4. Biochromes¶

This week I learned about the great possibilities of working with natural dyes and bioshades. Our main natural colour sources are plants, animal, microorganisms and minerals. With all of these, we are capable to develop inks, dyes and pigments. Main natural dyes projects I worked with this week were BIOSHADES WITH MICROORGANISMS and ECO PRINTING.

Natural Dyes Composition¶

Main Ink's Composition: Vehicle (water, ethanol 6%, oil or gel), binder (arabic gum), mordant (iron, alum, etc) and additive (salt, vinegar, etc).

For each dye we will prepare is very important to keep a proper documentation indicating dye source (name, origin, date), recipe (quantities, time, vehicle, binder, stabilizer, modifies, thickener) and catalogue (by material and color).

Oxidation can't be stopped, test, so always measure the vehicle-s pH level. Water is the most common vehicle.

Type of Dyes:¶

Acid, Basic, Direct dyes, mordant dyes, vat dyes, reactive dyes, disperse dyes, azoic dyeing, sulfur dyes, food dyes. Not all natural sources of coloring are safe!

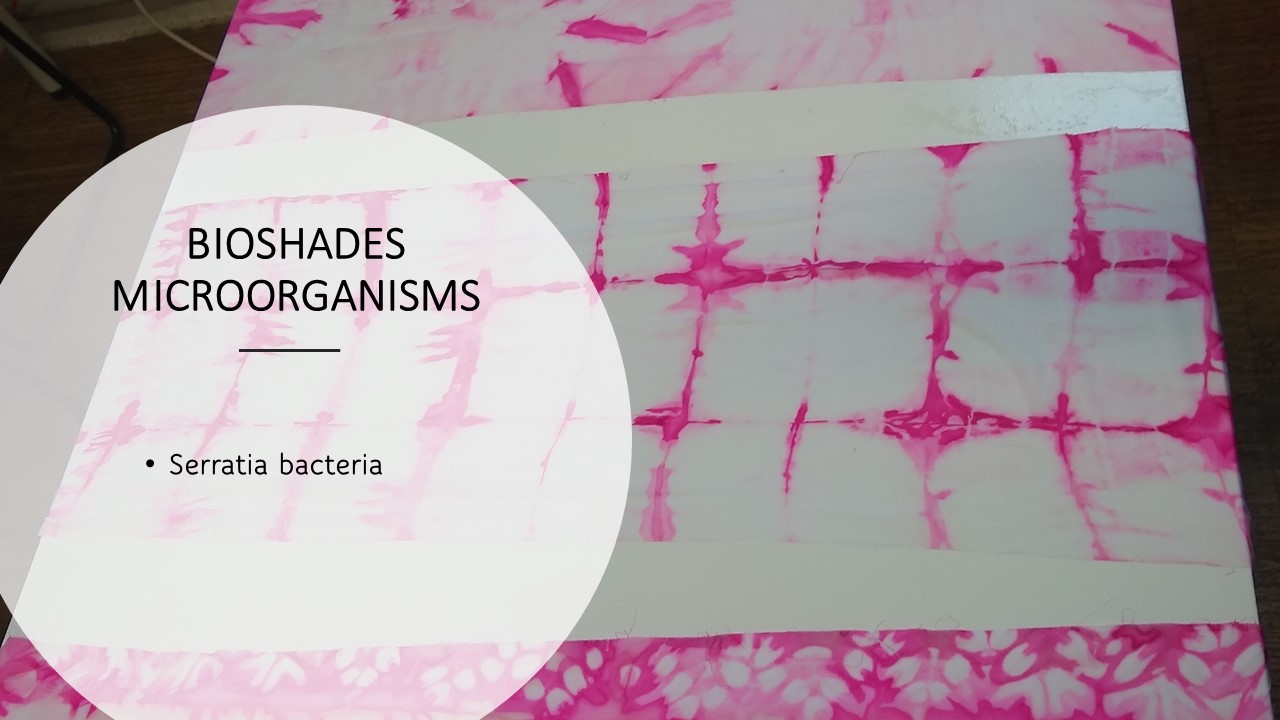

