4. Biochromes¶

This week was exactly the week I was waiting for! Discovering natural dies was super fun and inspiring! We were working as a group so it was a generous and kindly week, a true moment of sharing with people, fabrics and nature.

This is a picture of the results we had. We look so proud aha

Dying Process¶

FABRICS AND INGREDIENTS¶

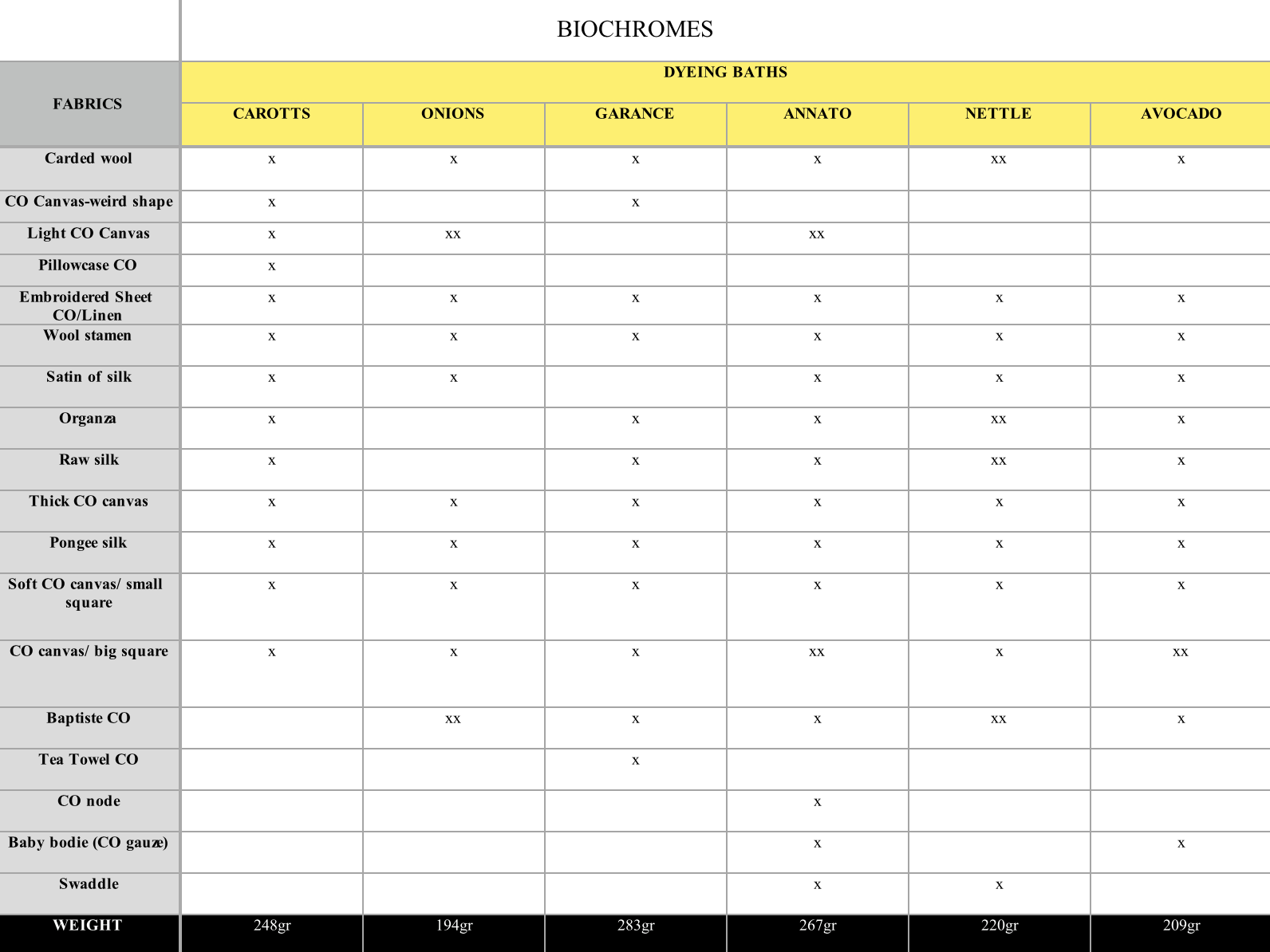

First, we had to make a plan because we wanted to experimente a lot of colors and fabrics. There were plant and animal textiles with different properties (silk, silk organza, coton, wood,…) see excel board.

We decided to do 6 baths, with 6 different dying stuff.

We grouped different samples to test in the different baths.

Then, we weighted different sample groups to calculate different ingredients which we needed to do mordanting baths.

The important is to calculate the total amount of fabrics per bath.

TIPS + when the fabric looks used or has marks, put it at the end in the bath and without the other fabrics because it might have consequences on the dying result. Be careful with rust marks (iron).

-

think of a way to attach and reconize which fabric you put in which bath.

-

be careful with wool and silk, they are delicates fabrics so you have to avoid thermal shocks. Wool will felt and silk will loose its shinny.

-

hibiscus, curcuma and beetroot (react also to the sun) are not very good for dies because it doesn't last.

-

very good fabrics : "voile de coton", muslin/chiffon, fibre bio, green-ing, brodeuse voyageuse

MORDANTING¶

Recipes :

1st mordancing bath : Carrot + Onion = 452g of fibers

We had to put 20% of the weight in alum : 90g alum

Half of the alum weight in sodium carbonate :45g

Vinegar 1L = 100g of alum - 90 cl vinegar

And water 3L water = 100g fibers : approximativly 8L water

2nd mordanting bath : Madder + Anato = 550g of fibers

20% of the weight in alum : 110g alum

And water

3rd mordancing bath : Nettle + Avocado = 507g

500ml vinegar

20% of the weight in alum :100g alum

50g calcimine? / lime (chaux)

Water

Process :

We have distributed and soaked fabric groups in the three baths.

Fabrics in the baths remained a minimum 45min.

