8. Open source hardware: from fibers to fabric#

This week I worked on a knitting machine (manually)

Research#

inspired by kniting machines in mexico

Process#

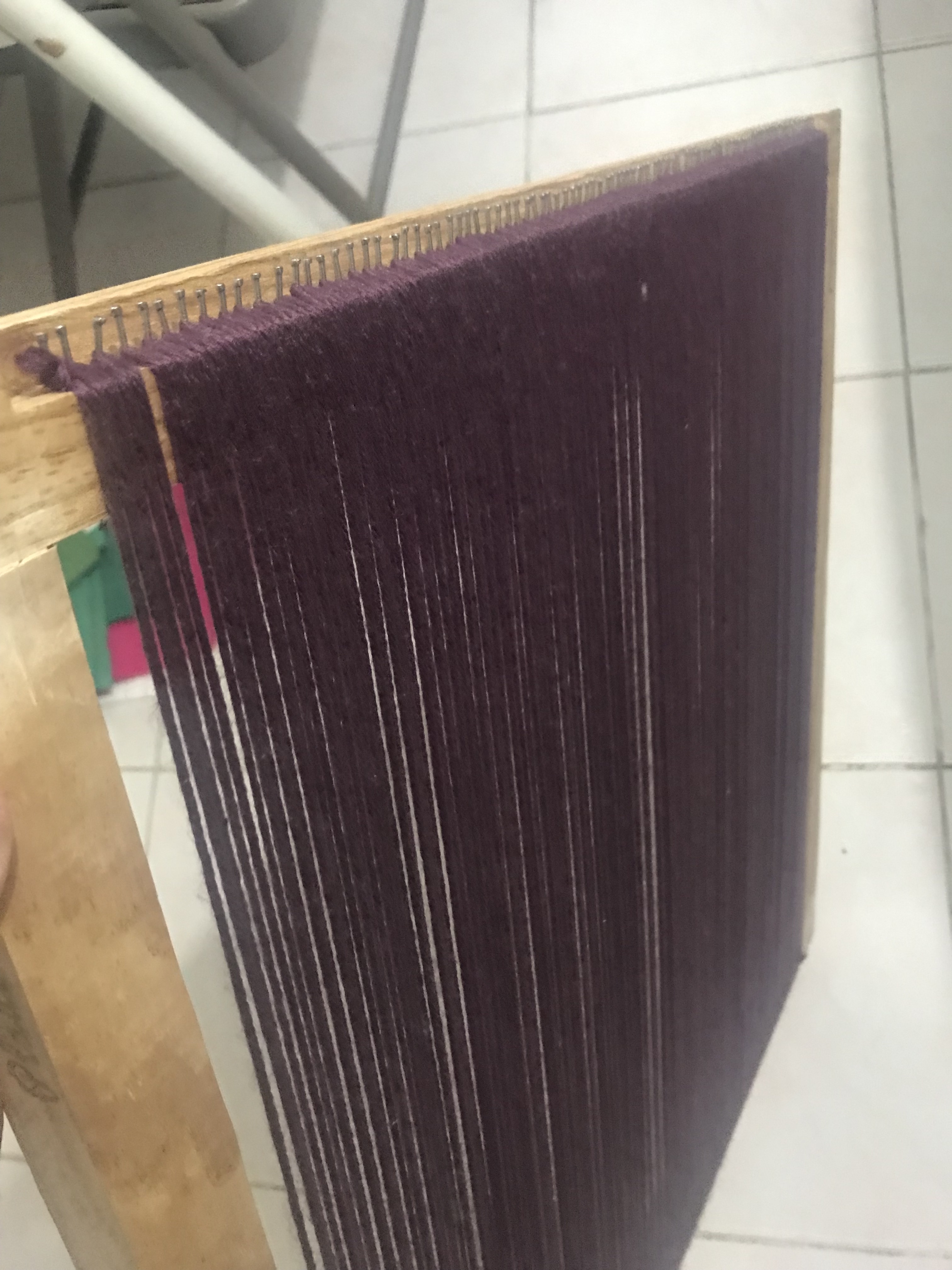

I did a knitting machine by setting 0.5 separated nail around a wodden frame

as this

Then i started to pull the threads around the nail creating paralell rows with threads

