Development Timeline

-

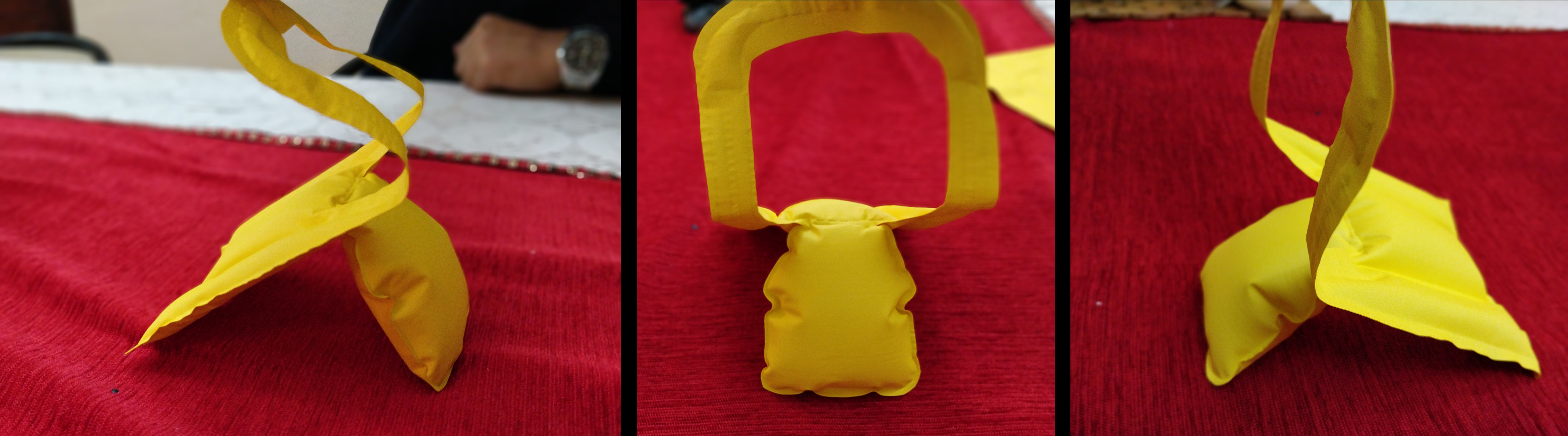

1. Design Concept

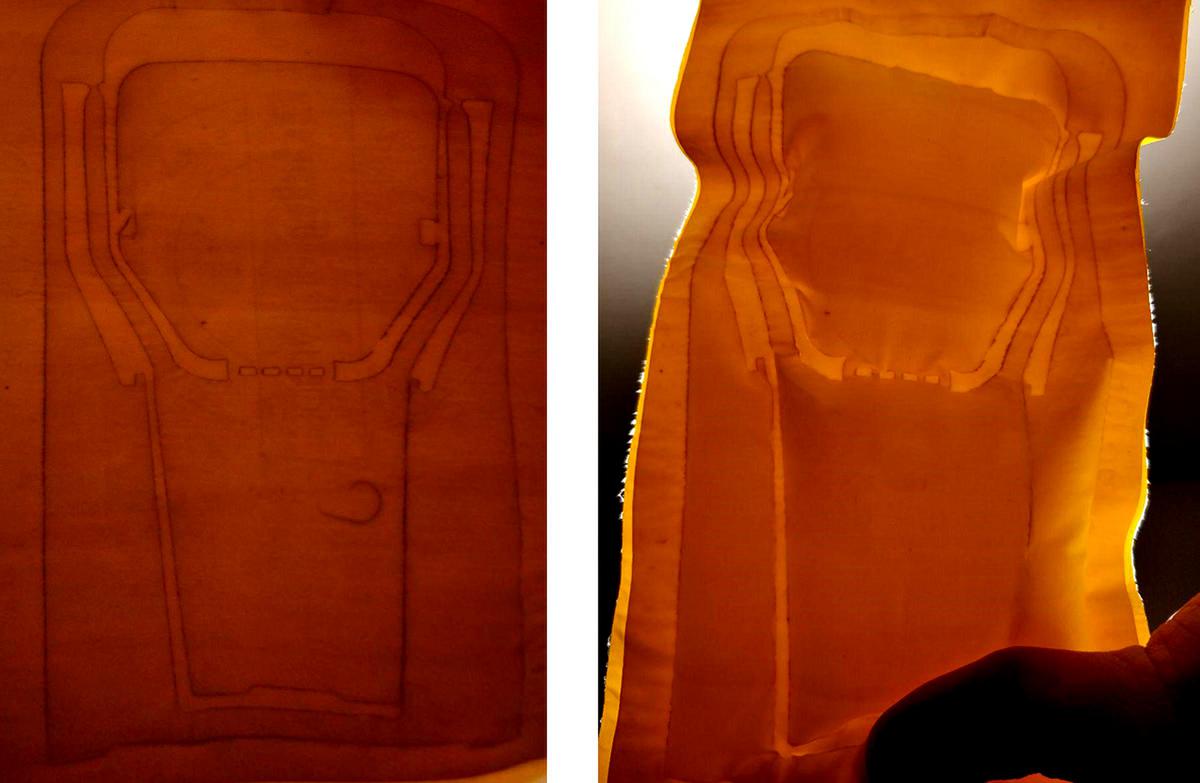

I started by understanding the need of Soft Robotics decided to proceed with making an Evacuation chair, which can float on water as well as could be used on stairs during emergencies. Therefore, I designed what you can see on left using AutoCAD. Dont forget to keep an outlet for airflow which I forgot on my first trial :P

