4. BioChromes¶

Context¶

"The textile industry is one of the most polluting and unsustainable in the world. Among its most harmful stages is fabric dyeing, where millions of tons of untreated chemicals are released into rivers each year. After the Industrial Revolution, the discovery of the first synthetic dye — mauveine — in 1856 by William Henry Perkin marked the beginning of an era of industrial and unsustainable color production. Synthetic dyes, derived from petroleum and heavy metals, consume vast amounts of water and energy, leaving a lasting impact on the environment.

-

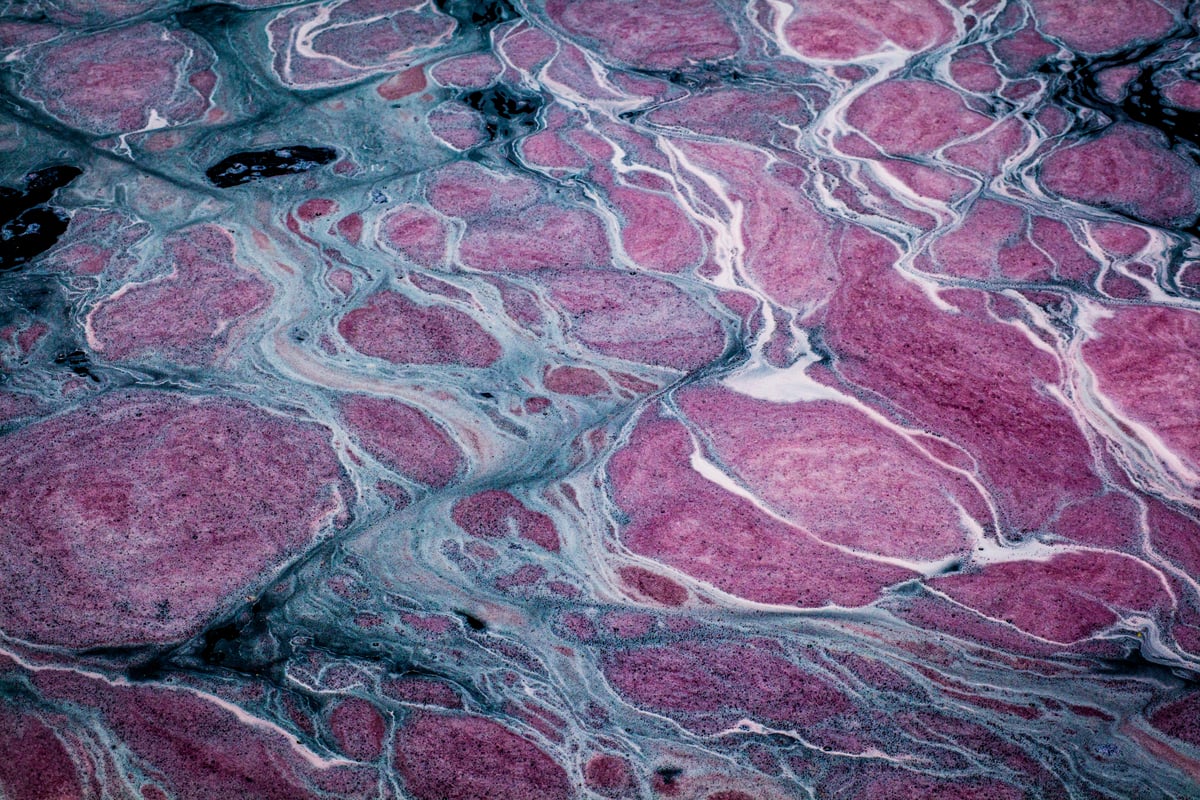

Image of dyes dumped in ocean waters by fast fashion factories from Greenpeace, Cihaur River, greenpeace.org*

-

Image of a landfill with mountains of clothes due to fast fashion from the University of Queensland, psci.princeton.edu.*

Sustainable Color: Key Milestones¶

1960s–70s: Ecological Awareness¶

Post-WWII synthetic dyes raised toxicity concerns. Environmental movements and Rachel Carson’s Silent Spring (1962) sparked interest in natural dyes. Miriam Rice pioneered mushroom-based pigments, inspiring artists and craft workshops.

Refs: Rice, M. The Art of Natural Dyeing; Carson, R. Silent Spring

1990s–2000s: Eco-Fashion¶

Fashion began exploring biodegradable dyes and non-toxic mordants (alum, tannins). Techniques reduced water and energy use.

Refs: Fletcher, K. Sustainable Fashion and Textiles; Shen, L. & Li, Y. Eco-friendly Dyeing

2010s–Present: Biochromes & Biodesign¶

Artists and researchers cultivate pigment-producing bacteria, fungi, algae, and yeasts (“living colors”). Projects include Biodesign Challenge and Fabricademy.

