BioChromes¶

This week class focuses on exploring colouring alternatives to the current ones. Bridging craftsmanship techniques and technology, to explore alternative colour sources and their processing. Ranging from plant based, insect base and bacteria based pigments.

The assignements are:

This week class focuses on exploring colouring alternatives to the current ones. Bridging craftsmanship techniques and technology, to explore alternative colour sources and their processing. Ranging from plant based, insect base and bacteria based pigments.

The assignements are:

- Produce at least one natural dye or bacterial dye: Natural dye (modifying it’s colour and mordanting it in different ways to dye at least 2 different categories of fibers) or bacterial dye (Explored dyeing with bacteria of different fibers and/or bacteria)

- Produce at least one botanical or bacterial ink: Botanical Ink (explore different materials, recipes and understand how to adjust them based on the ingredients) or Bacterial Ink (explore bacteria solvents and understand how to adjust or use the inks)

- Document your recipes, the ingredients and process and if there have been changes, document your unexpected discoveries

- Name your materials, classify them by typology and display them in a systematic order of samples

- Submit some of your swatches to the analog material library of your lab. (20cm *20cm aprox) (extra credit)

Inspirations¶

I scroll a lot on instagram and some artist dye their material, here come my favorite accounts for quilting and sewing

Check their profils:

Check their profils:

- Sarah Gagnon at pelicanquilts

- Heidi Iverson at honeyfolkclothing

- Lanni Loucks at likehoneytextiles

Mentoring¶

At Le Textile Lab in Lyon, we had the chance to be mentored by Charlotte Julien from Wednesday to Thursday. Charlotte was a graphic designer when she started using inks from plants to make screen prints. After five years of exploration she has created her own line of clothing called Marga, made mainly from old sheets and dyed by herself. She shares her love for dyeing through initiation and deepening workshops.

Pictures from marga.creation

Pictures from marga.creation

Dye process and workflow¶

Mordanting : prepare your fibres¶

To can received the dye color, the cellulosic (linen, cotton, hemps...) and the proteinic (silk and wool) fibres need to be opened, this step is call mordanting.

* fiber

* 30% of the total fibre weight of potassium alum

* 5% cream of tartar (potassium bitartrate)

* 10% of the total fibre weight of tannins (extract of Gall nut) for cellulosic fibres

* a large pan

* a large mixing spoon

* a thermometer

* a heat source

Mordanting is a step by step process than should take 2 to 3 days to let the fibres breath between each step.