-

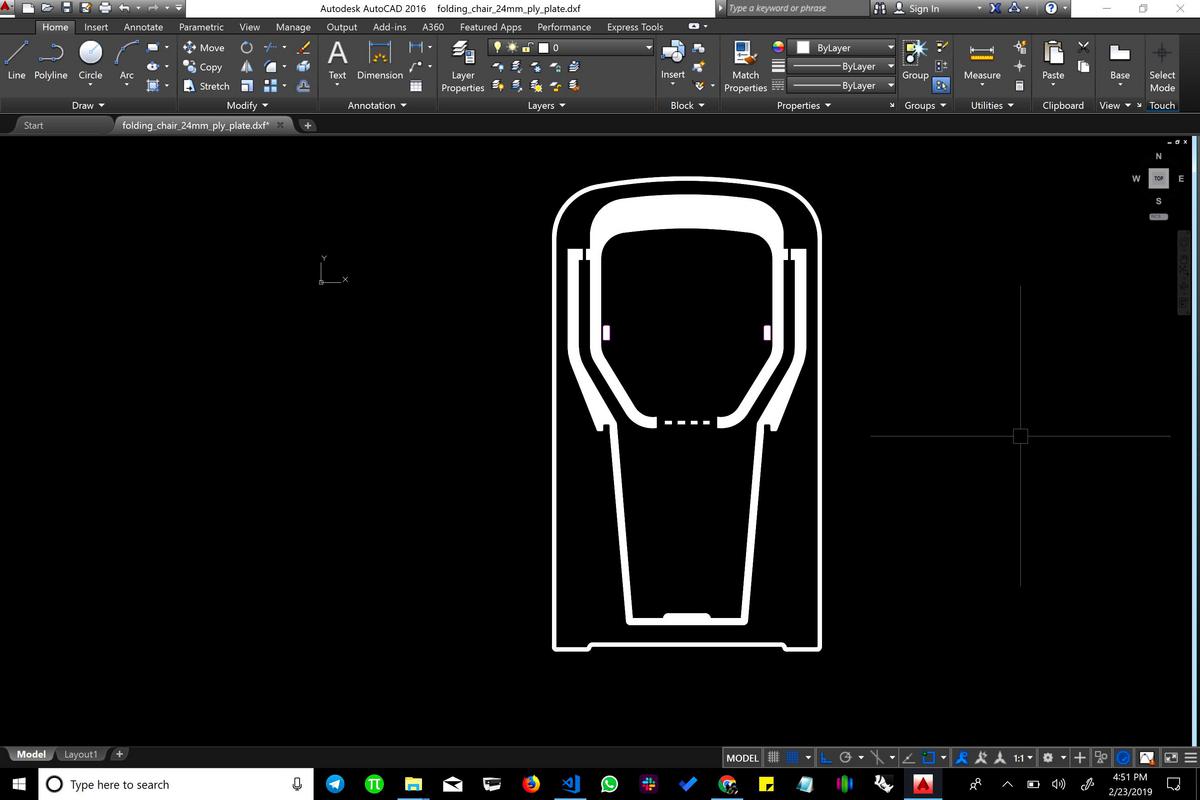

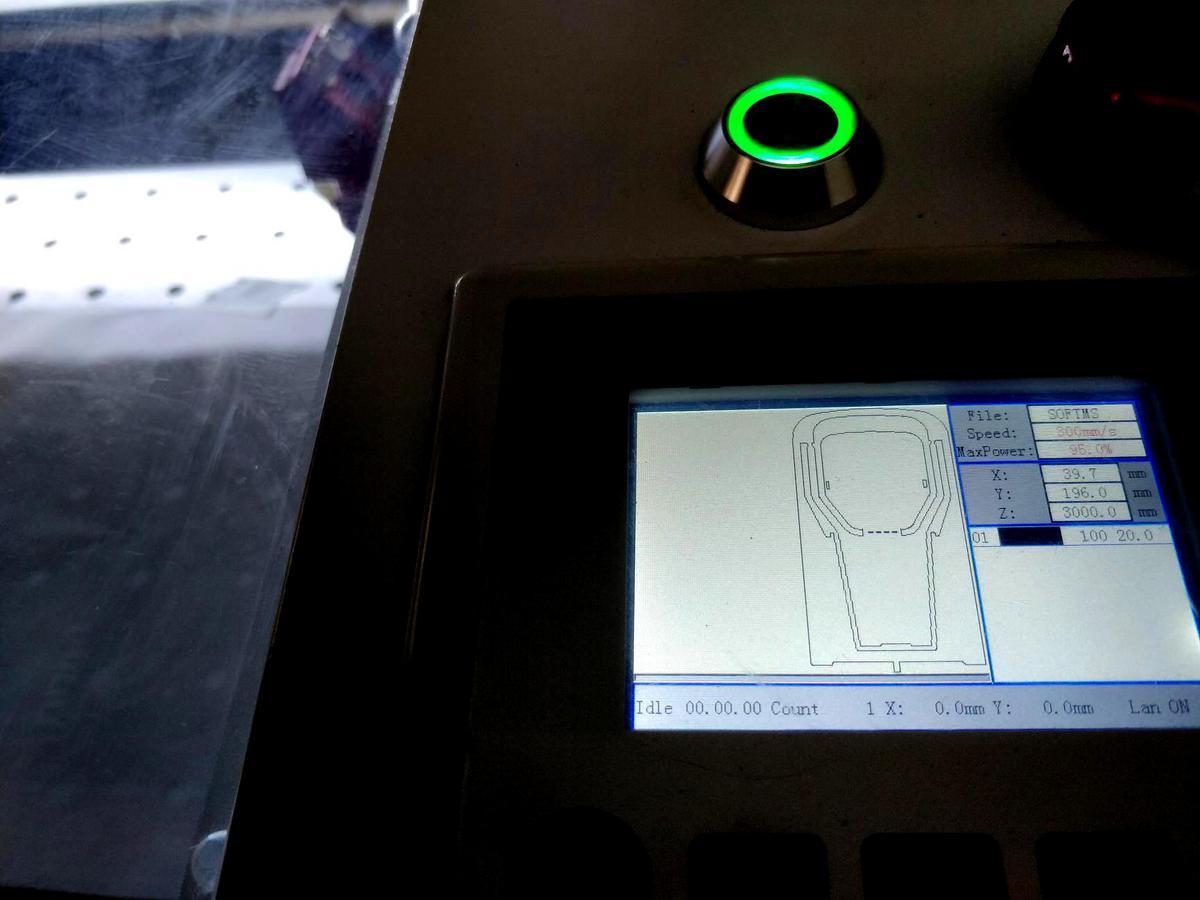

2. Laser cutting

So, there are two parts to this design, one is Vinyl heat transfer sheet which is not required to be laser cut and is not even recommended. Other part is baking or parchment paper which I have laser cut as per my design, I am using RD works for cutting my baking paper, where my settings are Power is 20 and speed is 100

-

3. Settings

After installing paper on the bed, I uploaded my file, You need to keep the chiller as well as the Exhaust fan ON before you start cutting, also the laser cutter I am using in our lab already has a safety glass to avoid contact with laser but we still recommend to wear safety goggles if you plan to give a close sneak peek.After laser cutting, the assembly began.

