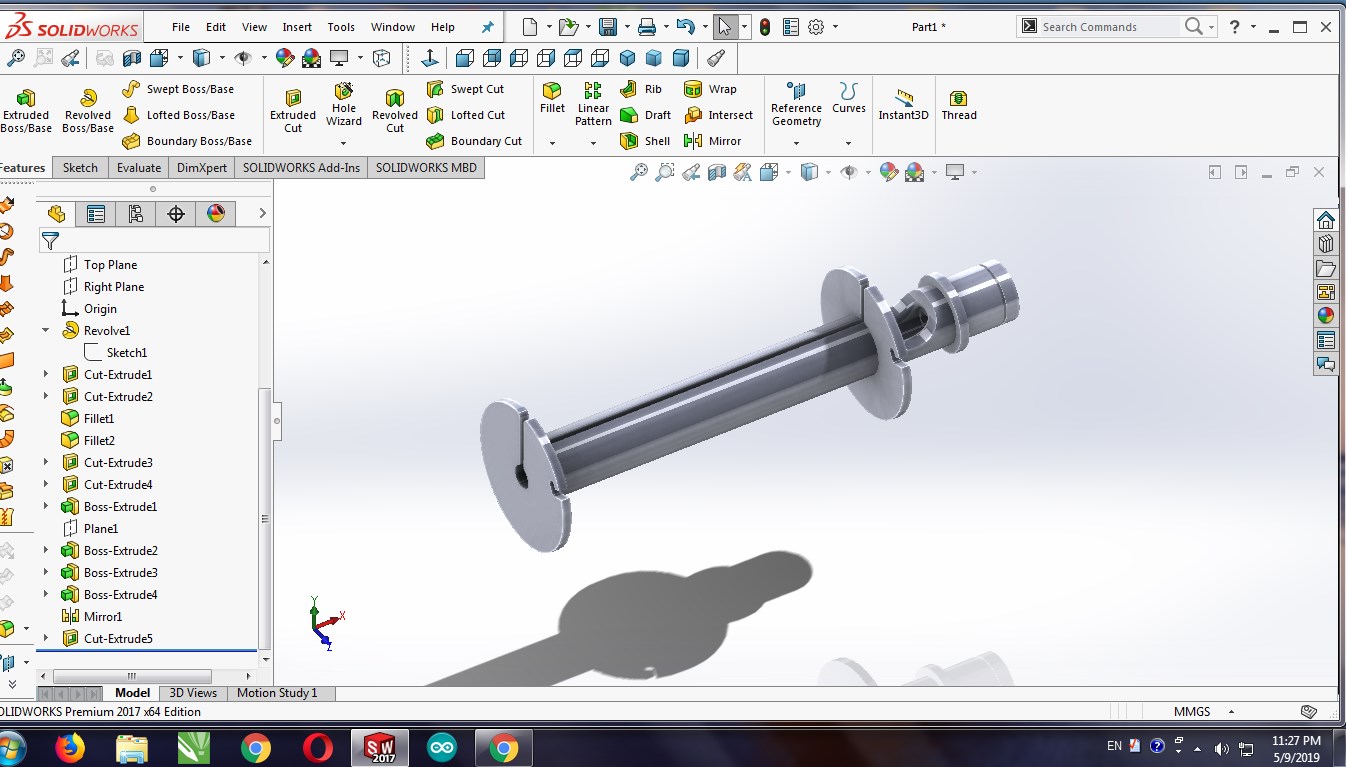

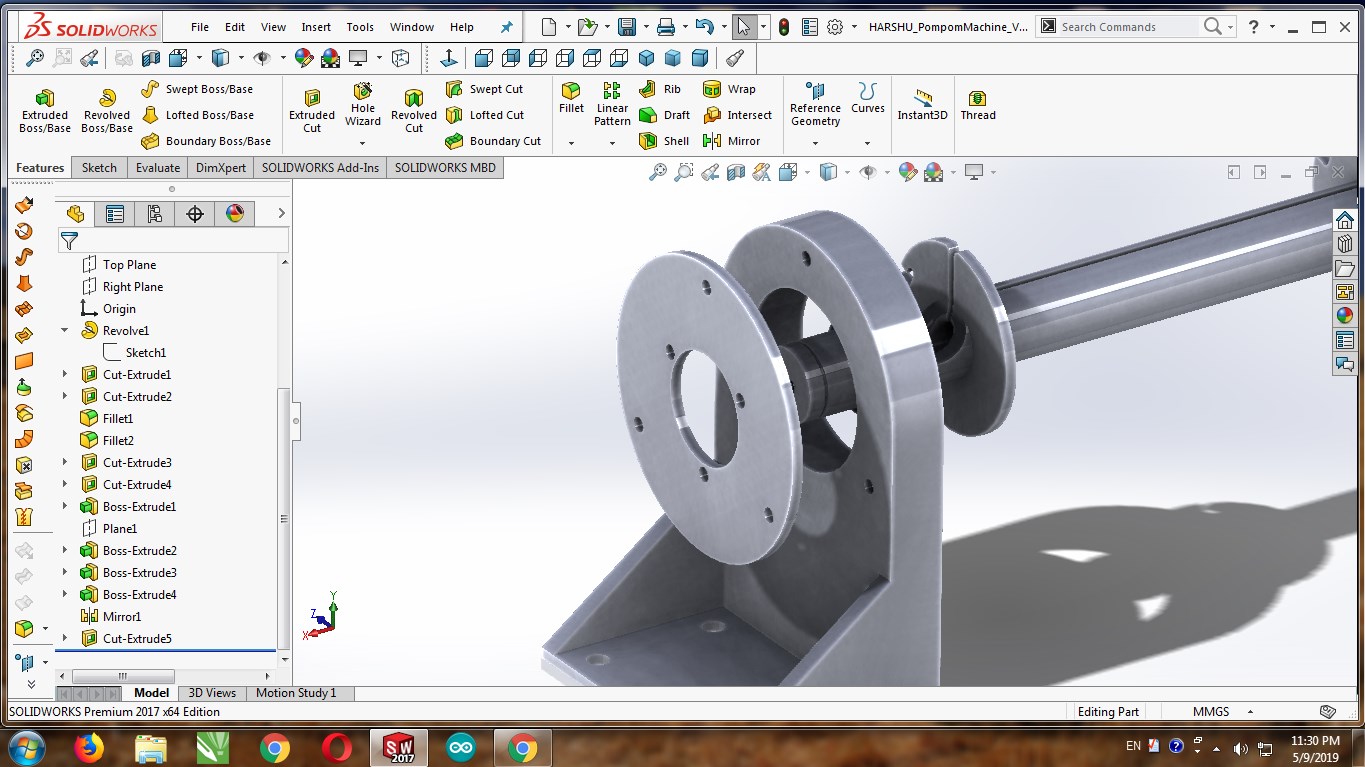

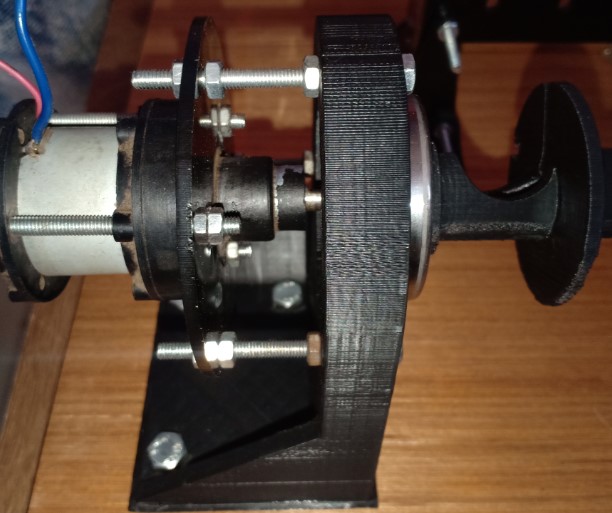

I design machine in solid works. I design whole machine model. And make 3d model in sketch fab. In this machine design , I design two main parts spool and bearing holder part. Which was very hard to design . So, Shubham help me and teach me machine designing.

