12. Skin Electronics#

For this task I wanted to concentrate on making a decorated beauty mask, similar to fresh collagen patches. I tried to imagine a beauty recipe, a material that is cast in the mold can also be used as a track for an electrical circuit.

Research#

First I made a search to find out if there were molds for beauty masks in a kit based on collagen.

I was inspired by the creation of this conductive carbon-based paint . Vegetable carbon is an ingredient widely used in cosmetics and face masks in particular ways.

In addition it is a very scenic pigment as well as coloring. Great for creating a pattern or decoration that can also be functional.

Also there are some brand that use electricity (powered by phone) ina a facemask like playskin

Molds#

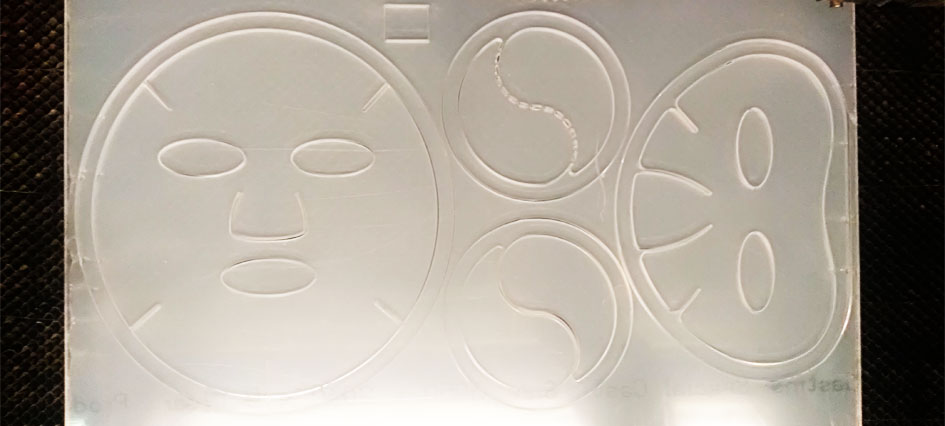

To obtain a fresh, flexible biosilicone face mask it is necessary to have a mold. I found online references of existing forms for start the design the file dxf, for the lasercut. I made a first test for the drying speed with the silicone rubber in order to test the shape of the basic molds

As a first test I created some molds to create different types of masks:

- full face mask

- T zone

- eye patches (two types)

I made a first test for the drying speed with the silicone rubber in order to test the shape of the basic molds. The shapes obtained work quite well. At this point I start thinking about the type of decoration to be silked to evolve the complexity of the mold.

![]()

![]()

Afterwards I switched to the recipe to obtain a similar consistency with a biological material. I used the recipe of flexible bioplastic based on Agar as a starting point by modifying the doses.

- 25g Agar Agar

- 7g Glycerine

- 200ml water

- a collagen tablet

- 4 vegetable carbon tablets (to be added to 1/3 of the liquid)

![]()