Focus: dyes from plant/food waste (turmeric, beetroot), chromogenic bacteria (Janthinobacterium, Streptomyces, Serratia), biological printing, and living textiles.

Goal: circular, post-petroleum color economy.

Refs: Hodge, C. Biochromes: Living Color in Design

Biochromes propose

- Reconnecting color to nature and its regenerative processes

- Combining traditional craftsmanship and biotechnology

- Using sustainable color sources: 🌿 plants, 🐛 insects, 🦠 bacteria — in sustainable form

Biochromes¶

"THEY ARE NOT JUST NATURAL DYES, BUT BIOLOGICAL SYSTEMS THAT GENERATE COLOR IN A SUSTAINABLE, DYNAMIC, AND INTERACTIVE WAY

BIOCHROMES = "biological pigments," [living colors] meaning colors produced biologically by microorganisms, plants, or natural reactions.

They are opposed to synthetic pigments (derived from petroleum) because:

- 0 waste

- biobased and biodegradable, often non-toxic,

- locally positive: they can be grown or extracted in the laboratory or kitchen.

These substances represent a sustainable response to the environmental impact of synthetic dyes.

Biochromes emerge as an expression of an ecological and circular approach to design, in which color becomes not only an aesthetic element but also a tool for critical reflection on the provenance, durability, and biodegradability of materials.

Natural Color Sources¶

| Domain | Source | Color Archive | |

|---|---|---|---|

| Organic | Animal | INSECT, MOLLUSC | |

| Bacterial | BIOSHADES.bio TCBL, TextileLab AMSTERDAM,C.raspanti, N.Papakostantinou |

||

| Botanical | PLANTS, SEEDS, FRUITS, FLOWERS, STEMS, LEAVES, BARK, ROOTS, BERRIES, WOOD, ALGAE | BIOCRHOMES.org COLOR ARCHIVE Local color, TEXTILELAB AMSTERDAM |

|

| Composite | |||

| Fungal | MUSHROOMS, MOLDS | Miriam Rice, MUSHROOMCOLORATLAS.org by Julie Beeler | |

| Inorganic | Mineral | MINERALS, OXIDES, OCHERS, EARTHS, SOILS, CLAY, SALTS, METALS | ANE BAZTARRIKA 2016, TextileLab AMSTERDAM |

Same biological color source can be transformed into multiple forms depending on whether it needs to penetrate, coat, or flow on a surface, we can obtain inks, dyes, and pigments.

Classification of the major natural pigments

Ding, N., Zhou, Y., Dou, P., Chang, S. K. C., Feng, R., Hong, H., Luo, Y., & Tan, Y. (2024). Colorful and nutritious abundance: Potential of natural pigment application in aquatic products. Food Innovation and Advances, 3(3), 232–243. https://doi.org/10.48130/fia-0024-0023

Biochromes forms¶

Natural vs Synthetic Fibers Source - cottonworks.com

Source - cottonworks.com

Natural Fibers Classification¶

| Category | Source | Examples | Characteristics |

|---|---|---|---|

| 🐑 ANIMAL FIBRES (Protein fibres) | Wool / hair fibres | Sheep, alpaca, goat (cashmere, mohair), camel, rabbit (angora) | Elastic, warm, sensitive to heat and pH |

| Silk fibres | Silkworm Bombyx mori, wild silk (tussah) | Smooth, lustrous, very absorbent | |

| Other protein fibres | Milk (casein fibre), feathers | Sensitive to alkaline pH | |

| 🌿 VEGETAL FIBRES (Plant fibres) | Fibre from seed | Cotton, kapok | Soft, short, resistant, good absorption |

| Fibre from bast (liber) | Flax, hemp, jute, nettle | More rigid, long, excellent breathability | |

| Fibre from leaf | Sisal, abacá | Resilient, rough texture | |

| Fibre from fruit or residue | Coconut, banana | Coarse, absorb less dye |

THREADS, YARNS, FABRICS AND FELTS

| Category | Description | Structure / Use | Notes on Dyeing |

|---|---|---|---|

| Threads | Long continuous fibres spun for sewing or weaving | Continuous, fine, strong | Smooth surface; absorbs dye evenly |

| Yarns | Twisted threads (single or double) used for knitting or weaving | Twisted structure adds strength and elasticity | Twist density can affect dye penetration |

| Fabrics | Woven, knit or felted surfaces (plain, satin, twill, knit) | Formed from interlaced or looped yarns | Density and weave type influence dye uptake |

| Felts | Wool or blended fibres compacted with moisture, heat and pressure | Non-woven, dense structure | High dye absorption due to open fibre network |

