4. B I O C H R O M E S¶

Living colours

Where do colours come from and what is their history ?

"Colour is fundamental to our experience of the world around us" - Kassia St Clair The Secret Lives of Colour

I N S P I R A T I O N¶

_ 1 Cdéco.fr

__ 2 Jamie Young @thebarefootdyer

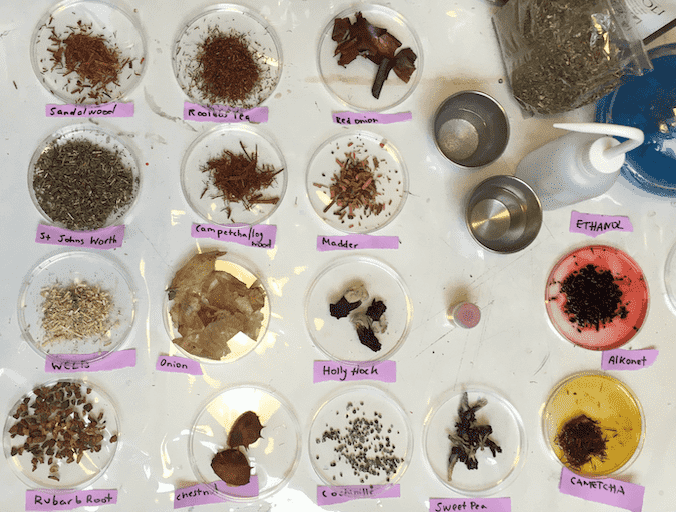

___ 3 Mattricaria

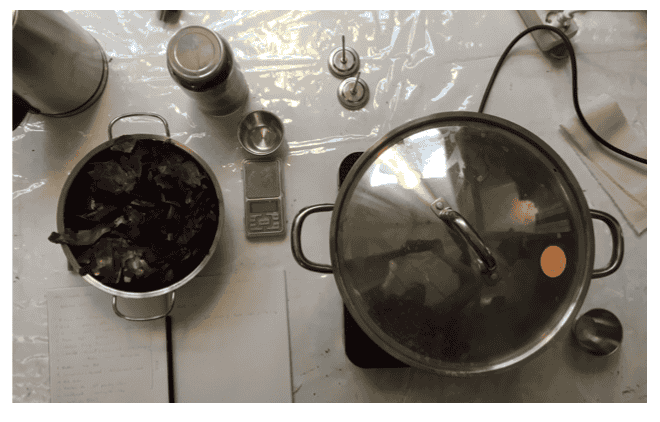

____ 4 Natural dyes in India Journals of Color

R E S E A R C H¶

I N F O R M A T I O N / R E C I P I E S¶

Dyeing to tell you about weld!

Shepherd Textiles - Natural Dyes

Maiwa's Natural Dyes - What they are & how to use them

The Maiwa guide to Natural Dyes Downloadable PDF

Biochromes Lecture Fabricademy 2023-24

C O N T I N U E D _ R E A D I N G¶

The Secret Lives of Colour - Kassia St Clair

Interaction of color - Josef Albers

Wild Colour - The Complete Guide to Making and Using Natural Dyes - Jenny Dean

L E C T U R E _ N O T E S¶

Natural Sources of Colour

- Animal (insects, mollusca)

- Botanical

- Mineral (oxides, ochers, clay, soils)

- Baterial

- Funagl (mushrooms, mold)

Forms of Colour

- Ink (dense liquid, soluable, dispersed)

- Dye (liquid bath, soluable)

- Pigment (powder, insoluable in water)

N A T U R A L _ D Y E S¶

P R E P A R I N G _ F I B E R S¶

Types of fabrics

- Natural Fibers - (brilliant colours) e.g. wool, silk, angora, mohair, alpaca, camel

- Vegetable Fibers - (can achieve brilliant colours over time) e.g. cotton, linen, hemp

- Man-made fibers - (would not recommend with dying)