- Spool part design

- Bearing join design

- Comb and stand for Multicolor pom pom

- Make a stand to hold woolen yarn

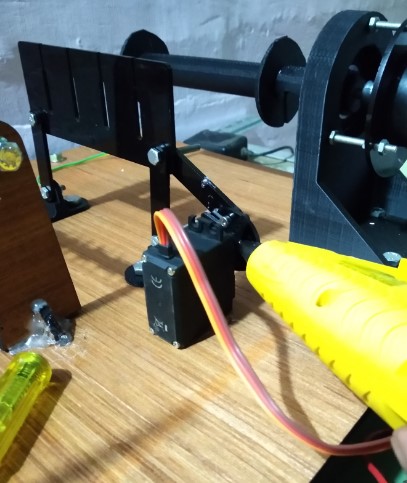

- DC motor to spool and servo motor for moving comb

- Whole Machine design

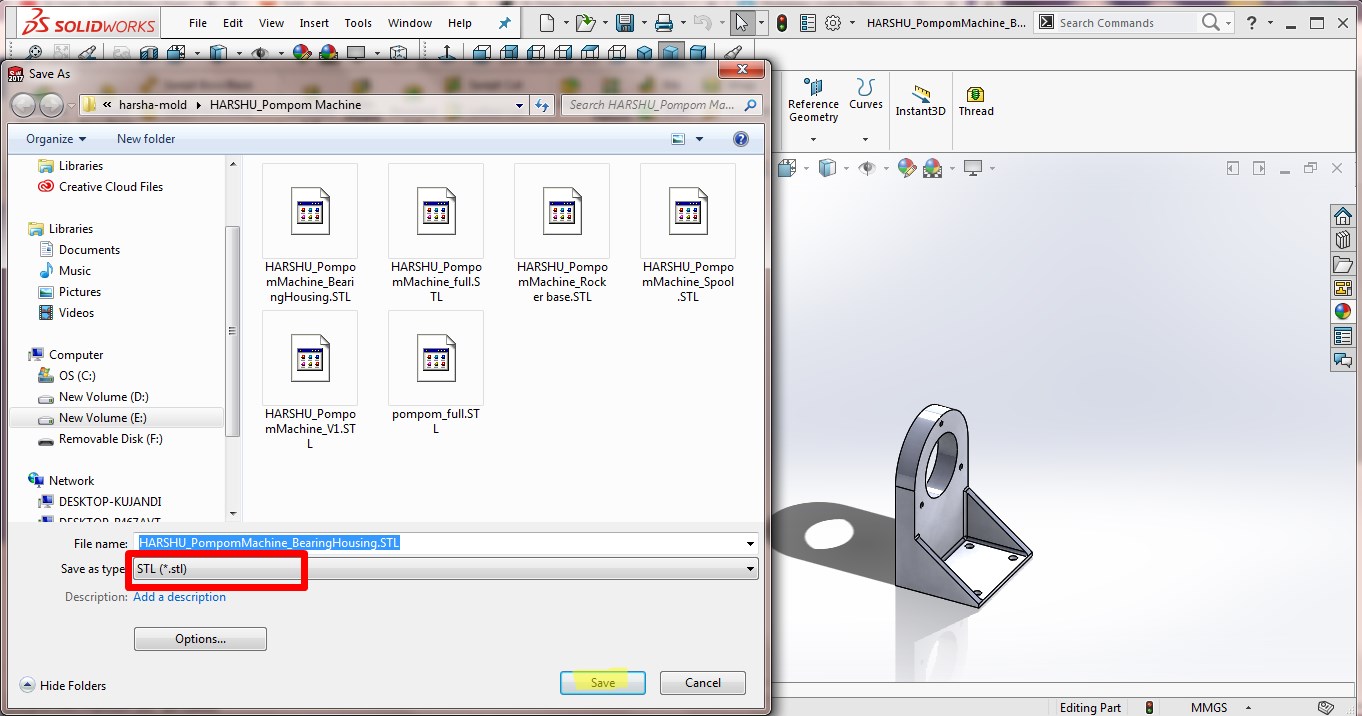

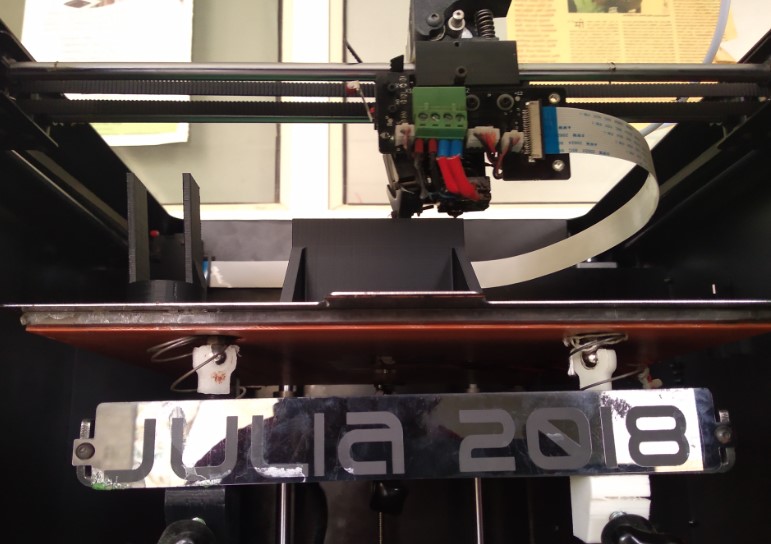

3d printing parts#

- Save file as Stl

- Import in fractory of making gcode

- Start 3d printing