Fabric creation methods: felting weaving knitting

Fibers Preparation¶

| Step | Description |

|---|---|

| 1. Make Skeins / Cut Tissue Samples | Make skeins of the yarn and threads – 4× around the arm (depending on fibre volume – 3, 5 or 8). Cut tissue samples. |

| 2. Weight of Fibres (WoF) | Weigh the dry fibres. Then calculate and weigh the tannin, scouring agent, mordant, and dyestuff based on the Weight of Fibre (WoF). |

| 3. Scouring Bath | Animal fibres: Rinse gently with lukewarm water and a little pH-neutral soap. Avoid temperature shock, which can damage animal fibres. Vegetal fibres: Boil for 30 minutes with sodium carbonate (soda ash) – 2 tablespoons for 4 litres of water. |

| 4. Tannin Bath | (Optional – for vegetal fibres only) Boil for 30 minutes in water with 10–15% tannin (based on WoF). Remove fibres and rinse. Improves mordanting. |

| 5. Mordant Bath | Animal fibres: Submerge in lukewarm water with 10–20% alum (WoF) and 5–10% cream of tartar or vinegar (WoF). Gently simmer, then turn off the heat and leave fibres in the bath for 1 hour. Avoid temperature shock. Vegetal fibres: Boil with 8–10% alum (WoF), then turn off the heat and leave fibres in the bath for 1 hour. |

Mordants and Scouring Agent¶

| CATEGORY | EXAMPLES | CHEMICAL NAME / FORMULA | PURPOSE |

|---|---|---|---|

| SCOURING AGENTS | SODA ASH (Na₂CO₃), NEUTRAL SOAP | Sodium carbonate, Na₂CO₃ | Used before mordanting to clean plant fibres (cotton, linen, hemp) from waxes and oils; raises pH. |

| MORDANTS | ALUM (KAl(SO₄)₂), IRON (FeSO₄), COPPER (CuSO₄) | Potassium aluminium sulphate, KAl(SO₄)₂ | Creates a bridge between fibre and dye molecules (bind dye to fibre); improves colour absorption and fastness. Used for both plant and animal fibres. |

| ASSISTANTS / PH MODIFIERS | CREAM OF TARTAR (KC₄H₅O₆), VINEGAR, LEMON JUICE | Potassium hydrogen tartrate, KC₄H₅O₆; Acetic acid; Citric acid | Used together with alum to stabilize pH and brighten colours (especially for wool and silk). Adjust pH, modify tone or brightness of colour. |

| FIXATIVES / ADDITIVES | SALT (NaCl), SODA (NaHCO₃) | Sodium chloride, NaCl; Sodium bicarbonate, NaHCO₃ | Helps fix natural dyes on fibres; modifies hue or saturation during dyeing. |

Inspiration!