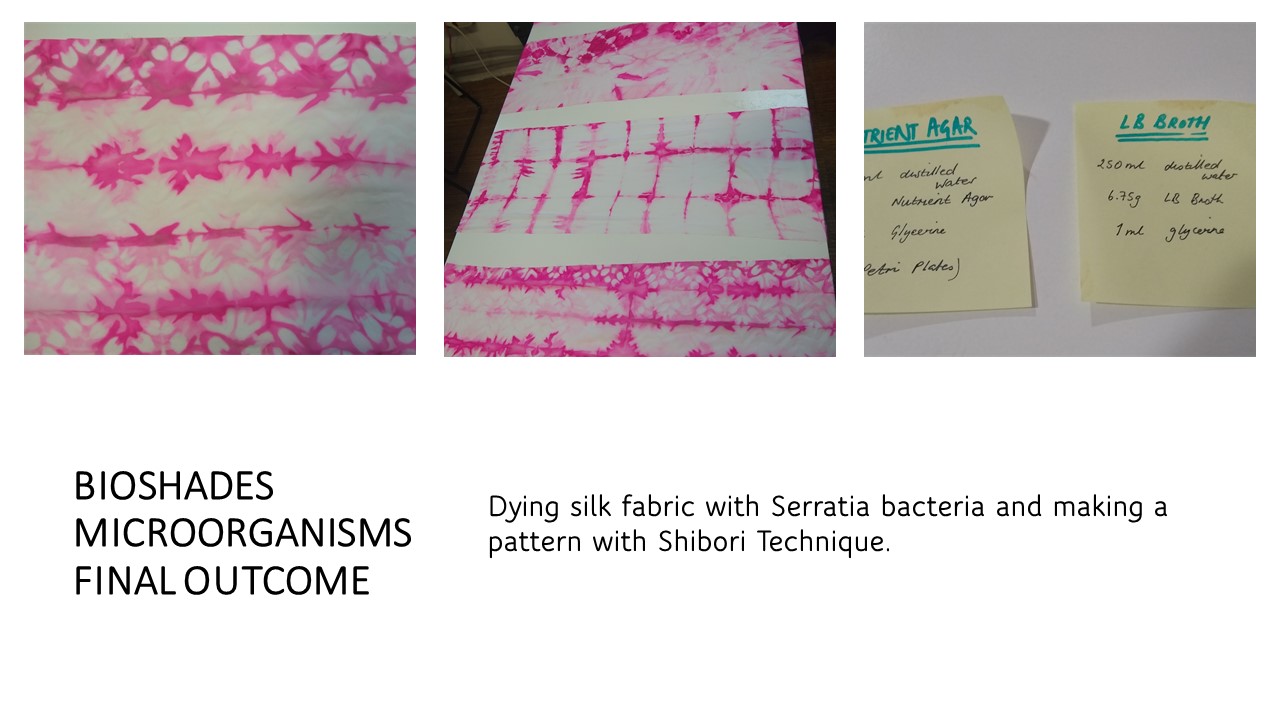

Bioshades with MICROORGANISMS- Useful facts:¶

- They multiply by cell division at different rates and their adaptability to environmental changes and extreme environmental conditions is enormously high. Microorganisms are a great source of incredible patterns. For each bacteria at least we can get 45 shades of color.

- Color, derived from bacteria, is a 100% natural biological product.

- During production, no valuable raw materials, for example crude oil is needed, as it is usual in the production of synthetic colors.

- Suitable bacterial strains are stored in laboratories and can be reproduced and multiplied as required.

- These are just some of the gigantic benefits of bacterial color for our climate, our environment and our health.

- No farmland or greenhouses are required to grow the color suppliers, the occurrence of bacteria is independent of the seasons and weather conditions or geographical location. No fertilizers are needed. This represents a clear advantage over the production of other vegetable and plant dyes.

Main microorganisms shades are the following:

