6. Biofabricating¶

Bioplastic ( with Buganvilla or Goldenberry Leaves), Fruitleather (Goldenberry), Labgrown leather for Smart Wearables¶

The Inspiration¶

Main inspiration was the texture of Bouganvilla Flowers (Flor de Papel in Spanish) and Goldenberry’s calix (Aguaymanto).

While Bougainvillea’s flowers have a wide variety of colors, so this give us a wide spectrum of biochromes we can experiment with. It-s known

that Goldenberry’s were one of the most preferred fruits by the Inka’s royalty and in this project we’ll do our best to reassemble the beautiful

golden color of its calix . It is considered "the lost Inka crop" and traditions relate that It only belong to the Inka’s royalty gardens, Goldenberry

was one of their favorite plants, so It was cultivated with great dedication in the Sacred Valley of the Inkas. The Inkas were prosperous farmers and eminent

astronomers. Their crops were guided by the observation of the stars, so that the sun, moon, lightning and rainbows were some of the most important deities.

Both Bougainvillea’s flowers and Goldenberry’s calix have an inedible husk of a texture like Chinese paper. Goldenberry calix protects its spherical fruit from external factors that can affect it is small and pleasant taste.

Research¶

- In the food industry, it has been possible to replace the properties of Goldenberry’s Calyx with a bioplastic made with Alginate and some studies had revealed that Calyx properties had been simulated successfully. Therefore, Alginate is an efficient edible coat for preserving its quality, bioactivity, natural and health contents (1% Alginate, 100% water, 20% Glycerine prepared at 45 Celcius degrees).

- Bracts of Bougainvillea glabra, differ in colour from the non-bract leaves, and attract pollinators.

- Many plants with bracts don’t look like this, however. There are plants with bracts that have evolved to attract pollinators.