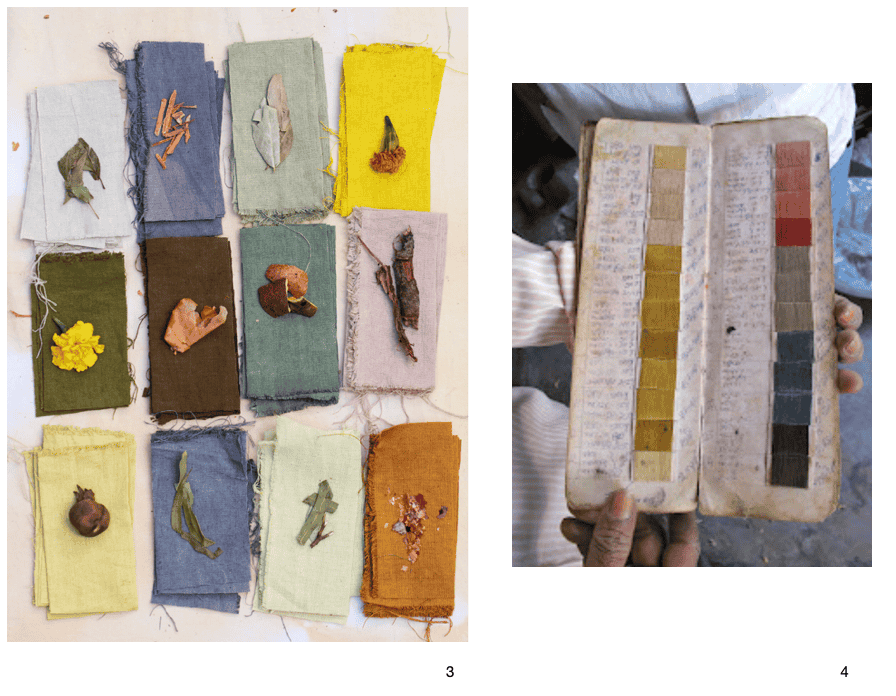

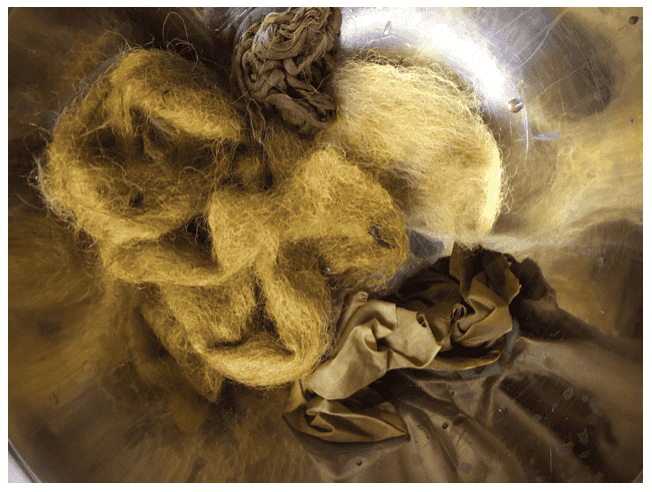

_ 1 Organising & weighing wool 'fluffies' 10 grams each of Netherland wool + 5 grams of South American Merino wool

_ 1 Organising & weighing wool 'fluffies' 10 grams each of Netherland wool + 5 grams of South American Merino wool