TIPS : + pour vinegar step by step and wait until it's transparent to put the fabrics

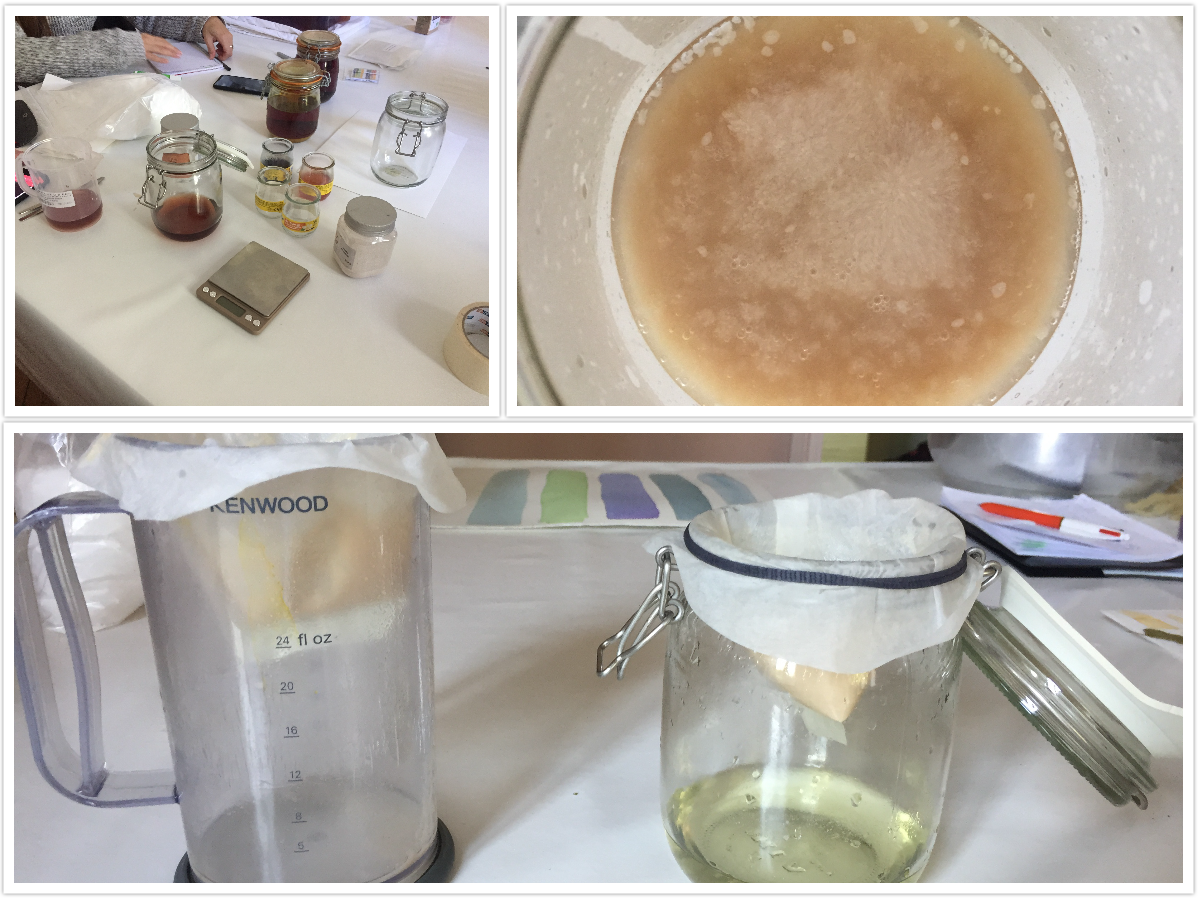

DECOCTIONS (DYEING BATH & FILTERING)¶

Then we weighed the different dying stuff to prepare and make dyeing baths.

Quantities to add according :

- Dry dying stuff : 100% of fiber weight

- Wet dying stuff : More of fiber weight

- Dying extract : 10% of fiber weight

Weight of different dying stuff for our baths :

- Leaf carrot : 75g wet and 125g dry

- Onion : 44g dry (because colour is very intense so no need to put 100% WOF)

- Madder : 28,3 g (extract)

- Anato : 100gr dry (total weight of what we have)

- Nettle : 350 g

- Avocado : 210g dry

Except the madder, the different dyeing stuff was immersed in hot water to make the decoction.

Baths remained one all night in hot water to activate the dye colour.

1 hour minimum of maceration is needed (the more time the better).

In our case we left the baths overnight, except for the madder (because it is an extract). That we did the same day.

TIPS:

+ Do NOT boil the decoction/maceration

-

it's better to take dry stuff

-

to mix decoction and bath, use one spoon per bath and one in wood, not in iron

-

it';s better if the fabrics if wet than dry when you put it in the bath

DYEING DAY¶

- 1.Filter the decoction (it’s possible to add water to the decoction so that the textile are soaked enough)

- 2.Raise the temperature of the dye to around 45 °

- 3.Once at 45 °, we put the fabrics into the bath

- 4.Then continue raising the temperature slowly/gradually to around 60/70 °

- 5.Once the bath temperature is around 60/70 ° - time/count 45min before taking off the textiles of the bath

Important notes :

- when filtering the bath we kept the ingredients for future experimentations with inks/pigments - we placed the different ingredients on cardboard and let them dry, we grinded some, as carot’s leaf and nettle, directly before drying.

- Stir the textiles regularly in the bath.

- Textiles should not be too tight in the bath, and be easily submerged so that the dye can act evenly on the fibers. In order to have a more uniform shade and result

I did some knots on my tissu called Shibori.