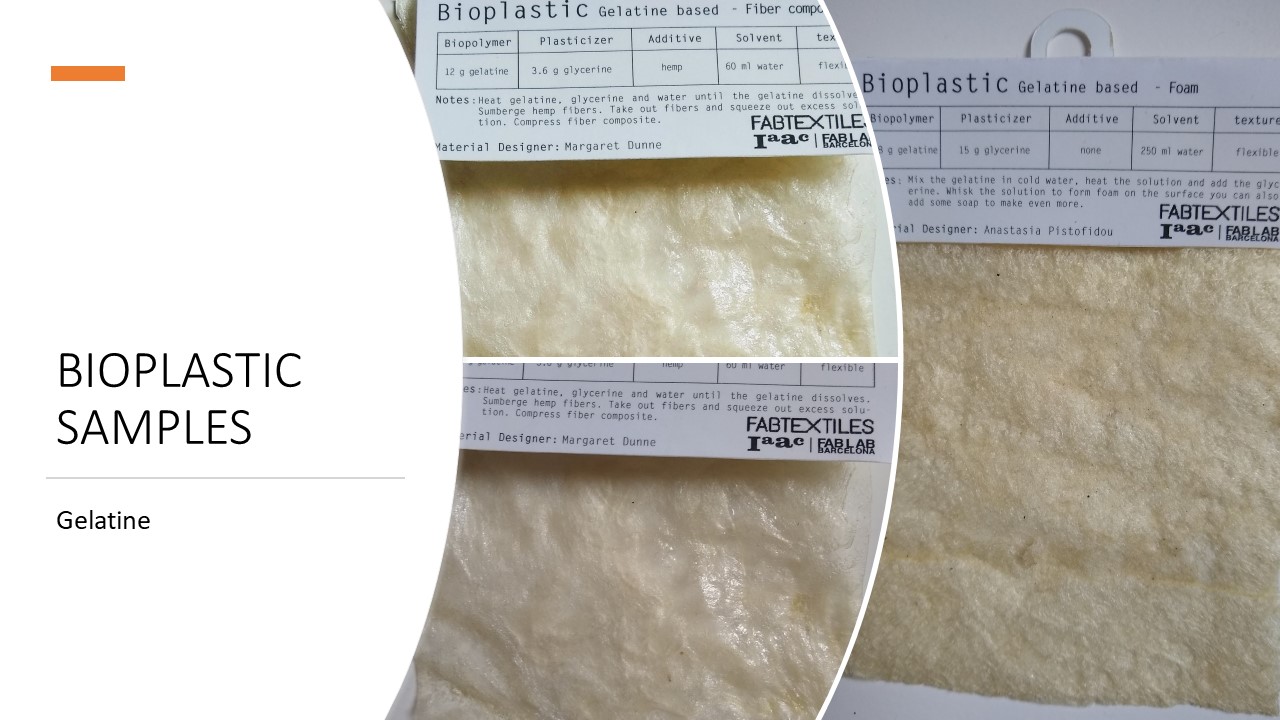

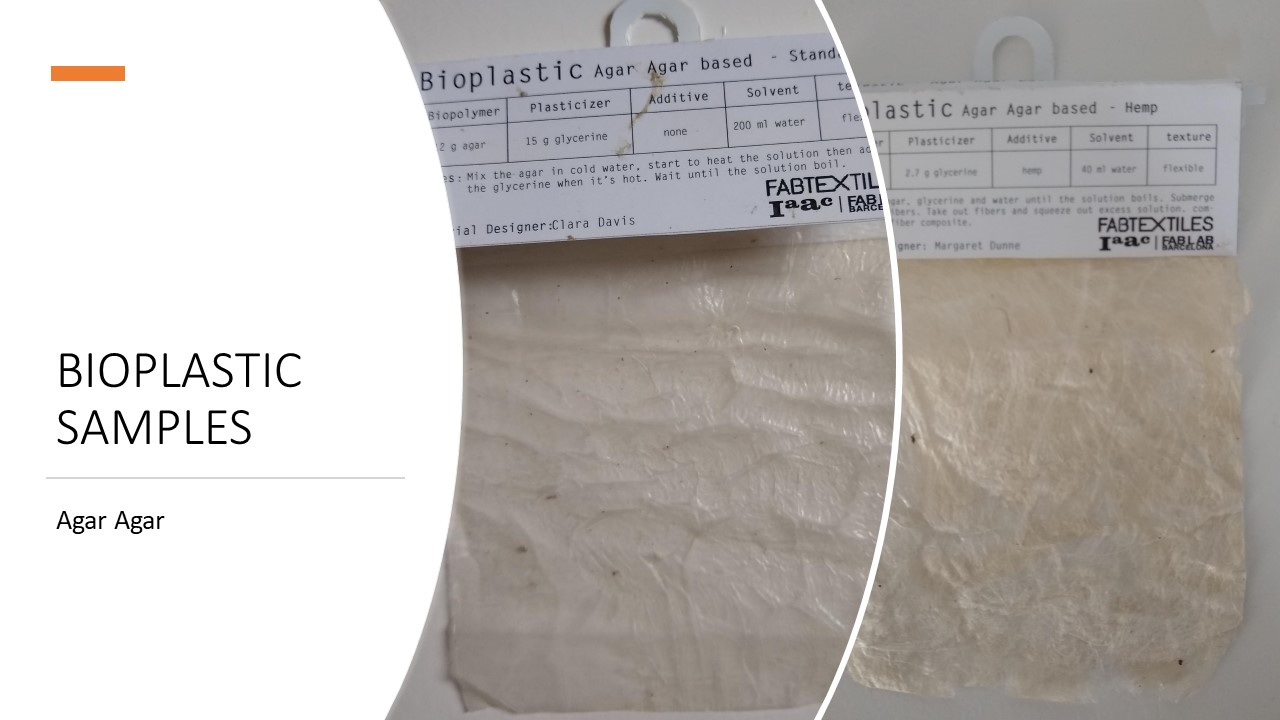

Some Bioplastic Samples¶

Goal to Achieve¶

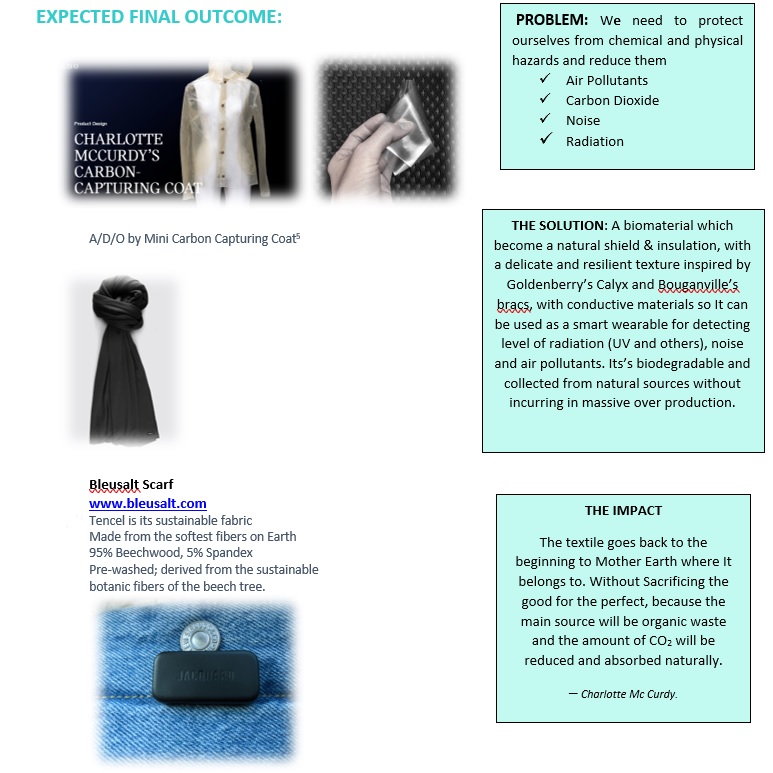

To create a biomaterial with a similar color, texture and properties of Goldenberry ’s calix and Bouganville’s fracs, the biomaterial should also be durable and resistant, so It can be used for creating slow fashion accessories such smart scarves, blouses and curtains that are light, with paper texture, durable and capable to protect us from any air pollutants and radiation, as well as, providing us a wide variety

of vibrant natural colors that can connect us with nature. The biomaterial can be recycled and used us compost in the future.

To create a biomaterial with a similar color, texture and properties of Goldenberry ’s calix and Bouganville’s fracs, the biomaterial should also be durable and resistant, so It can be used for creating slow fashion accessories such smart scarves, blouses and curtains that are light, with paper texture, durable and capable to protect us from any air pollutants and radiation, as well as, providing us a wide variety

of vibrant natural colors that can connect us with nature. The biomaterial can be recycled and used us compost in the future.

Materials and Tools¶

-Bioplastics Various Recipes made with Gelatine, Alginates, Agar and Micelium.¶

-High precision balance¶

-Magnetic Stirrer for minimizing air bubbles of bioplastics recipes.¶