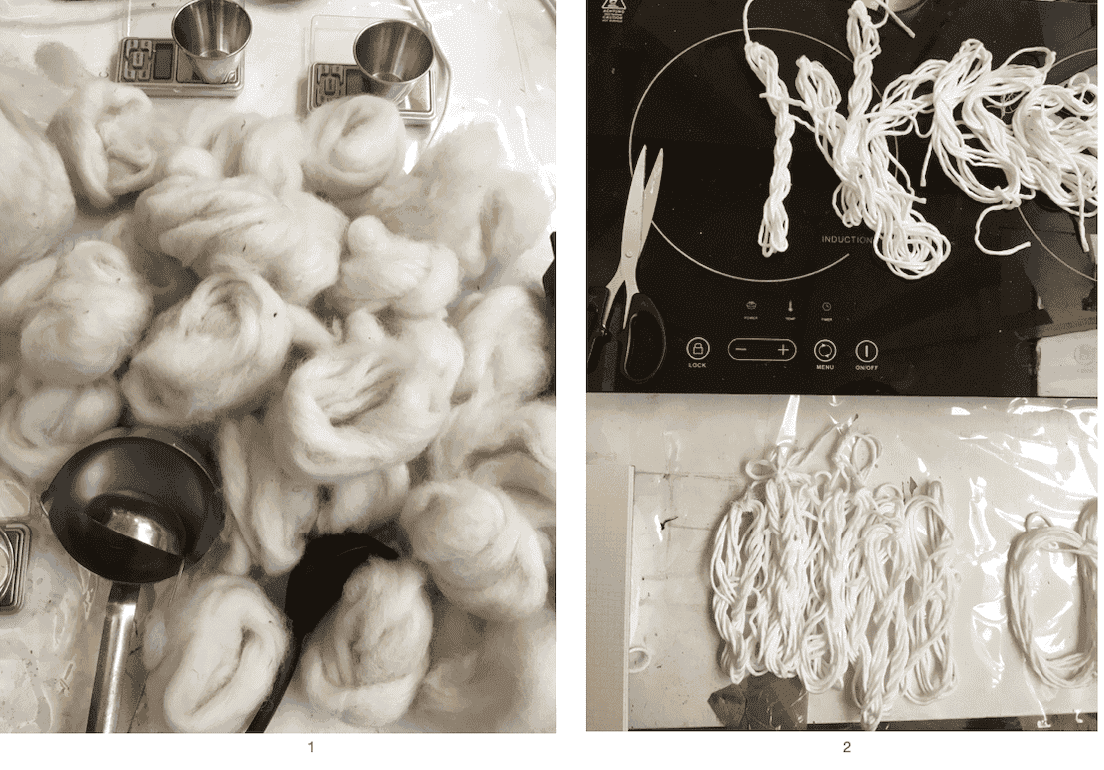

__ 2 Organising and bundling cotton yarn (roughly 3 grams each)

M E T H O D 1

Step 1 - W E I G H

Weigh fabrics when dry WoF = Weight of Fibers

Step 2 - S C O U R

Scouring is cleaning and removing the fibers from any dirt & oil.

- Place fibers into a large pot of water

- Add Soda (Sodium Carbonate) 10% WoF

- Simmer for approx 45 minutes - 1 hour. Stir occationally.

Allow fibers to cool down slowly and then rinse in hot water

NOTE

Rinse Fibers gently

Do not shock fibers (boiling hot from cold) - animal will felt

Boil Vegetable fibers

Step 3 - T A N

Tanning keeps colour in fabric for longer

- Use on vegetable fibers (cotton, linen)

- Sodium Carbonate, Oak galls, Tara Pods, Myrobalan, Sumac, Catechu, Pomegranate

Step 4 - M O R D A N T

Mordanting works as a catalyst to bind the dye pigments to the fibers. Modanting helps keep the colours intact and making more permanent.

- Boil enough water to cover all of your fibres (use tepid water for wool)

-

Add Alum (Potassium Aluminum Sulphate)

Animal fibers (wool) = 10-20 % WoF of Alum + 8 % WoF of Acid (Tartaric acid/ Cream of Tartar) Plant fibers (cotton) = 10-15 % WoF of Alum -

Mix thoroughly until dissolved.

- Wet your fibres.

- Simmer for 1 hour. Stir occasionally

- Remove and wash with water.

- If using leftover mordant water to mordant again, you assume the strength of the mixture is half the strength and calculate dependently.

- Cold Alum Mordanting - leave for 1/2 days

Cotton fabric mordanted 10-15 % WoF

P R E P A R I N G _ D Y E S¶

Selection of various Dye Material

N A T U R A L _ D Y E _ M A T E R I A L¶

| Name | Dye Colour | Measurement | Dyestuff | Mordant | Fun Fact | Other Names |

|---|---|---|---|---|---|---|

| Sandalwood | Red | 100 % WoF | wood chips or powder | Alum | interesting for inks | Saunderswood |

| Rooibos | Soft peach | % WoF | tea leaves | Alum | ||

| Red Onion | green | 50 - 25 % WoF | skins | Alum (Copper or iron pre mordants affect colour) | contains tannins | |

| Madder | Red | 100 % Wof (red) 50 % (peach) | Roots | Both mordants and modifiers work. | Do not boil. Possibile to produce 25 shades with 1 dye bath | |

| Logwood | purple | 25 % WoF | dried chips | Alum=Purple, Iron=Dark, Copper=Blue hues | good for staining / painting | Campeche |

| St John's Wort | yellow/green | 100 % WoF | flowers, plant tops | Alum | Medicinal | Hypericum perforatum |

| Weld | Yellow (primary) | 20/30 % WoF +1/2 Sp Chalk | Stem and flower dye | Alum (copper or iron will effect final colour) | Very light and wash fast | Dyer's Rocket |

| Golden Onion | yellow/orange | 25 % WoF | skins | Alum | mix with other dyes e.g madder to intensify colour | |

| Hollyhock | pink/purple | 100 % WoF | Flowers (fresh or dry) | give pale results to vegetable fibers, react well to modifiers | ||

| Rubarb Root | yellow | 100 % (leaves), 50 % (roots) WoF | roots, leaves | natural mordant | ||

| Horse Chestnut | beige | 30 % WoF | outer shell | Alum | ||

| Cochineal | fusia/pink/purple | 5-10 % WoF | insect | Alum (brilliant colours), Cream of tartar (red) | Ground up | Carmine (lake pigment) |

| Sweet Pea | blue | 50 % WoF | flower | Alum | ||

| Alkanet | red/blue | 100 % WoF + 1 liter Ethanol (96%) | Root flakes | Alum | Extract dye using solvent (Ethanol), flakes can be extracted multiple times | |

| Avocado | gentle pink | 100 % WoF + half teaspoon Sodium Carbonate | pits (chop) and skins | soy binder | gently simmer |