-

Dye book - Isobel Leonard - TextileLab Amsterdam Waag FutureLab

-

Inks & folds - Germarillis Ruiz - FabLab Bcn

-

Woven documentation matrix - Riley Cox - TextileLab Amsterdam

-

Comparison inks - Stephanie Johnsons - TextileLab Amsterdam

-

Documentation formats - Julia Karas - FabLab Bcn

-

Artistic intervention - Kate Reed - Dassault Systems

Research¶

References & Inspiration¶

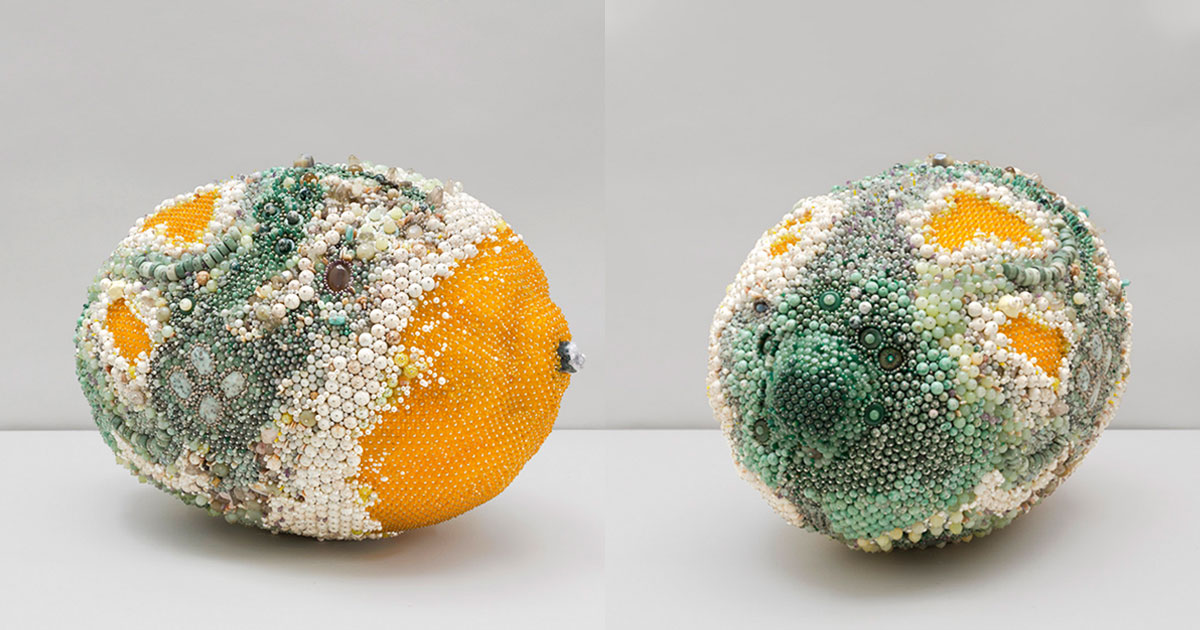

I am fascinated by nature and all the resources it can offer. I dream of a sustainable world, driven from the ground up, and I believe that combining ancestral practices with modern technology is the most positive way to move toward the future. Works such as Kathleen Ryan’s mold sculptures, Dasha Plesen’s slime mold creations, Natsai Audrey’s bacterial textile patterns, and the color experiments by Kathy Hattori, MycoPigments, and Sasha Duerr have inspired me to experiment and explore. I enjoy letting curiosity guide the process, embracing unexpected results, and discovering new possibilities for innovation and expression.

BioChromes Inspiration Moodboard by Carlotta Premazzi

BioChromes Inspiration Moodboard by Carlotta Premazzi

- Kathleen Ryan ‘green-eyed monster’, 2019, image courtesy of françois ghebaly, designboom.com

- One of many slime mold creations from Dasha Plesen, yahoo.com.

- Natsai Audrey, Color Patterns in the Clothes of the Future will be Made by Bacteria, abiotech.eu

- Kathy Hattori, Botanical Colors Eco Print Scarf, botanicalcolors.com

- mushroom and lichen dye palettes, mycopigments.com

- The Seasonal Color Wheel by Sasha Duerr, botanicalcolors.com

Process and workflow¶

A collaborative works and tuts pictures by CARLOTTA PREMAZZI, BERRAK ZEYNEP OKYAR

Tutor: CAROLINA DELGADO | Lab Assistant: MAGDA BARREIRA.

Protocols from BioChromes with Food waste. Introduction to Natural Dyeing Workshop - Carolina Delgado, CIAUD, Lisbon, Portugal

about tuts images

-

Biolab Images credit: CARLOTTA PREMAZZI and BERRAK ZEYNEP OKYAR

-

Images credit: CECILIA RASPANTI

-

Images is optimised in size with resolution 72 and passed through tinypng for final optimisation.

GENERAL TIPS

- be precise and clean, write down everything, every little detail produces big changes

- Clean the syringe with alcool 70% and distilled water and put glycerin on the rubber of the syringe and worked very well

Tools & Ingredients¶

TOOLS

- INOX POT AND CONTAINERS

- SCOOPS

- SCALE

- STOVES

- INDUCTION PLATE

- PH TEST

- GLASS CONTAINERS

- MAGIC WAND

- COFEE FILTER

- PAINTBRUSH

INGREDIENTS

- NATURAL SOURCE

- NATURAL SOAP

- FIBERS

- PAPERS

- DISTILLED WATER

- ALCOHOL

- SODA ASH

- ALUM

- SODIUM ALGINATE

- GLICERUN

- ARABIC GUM

Fiber Preparation¶

ingredients

- ALUM (Potassium aluminium sulphate) KAl(SO4)2 [10% =7,3 g]

- TARTAR (Potassium bitartrate) KC4H5O6 [5%=4.05 g ]

- 1,4 ml DISTILLED WATER

- NATURAL SOAP

- FIBERS 72,9g

fibers

- 100% WOOL ROW PORTUGUESE MERINO SHEEP,* 100% WOOL ROW(7MM) * PORTUGUESE MERINO SHEEP

- COTTON SHEETS

- RAW COTTON

- RECYCLED COTTON

- 100% LINEN OLD

- COTTON

- COTTON

- 100% SILK

tools

- INOX POT AND CONTAINERS

- SCOOPS

- STOVES

- INDUCTION PLATE

-

Make Skeins of the yarn and threads – 4 x around the arm (depending on fibre volume - 3, 5 or 8).

