6. BioFabricating Materials¶

Credit to (www.labs.art.fsu.edu/digital-media-fab-lab-featured-research-initiative-open-source-biomaterials/)

Credit to (www.labs.art.fsu.edu/digital-media-fab-lab-featured-research-initiative-open-source-biomaterials/)

This week we dived into the world of Biomaterials. For the ones who don't know what biomaterials are; they are substances that can be decomposed or broken down by microorganisms and other living organisms.

Many people are researching and trying to invent new recipes to create such materials, hoping that one day we will be able to replace harmful fabrics to the environment with Biomaterials.

There are two types of Biomaterials: * Crafted * Grown

And this week we got to experiment and explore both of them.

Crafted biomaterials¶

You always needs these ingredients in order to craft biomaterials; a polymer, a plasticizer, and a solvent

Below you will find the recipes in worked on

Documenting and comparing experiments¶

TEST SERIE BIO-PLASTIC¶

| Material pic | Material name | Polymer | Plasticizer | Solvent | Additive |

|---|---|---|---|---|---|

|

Gelatine Biosilicone | gelatine 48 g | glycerine 24 g | water 240 g | Different dye-baths |

|

Agar agar Bioplastic | agar agar 4 g | glycerine 12 g | water 100 g | Onion dyebath |

|

Gelatine Bioresin | gelatine 24 g | glycerine 4 g | water 120 g | Summaq - Charcoal - Soap - Food coloring |

|

Gelatine Bioplastic | gelatine 24 g | glycerine 6 g | water 120 g | Madder - Wool - Cotton threads |

|

Alginate | sodium alginate 12 gr | glycerine 40 g | water 400 g | Food coloring |

1. Gelatine Biosilicone

For this recipe we started by heating the water (240g) till it almost boiled then we first added glycerin (24g) then the gelatine (48g)

We kept on stirring the ingredients gently till the mixture was a bit gooey, that's when we removed it off heat and started casting the material into petri dishes that were already filled with dyes from BioChromes week.

2. Agar Agar Bioplastic

Agar agar is a powder similar to gelatin but the difference is that it's extracted from plants whereas gelatin is animal based.

For this recipe I started by heating an onion dyebath (100g) till it almost boiled then I added glycerin (12g) then the agar agar (4g)

I poured the ready mixture into a different mold this time and I had to pin the mold to the table as the mold started to bend due to the heat of the liquid

3. Gelatine Bioresin

After adding all the ingredients (gelatine 24g, glycerine 4g and water 120g) following the same steps I did for the previous two materials, I added also added summaq to add more color and texture.

After pouring the mixture to petri dishes, I experimented by adding dish-soap to get a foamy and bubbly feel to the final results.

One of the problems I faced here, was that the Biosilicone got stuck to the glass petri dishes after it dried. So I had to pour hot water to the outsides of the dish and was able to remove the materials.

4. Gelatine Bioplastic

Here I followed the same steps by adding (gelatine 24g, glycerine 6g and water 120g) I also added Madder to get a different color.

I then used local wool and cotton threads to make the samples stronger

5. Alginate

For this one, there is no need to heat the water. We just have to mix the ingredient together really well preferably using a mixer. (sodium alginate 12 gr, glycerine 40g, room temperature water 400g). It's advised to leave the mix for at least 24 hours to set and to get rid of the water bubbles that were created due to the mixing.

Here you can see the bubbles in the mixture before it

sets

Here you can see the bubbles in the mixture before it

sets

Then we mixed sodium and water (100 ml Water * 10 ml Sodium Chloride Hydrate) as we need to spray the material with this mixture in order for it to dry.

I also created Bioyarns with this mixture, you just need to draw the mixture with a needle and cast it in a sodium chloride + water hydrate and then take it out and let it dry.

Created the yarns using a needle

Created the yarns using a needle

Added the yarns to the water and sodium chloride hydrate

Added the yarns to the water and sodium chloride hydrate

The yarns before the dry

The yarns before the dry

Grown biomaterials¶

Kombucha Leather Kombucha Leather is a flexible bio-material alternative to leather is made from cellulose nanofibrils spun by bacteria and yeast. This material grows thicker over time and can become paper thin or leather like.