R E C I P E S¶

Recipes used for dye experiments 2

| Dye Material | Measurment | Original Colour | Dye Colour |

|---|---|---|---|

| Red Onion Skins | 50g | Red | Green (mustard) |

| Madder | 100g | Brown | Red (various shades can be achieved) |

| Weld | 20g | Yellow/Green | Yellow (bright) |

| Sweet Pea | 20g | Blue/Purple | Blue/Purple (pale) |

| Holy Hocks | 20g | Black/Purple | Green (pale) |

| St.John's Wort | 30g | Brown/Green | Golden Green (pale) |

All recipes include

- 2 liters of water for dye bath

- Fabric bag for any loose dye material e.g. tea bag idea

- Rinse the fibers well and wash in pH-neautral solution.

- Some colours can be extracted in ethanol

Set up for Dye Bath

Materials / Tools

Pots, hob, measuring scale, whisk, fabric bags, dye material, iron, citric acid, treated and prepared fabric

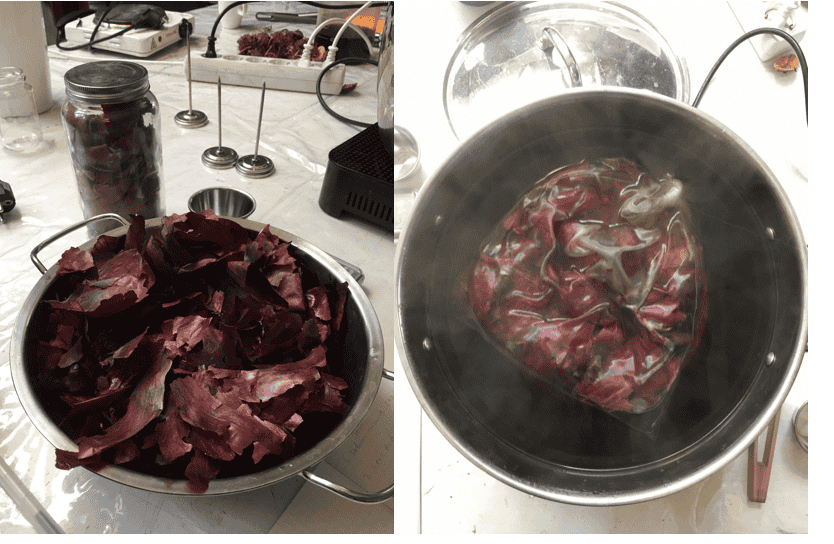

Onion Skins 50 % WoF measured out / Onion skins placed in bag in dye bath

R E S U L T S¶

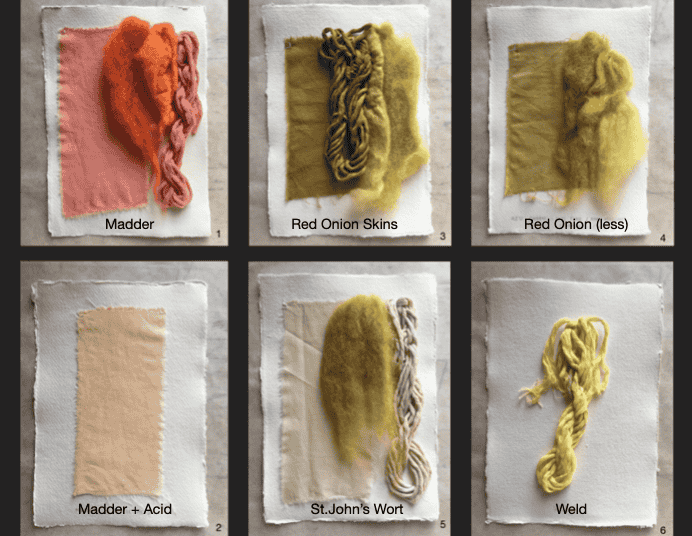

_ 1 Madder (100% WoF)