-

Weight of Fibres (WoF) Weight the dry fibres and, calculate and weight tannin, scouring agent, mordant and Dye stuff.

6/2 samples for each fibers -

Scouring Bath

Animal: Rinse gently with luke water and a little soap (pH neutral soap). Avoid shocking with hight temperature damages animal fibres.

Vegetal: Boil 30 min with sodium carbonate (Soda ash) - 2 tbs for 4 Lt water. -

Mordant Bath

Animal:Submerge with luke water with 10-20% Alum/ WoF, and 5-10% cream tartar/ WoF (cream tartar, or vinegar), and gently simmer. Dip fibres in the bath (turn off) for 1 h. Avoid shocking temperature.

Vegetal: Boil in 8-10% alum/ WoF, dip fibres in the bath (turn off) for 1 h.

OBSERVATION

- if you want use it with modifiers make almost 3 skeins-samples for each fiber.

- Clean the syringe with alcool 70% and distilled water and put glycerin on the rubber of the syringe and worked very well

Recipes¶

Red Cabbage Dye¶

ingredients

- 170 gr RED CABBAGE

- 1,4l DISTILLED WATER

- 72,9g gr FIBERS

tools

- PH TEST

- GLASS CONTAINERS

- SCOOPS

- INDUCTION PLATE

recipe

- 100 gr Red cabbage and 1 Lt water, boil 1 hour. Water will evaporate to 1/3.

- Remove the cabbage pieces.

- Add fibres and simmer for 40 min at 80ºC. (Leave in bath 12h).

- Measure pH (approx. pH 5) divide fibres in 3. 1/3 rinse and dry.

Red Cabbage Dye Modifies¶

ingredients

- 400 ml RED CABBAGE DYE (100 ml each modify)

- 0,5 g SODIUM ALUM

- 0,026 g SODA

- SODIUM ALGINATE

- 72,9g gr FIBERS

tools

- PH TEST

- GLASS CONTAINERS

- SCOOPS

- INDUCTION PLATE

recipe

- Modify with acid bath: pH 2/3, with alum (or tbs vinegar or lemon juice). 2. Submerge 2/3 of materials for 5 min. Rinse and leave to dry.

- Modify with alkaline bath: pH 9/10, with soda ash. Measure the water pH and then adjust it starting with 1g per 0,5 L water.

- Submerge 3/3 of materials for 5 min.(for ACID MODIFICATION 5 min, for Alkaline 1 min) Rinse and leave to dry.

- Unmodified fibers Bath , 30 minutes | Acid-modified fibers Bath, 5 minutes | Alkaline-modified fibers Bath, 1 minute.

| INGREDIENTS | A_ACID | B_NEUTRAL | C_ALKALINE | D_ALKALINE |

|---|---|---|---|---|

| CABBAGE DYE | 100ml | 100ml | 100ml | 100ml |

| pH MODIFIERS | +0,5g ALUM | +0,03g SODA ASH | SODA ASH +0,2g | |

| pH TEST | pH3 | pH6 | pH7-8 | pH11 |

| EXPETED COLOR | pink | purple | blue-purple | green |

| OBTAINED COLOR | purple-red | purple | blue | green |

BATH TIMING

- The stronger the alkalinity, the shorter the fiber should stay in the red cabbage dye bath. The natural pigment in red cabbage, anthocyanin, is highly pH-sensitive, in highly alkaline environments (pH > 10), the pigment breaks down quickly; the color may fade, turn grayish, or disappear completely if left too long.

- Suggested guideline: ** Alkalinity level Soda Ash amount Estimated pH Time in dye bath ** Light ~0.03 g ~7.5–8 up to 1–2 min ** Medium ~0.06 g ~9 max 1 min ** Strong ~0.2 g ~10.5–11 30–45 seconds ** Very Strong >0.2 g >11 15–30 seconds ⚠️

OBSERVATION

- Fist cabbage dye was very weak, a second one was made the day after.

- Merino Wool from Alentejo, Portugal [Zagal and João Yarn from Rosa Pomar Brand]It is very hard to dye; with a first bath, it dyed almost nothing in the planned time.