Process and time followed for each bath (increase temperature slowly):

- Leaf carrot : [IN] 11:50 - [70°]12:35 - [Minimum] 13:20 - [OUT] 14:10

- Onion : [IN] 11:15 - [70°]12:00 - [Minimum] 12:45 [OUT] 13:40

- Madder : [BATH] 11:30 - [IN]12:51 - [70°]13:35 - [OUT]15:20

- Annatto : [IN] 11:00 - [70°]11:45 - [Minimum] 12:30 - [OUT] 14:20

- Nettle : [IN] 11:55 - [70°]12:40 - [Minimum] 13:25 - [OUT] 15:25

- Avocado : [IN] 11:30 - [70°]12:15 - [Minimum] 13:00 - [OUT] 13:40

WASH & HANGING¶

Wool and silk are delicate fabrics so they need to be washed with attention to avoid thermal shock. In general, fabrics have to be well washed with clean and clear water.

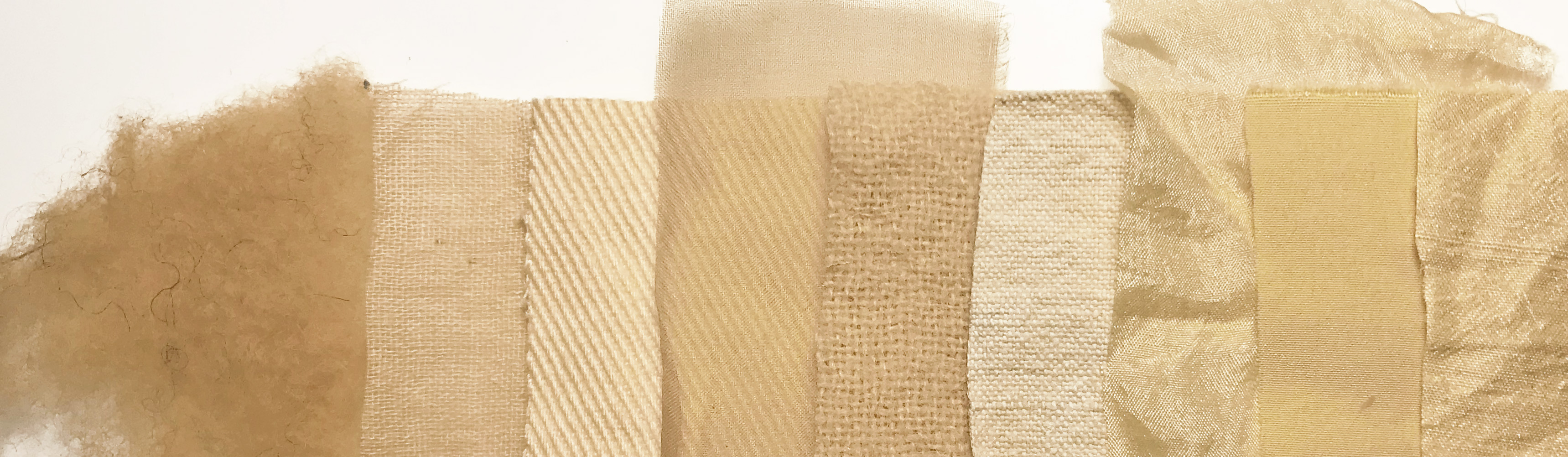

We hung dying fabrics outside so they dried super quickly. It was beautiful to see the result with the light of the sun. One of the best parts of the process :)

TIPS : Keep the liquid in a closed recipe for futher utilization, out it in the dark and add one drop of clove HE.