__ 2 Madder + Citric Acid (1%)

___ 3 Red Onion (50%)

____ 4 Red Onion less time (cotton) / non mordant (wool)

_____ 5 St. John's Wort (30%)

______ 6 Weld(60%)

_ 7 Cochineal

__ 8 Cochineal + Cirtric Acid

___ 9 Horse Chestnut

____ 10 Rhubard Root (30%)

_____ 11 Rhubard Root + Iron

______ 12 Holy Hock (20%)

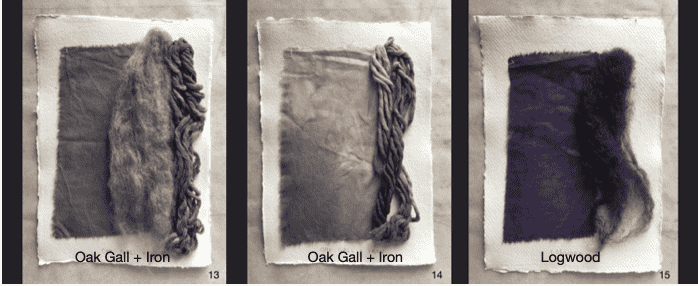

_ 13 Oak Gall + Iron (35%)

__ 14 Oak Gall + Iron(gradient)

___ 15 Logwood

M O D I F Y¶

Modifying dye colours

The use of modifiers extends the range of colours available from a single dye bath.

Can result in a dramatic or subtle colour change.

- To assess the colour change it is a good idea to keep some of the initial dye bath unmodified.

- Some modifiers change the pH value of the dye to make it more acidic or alkaline. Others act as after-mordants.

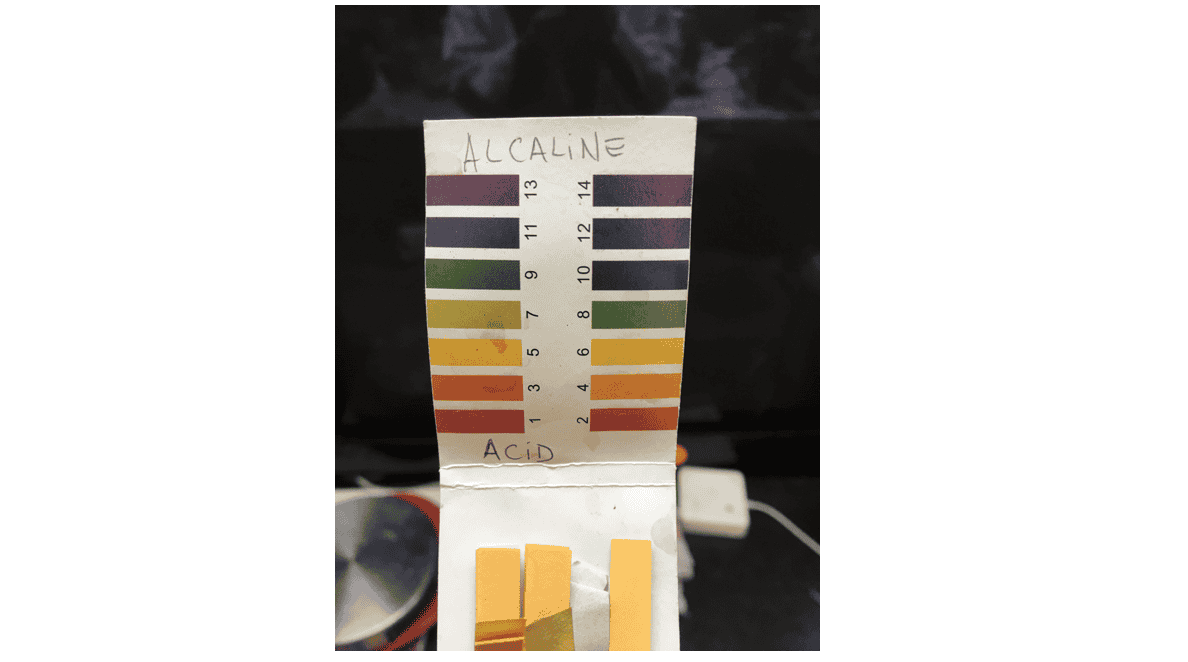

Using pH test strips is helpful to know how Acidic / Alkaline a solution is

Acidic Modifier =

- Usally turns colours to a lighter shade / more yellow in tone.

- Tends to change red tones to orange, and make purple dyes more red.

- Can be added to dye bath or separate pot of water.

- Can also be applied wthout heat, just soak fibers in cool solution until colour is right.