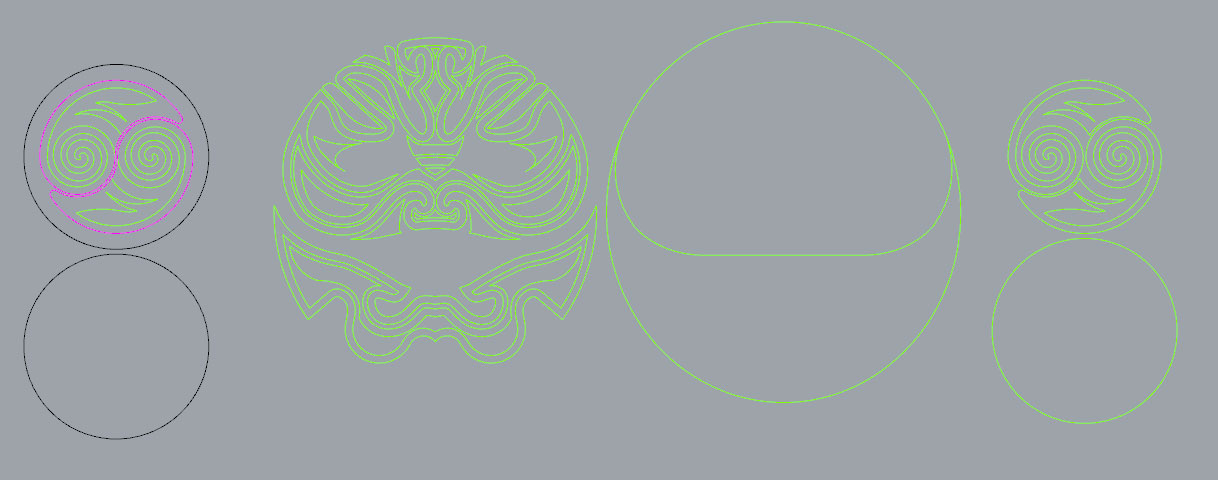

Decorative Patten#

For the realization of the decorative pattern I was inspired by the graphics of the Maori masks. I developed a unique pattern for the T zone and the top of the full face mask making the modular decoration for both molds. For the eye patch I used the same style with potential tracks for 5 mm wide circuits. I developed in a second time the decoration for the carbon component. It is imprinted in the liquid biosilicone with a half-mold. When the base solidifies (15 minutes), it is possible to proceed with the vegetable carbon mixture.