-2 burner stove¶

-Beaker and Graduated Cylinder¶

-Mixing bawls¶

-Small pots with handles¶

-Dropper¶

-Chronometer¶

-Mortar and Pestle¶

-Heat resistant gloves, respiratory protection mask, goggles¶

-Recommended Safety Precautions: Prevent burns by and spills by carrying carefully the pots with the biomaterial recipes. In case of any spills clean them inmediately. Make sure you use small pots with hangers, apron and kitchen gloves.¶

Biomaterial Various Recipes and Documentation:¶

Useful Links:¶

- El Hilo Conductor (Thread Conector Peruvian Tradition and Fashion) Tradición y Moda en Perú by Olga Zaferson Aranzaes.

- Colores Historia de su significado y fabricación by Anne Varichon.

- Hoja Botánica del Aguaymanto elaborada por Proy. Peru Biodiverso (Mincetur y Minam).

- Aguaymanto Ficha Técnica Sierra Exportadora

- Agraria, F. p. (2017). Resultados y lecciones en cultivo de goldenberry (Physalis peruviana L.) en la zona central de Chile : proyecto de innovación en Región del Maule : Frutales / Berries. Recuperado el 30 de 10 de 2019, de http://bibliotecadigital.fia.cl/handle/20.500.11944/145587

- Bio Filter : bioplastic + activated charcoal

Biofabrication Process:¶

Biomaterial Tests: Traction, Abrasion, Color, Microscopic Views¶

Conclusions¶

-

A proper documentation of any design must include anthropologic, ethnographic, sociographic, biotechnology and neuroscience sources of information and data.