Source www.sciencebuddies.org/science-fair-projects/project-ideas/GreenChem_p010/green-chemistry/vegan-kombucha-leather

Source www.sciencebuddies.org/science-fair-projects/project-ideas/GreenChem_p010/green-chemistry/vegan-kombucha-leather

* 1L water

* 1.5 to 3 gr of black tea (green tea can also be used)

* 100 gr sugar

* 1 cup of SCOBY solution

* SCOBY mother

* 1 tea spoon commercial honey

* vinegar

-We started by making the tea. By boiling water with tea bags (black or green) and adding the sugar and honey

-We left the tea to cool down

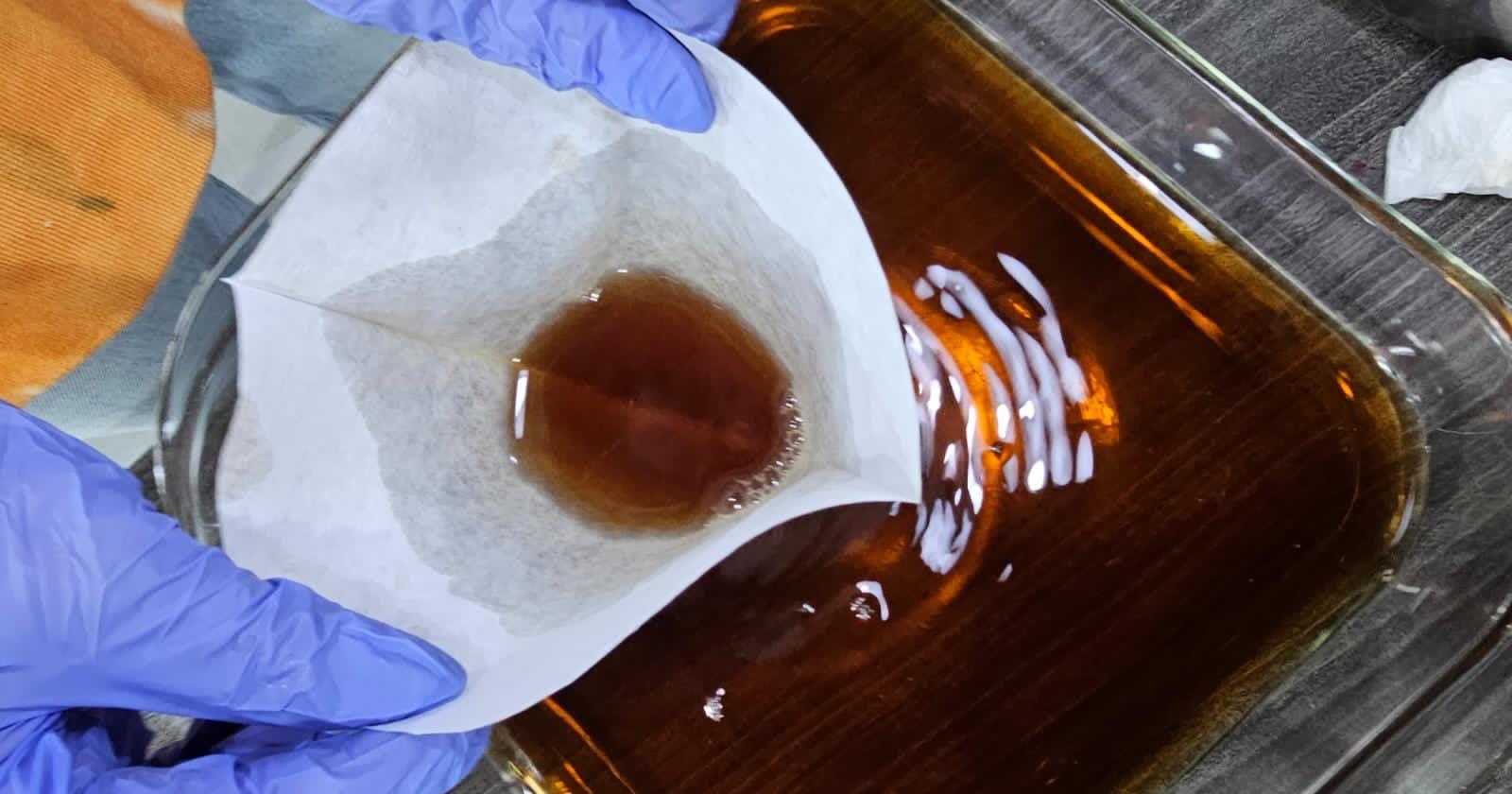

-After that we filtered the tea by using a coffee filter to make sure it's very clear

-We sterilized out container with hot water and Vinegar

-We then added the tea to our container

-Vinegar was added to the mix to change the PH of the tea. PH level of 3 is the ideal number

-A cup of SCOBY solution was added to our tea

-A SCOBY mother was moved to the solution

-Finally we covered our container with cotton fabric and moved it to a clean area

Here are some pictures of the process of making our leather