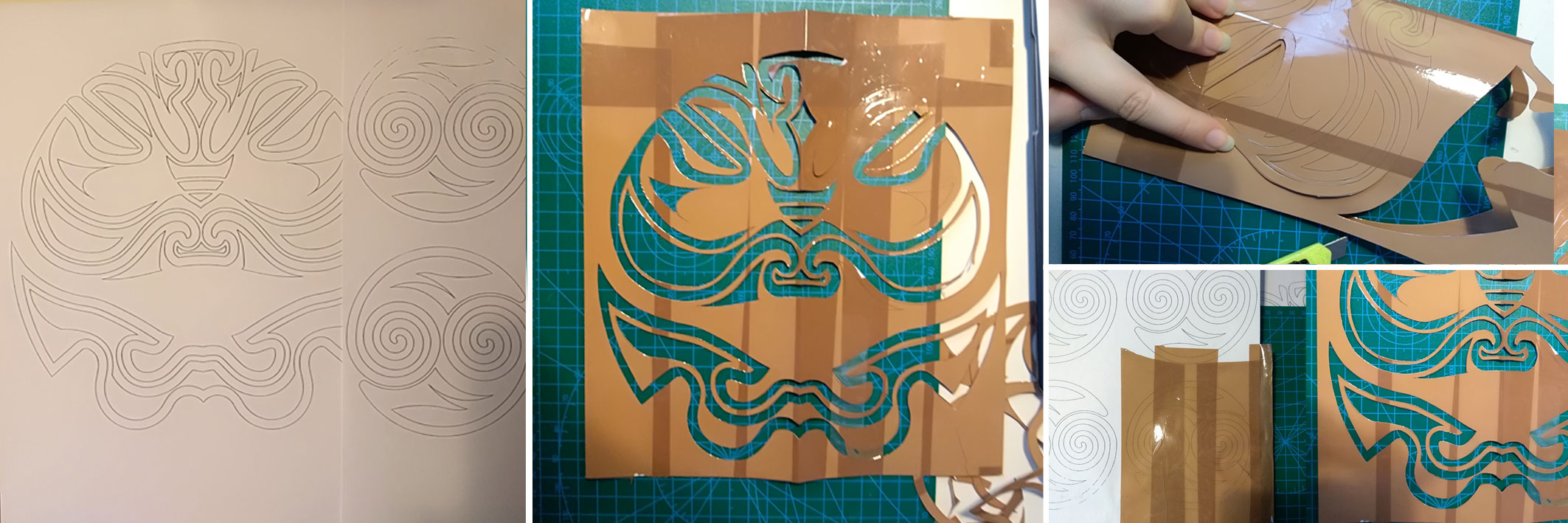

Paper pattern#

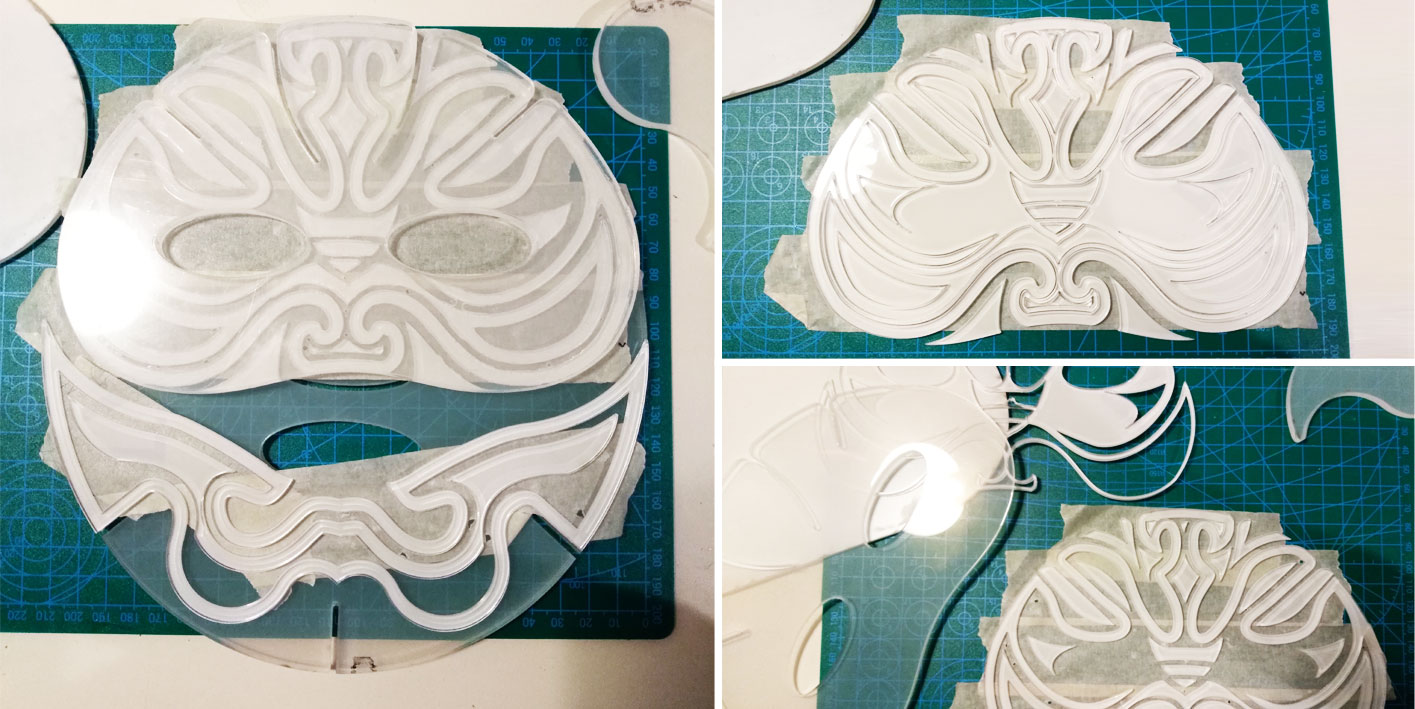

Unfortunately I prepared the necessary laser decoration on Saturday but I had bad luck and the machinery on that day was unusable. I tried to reproduce the pattern by hand by printing it and carving the waterproofed paper with the tape.

this attempt was unsuitable from the beginning but without alternatives I still had to wait for the laser machine to work on Monday