Red Cabbage Bio Yarn/Bioscreen/Biomaterial¶

ingredients

- 600 ml CABBAGE DYE (150 ml each modify)

- 10ml GLICERIN

- 4gr SODIUM ALGINATE

- 72,9g gr FIBERS

tools

- PH TEST

- GLASS CONTAINERS

- SCOOPS

- MAGIC WAND

recipe

- Mix with glycerin and sodium alginate with a kitchen wand [alginate-based material]

- tested on paper and fabric

- Insert into a syringe and create the thread inside the water without letting the syringe touch or immerse in the liquid

- remove the threads from the liquid and dry

- alginate-based mold stored in dehydrator

| INGREDIENTS | A_ACID | B_NEUTRAL | C_ALKALINE | D_ALKALINE |

|---|---|---|---|---|

| CABBAGE DYE | 100ml | 100ml | 100ml | 100ml |

| GLICERIN | 10ml | 10ml | 10ml | 10ml |

| SODIUM ALGINATE | 4g | 4g | 4g | 4g |

OBSERVATION

- Tool Preparation_ Syringes: Wash thoroughly with alcohol and distilled water; for smoother handling and easier extrusion, apply a small amount of petroleum jelly (Vaseline) around the inner tip. Molds: Clean with alcohol and distilled water. Then spray a fine mist of calcium chloride solution (e.g. 5–10%) inside the mold before pouring the alginate mixture.This initiates surface-level gelation and helps release the final bioplastic form, ensuring the alginate doesn't stick to the mold walls. ⚠️ Be careful not to inhale the mist — use in a well-ventilated area.

- The bio-alginate yarns, when freshly made, were shiny, plump, and beautifully colored.

- Once dried, they lost elasticity, color, and volume.

- The molds, however, produced visually interesting biomaterials — with vibrant colors and partially transparent areas that enhanced their aesthetic appeal.

Recycling Red Cabbage Dye into pigments¶

ingredients

- 100 ml leftover RED CABBAGE DYE( solution )

- 200 ml DISTILLED WATER

- 10 g ALUM (Potassium aluminium sulphate) KAl(SO4)2

- 5 gr SODA ASH (Sodium Carbonate)

tools

- PH TEST

- GLASS CONTAINERS

- SCOOPS

- SCALE

- INDUCTION PLATE

- INOX POT AND CONTAINERS

recipe

- The Red cabbage Dye was stored and reduced, obtain 100 ml.

- Mix distilled water with alum (100ml+10g)

- Mix distilled water with soda ash(100ml+5g)

- Mix Red cabbage Dye with alum solution and then with the soda ash solution in a high jar

- Tested dye on paper

- Tested dye on fibers (4 days bath)

- Stored in the fridge 3 days

- Filter with a coofee filter, dry and storage

OBSERVATION

- The sostance is filtering for create the lake pigment, obtaining a powerfull blue pigment.

Using the Lake Pigments¶

Once you’ve obtained and filtered your lake pigment, you can transform it into different kinds of natural paints and inks:

| Application | Binder / Medium | Result | Drying Time | Durability | Notes |

|---|---|---|---|---|---|

| Watercolor | Gum arabic + few drops of glycerine | Transparent, fluid paint | 1–2 hours | Medium | Adjust water amount for opacity; reactivates with water |

| Oil paint | Linseed oil | Dense, glossy texture | 2–5 days | High | Grind well to avoid lumps; cures over time |

| Tempera | Egg yolk | Matte, quick-drying finish | 30–60 min | High | Prepare small quantities; perishable binder |

| Ink | Alcohol or vinegar + few drops of gum arabic | Fluid, deep color | 15–30 min | Medium–Low | Filter for smoother flow; store in closed bottle |

| Bioleather / Bioplastic tinting | Mix pigment into gelatin, agar, or starch base | Natural coloration | 24–48 hours | Medium | Add before casting for even tone; dry slowly to prevent cracks |

Hibiscus sabdariffa L. Dye¶

ingredients

- 60gr HIBISCUS sabdariffa L. (Happy flora)

- 1,4l DISTILLED WATER

- xxx gr SODA ASH (Sodium Carbonate)

- 72,9g gr FIBERS

tools

- PH TEST

- GLASS CONTAINERS

- SCOOPS

- INDUCTION PLATE

recipe

- 100 gr of Hibiscus flowers into +/- 2Lt. After boiling, turn to 80ºC for 30/45 min.

- Submerge the materials for 30 min. Turn off and keep in the bath all night for darker reds (lighter shades of pink take them after 30min).

- Measure pH (approx. pH 2) and divide fibres in 3. 1/3 rinse and dry.

Hibiscus sabdariffa L. Dye Modifies¶

recipe

- Modify with acid bath: pH 2/3, with alum (or tbs vinegar or lemon juice). 2. Submerge 2/3 of materials for 5 min. Rinse and leave to dry.

- Modify with alkaline bath: pH 9/10, with soda ash. Measure the water pH and then adjust it starting with 1g per 0,5 L water.