- Indigo: Vogesella Indigofera Vogesella Indigofera Biodata

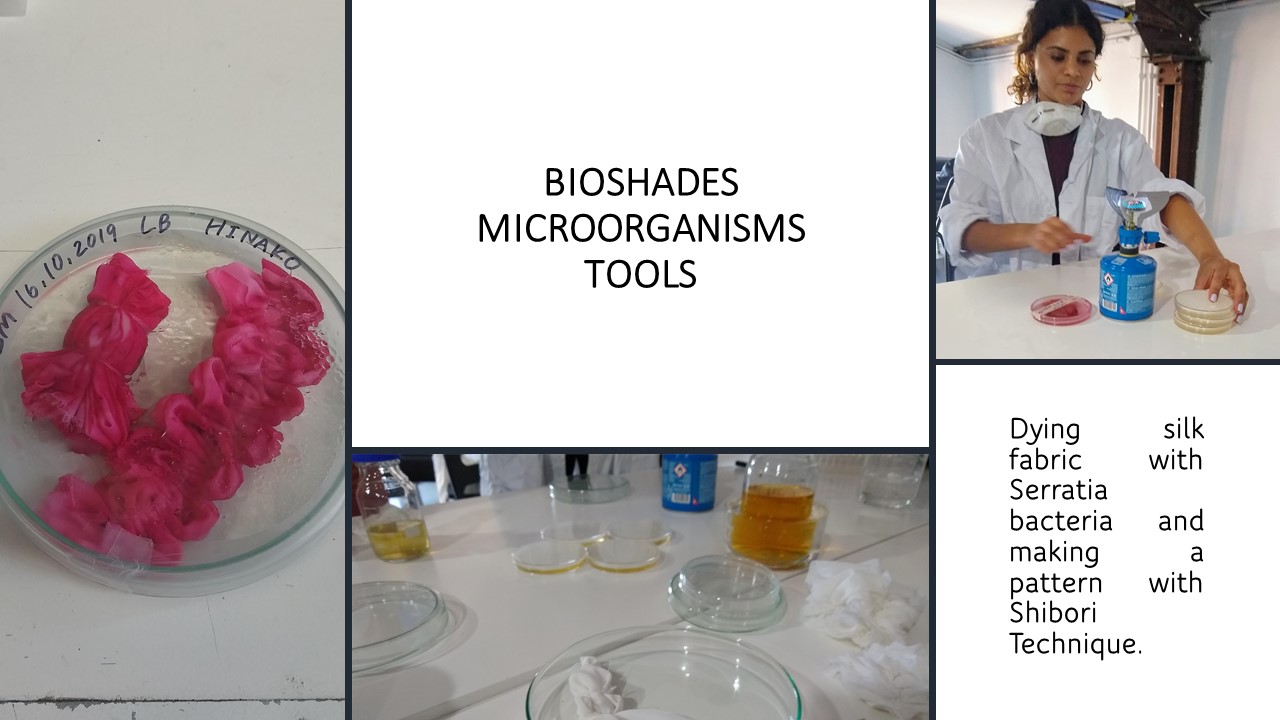

- Reds: Serratia Marcenses Serratia Biodata

- Purple gray: Janthinobacterium Lividum Serratia Biodata

The RECIPE: Bioshades with SERRATIA MARCENSES bacteria.¶

- Leave Serratia bacteria rest at 24 celcius temperature.

- 4 grs nutriant Agar

- 200ml distilled water

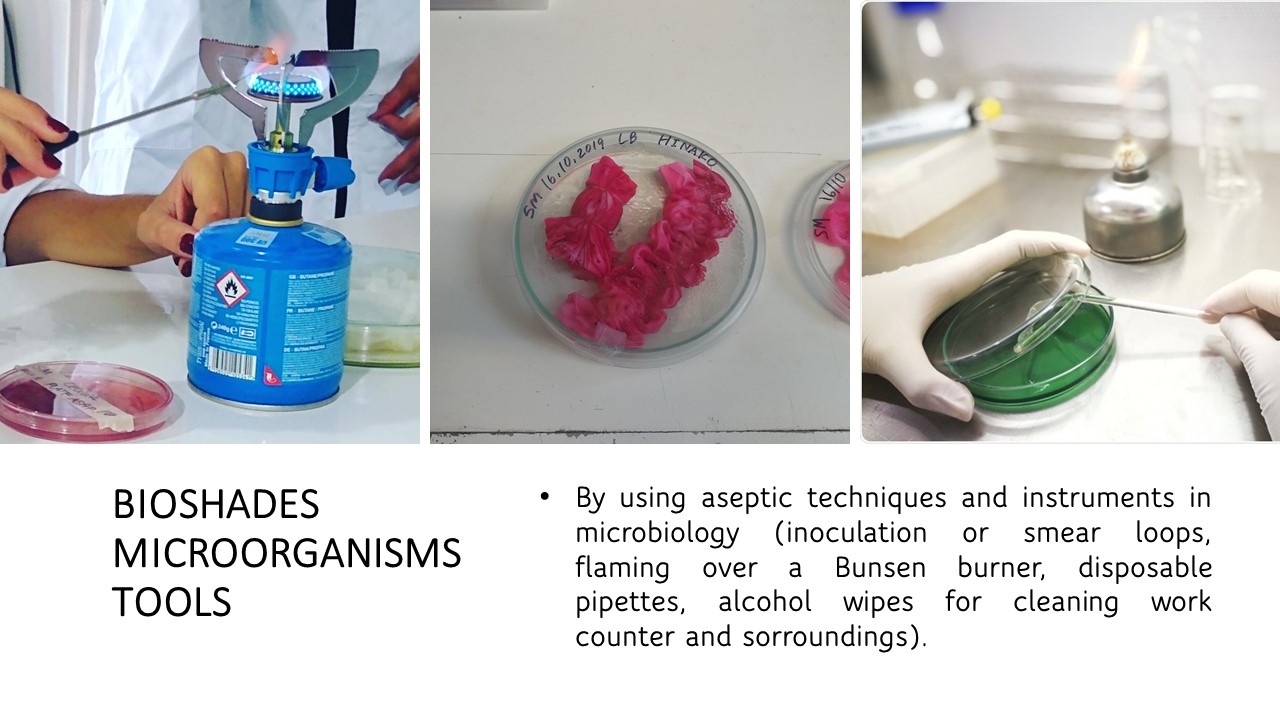

The PROCESS: Bioshades with SERRATIA MARCENSES bacteria.¶

- First, sterilize in autoclave the fabric and glass recipients to be used wrapped into autoclave bags recipient (PF15).