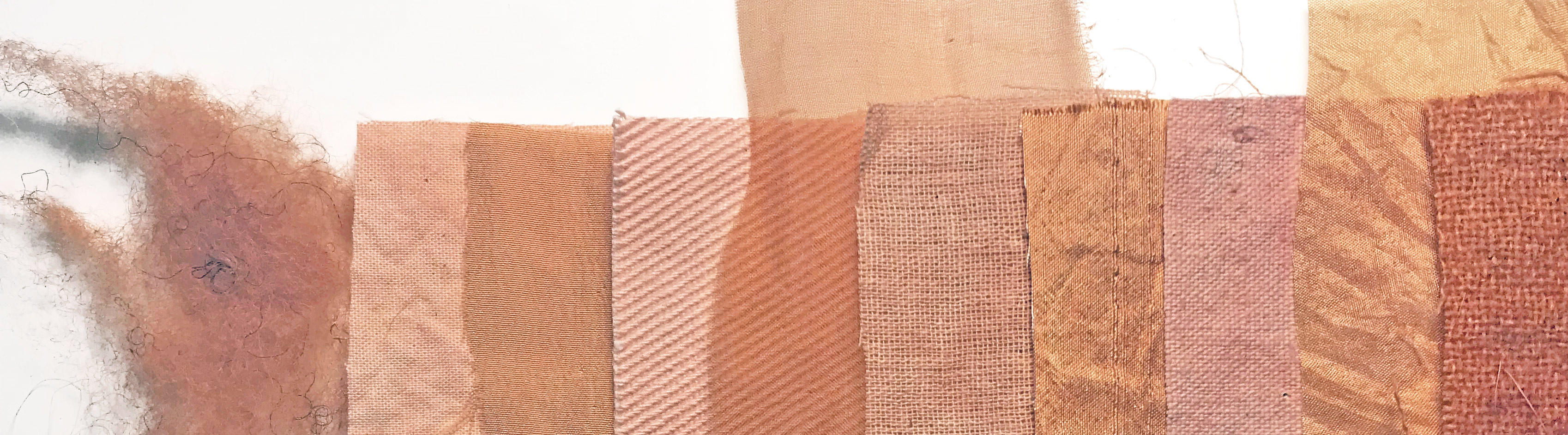

SAMPLES:¶

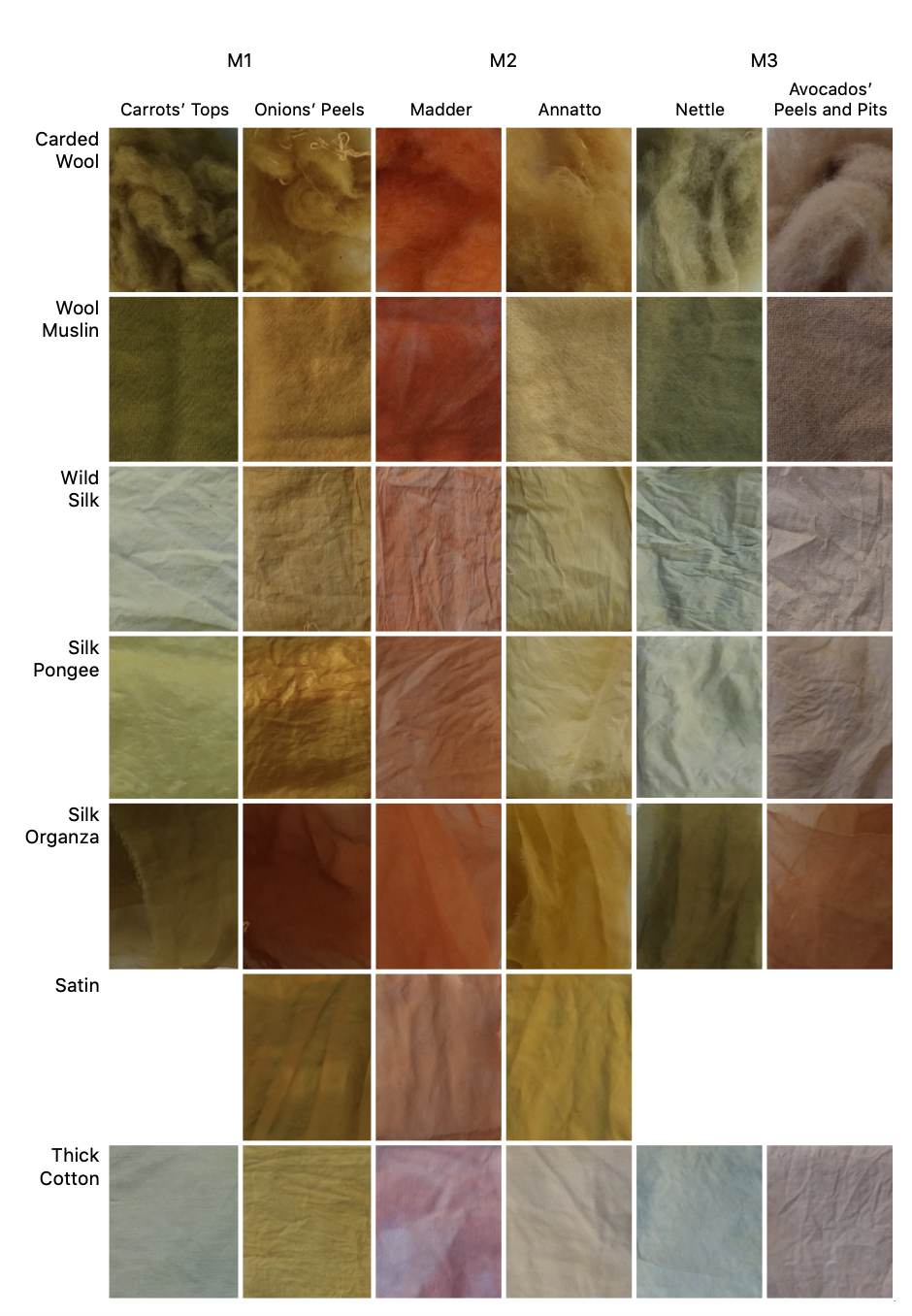

When the fabrics were dry, we took pictures of every pieces. Then we made compositions out of it.

Last step was to organise and cut a piece of every fabrics with the different dyes in order to put it on a book. One per fabricacademers and one for the TexileLab.

For not making mistakes we drew our last board:

-

Per dye

-

Fabrics names (fr/eng:)

-

Piece of fabric

ONION

ONION

LEAF CARROT

LEAF CARROT

NETTLE

NETTLE

ANNATO

ANNATO

AVOCADO

AVOCADO

MADDER

MADDER

IRON EXPERIMENTS¶

Samples before iron

Samples before iron

Results with iron

A way to modify the obtained colours is to modify them with Iron. This will give you beautiful greys and khakis depending on which plant you used first.

Recipe for a solution with 100% Iron

- 200g Iron (sulfate)

- 2L Vinegar

- 100g Sodium carbonate

Be careful it blows up if you add the Sodium carbonate entirely ! You need to do it step by step. To use it for modifying the fibers' colours, you need to dilute this solution and make it with a maximum concentration of 10% Iron otherwise it will damage the fibers.

For example, if you made 1L of solution 100% Iron and you want to have 10%, you need to dilute 100mL of Iron 100% in 900mL of water (at room temperature).

SCREEN PRINTING¶

Screen-printing paste = extract + water + gum + oxalic acide (anti-precipitant) + mordanting agent Preparing the gum tragacanth gum : 30g for 1L hot water guar gum: 20g for 1L hot water

Preparing the paste (for 100mL) 1g (2%) to 5g(5%) of extract | 50mL hot water | 5g alum | 0,5g oxalic acide | 50 mL gum

For textiles made of cellulose, you need to add a third of the volume of beaten egg whites to the paste. Then, after screen printing with this paste, you have to fix the screen printed pattern by putting the fabric in steam for at least one hour.

NOTE : If you are working on textiles which are already naturally dyed, you can add Iron to the paste (with the same extract). The screen printed pattern will appear the same colour but darker.

NOTE : this paste isn't opaque ! The chosen colour will blend with the background's colour. For instance, if you screen print blue on a yellow fabric, the screen printed pattern will turn out to be green.