-

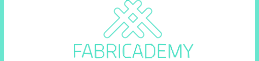

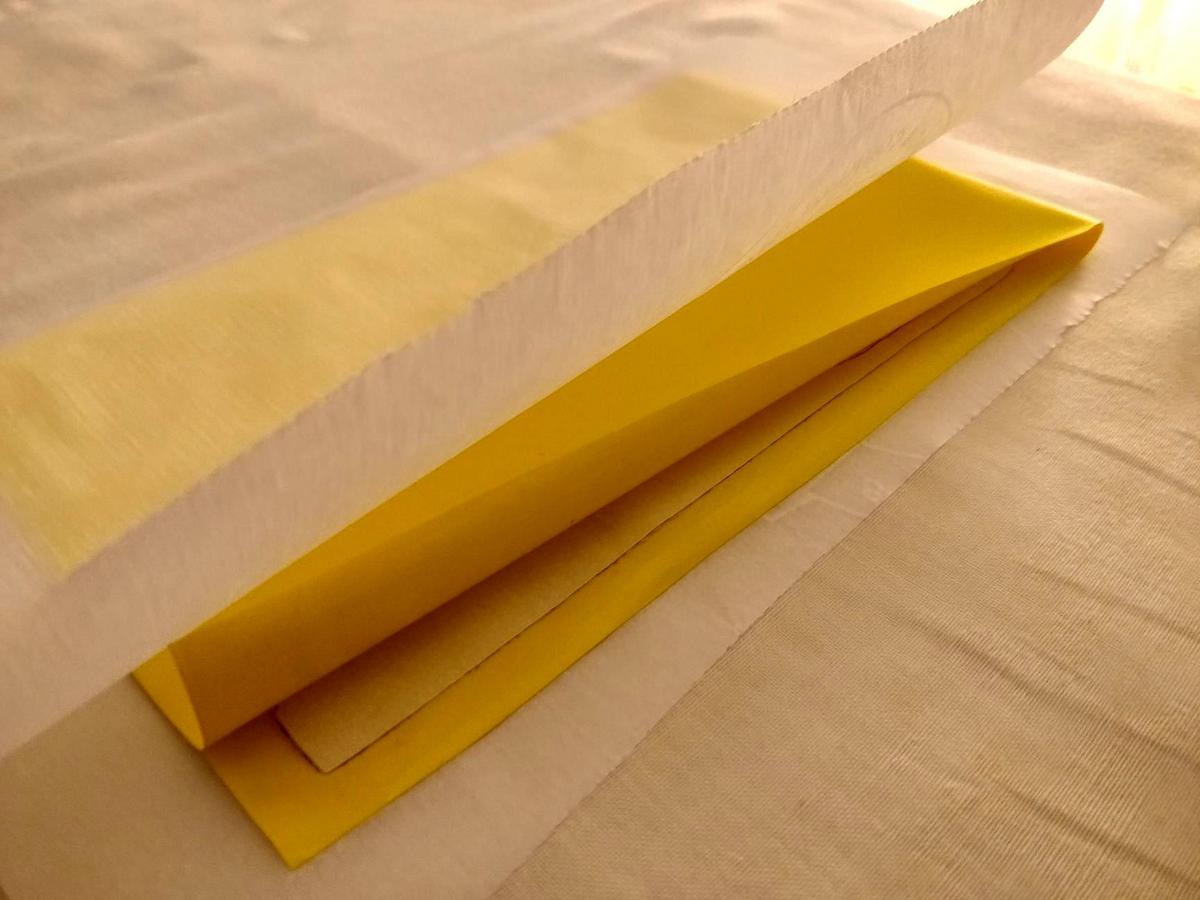

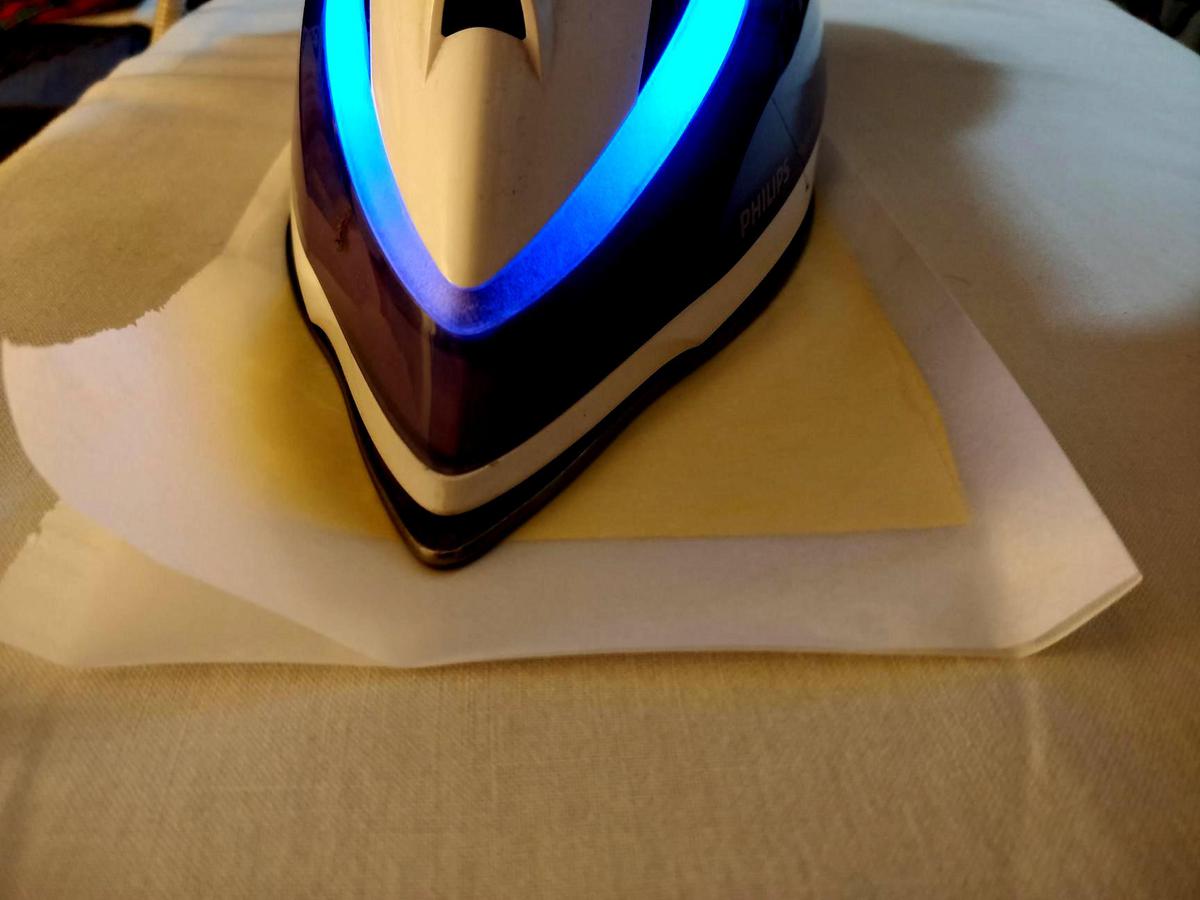

4. Orientation

The piece you see on the left is shows how I plan to orient my pieces, before that If you touch your Vinyl sheet you will one glossy side and one matt side before peeling, but after you peel off the transparent cover from it, you will see glossy became Matte and matte became glossy, Now I will keep the glossy side facing inside (after peeling) and matte side facing outside, now Im using Baking Paper at the base so that Vinyl doesnt stick to the ironing cloth below, then I have my Piece of Vinyl, then goes my Laser cut baking paper, well wait before you press, read next step.

Tips and Tricks

Info Panel

Warning Notes

Danger Panel

Some fabrics (Course and dry) are prone to catch fire. Always stay alert Laser cutting.

Success Panel

F.A.Q.

I usually ask the Global team or myself questions relevant to the week's task.I plan to use this section to help me document for our lab's next batch of students important questions and their answers discussed during Global review/Recitation.

Objectives | Tasks at hand

On your left you can see one of my earlier assignments experiments with Nitinol. Its an Actuator swatch from my week 9 assignment. For this week, I will be designing an exercising/yoga relaxation chair prototype which can be used for recreational purpose of doing balancing activities in different yoga poses. etc. This is just a small prototype where we can ssume that this can be folded and kept , this can be utlised in emergencies.

Reffered Links

Dec 04, 2018

Dec 04, 2018

Dec 05, 2018

Dec 05, 2018