- Second, by continously sterilizing the instruments and tools, poor very tiny drops of Serratia bacteria into the fabric.

- Finally, let the bacteria work on the fabric for 02 days.

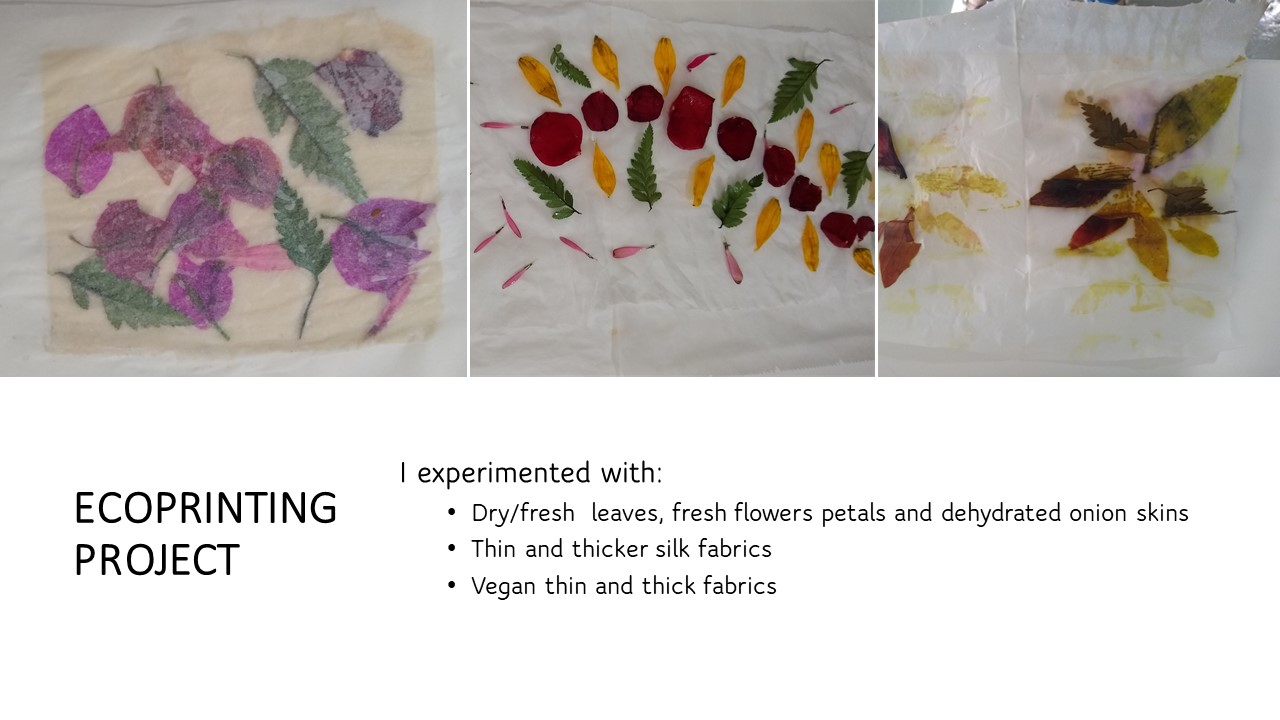

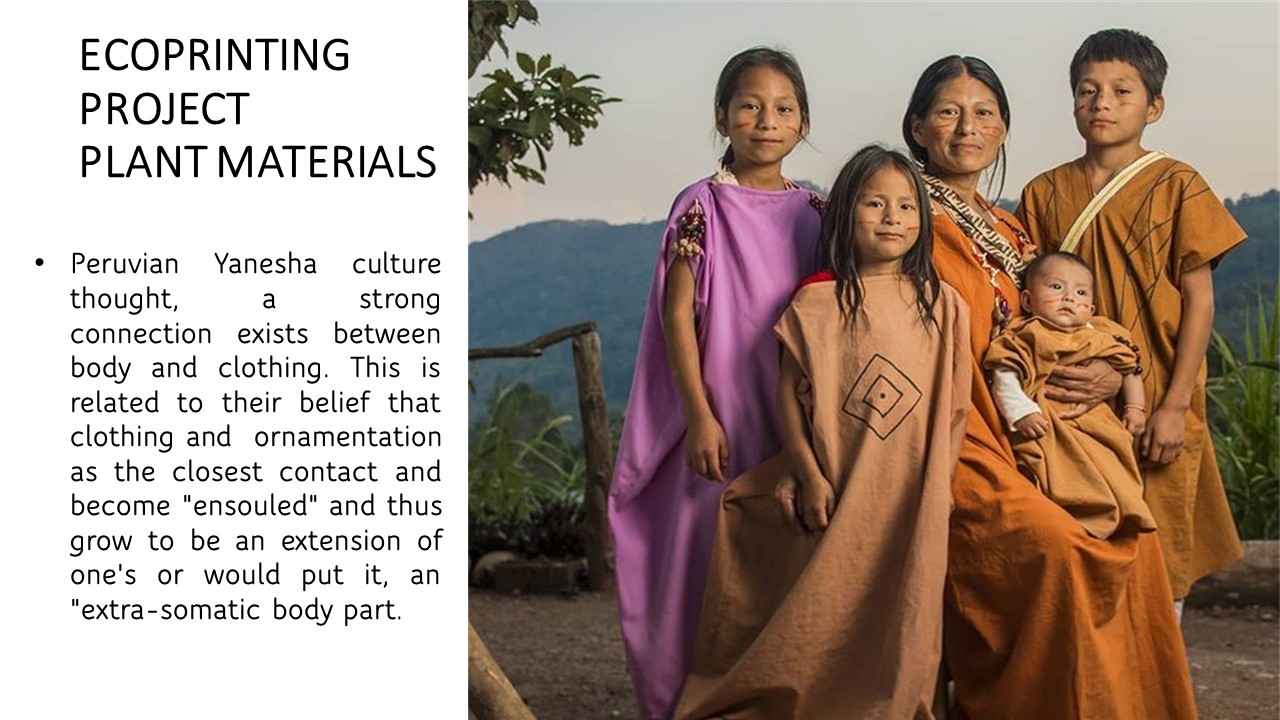

ECOPRINTING Project¶

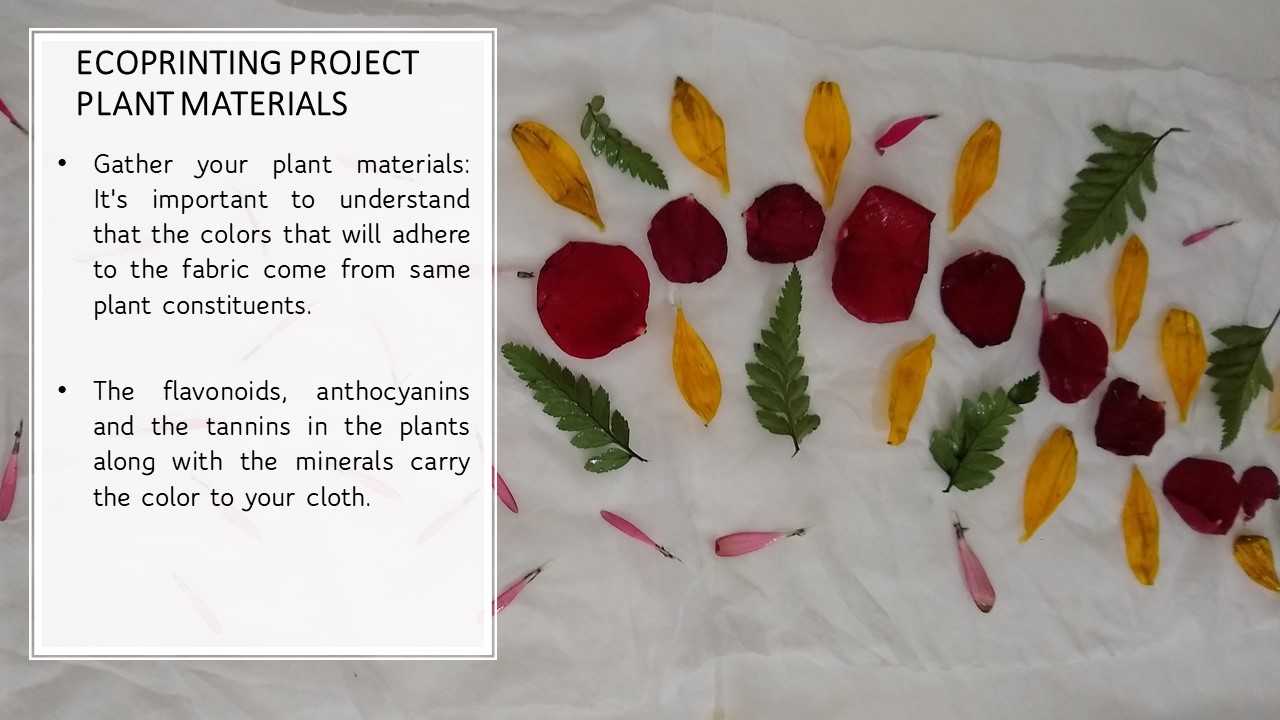

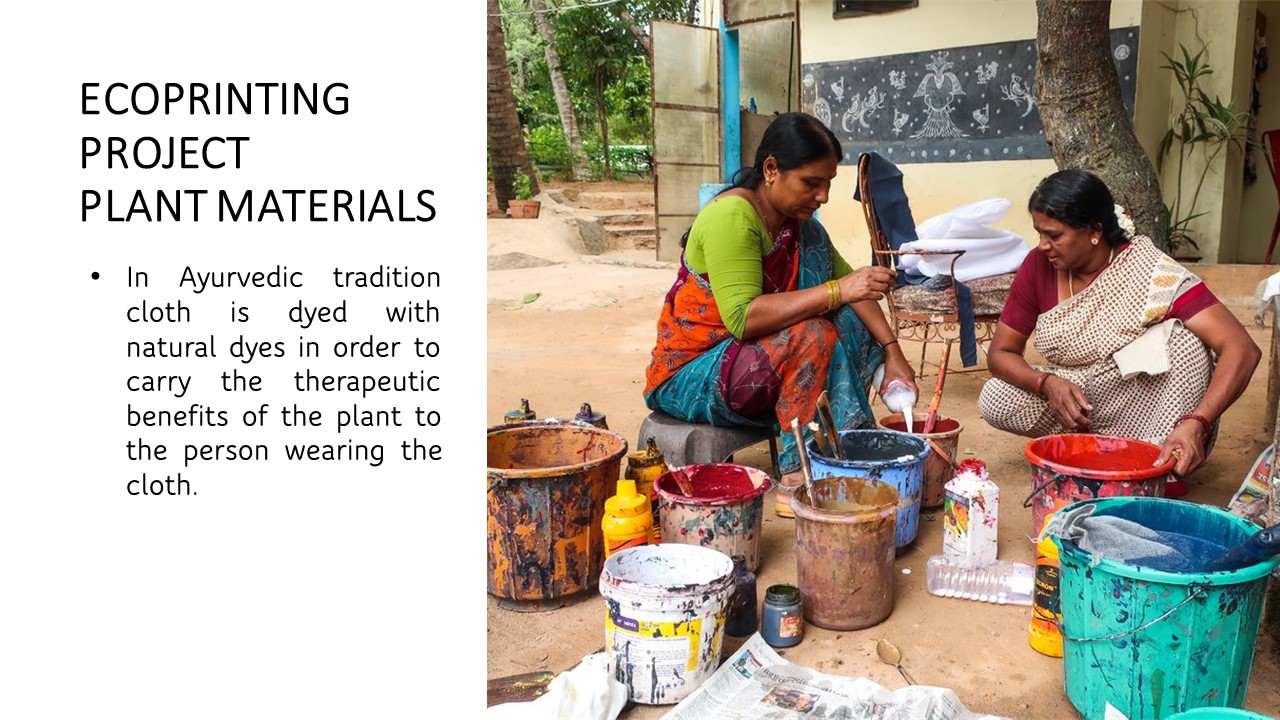

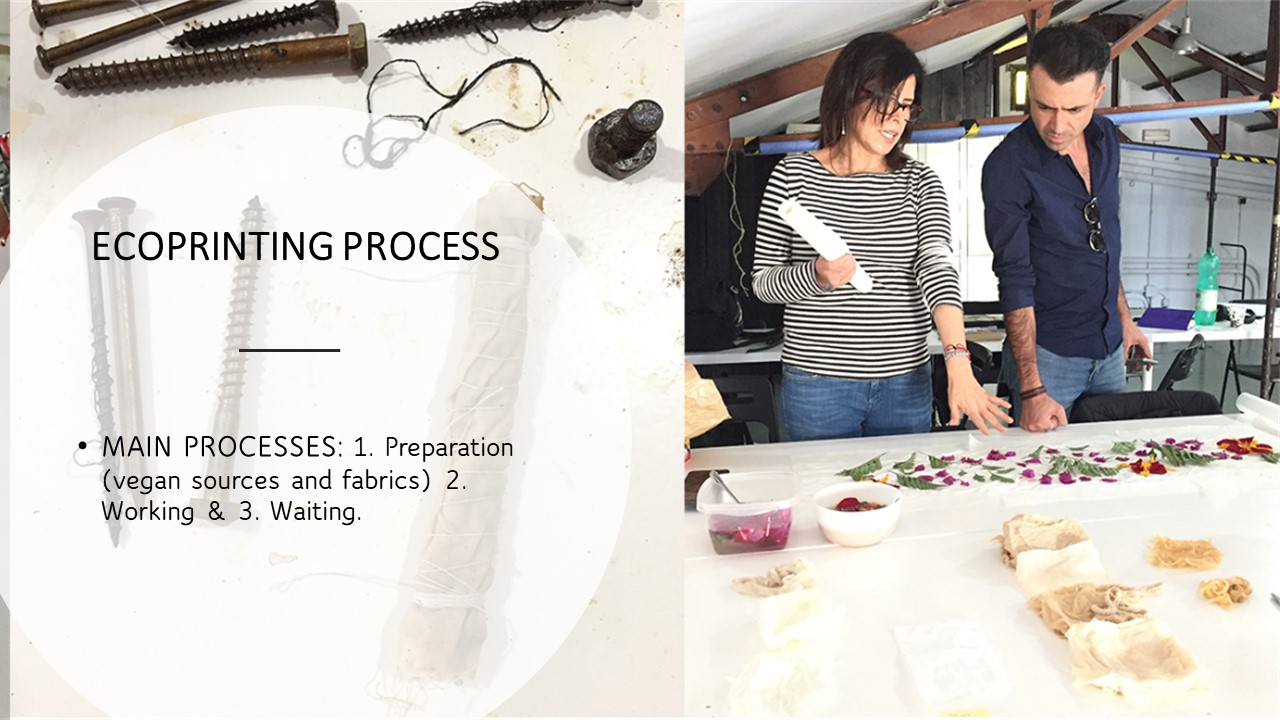

- The way I understand it, Eco Printing is a form of natural dyeing where the colors from plant material are transferred to paper or fabric via steaming or boiling.

- Best fabrics for Eco Printing: Wool, Cottom and Silk. Although Silk seems to work better than cotton and wool.

- Natural Color Sources: Recommended sources of dyeing high tanning leaves and flowers such oak, maple, fruit trees. Geranium and roses flowers seem to work best as well. In regards of leaves of autumn might work much better than young leaves of spring.