- Submerge 3/3 of materials for 5 min. Rinse and leave to dry.

| INGREDIENTS | A_ACID | B_NEUTRAL | C_ALKALINE |

|---|---|---|---|

| HIBISCUS DYE | 120or150ml | 120or150ml | 120or150ml |

| SODA ASH | 1,25g | +2,15g | |

| pH TEST | pH2 | pH6-7 | pH9-11 |

| EXPETED COLOR | Bright red | Lavender/purple | Blue to greenish |

| OBTAINED COLOR | Strong red | Softgray-dark gray with a slight hint of blue | kaki-brown-DarkOliveGreen |

BATH TIMING

- The more alkaline the bath, the shorter the exposure time, to prevent degradation of hibiscus color and fibers. The natural pigment in red cabbage, anthocyanin, is highly pH-sensitive, in highly alkaline environments (pH > 10), the pigment breaks down quickly; the color may fade, turn grayish, or disappear completely if left too long.

- Suggested guideline: ** Alkalinity level Soda Ash amount Estimated pH Time in dye bath ** Acid Base ~0.03 g ~7.5–8 30 min ** Mild Alkaline ~0.06 g ~9 3–5 min ** Strong Alkaline >0.2 g >11 1 min

A – Acidic Base None ~pH 2 30 minutes Bright pink / magenta B – Mild Alkaline +1.25 g ~pH 6–7 3–5 minutes Purple-grey / mauve C – Strong Alkaline +2.15 g ~pH 9–11 1 minute Grey-green / dull olive

OBSERVATION

- The hibiscus dye produced an acidic, bright pink color.

- Sample A resulted in a stronger pink tone, Sample B in a lighter pink leaning toward lilac, and Sample C showed hues shifting toward greenish-blue and violet.* Once dried, the colors faded significantly — except for the recycled cotton yarn, which retained more intensity.

- Merino Wool from Alentejo, Portugal [Zagal and João Yarn from Rosa Pomar Brand]It is very hard to dye; with a first bath, it dyed almost nothing in the planned time. Hibiscus wool samples were left to soak overnight in the unmodified solution and did not produce a satisfactory result.

- During drying, the fabrics overlapped slightly, creating soft melange color effects.

- The second round of Hibisco Modifies produced very strong dark colors

Hibiscus sabdariffa L. Bio Yarn/Bioscreen/Biomaterial¶

ingredients

- ?ml CABBAGE DYE

- 10ml GLICERIN

- 4gr SODIUM ALGINATE

- 72,9g gr FIBERS

tools

- PH TEST

- GLASS CONTAINERS

- SCOOPS

- MAGIC WAND

alginate BioChromes silkscreen paint in prep linen, applied with brush without the silkscreen

alginate BioChromes silkscreen paint in prep linen, applied with brush without the silkscreen

recipe

- Mix with glycerin and sodium alginate with a kitchen wand [alginate-based material]

- tested on paper and fabric

- Insert into a syringe and create the thread inside the water without letting the syringe touch or immerse in the liquid

- remove the threads from the liquid and dry

- alginate-based mold stored in dehydrator

| INGREDIENTS | A_ACID | B_NEUTRAL | C_ALKALINE |

|---|---|---|---|

| HIBISCUS DYE | 120ml | 120ml | 120ml |

| GLICERIN | 10ml | 10ml | 10ml |

| SODIUM ALGINATE | 4g | 4g | 4g |

OBSERVATION

- Tool Preparation_ Syringes: Wash thoroughly with alcohol and distilled water; for smoother handling and easier extrusion, apply a small amount of petroleum jelly (Vaseline) around the inner tip. Molds: Clean with alcohol and distilled water. Then spray a fine mist of calcium chloride solution (e.g. 5–10%) inside the mold before pouring the alginate mixture.This initiates surface-level gelation and helps release the final bioplastic form, ensuring the alginate doesn't stick to the mold walls. ⚠️ Be careful not to inhale the mist — use in a well-ventilated area.

- the Hibiscus A Dyed was too liquid for the Yarn Production, the red dye not work for extruding suggests that is because of hibiscus behind to acid. Future note: dilute more in water may alter the colour concentration but help on this effect. *After drying in the dehydrator: the yarns were very dull, stiff, and dry. The biomaterial discs showed different results:

- Sample A was very dry and hard;

- Sample B was too thick and didn’t dry properly, showing mold — it was left to dry further with a small fan for one more day;

- Sample C was soft and transparent.