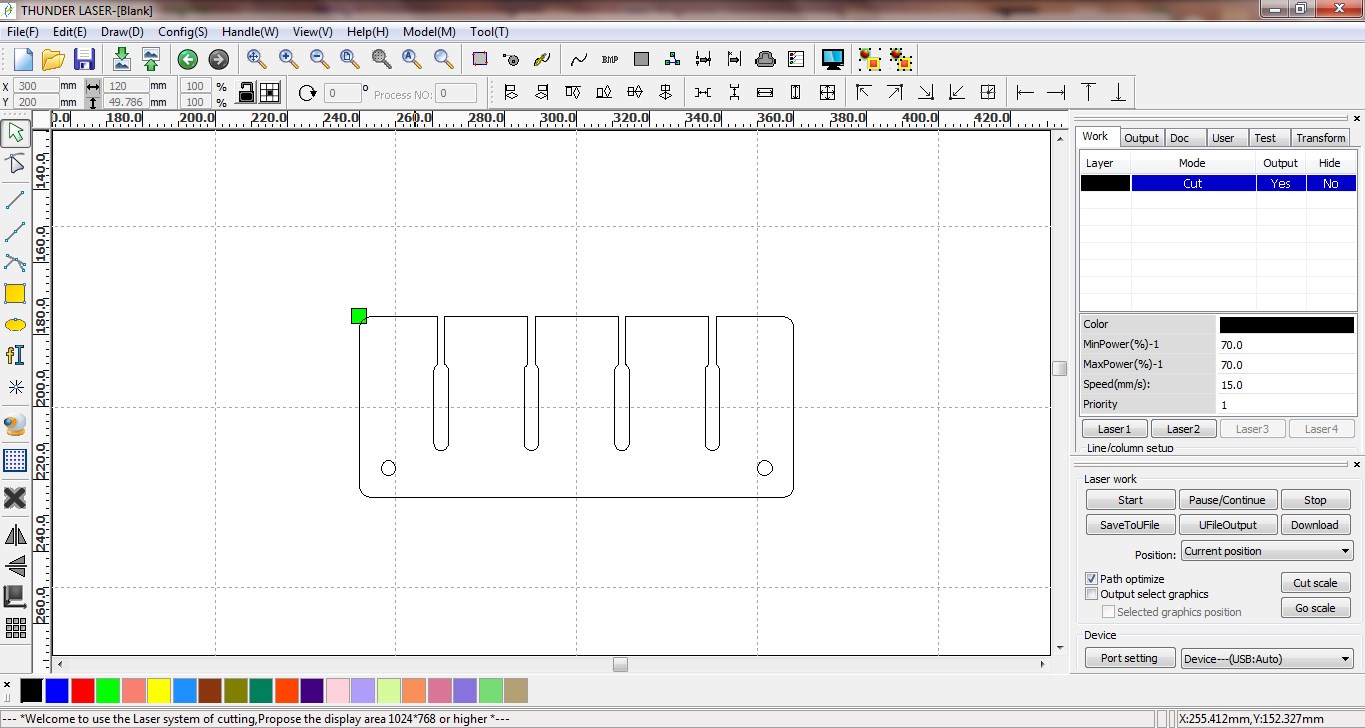

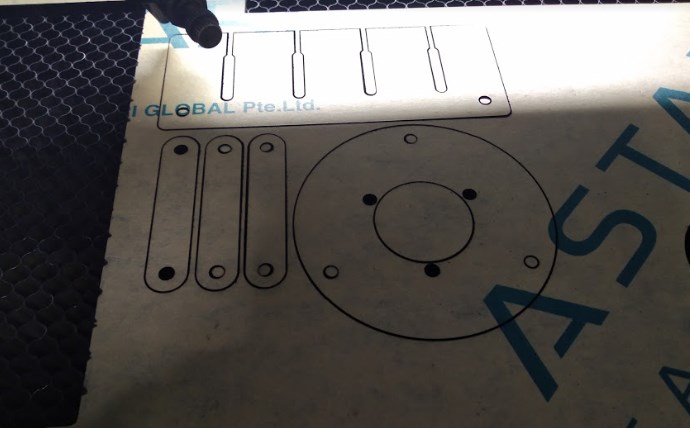

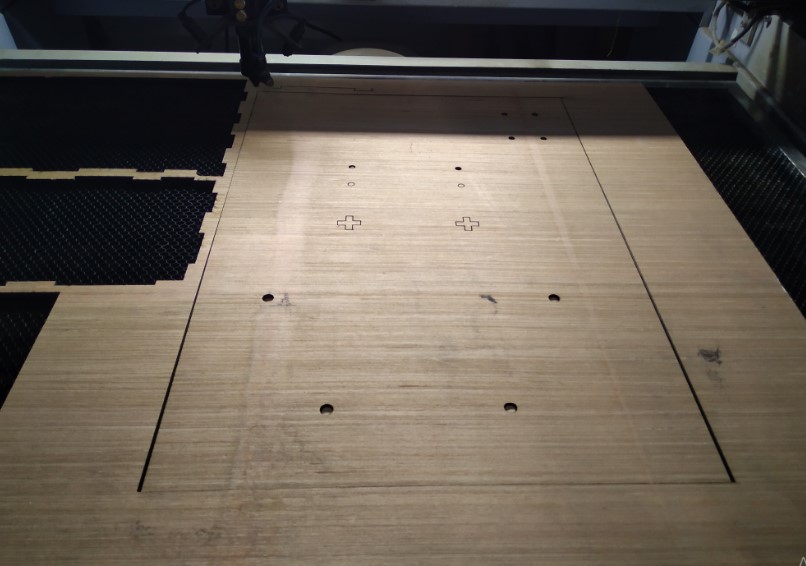

Laser cutting parts#

- Save file as Dxf

- Import in Rd works

- Laser cutting parts ready.