- Steaming seems tobe a better process, very important not to rush this process.

- STEP 1 PREPARATION: Scour the Fabric: First we must wash the fabric with a gentle detergent to remove any dirt, sizing or fabric coating. Note: some fabrics are sold as RTD Ready to Dye. Second option: Soak fabric 50/50water and vinager for cottom, For silk will be 2-1 water vinegar before placing the plant material.

- STEP 2 MORDANT OF FABRIC: Mordant the Fabric: One method could be by spraying the fabric with a mix of water, alum and washing soda or soaking the whole fabric in water with alum and then rinse it prior starting the dyeing process. Mordanting makes the color fast and inhibits fading with light and washing. Tip: For silk 12 grams of Alum for 100 grams of silk or wool fabric. Let it heat at low temperature for 45 minutes. 15% Alum to 100% of fabric. Mordant fabric with Alum first and then with iron 1 teaspoon to 1Lt water or 3% of weight. Under dye the fabric with natural dyes: Optional process in case you want to create a dye bath for the fabric.

- STEP 3 SOAK natural sources of color first in a solution of vinegar and water and then in water with rusted cloves before placing then into the fabric,

- STEP 4 Place plants, leaves and flowers on the pattern and design that its desired.

- STEP 5 Cover the project with a resist which can be recycle plastic. Other method will be to place fabric on top of the plastic and then place the plants, leaves or flowers on half of the area and then cover the plants and flowers with the other half of the fabric, in such a way that plant material is sandwiched between two layers of silk. At this point you can pound them to break the plant cells.

- STEP 6 Roll up your plant materials tighty and wrap them with a string.

- STEP 7 Leave the piece steam on low for 2.5 - 3 hrs. Important the bundle shouldn't have direct contact with the bottom, we can place the bundle on top of glass jars or dowel rods or place the bundle in a steam basket. TIP: Do not rush the process allow the pot and bundle cool down to room temperature of its own accord. During the cooling off period the vibrant colors are bonding with the fabric.

- STEP 8 Finally unwrap your bundles, remove the plant materials, rinse and wash the fabric using a mild soap. TIP: Restore pH of the fabric by rising it in water where you have added a tablespoon of vinegar. A second a final rinse with just water.

- STEP 9 Let the fabric dry ( hang it and dry). Iron it with temperatures below 185 F. - Weight of fabrics being used: Thinner 4 grs and thicker 31.