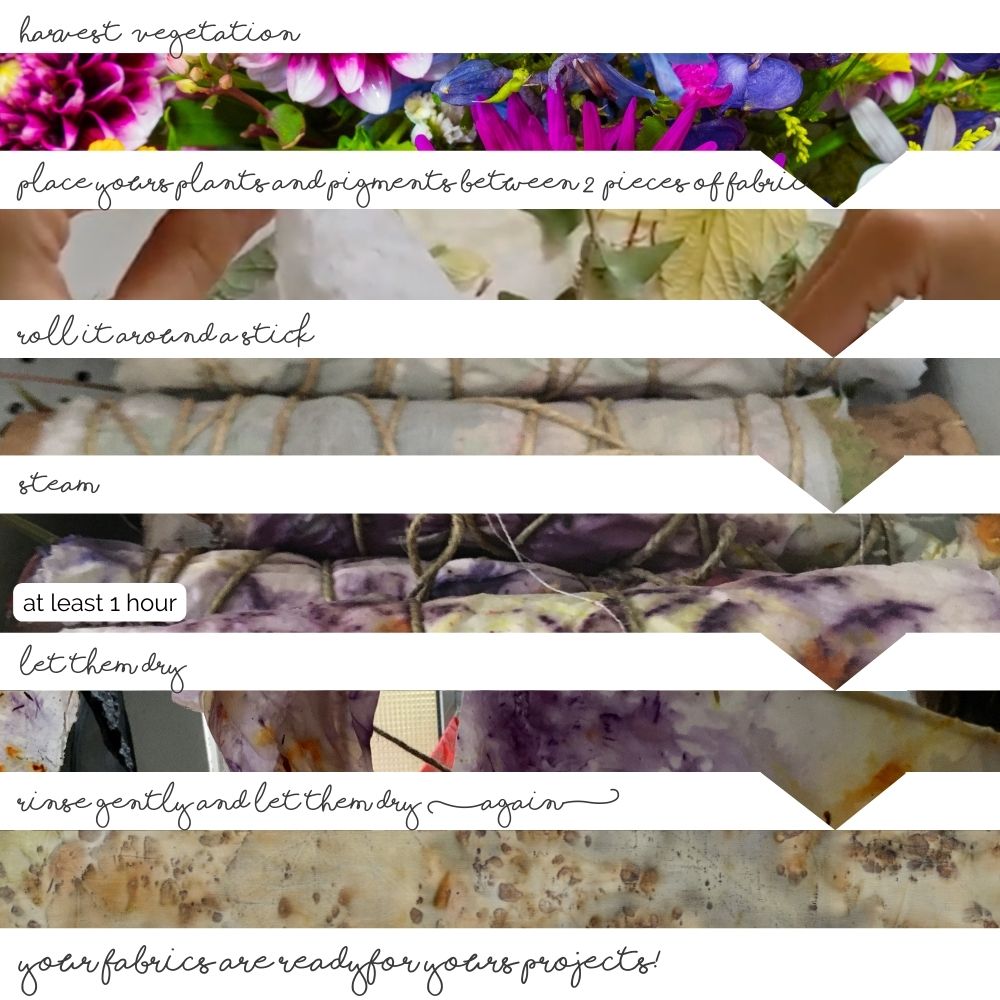

Ecoprint¶

If you are not looking for solid colors and want creatives print, you can try ecoprint.

* fiber

* Vegetation

* natural pigment

* a couscous maker or pot equipped for steaming

* a heat source

Dyeing solid colors¶

The dyeing stage also requires some preparation of the baths.

* fiber

* Dry dyeing plant : 100% of fiber weight or more if you want intensity

* Dying extract : 10% of fiber weight or more if you want intensity

* a large pan

* a large mixing spoon

* a thermometer

* a heat source

Dyeing is, as mordanting, a step by step process than should take 2 days to allow the colors to unfold in the bath and the fibres.

For best results, the fibres must be given plenty of room to spread out in the pan.