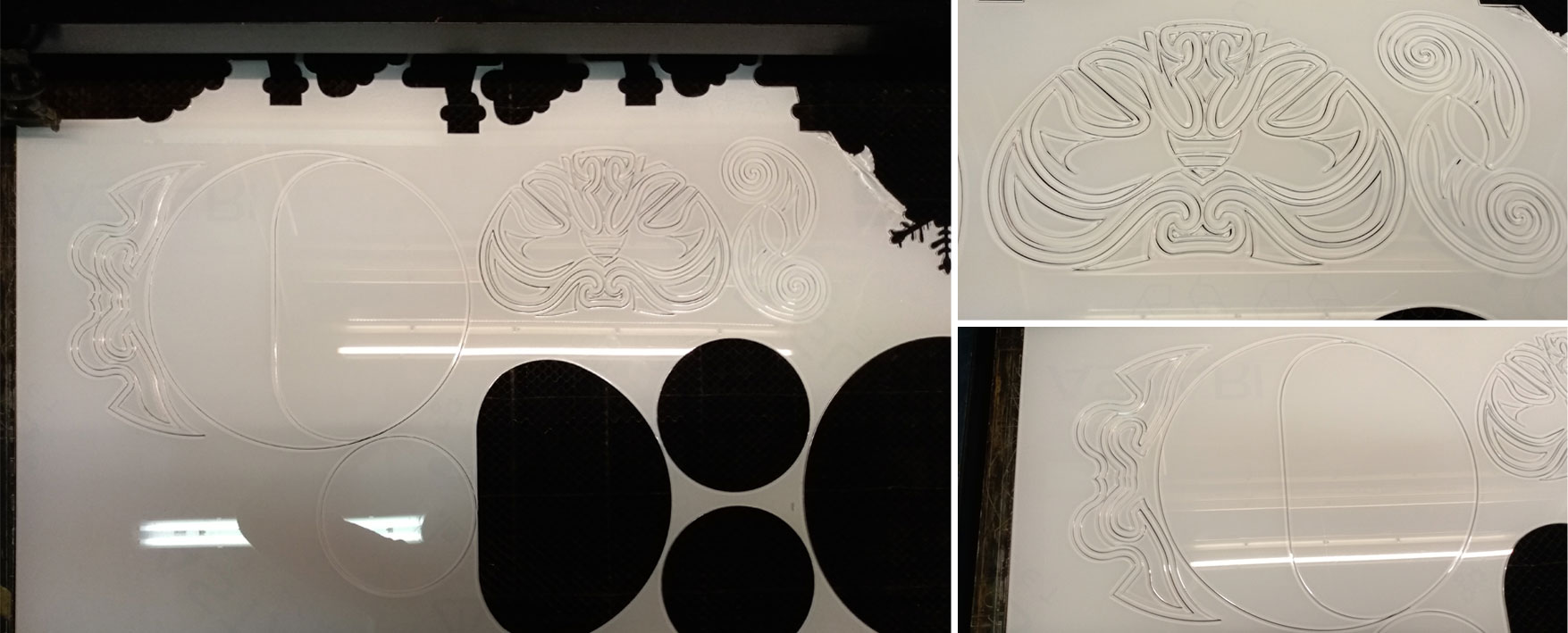

Pmma mold#

Monday I laser cut the molds of the pattern and in the evening I tried to redo the mask of the entire face. I mounted the two halves with their bases (only the upper part can also be used for the tzone module).

Results#

with paper pattern#

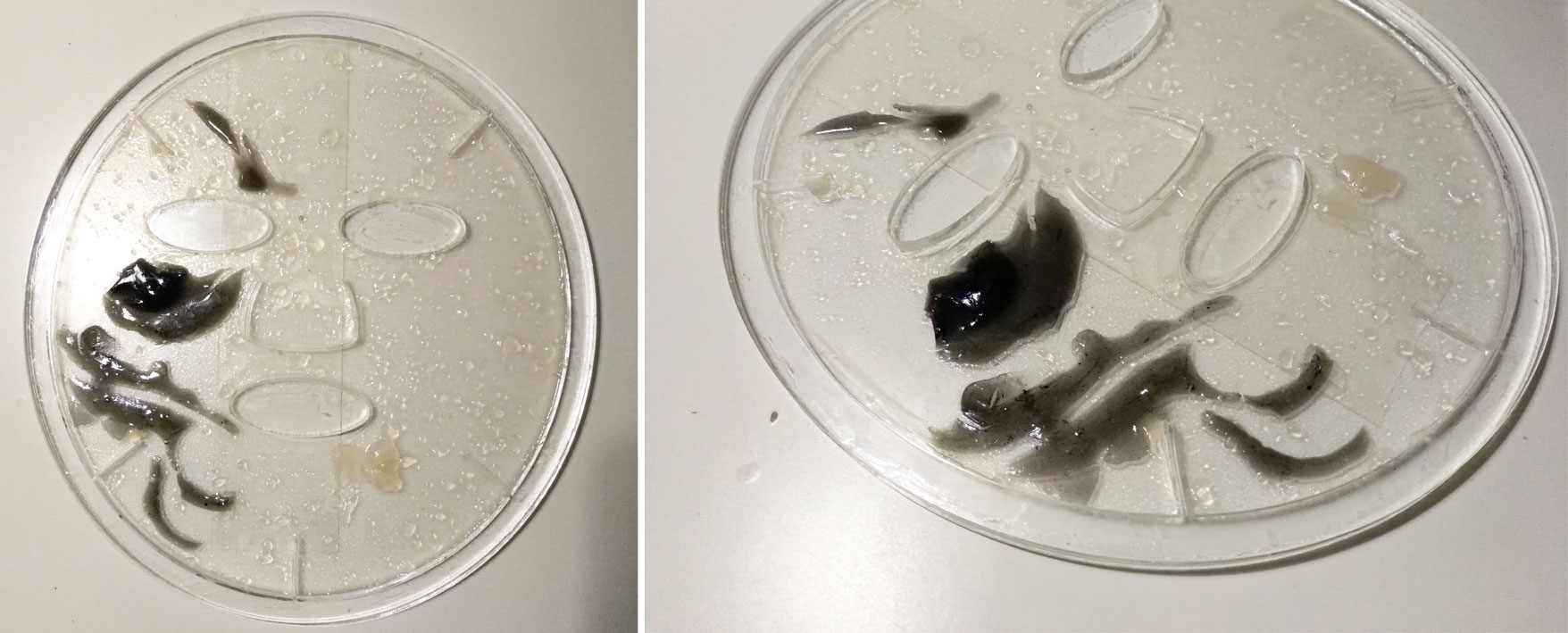

I tried several times to pour the bio-silicon into the molds. In the very first time the consistency of the result was too inflexible. when I tried to unmold the piece it broke. I added more water to the mixture and this step has improved the consistency but leaving lumps of agar that have not completely melted.

