Tips and Tricks

Info Panel

Before Laser cutting or Vinyl cutting a Fabric, its very important to make sure, there are as less of creases as possible on the fabric. We want the fabric stretched upto a reasonable amount to lay it flat.

Warning Notes

A soft fabric is harder to circular fit. Treating it with starch to make it hard and then joining the modules to be washed post that is an effective time saving technque for such inhouse small-scale projects.

Danger Panel

Fabric is the easiest media after cardboard and vinyl/sheets to catch fire if the laser is : 1) Out of Focus; 2) Speed is too slow; 3) Power is too high; 4) Fabric is not flat.

Some fabrics (Course and dry) are prone to catch fire. Always stay alert Laser cutting.

Some fabrics (Course and dry) are prone to catch fire. Always stay alert Laser cutting.

Success Panel

The Success of Laser cutting on fabric is dependent on three factors: 1) Honeycomb bed and effective exhaust; 2) A longer focal length of the lens for more creased fabrics; 3) An effective power : speed ratio

F.A.Q.

I usually ask the Global team or myself questions relevant to the week's task.I plan to use this section to help me document for our lab's next batch of students important questions and their answers discussed during Global review/Recitation.

Since a flat design needs to be printed on a fabric to get its 3d shape in 4d printing-the model is a flat model and is not the same shape as the final piece.

2. As for the mould, since we wanted to make a low cst mould, you will notice the digital bodies week was used as our base model from cardboard over which a vacuum seal and thereafter the composites were vacuum pressed. Its a valid technique of composites used in quite a few industries that compress using vacuum instead of physical compression.

2. As for the mould, since we wanted to make a low cst mould, you will notice the digital bodies week was used as our base model from cardboard over which a vacuum seal and thereafter the composites were vacuum pressed. Its a valid technique of composites used in quite a few industries that compress using vacuum instead of physical compression.

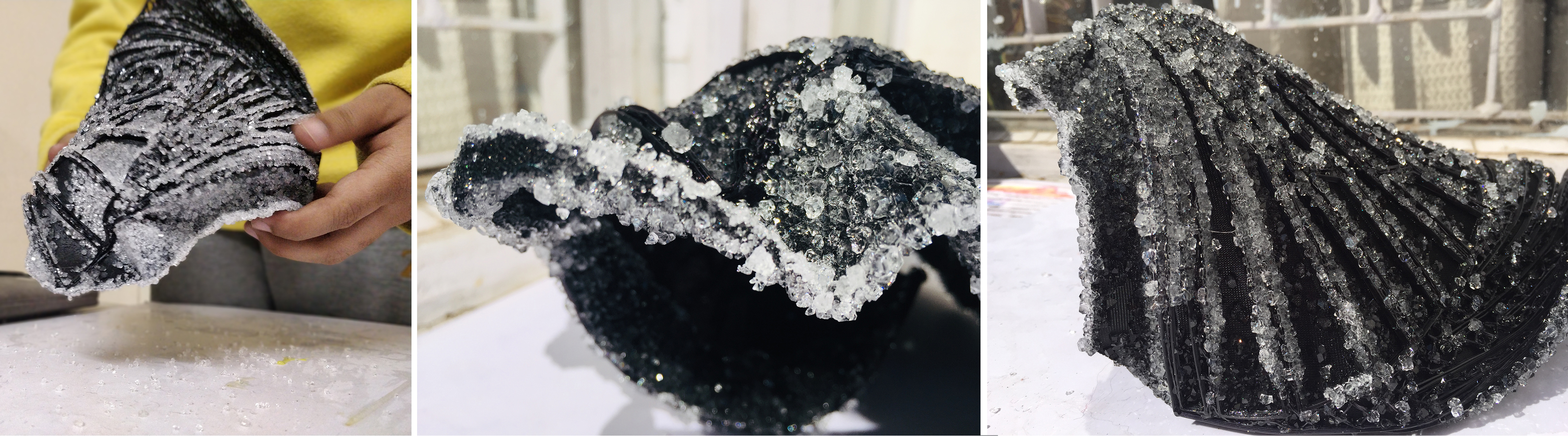

Crystallisation, 4d Printing over stretched fabric and composites using resing were three seperate assignments carried out overlaid over each other to study different effects.

Objectives | Tasks at hand

For this week, I will be making an alien helmet as well as use crystallisation as a process for hardening the shape of my 4D form from last week.

EXTRA: Below shown is a video from my Flexible Composite assignment | Fab Academy 2017Reffered Links

Oct 31, 2018

Nov 01, 2018

Nov 02, 2018

Nov 03, 2018