NOTE : the screen printed patterns are printed into the fibers (not only on the surface)

Kombucha¶

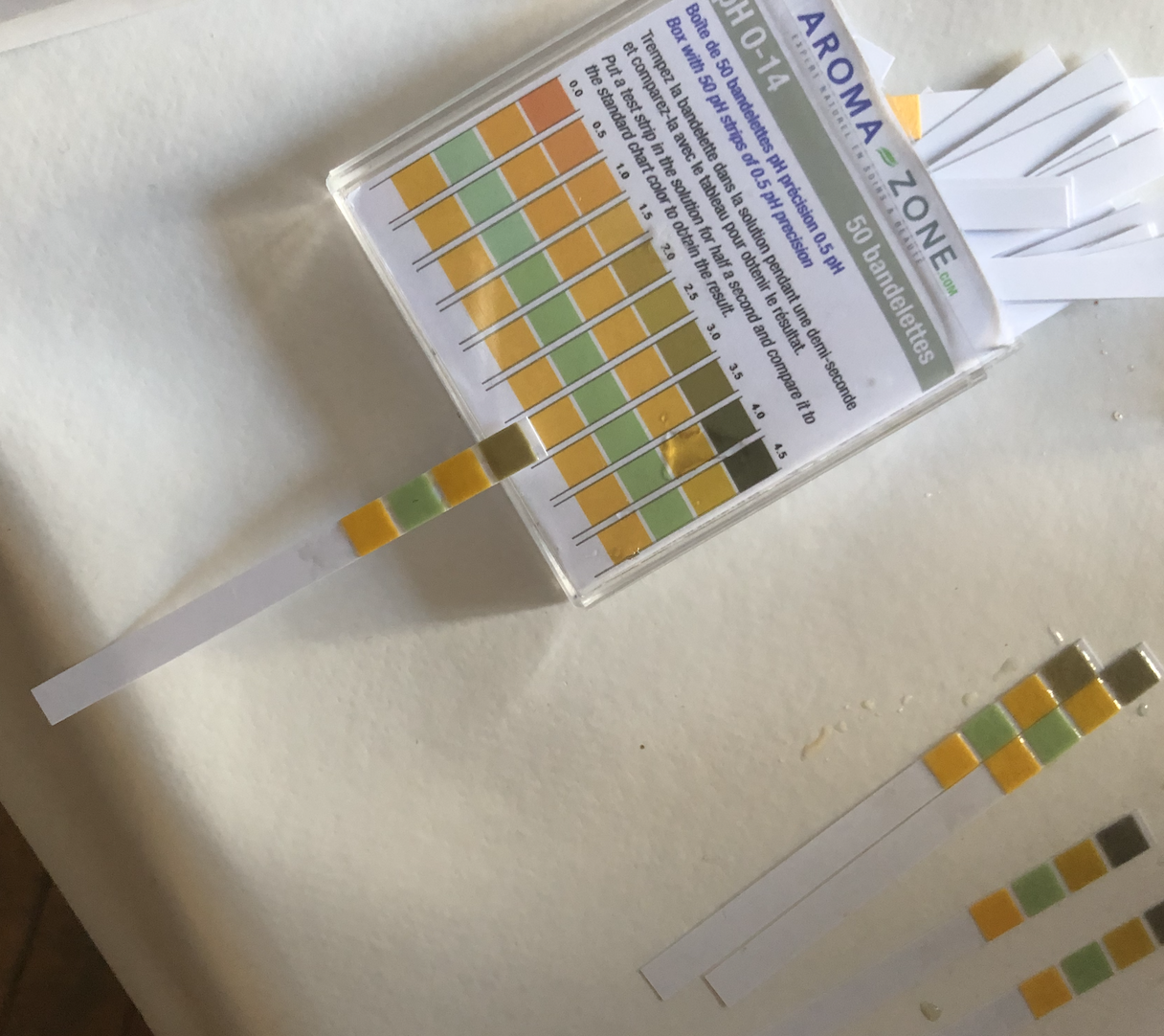

To be ready for the week of biomaterials, we started our Kombucha.

We used a classical recipe with black tea to start with and later on we might make other recipes.

So here is the recipe:

For 1L of water :

-

1,5 to 3 gr of tea ( we used black tea,but it can be any tea, depending what color of material you want)

-

100 gr. of sugar

-

Vinegar from 0 to 100ml (depending on PH of your liquid)

-

Scoby mother

In our case as we want a little bigger of a piece of Kombucha material, so we made 7 L of water.

For 7L of water :

-

21 gr of black tea (+ filter bag or tissu)

-

700 gr of sugar

-

Vinegar - we added around 100 ml of vinegar untill it got to PH 3

-

Scoby mother - 15cm ø

STEPS :

-

Prepare all the ingredients, tools, utensils that you need at your workspace.

-

First we sterilise our equipment, especially the tray where you gonna grow your material and make sure that all is clean as Kombucha can get contaminated by various microorganisms around us.

-

We boil water in a pot and add tea into it and keep boiling a bit, in our case we didn't have extra pots, so we added boiling water directly in a plastic tray and then we added tea in a coffee filter bag closed with a thread that leaves don't go all over.

-

And then we add sugar and mix it well until it dissolves, the best to do is to add it while its hot, it will work better.

-

Now its time to let it cool down until room temperature, for us it took almost 2 hours for 7L of water. If we add Scoby into hot liquid it will most likely kill it, so we better wait.

-

When our liquid has reached the room temperature we meausure the PH with PH strips or PH meter, french tap water meauseres around PH 7. So we added around 100 ml of Vinegar until it got to PH 3.

-

And now when we set up good sweet, acicid conditions we can add our Mother Scoby, make sure you do it with gloves or desinfected hands.

-

We cover it with thin breatable cotton fabric that insects and dust can't get in, put elastic around that its well covered and can be easily open for our weekly check-ups.

-

Place it in a warm (ideally 30' degrees Celsium) temperature, we put it on a specail matrass for germination of seeds. The speed of growth depends on the temperature of the ambiance.

-

And the last important thing - don't move the tray while the Kombucha is growing, keep it in a dedicated place. The desired Kombucha material will appear in about few days - week as a thin layer. The second part of the Kombucha travel will be later on the Biomaterials week.

Inks and pigments¶

We made pigments from the red onion dye bath. Pigments can be used for inks, biomaterials, oil paint… Pigments dissolve very well in oil but not in water.