Alkaline Modifier =

- Usually make colour more pink in tone, but can change colours dramatically.

- e.g Elderberry purples and pinks become green, while rhubarb yellow turns light red.

- Apply to animal fibers without heat (otherwise fibers may damage / disintergrate).

- Vegetable fibers may be heated, or add modifier to dye bath.

Copper modifiers =

- Usually make colours more green / brown in tone (darker).

- Sometimes copper doesn't affect the shade, however it's addition will generally improve the fastness (usefull when a premordant has not been applied).

- If using as modifier = stir into bath, add wetted fiber and simmer for 10/15 minutes.

- Full after-mordanting effect = simmer the fibers for 30 minutes.

Iron modifiers =

- Tend to make the colours darker and more somber in tone.

- Improve the fastness of most dyes.

- Iron modification process called 'saddening'. Can turn yellows olive green and if used with dyes rich in tannin, it can make colours dark grey, almost black.

- Add to the dye bath or pot of water and stir it well. Can be applied without heat wo many plant dyes.

- Simmer for about 5 minutes (takes effect quickly)

Modifiers in Crystal form =

- Modifiers can also be used in powder / crystaline form.

- Add 1 or 2 teaspoons of powder or crystals to hot liquid and allow to dissolve.

Other Modifiers

- Clear Vinegar = acidic modifier.

- Ammonia, wood ash water = alkaline modifier.

- Homemade copper and iron liquors made as mordants can be used as modifiers.

Wood Ash water Recipe: 1. Remove the cold ashes from wood burning stove and place in plastic bucket. 2. Fill with cold water and leave ashes to steep for a week, until the liquid turns yellow and feels slimy. 3. Decant the liquid into a container without disurbing the ash sediment, stored indefinitely. 4. To use as modifier: add half a cupful to the dye bath or seperate pot of water.

Always rinse and wash well

P R E C I P I T A T I O N¶

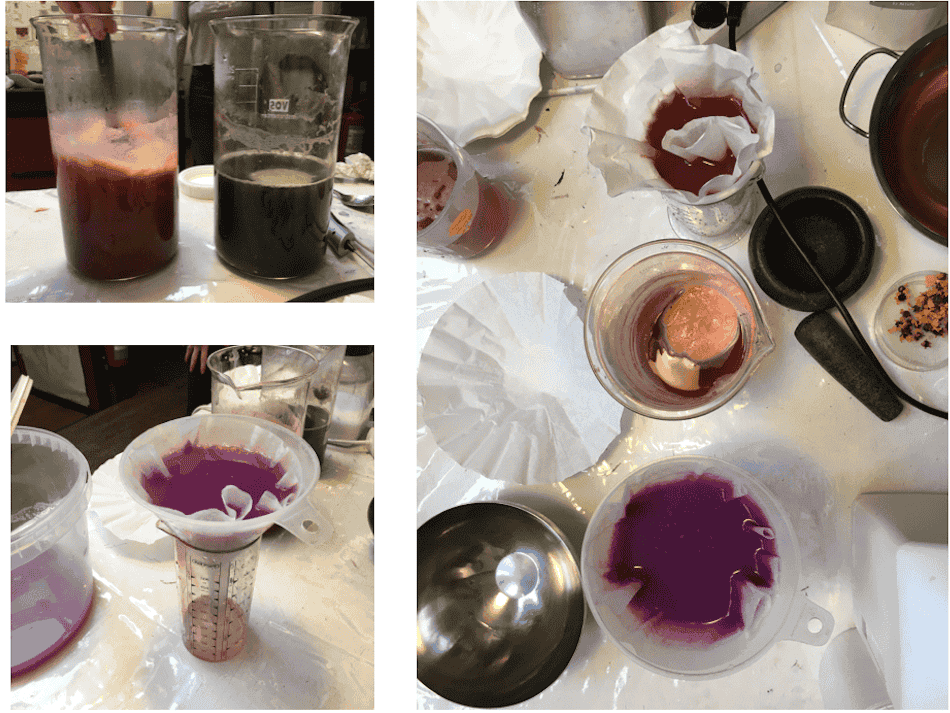

Pigment Extraction - Precipitation of Dye Bath 3

Making used dye bath into pigments / inks = Recycling colours

Alum and Soda = dries dyes

R E C I P E¶

1 litre of dye bath

15 grams of Alum into residue dye bath (hot) & dissolve (feel it!)