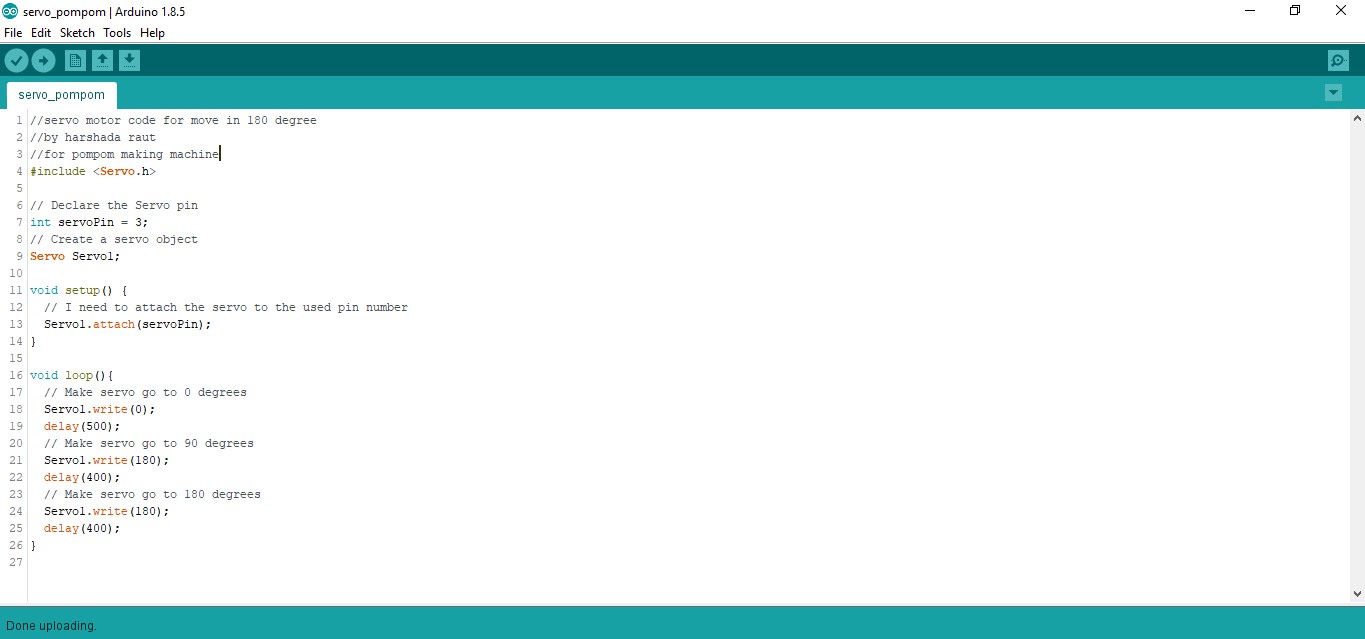

Programming servo motor#

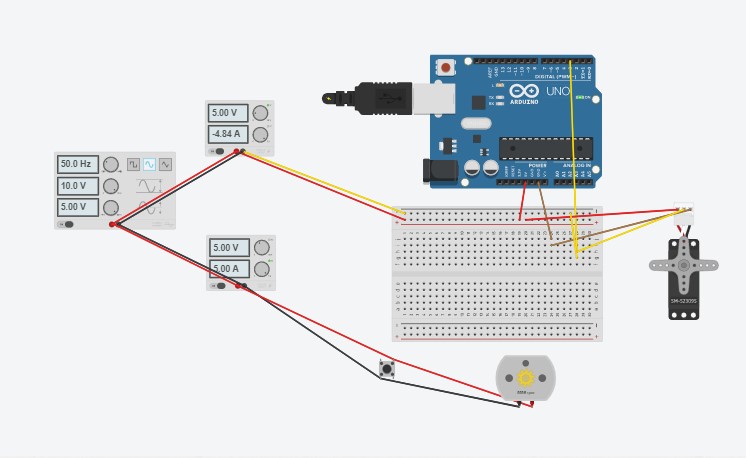

- Programming servo motor code with Arduino uno.

-

Connection and upload code.