This is the recipe :

Ingredients : - 200mL of the dye bath, 20g of alum, 5g of sodium carbonate - put 200mL of dye bath in a jar - dissolve 20g of alum in hot water in a pot - dissolve 5g of sodium carbonate in hot water in an other pot - put the alum solution in the jar (with the dye bath) - add slowly the sodium carbonate in the jar, be careful because it may go up - let the jar oppen for 2 hours.

The solution will separate into 2 phases, one liquid and one solid. After 2 hours, it must be filtered (we used a coffee filter), then dried and grinded. We didn’t have time enough to grind it because it wasn’t dry.

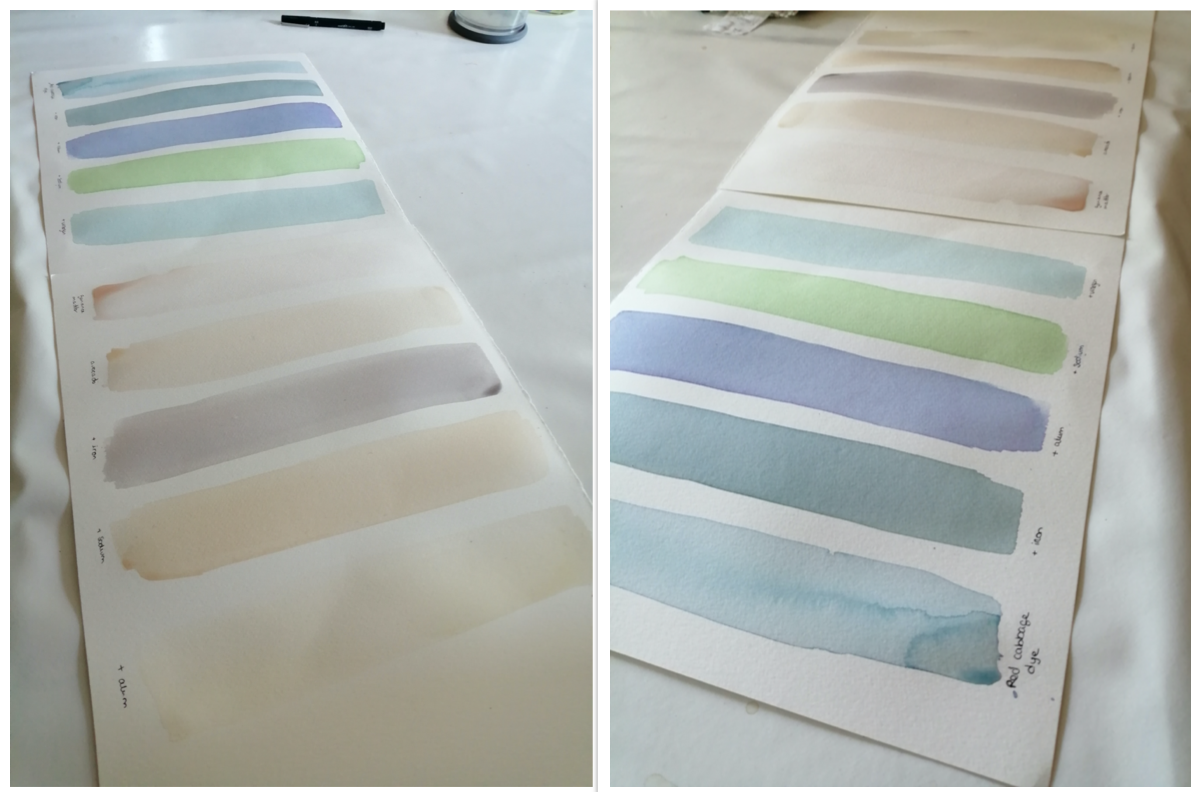

Diane showed us how to make ink from red cabbage. She immersed it and boiled it in hot water (time?). Then, we took some of the liquid and put it on paper : it gives a purple.

Then, we tried to add different elements in the ink to change the colour :

- iron (from steel wool) : it becomes blue

- alum : it lightened the colour

- vinegar : it becomes pink

- sodium carbonate : it becomes green.

There is another way to make ink with 90% ethanol that we didn’ tried. For instance it works very well with turmeric, we have an example of this ink in Oullins.

We also tried to make screen printing ink with guar gum. We mixed 200mL of madder dye bath with 20g of guar gum and we heated it up. This experiment was not successful : the mixture was too thick and viscous, moreover guar gum didn’t melt properly.

TIPS : + iron ink : ethanol, "jus de fer"(it's transparent so it reacts only with other colors)