Hibiscus sabdariffa L. Ink¶

ingredients

- 60 gr used Hibiscus

- 100ml DISTILLED WATER

- 200ml alcohol

- 0,05-10g ARABIC GUM

tools

- SCALE

- GLASS RECIPES

- SCOOPS

- COFEE FILTER

recipe

- 1 hour Hibiscus bath with alcool

- Filter with a coffee filter

- Test on acquarela paper

- Prepare Arabic Gum with Distilled water (50º)

- Mix the Arabic Gum prepared with hibiscus ink for thickness

- Stored in the fridge Hibiscus used and Hibiscus dye

OBSERVATION

- The Hibiscus Ink was very liquid and acidic, so I gradually added gum arabic to thicken it. When added cold, the gum arabic didn’t dissolve properly — it needs to be prepared with distilled water at around 50ºC. The final texture of the ink was not fully satisfactory, and the mixture caused a color shift toward gray. After three days, the filtered ink appeared grayish when tested on watercolor paper.

TIPS

- Prepare Arabic Gum in a 50º solution

Turmeric Ink¶

ingredients

- 4 gr turmenic podwer

- 200ml alcohol

tools

- SCALE

- GLASS RECIPES

- SCOOPS

- COFEE FILTER

recipe

- Mix turmeric powder with alcohol and stir

- Tested ink after 1 hour

- Stored in the fridge

OBSERVATION

- The Turmeric Ink produces a bright, vibrant yellow.

Paprika Ink¶

ingredients

- 4 gr paprika podwer

- 200ml alcohol

tools

- SCALE

- GLASS RECIPES

- SCOOPS

- COFEE FILTER

recipe

- Mix paprika powder with alcohol and stir

- Tested ink after 1 hour

- Stored in the fridge

OBSERVATION

- Paprika Ink stays very light even after 3 days in the bath, resulting in a soft peach color.

- Mixed with the Turmeric Ink, it turns into a ssoft yellow/light peach shade.

Documenting experiments¶

Still preparing the final swatches archive, the fibers are pressed with weights to avoid being ironed with heat.

RESULTS_Hibisco Dye Result on fibers/paper_¶

Dye Test on paper and fibers by Carlotta Premazzi

Dye Test on paper and fibers by Carlotta Premazzi

| A | B | C | |

|---|---|---|---|

| pH Modification | +1,25g SA | + 2,15g SA | |

| alginatebioscreen | acqaurela paper | acqaurela paper | acqaurela paper |

| alginatebioscreen | linen | linen | linen |

| alginatebioscreen | cotton | cotton | cotton |

| alginatebioscreen | acqaurela paper | acqaurela paper | acqaurela paper |

| dye | paper | paper | paper |

| dye | linen | linen | linen |

| dye | cotton | cotton | cotton |

| dye | cotton sheets | cotton sheets | cotton sheets |

| dye | silk | silk | silk |

RESULTS_Ink Result on Acquarela paper_¶

Ink Test on aquarela paper by Carlotta Premazzi

Ink Test on aquarela paper by Carlotta Premazzi

| Cabbage Dye | Hibisco Ink | Turmenic Ink | T+P Ink | Paprika Ink |

|---|---|---|---|---|

| 200ml alcohol | 200ml alcohol | 200ml alcohol | ||

| 60g flowers | 4g podwer | 4g podwer | ||

| BLUE-GREEN-VIOLET | GRAY | YELLOW | PEACHY YELLOW | LIGHT PEACH |

- Lecture on October 7st, 2025 Global Instructor: Cecilia Raspanti

- Tutorial on October 8st, 2025 Global Instructor: Cecilia Raspanti

- Local Tutor: Carolina Delgado

🔗 References & Tutorials

- Make Ink : A Forager's Guide to Natural Inkmaking

- NATURAL PALETTES: Inspiration from Plant-based Color

- Botanical Inks: Plant-to-Print Dyes, Techniques and Projects

- Tintes-Mexicanos-Leticia-Arroyo-Ortiz

- https://www.wildcolours.co.uk/

- https://biochromes.archivesofthefuture.org/

- https://localcolor.amsterdam/

- Soft tools - Stephanie Vilayphiou - GreenLab

Learning outcomes

- Research skills: the participant has acquired knowledge through references and concept development

- Technical skills: Master techniques mordanting, dyeing (botanical or bacterial), pigments

- Process skills: Anyone can go through the workflow and recipes, understand them and reproduce it

- Final outcome: the participant understands various stages of color as: dye, inks and pigment

- Originality: Has the research been thought through and elaborated?

Student checklist

- [ ] Include some inspiration: research on artists or projects that on natural/bacterial dyeing, local ingedients and resources

- [ ] Produce at least 1 natural dye with modifiers on fabric

- [ ] Produce 1 ink OR 1 pigment

- [ ] Document your recipes, the ingredients and process and if there have been changes, document your unexpected discoveries

- [ ] Submit some of your swatches to the analog material library of your lab (20cm x 20cm approx)