-

Due to its high water and temperature resistance I decided to work in a bio textile material made with Alginates and experiment with different type of fibers. Alginate Bioplastic is very heat resistant, even when casted in a thin film, it can withstand temperatures up to 150 degrees celsius. A second option will be to experiment with a mix of Agar and Alginate until we get the required smart biomaterial properties. A third option will be to experiment with macrobacteria such Mycelium+ Alginate + Organic Fibers due to its thermal conductivity and resistance, as well as, possible structure possibilities.

- Working with Alginate, Agar or Mycelium will enable us to minimize our water consumption in the fashion industry.

- By combining two functions of alginate gel and activated carbon, an activated carbon-containing alginate bead (AC-AB) adsorbent was developed and successfully used to simultaneously remove different heavy metal ions and toxic organics. With its high capacity and high selectivity for toxic heavy metals, the AC-AB adsorbent has enormous potential for application in drinking water treatment technologies. Quantitative analysis showed that almost all of the adsorption of toxic organics, such as p-toluic acid, is caused by the activated carbon in the AC-AB adsorbent, whereas the alginate component has a major role in the removal of heavy metals. A 50-L solution containing eight heavy metals (Pb2+, Mn2+, Cd2+, Cu2+, Zn2+, Fe2+, Al3+ and Hg2+) and four mineral ions was run continuously through a filter cartridge packed with 160 g of the AC-AB adsorbent. Additionally Alginate is a great source of storing energy and capturing CO2, that’s the main reason why we found quiet interesting mixing Alginates and Carbon.

- By combining two functions of alginate gel and activated carbon, an activated carbon-containing alginate bead (AC-AB) adsorbent was developed and successfully used to simultaneously remove different heavy metal ions and toxic organics. With its high capacity and high selectivity for toxic heavy metals, the AC-AB adsorbent has enormous potential for application in drinking water treatment technologies. Quantitative analysis showed that almost all of the adsorption of toxic organics, such as p-toluic acid, is caused by the activated carbon in the AC-AB adsorbent, whereas the alginate component has a major role in the removal of heavy metals. A 50-L solution containing eight heavy metals (Pb2+, Mn2+, Cd2+, Cu2+, Zn2+, Fe2+, Al3+ and Hg2+) and four mineral ions was run continuously through a filter cartridge packed with 160 g of the AC-AB adsorbent. Additionally Alginate is a great source of storing energy and capturing CO2, that’s the main reason why we found quiet interesting mixing Alginates and Carbon.

- According to the Alginates Data Sheet and Specifications, Alginates are capable to absorb and store a significant amount of water and nutrients. It’s pH level is usually slightly Alkaline. This tell us that our recipes might need a less amount of Activated Carbon than the recipes that were developed with regular gelatin.

- Some previous recipes had mix Gelatin with Activated Carbon and depending of the recipe some of them had been more conductive than others, although I would like to experiment with the mix of Alginates and Activated Carbon for possible smart wearables.

- The most common used materials for the sensor implementation are conductive textile materials that can be yarns that ensure fabricating of textile electrodes via such conventional textile manufacturing technologies as weaving, knitting and embroidery. Another approaches offer solutions implemented via inkjet and screen printing, and such thin film technologies as sol-gel and sputtering methods (Xie, Yang, 2013; Rattfält, Björefors, 2013; Cho, Jeong, 2011). The textile electrodes fabricated by the mentioned conventional techniques demonstrate though higher efficiency in performance and usage (washing).

- The biological function of Alginates is to give strength and flexibility to the algal tissue and regulate the water content in the seaweed. It is these properties along with the ability to produce fibres from its isomers, which make Alginate the ideal wound dressing or a second skin garment. Alginate fibre will employ active fabrics that do not require work from the human body to provide their benefits. Fusion between fiber science and space technologies, optics, and pharmacy will be inevitable in the coming future.

- Due to main characteristics of biomaterials based with Alginates, Agar, Gelatine and Activated Carbon, in order to achieve our biomaterial goals. I must do further research in the natural properties of the main natural protective wrapping systems, its chemical structures, so we can apply some biomimicry when we start experimenting with the possible recipes.