-

iron = vinegar + steel wool

-

curcuma ink : ethanol and curcuma powder

Bacteria :)¶

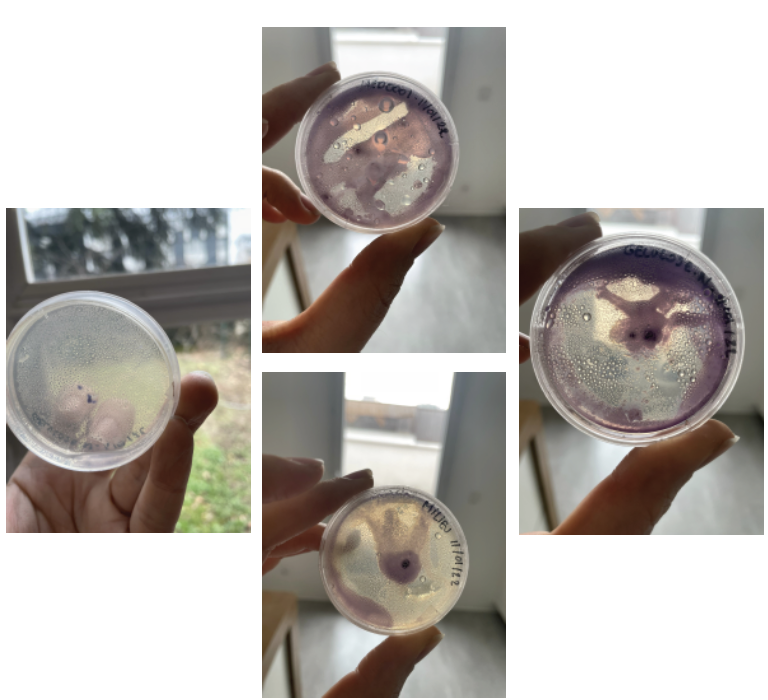

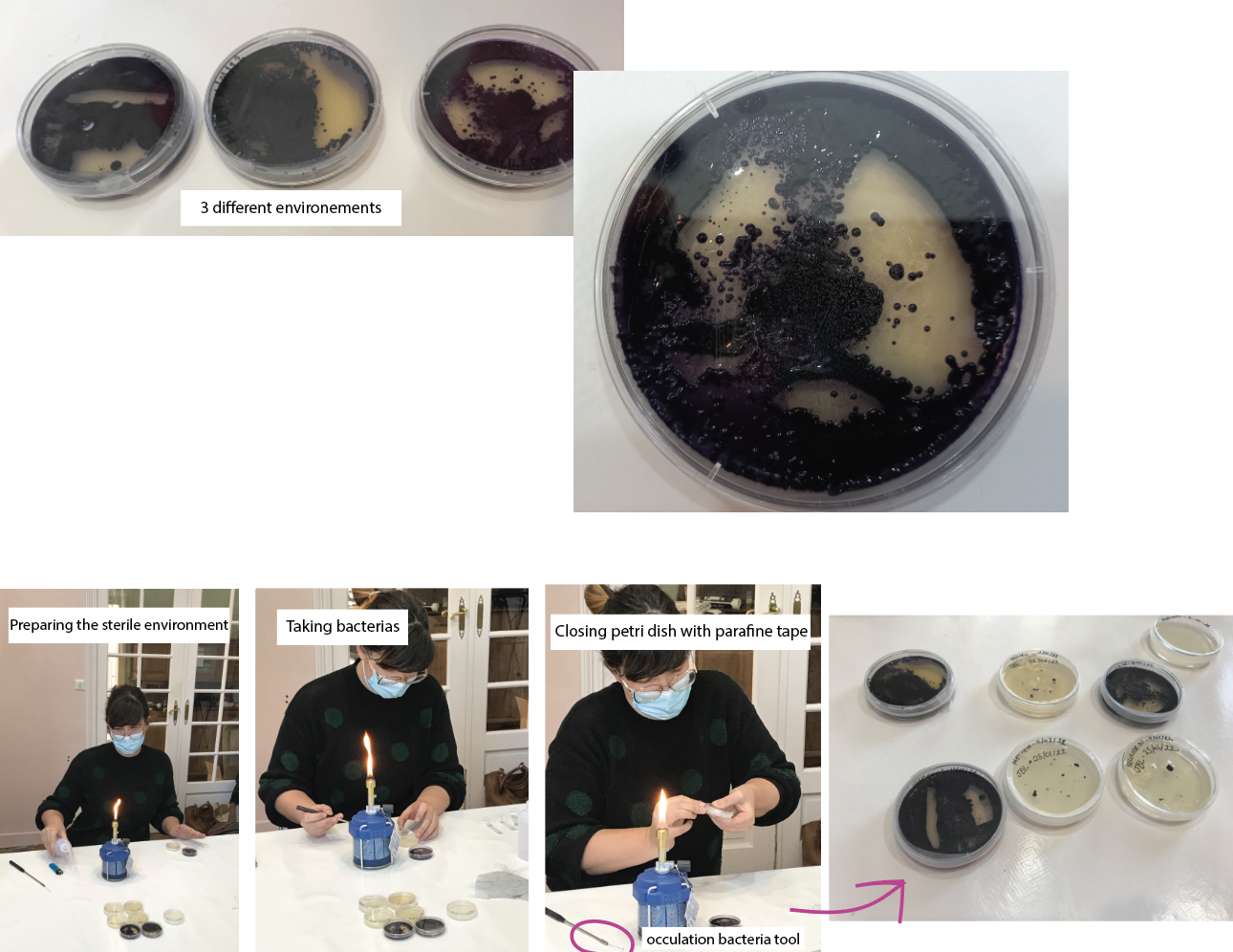

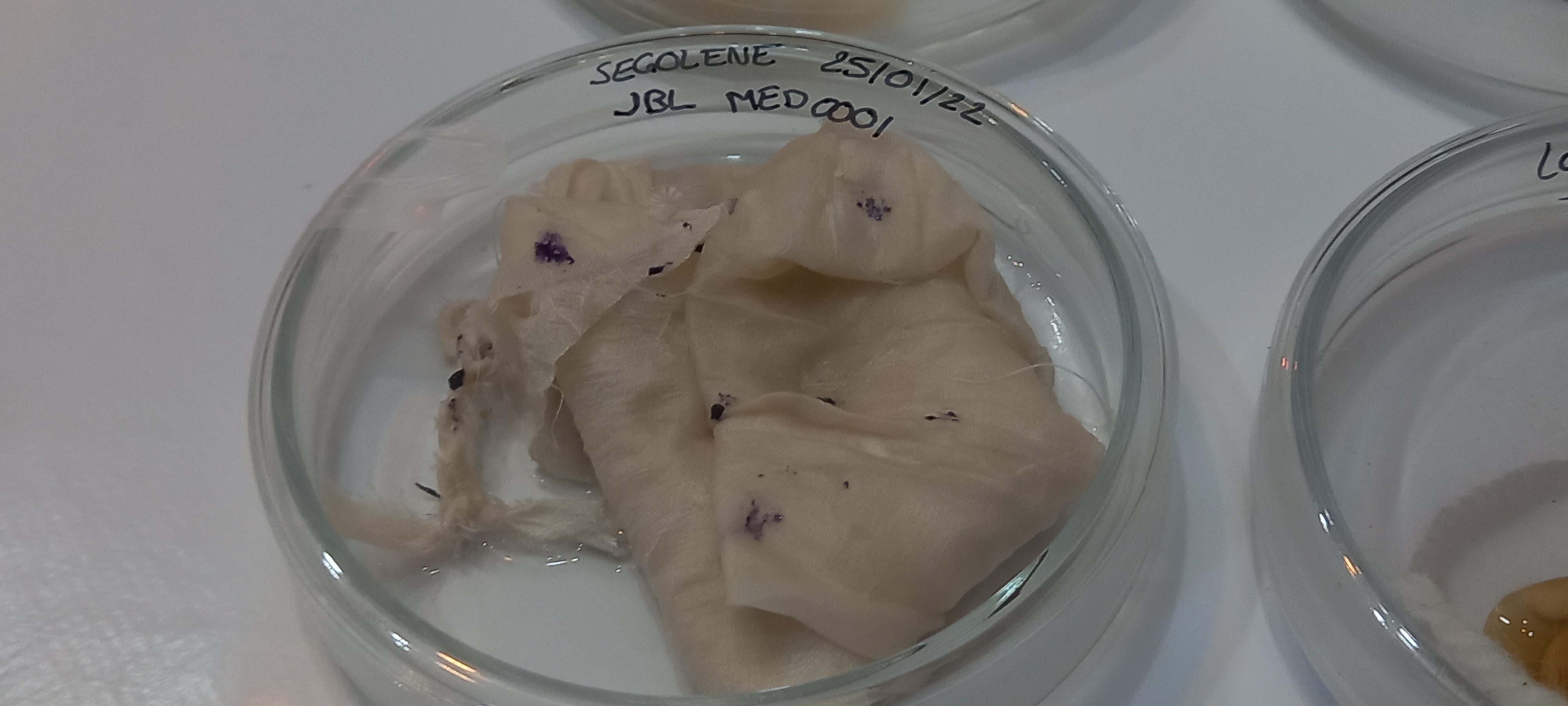

During Christmas holidays, Pauline started the process of growing bateria with 3 different environements!

