3. Circular Open Source Fashion¶

A modular garment is created from one or a few modular elements that allow the change of its shape, size and function. The goal of this week is to create a modular element to create a garment. It is through geometric shapes that the exploration of a modular model is possible since a module is infinitely repeated.

Reproduction of existing modules¶

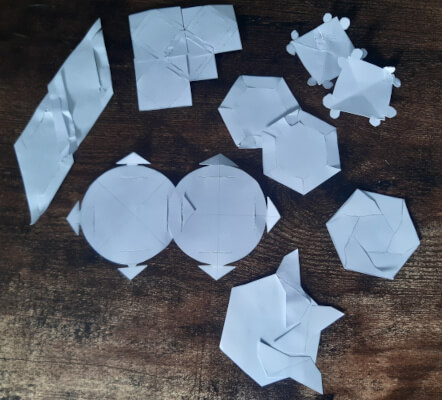

First of all, I was trying the patterns that already exists. This step is crucial for me to understand how it works and plan my own designs.

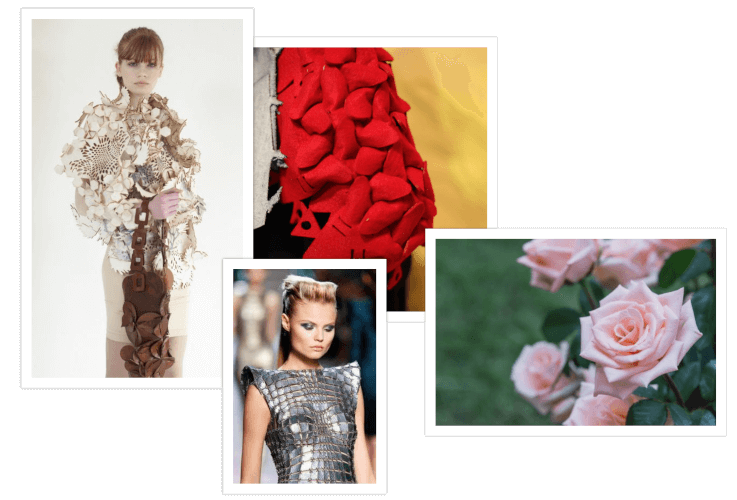

Inspiration¶

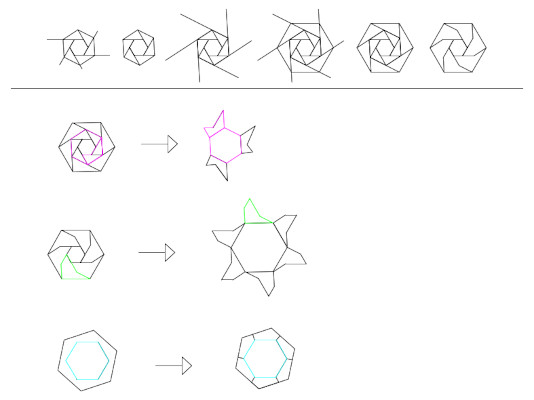

Module exploration¶

I looked for a modular design that is rose-shaped when assembled with other modules but simple in shape when it's independent to give the user a greater choice of assembly: extravagant or more temperate.

After several tries, I found my module. It is a hexagon inside another hexagon, with the same center and not the same orientation. Each module contains 6 tabs and 6 slots that allow it to interconnect with all other modules.

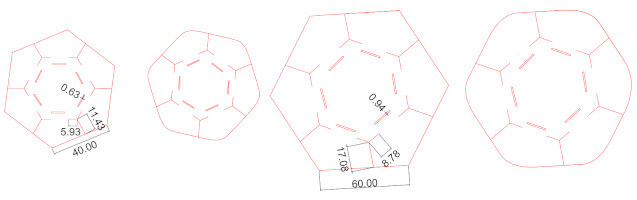

Then I wanted to test 2 different sizes (40 and 60mm side for the external hexagon) and two different external shapes (a hexagon and a hexagon with softened edges).

Paper prototype¶

Validation of prototypes. It works. I keep only two smaller prototypes for the future, not being satisfied from an aesthetic point of view.

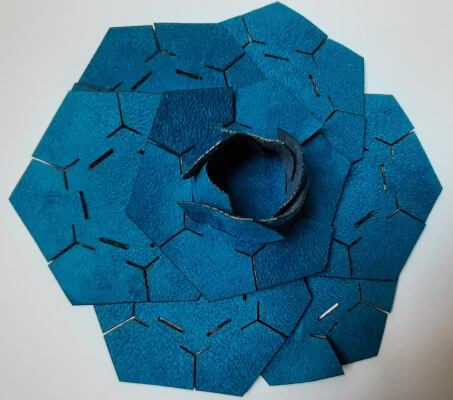

Fabric prototype¶

For my project, I need a fabric that is stiff enough that my petals won't sag and that is strong enough to hold up when assembled and disassembled. I chose a thick two-tone suede in petroleum blue and midnight blue.

| Laser cutter settings | |

|---|---|

| Cutting power: 95% | Cutting speed: 57 mm/sec |

The assembly and disassembly is easy with this fabric. The rendering is very satisfactory. The two prototypes are validated.

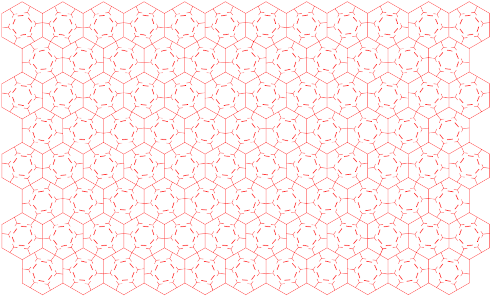

Laser cut Sheet and optimisation¶

Steps to realize in Rhinoceros software, the cutting board - with the module repeated several times - optimizing the space and the path of the laser cut (no double line):

- Select the module and use the Mirror command to duplicate the pattern using one of its sides as an axis of symmetry

- Remove the artifacts due to the duplication

- Repeat as many times as necessary

- Select the module and use the Explode command

- do not select the patterns and use the SelDup command to remove all duplicate lines from the modules. These will appear in yellow.

- Use the Delete command to delete all duplicate lines.

- Select all modules and use the Join command.

- Export the cut sheet as PDF.

I selected the prototype with sharpened edges as the final module because it was easier to optimize the cutting board for this model.

Assembly¶

I chose to put a lot of volume in the shoulders thanks to the flower assembly made several times. To make it fit, I decided to make a breastplate from this shoulder pad. Another assembly technique is done for this breastplate and highlights the flowers. It's an armor style assembly with the tabs totally hidden and the modules all interlocked.

Result¶

Tools¶

Biblio¶

Modular textile by Ece Tankal and Ilkim Er

Fabrication files¶

-

File: Laser cut sheets. ↩