- The development of desired material can be used in smart garments such Chameleon Mood Scarfs or Dynamic Skin Clothing due to desired functions, chemical and physical properties of the biomaterial. Perhaps by adding thermochromic inks: thermochromic liquid crystals (TLCs) and leuco dyes we could improve the biomaterial properties to the next level after evaluating the respective cost& benefits for instance.

- Some previous recipes had mix Gelatin with Activated Carbon and depending of the recipe some of them had been more conductive than others, although I would like to experiment with the mix of Alginates and Activated Carbon for possible smart wearables.

- The most common used materials for the sensor implementation are conductive textile materials that can be yarns that ensure fabricating of textile electrodes via such conventional textile manufacturing technologies as weaving, knitting and embroidery. Another approaches offer solutions implemented via inkjet and screen printing, and such thin film technologies as sol-gel and sputtering methods (Xie, Yang, 2013; Rattfält, Björefors, 2013; Cho, Jeong, 2011). The textile electrodes fabricated by the mentioned conventional techniques demonstrate though higher efficiency in performance and usage (washing).

- The development of desired material can be used in smart garments such Chameleon Mood Scarfs or Dynamic Skin Clothing due to desired functions, chemical and physical properties of the biomaterial. Perhaps by adding thermochromic inks: thermochromic liquid crystals (TLCs) and leuco dyes we could improve the biomaterial properties to the next level after evaluating the respective cost& benefits for instance.

- According to the Alginates Data Sheet and Specifications, Alginates are capable to absorb and store a significant amount of water and nutrients. It’s pH level is usually slightly Alkaline. This tell us that our recipes might need a less amount of Activated Carbon than the recipes that were developed with regular gelatin.

- Some previous recipes had mix Gelatin with Activated Carbon and depending of the recipe some of them had been more conductive than others, although I would like to experiment with the mix of Alginates and Activated Carbon for possible smart wearables.

- The most common used materials for the sensor implementation are conductive textile materials that can be yarns that ensure fabricating of textile electrodes via such conventional textile manufacturing technologies as weaving, knitting and embroidery. Another approaches offer solutions implemented via inkjet and screen printing, and such thin film technologies as sol-gel and sputtering methods (Xie, Yang, 2013; Rattfält, Björefors, 2013; Cho, Jeong, 2011). The textile electrodes fabricated by the mentioned conventional techniques demonstrate though higher efficiency in performance and usage (washing).

- The biological function of Alginates is to give strength and flexibility to the algal tissue and regulate the water content in the seaweed. It is these properties along with the ability to produce fibres from its isomers, which make Alginate the ideal wound dressing or a second skin garment. Alginate fibre will employ active fabrics that do not require work from the human body to provide their benefits. Fusion between fiber science and space technologies, optics, and pharmacy will be inevitable in the coming future.

- Due to main characteristics of biomaterials based with Alginates, Agar, Gelatine and Activated Carbon, in order to achieve our biomaterial goals. I must do further research in the natural properties of the main natural protective wrapping systems, its chemical structures, so we can apply some biomimicry when we start experimenting with the possible recipes.

- The development of desired material can be used in smart garments such Chameleon Mood Scarfs or Dynamic Skin Clothing due to desired functions, chemical and physical properties of the biomaterial. Perhaps by adding thermochromic inks: thermochromic liquid crystals (TLCs) and leuco dyes we could improve the biomaterial properties to the next level after evaluating the respective cost& benefits for instance.

- Mycellium is a great biomaterial option for eco deco and construction due to its wonderful adhesion and union properties, although I found that

- working with only vegan natural fibers will assemble much better.

Main References¶

SUZANNE LEE Biocouture¶

Biocouture - Suzanne Lee from LAUNCH on Vimeo.

NERI OXMAN¶

TED TALKS - Neri Oxman from hazel on Vimeo.

Robert Thompson | Creating from Everyday Waste¶

Robert Thompson | Creating from Everyday Waste from urbanNext on Vimeo.

BIND Biofilm¶

BIND Biofilm from Wyss Institute on Vimeo.

Aguaymanto Physalis Peruviana¶

Physalis - Huari from Ollantay Sánchez Valle on Vimeo.