7 grams of Soda (Sodium Carbonate) - roughly half of alum

- Add Soda a little bit at a time (bath will bubble + turn colour)

- Stir

- Place mixture in a coffee filter in a funnel / sieve to allow all of the liquid to pass through

- The remaining residue is the pigment extraction which will solidify / turn to powder over time

Precipitation Process

Possibilities to experiment

- Can start neutral or experiment with more Acid / Alkaline mixture

- Extract multiple times

- Experiment with chalk and citric acid

- Can screenprint with it

- Add gum to make more viscose

- Can seal in jar and keep printing

- Let dry completely = powder

- Add chalk to water to make dye stronger

Recipe to make Watercolour (I have not yet tried it for myself)

Watercolour

+ Gum Arabic (liquid) little bit

+ Glycerin / Honey (little bit)

+ muller (bathroom tile + stone/ glass on glass)

- Mull in 8's (creates viscosity)

- Ensure particles evenly dispersed

- Can add Acid / Alkaline to change colour

- Put in funnel + filter / sieve / fine mesh fabric

I N K S¶

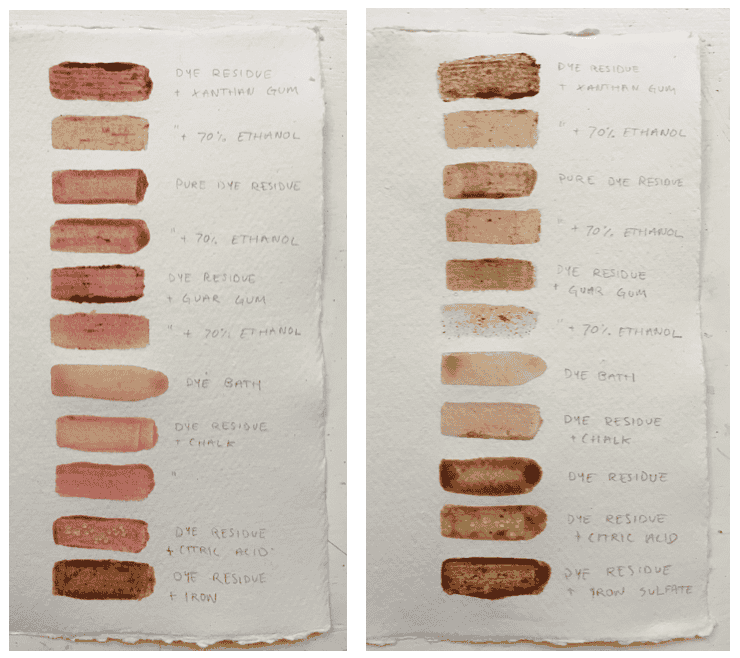

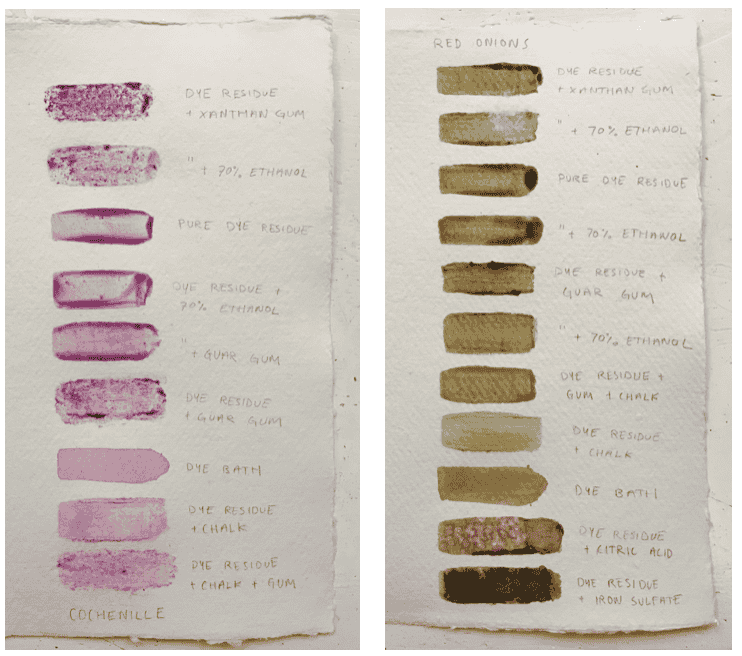

Results of precipitating Madder, Cochineal rinse bath, Red Onion dye bath and St John's Wort dye bath.