Then i started to pull the threads around the nail creating paralell rows with threads

After that i set some fabrics using a shuttle

After that i set some fabrics using a shuttle

Shuttle#

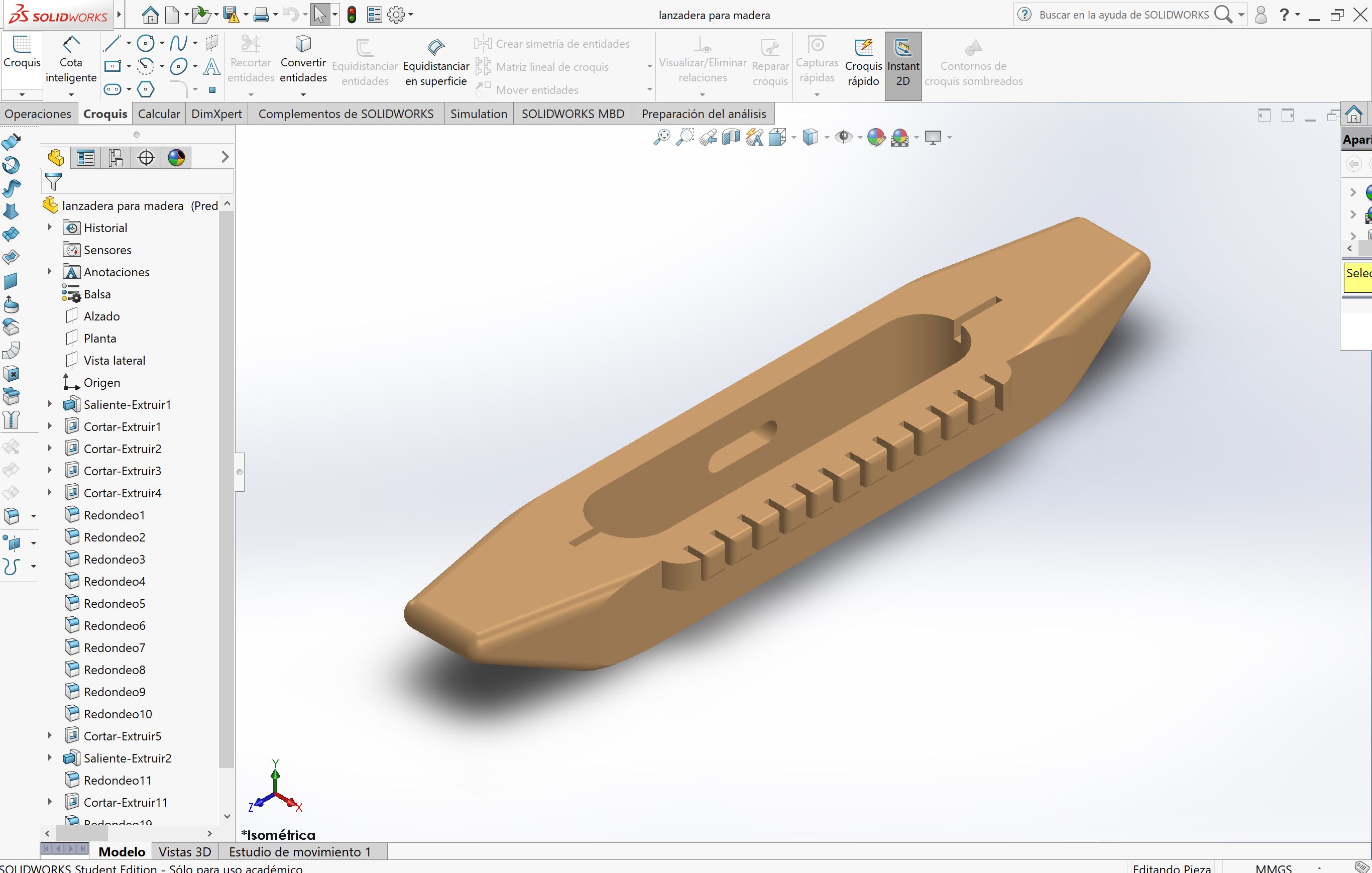

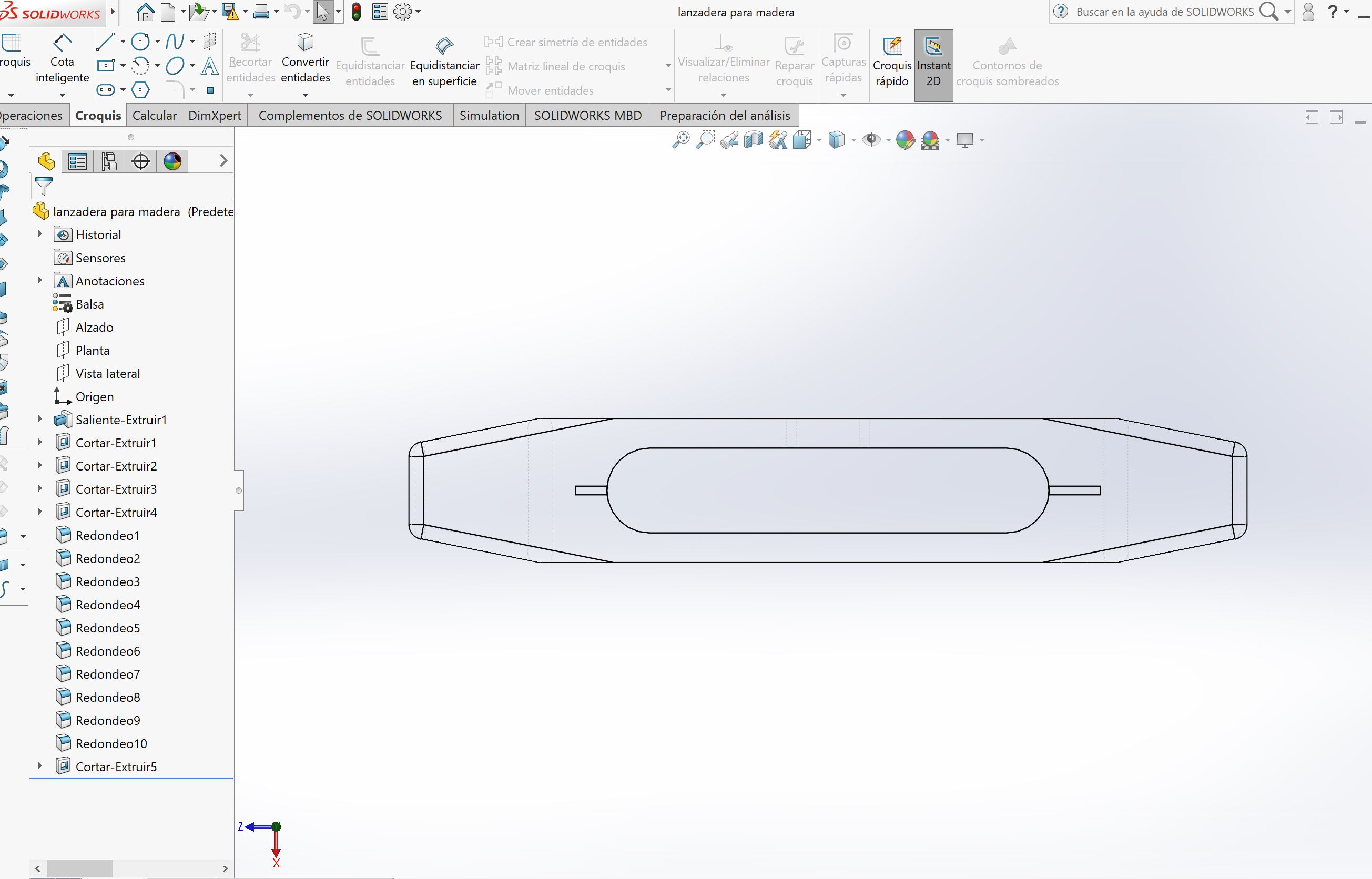

A shuttle is a tool designed to neatly and compactly store a holder that carries the thread of the weft yarn while weaving with a loom. Shuttles are thrown or passed back and forth through the shed, between the yarn threads of the warp in order to weave in the weft. So i designed a shuttle using solid works that also can be used to tighten the fabrics and the threads together.