![]()

![]()

in some images you can see the attempt (black parts) to create the pattern by hand with the paper mask pattern but it was too imprecise and long process and the gelatin began to solidify very quickly

with pmma mold#

![]()

I heated the unused gelatine to make it liquid again to pour it into the molds. This proportion has a really fast solidification time which made it impossible for me to use it with something else but a mold.

Below I have documented all the steps to get the molds for face masks.

The compound does not conduct electricity but it would have been interesting to have more time and experiment with different conductive elements to be integrated into the biosilicone.

12.skin electronics_gDalessandro from Greta Dalessandro on Vimeo.

Errors#

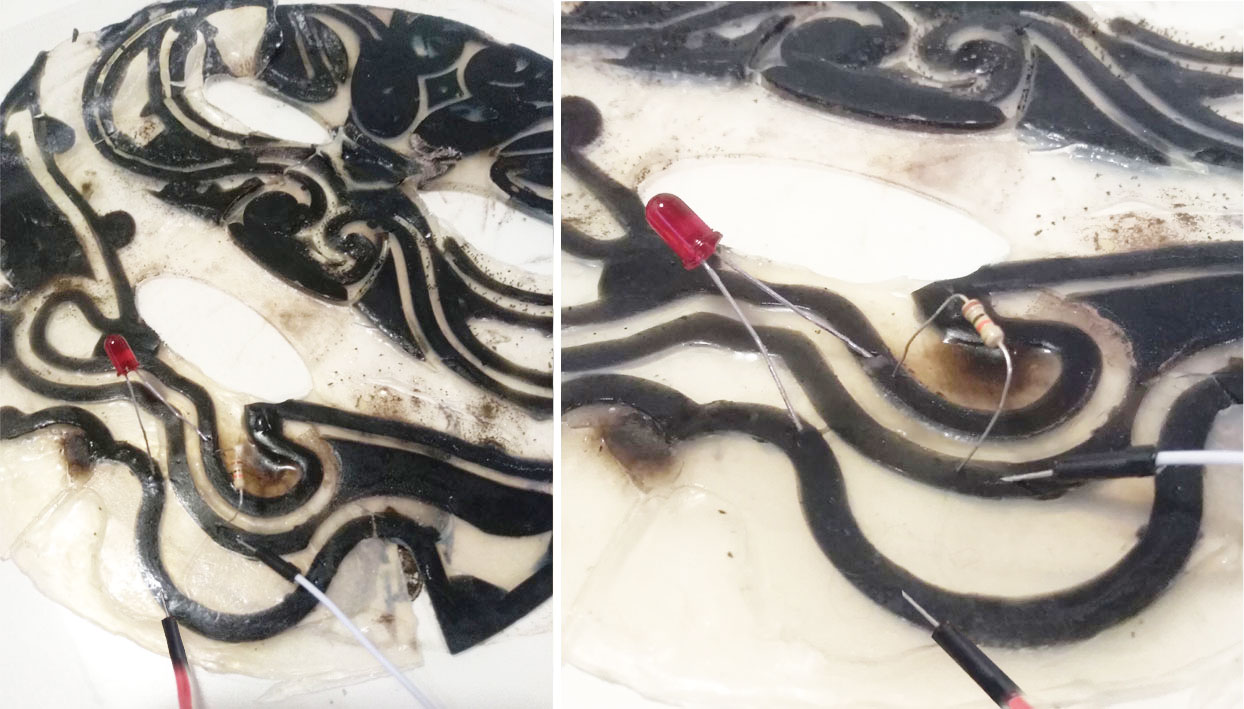

After extracting the masks from the mold, I immediately noticed that the electricity did not pass through the carbon decorations. The possibilities can be many … a low percentage of charcoal in the Agar biosilicone recipe is the most likely answer.

First of all I’ve used a multimeter but I don’t have documented the experiment. After a wile I’ve re tryed with a really basic circuit ad a battery like this one and again it doesn’t work.

The recipe for Biogelatine based in Agar take a wile to stabilyze. The material apparently solidifies in less than a minute but it’s not cohesive too, it flakes in a gelee way. Only when completely dry it becomes similar to a sheet, to the algae but without fiber