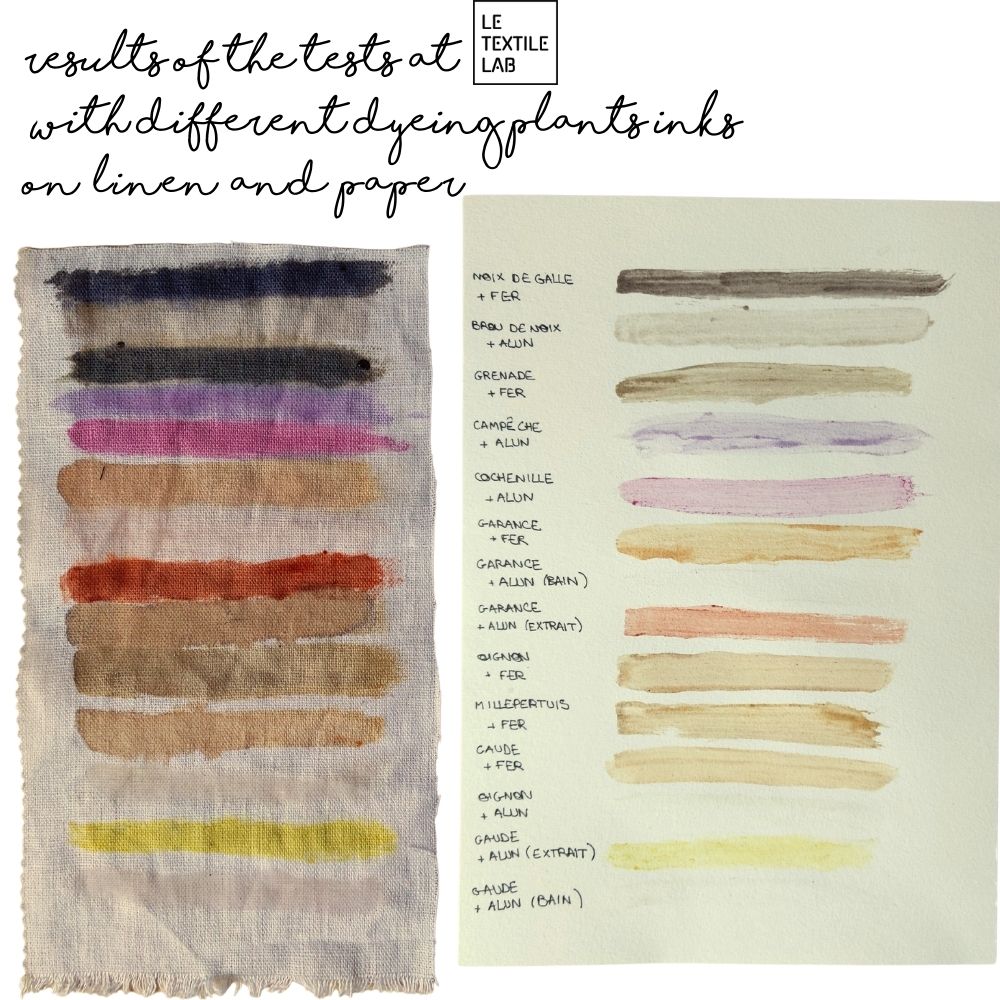

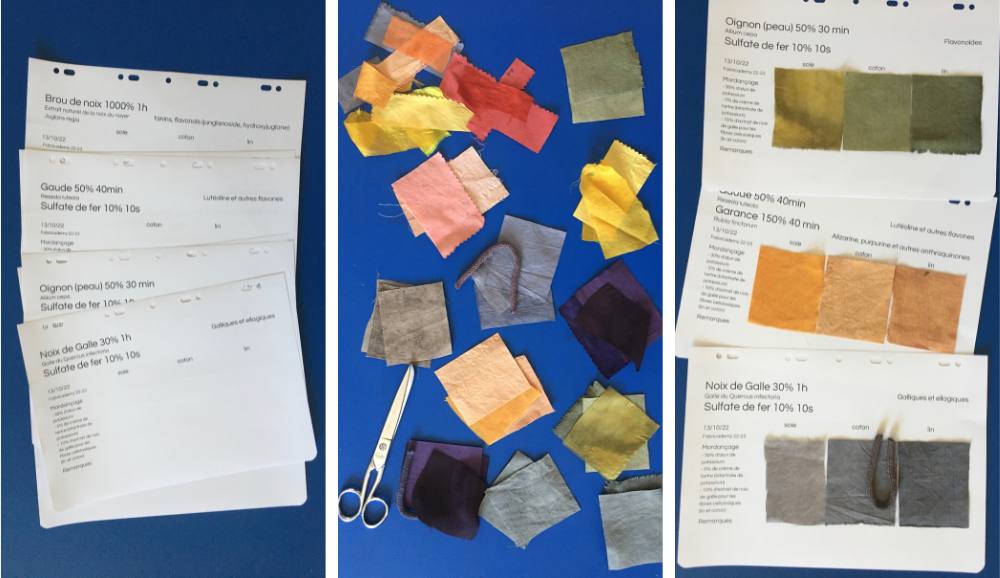

Here are the results of the tests with different dyeing plants on silk, linen and cotton

For best results, the fibres must be given plenty of room to spread out in the pan.

Here are the results of the tests with different dyeing plants on silk, linen and cotton

Small French-English dyeing glossary by Camille Barot

Ink process and workflow¶

As a pretty empirical process, the preparation of ink does not require much more than a good handful to mix the preparation.

* dye bath (made for the occasion or left over)

* as much alumina or iron acetate as dye bath

* thickener (such as guar gum) to be used according to the desired consistency

* container

* balance

* whisk

* Weigh the solid ingredients: Alum and soda crystals

* Dilute them separately with hot water (Alum needs more time to dissolve)

* Pour 200ml of filtered colour juice into the high rim container

* Add the diluted alum

* Gently add the soda solution

* Mix

* Leave to stand for several hours, until 2 phases appear (a liquid and a solid phase)

* Put the piece of cotton in the funnel to recover the solid phase

* Leave to filter for several hours/days

* Collect the precipitate (solid phase) with a clean spoon

* Dry in a dehydrator

* Grind the pigment with a mortar and pestle

* Store in a dry place

Pigment process and workflow¶

Pigments are a terific way to recyclied a dye. They can be use latter for watercolor, paint, material making...

* 200ml of filtered coloured juice

* 20g alum

* 5g soda crystals

* beakers with high rims (the reaction may foam afterwards)

* spoons

* funnel

* mortar and pestle

* spatula

* balance

* filter

* dehydrator

* Weigh the solid ingredients: Alum and soda crystals

* Dilute them separately with hot water (Alum needs more time to dissolve)

* Pour 200ml of filtered colour juice into the high rim container

* Add the diluted alum

* Gently add the soda solution

* Mix

* Leave to stand for several hours, until 2 phases appear (a liquid and a solid phase)

* Put the piece of cotton in the funnel to recover the solid phase

* Leave to filter for several hours/days

* Collect the precipitate (solid phase) with a clean spoon

* Dry in a dehydrator

* Grind the pigment with a mortar and pestle

* Store in a dry place

At that point, the pigments are not ready yet.

Screen printing¶

There are two ways to screen print with natural colours:

- by using inks obtained from dye baths as seen above

- by mordanting the fabric with acetate and then dyeing it.

* 200ml of 10/12% vinegar

* 12g of alumina or iron sulphate

* 10g of soda crystals

* Guar gum powder

* Spoons

* jars

* Spatula

* Bowls

* Pre-insulated screen printing frame

* Squeegee

* In a beaker, pour the vinegar

* then pour in the alumina or iron sulphate

* and finally the soda crystals.

* Beware of the acid-base reaction, it foams!

* Mix everything well, there should be no solids left.

* Add the guar gum gradually until you obtain a texture close to liquid honey

* place the fabric under the frame

* operate as for a classic screen printing

* let it dry

* dip in the dye bath

* let dry

* rinse gently

Acetates can be stored for a maximum of one week in a refrigerator in closed containers. Here are the results obtained this week with this method.

Le Textile Lab samplers book¶

I used Canva to do the modele of the Textile Lab sampler book. After printing, I cut all the fabrics samples and seew them. you can have a look at the process in this Instagram reel