-

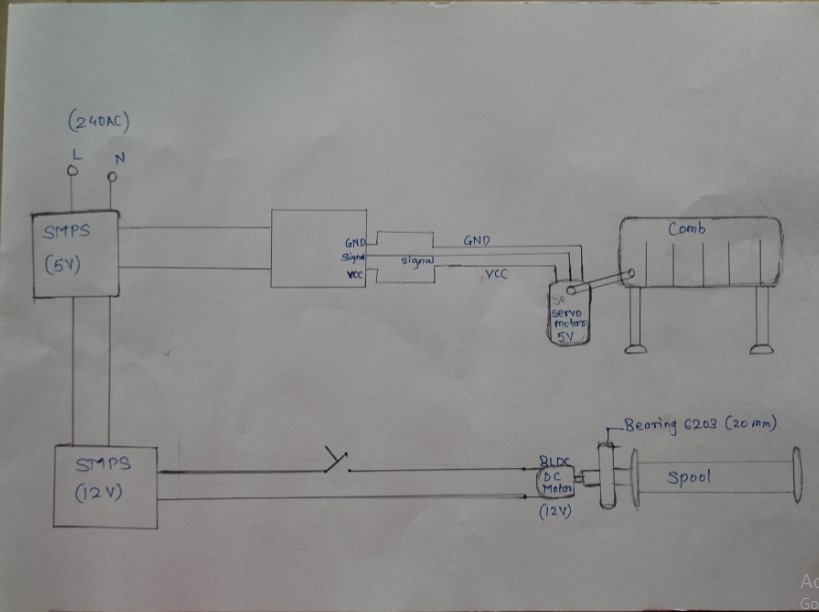

Circuit diagram

- Check DC motor

Assemble parts#

- Start to assemble laser cutting parts with screw and nut bold.

- Join Dc motor with bearing

- Join all with glue gun.

- Assemble laser cutting parts and join bobbin with nut bold.

- Part and assemble done.

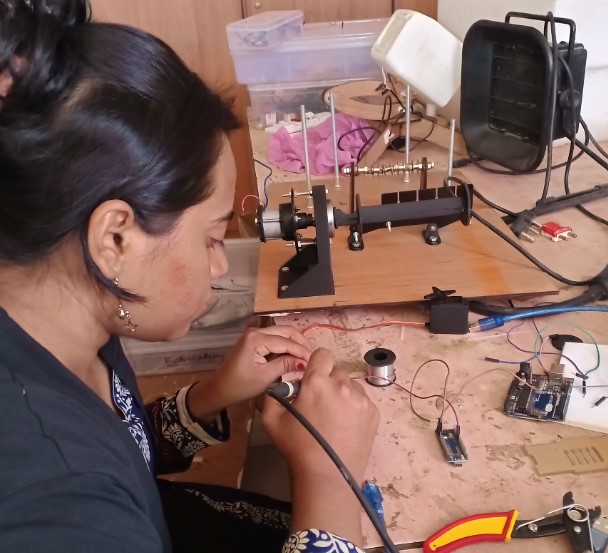

Testing servo motor and give Supply with SMPS.#

- Circuit of machine supply and connection.

- Soldering wire to positive and negtive.

- Test servo motor with 9v Supply.

- Stick servo motor to right place with glue gun.

- It’s done.

Yee…it’s ready.#

Original files#

Future plans for Pompom making machine#

I made this machine very simple way. But I want to do it more digitalize and advance more than we get in market. I will make direct cutter attached to the machine. Also I want to make it easy aand more user friendly.

What i learn(Experience)?#

In this Week, we have to do group assignment of open source hardware. So, first is learn How the machine work? and what kind of knitting machine in now - a days. I am happy because from last 1 year this machine was in the scrap And now it is in working process. And now, it’s become more interesting�.

And I learn machine design while making pom pom machine. I learn more in electronics. Great experience…:)

Useful links#

Gallery#

Fabricademy by Harshada raut is licensed under a Creative Commons Attribution 4.0 International License.

Based on a work at https://class.textile-academy.org/.

Permissions beyond the scope of this license may be available at http://vigyanashram.com/.