I made tests using each dye residue and various mixtures to see the changes of colour / texture / application on acid free Khadi paper

- Dye Residue + Xanthan Gum

- Dye Residue + Xanthan Gum + 70% Ethanol

- Pure Dye Residue

- Dye Residue + + 70% Ethanol

- Dye Residue + Guar Gum

- Dye Residue + Guar Gum + 70% Ethanol

- Dye Residue + Guar Gum + Chalk

- Dye Residue + Chalk

- Dye Bath

- Dye Residue + Citric Acid

- Dye Residue + Iron Sulfate

Madder / St John's Wort

Cochineal / Red Onion Skins

B A C T E R I A¶

We experimented with bacteria dying using silk fabric & Serratia Marcescens bacteria 4

M E T H O D¶

Step 1 - Prepare Fabric

-

Gather & tie silk fabric in chosen shibori technique - Many tutorials and inspiration can be found online e.g. Seamwork.

I gathered mine with cotton thread in a circular pattern -

Place in fabric in Petri Dish

Step 2 - Sterilize

Methods of Sterilization = Heat, UV light, Alcohol, Acidity

- Sterilize table and tools using ethanol and paper towels.

Step 3 - Prepare Food

Food for bacteria

-

NA (Nutriend Agar) - Yeast Extract

-

Broth (Agar + Beef Extract)

Mix containers of food with 300 ml Distilled water (demineralised -> more consisent) + peanut butter + stir

| Food | Nutrient amount | Demineralized Water | Peanut butter |

|---|---|---|---|

| Nutrient Agar | 9,3 gr | 300 ml | 0,5 gr |

| Luria Broth | 7,5 gr | 300 ml | 0,6 gr |

Step 4 - Autoclave

Sterilize fabric petri dishes & food

- Isolate petri dishes with fabric inside autoclave bags & seal + put in autoclave

- Place food bottles in autoclave (bottles should be slightly open so that they do not explode in the pressure cooker but tight enough so that water doesnt get in)

- Autoclave 121 degrees C for 20 minutes

NOTE - AUTOCLAVE

- Ensure no obstructions

- Close with screws (pretty tight, double check)

- Safety valve up = open (steam can escape) down = closed (builds up pressure)

- Keep valve open (up) until temperature of autoclave reached 100 degrees C, then close it

- Needs to go below 90 degrees before you can open

Step 5 - Combine

- Bunsen Burner + alcohol = sterile environment (blue flame + ethanol create a bubble of sterilization)

- Pour the food on top of the fabrics in the petri dishes (within the sterile bubble).

- Using inoculation loop (sterilize under flame) collect some colonies of bateria and place on fabric (sterilising loop after)

- Seal petri dishes with parafilm tape.

- Place petri dishes in the incubator (helps to create a controlled temperature at 18-20 degree celcius).

We left petri dishes in incubator for 3 days.

Step 6 - Inoculate

Final step was to Inoculate and kill the bacteria

- Place petri dishes in Autoclave

NOTE

- Label - Important to note: Name, What is it, Date

- Always clean everything with alcohol

- Obide by rules of the lab (tie up hair, wash hands before entering and after leaving)

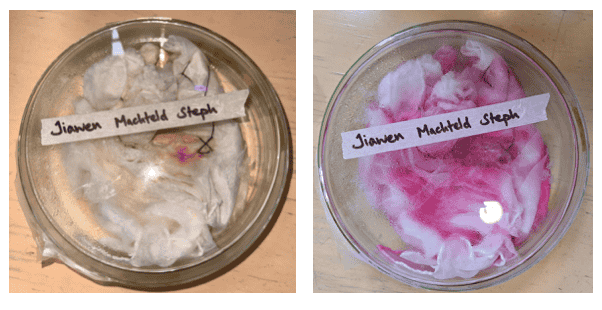

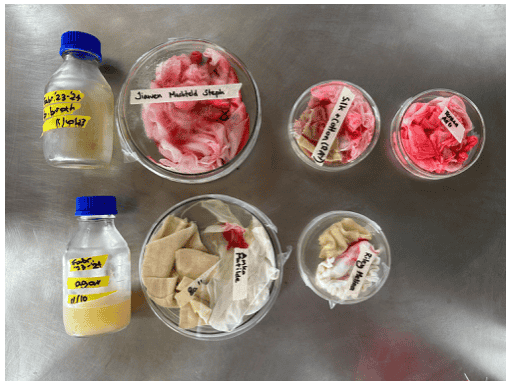

Images showing growth of bacteria over time

R E S U L T¶

Result of bateria dye on silk

Image shows the different growths

Top - Luria Broth (Agar + Beef Extract) = Bacteria grew very well

Bottom - NA (Nutriend Agar) - Yeast Extract = Bacteria did not grow very well