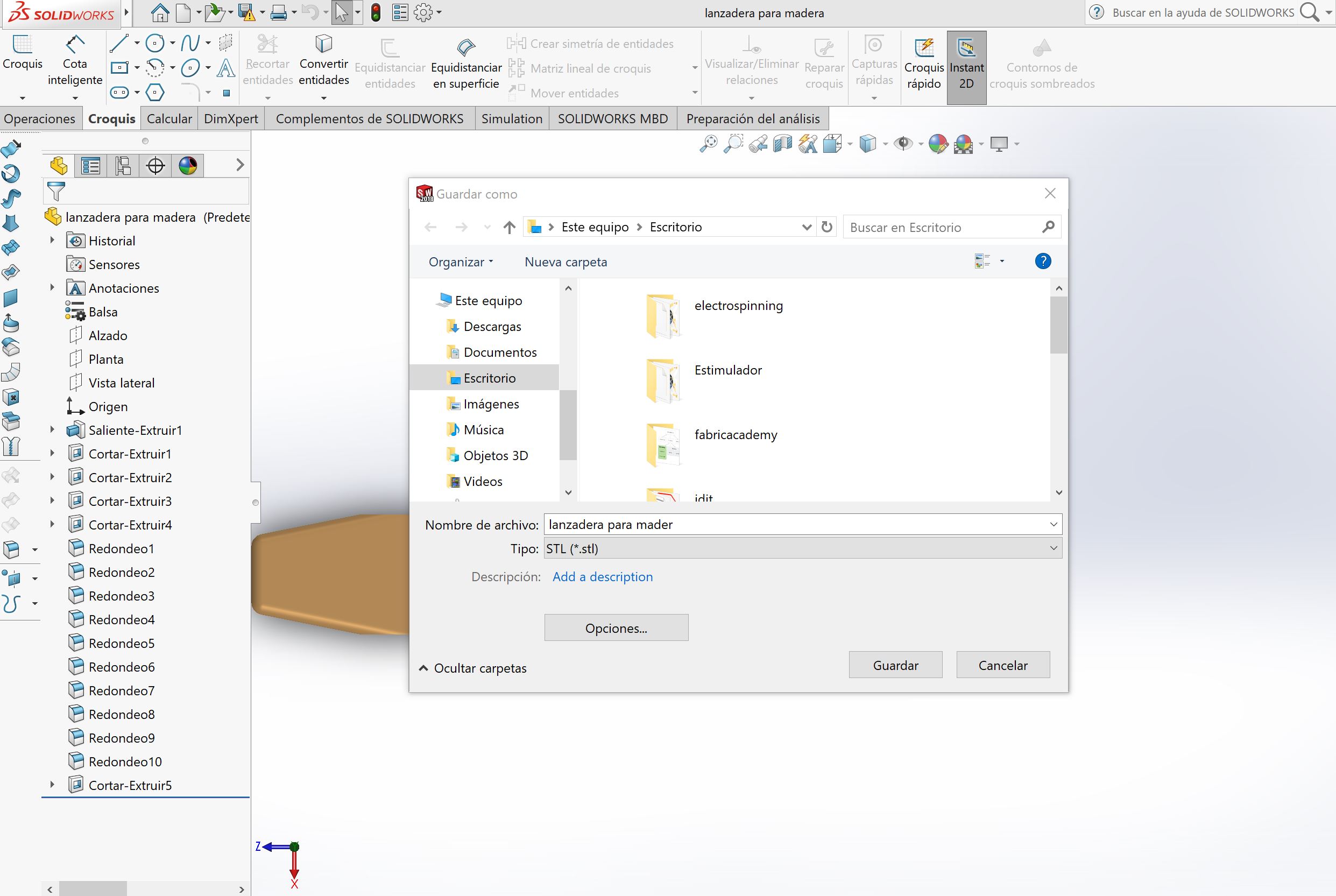

Then i save it as STL extension

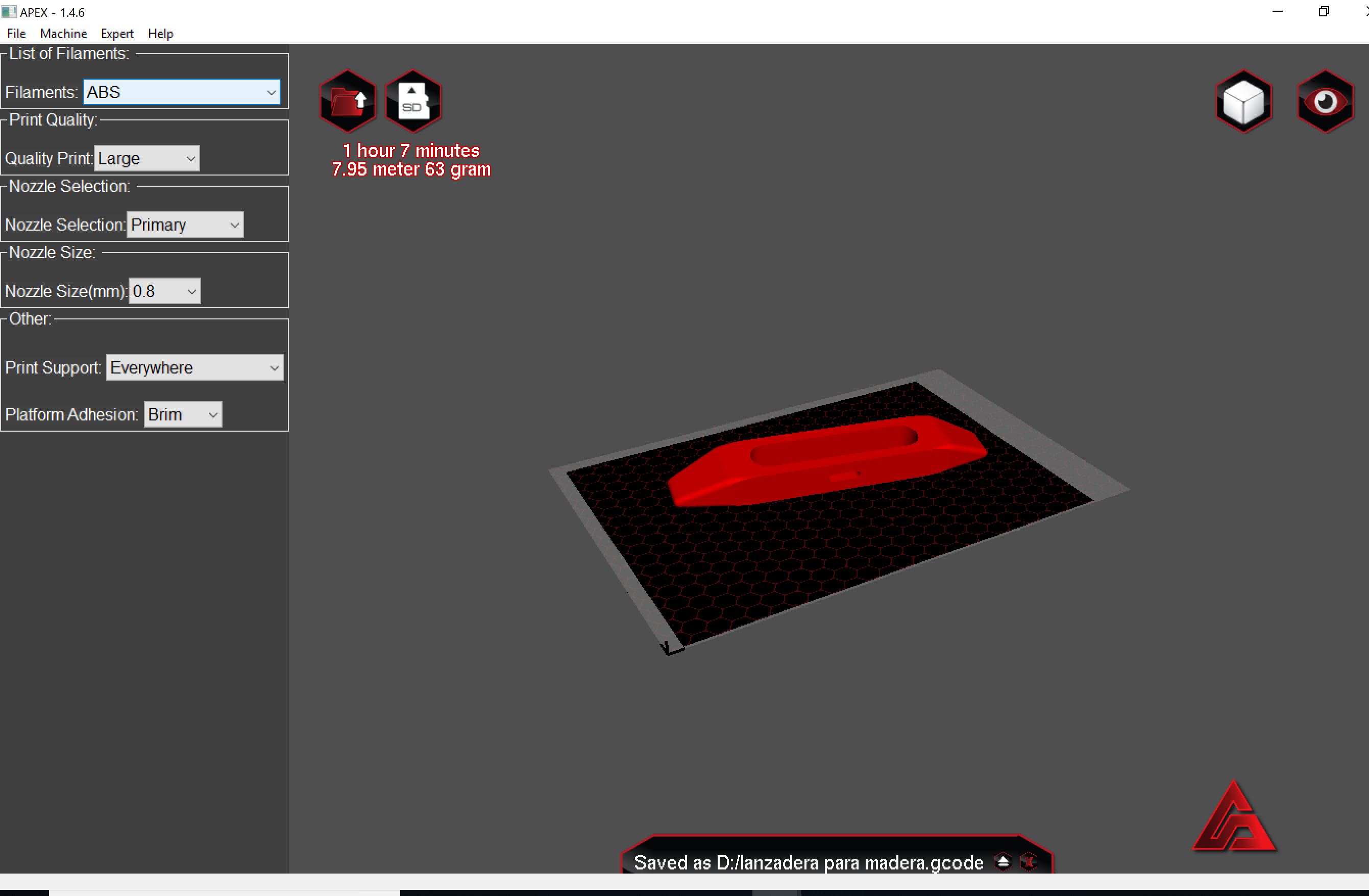

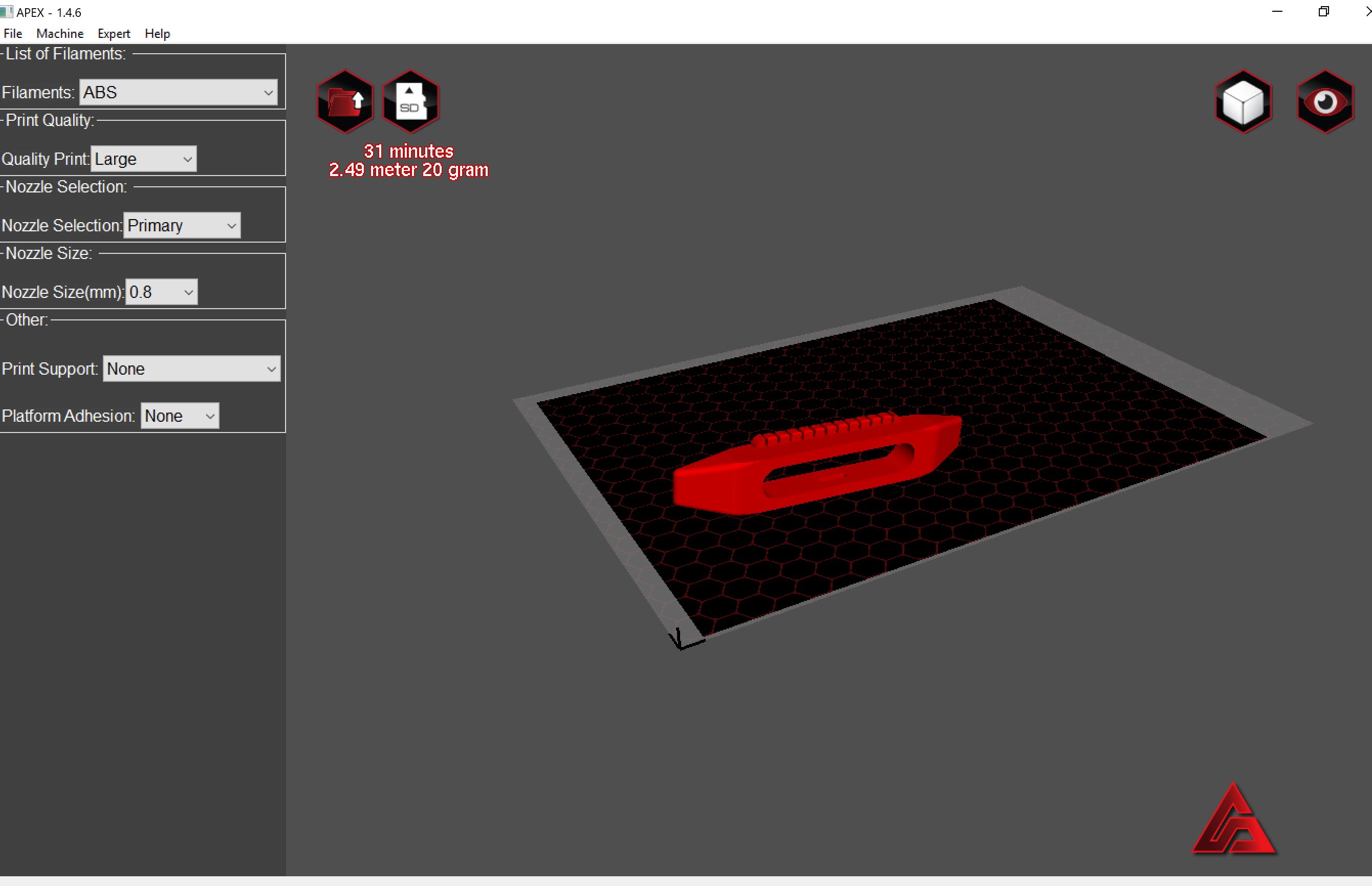

Then by using APEX i converted into gcode file ready to be 3d printed

Here you can download the file Shuttle

Knitting procces#

Then i started to knit the frame with differents yarns and fabrics, for this purpuse i created shuttle to make it easier

And finally i got

Material#

Wood /Wood Frame nail Wool cotton yarn

Conclusions#

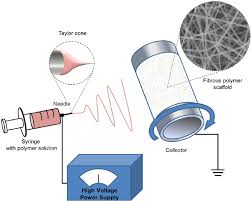

After creating this kniting machine i came up with the idea to create a 3d printer of fabrics by using a electrospinning tehcnique or by creating bioyarns

The main idea is to create a machine ables toextrude kombucha fibers that can adapt a form and creater fabrics and garments.

you can find more information about this idea which will be my final project , here https://class.textile-academy.org/2019/barbara.arteaga/projects/final-project/