Research¶

- Natural Color by Sasha Duerr

- Bioshades

- We love bacyteria

- Victoria Geaney Interview

- Natural Food Pigments

- Eco friendly dyes and dyeing

- Ecoprinting by Suzanne Dekel

- Eco-prints Learn the process of all natural eco printing

Useful links¶

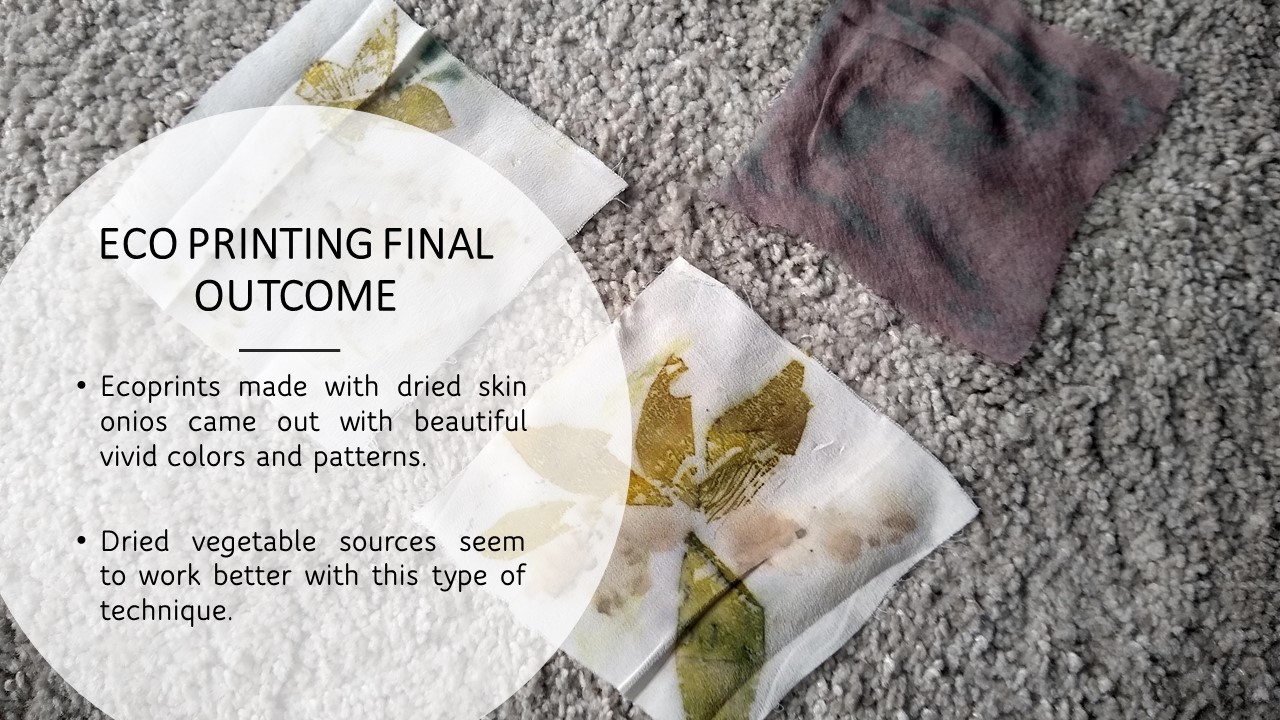

Main CONCLUSIONS and RECOMMENDATIONS:¶

- SAFETY comes FIRST, so do not forget to wear proper protective equipment while working with microorganisms and read DATASHEETS AND BIODATAS.

- Eco printing is a very relaxing coloring process, make sure you do not overcooked the bundle, because the natural colors might get darker or difused.

- For mordant the fabric is 1 hr of heating with water and Alum.

- For alcalizing Carbonates work much better than Bicabornates, pues el segundo tiende a aclarar el tinte.

- To acidify we can use a mix of water, vinegar and lemon.

- For coloring with red cabbage: chop cabbage, pour hot water and leave it boiling for 40 min. For animal fabric leave it overnight, if It is vegan fibers for 1 hr. We can experiment with lemon, vinegar and baking soda to get a wider spectrum of colors.

- For coloring with Avocado leave it warm on slow temperature for the whole night and in a bigger pot, and then with the fabric should be boilign up to 1 hr. 1 to 2 is the relation between the fabric and plant source of color for instance in avocado.

- When dyeing with Mushrooms a key factor of success is to control de pH levels.

- When dyeing with Hibiscus leave it for 30 min for shimering in low temperature, use dry hibiscus preferable. This dye works better on vegetable fibers.

- Animal fibers are more porous and absorb better the natural shades than vegetable fibers.

- Take in consideration that there are certain dyes that are more Ph and temperature sensitive than others for example the ones made with Col Lombarda or Red Cabbage. Also

- other natural dyes are considered fugitive dyes for example the ones made with berries,beets and rhubarb.

- Take in consideration the following aspects when you do your biochromes project. I found these tips very useful:

- 15 Reason Your Natural Dye Project FAILED (And Why You Should Do It Anyway)

Video¶

Microbiological-Textile-Futures¶

Microbiological-Textile-Futures from École des Arts Déco - Paris on Vimeo.