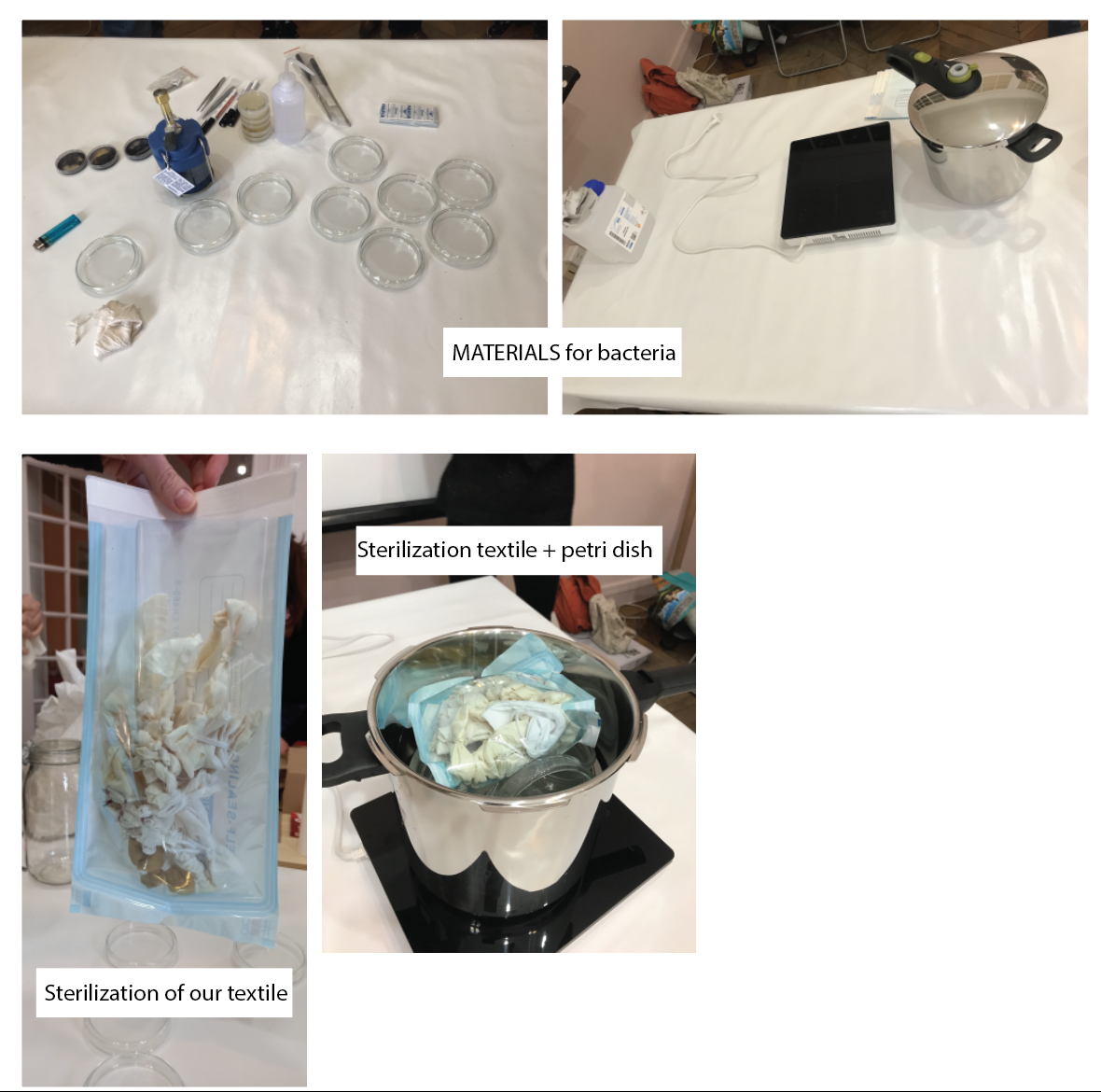

The 25th of January, we started the occulation bacteria dyeing with everybody. We had to sterelize everything and be very meticulous with the materials. We create a sterilized environnement thanks to camping gaz and ethanol.

We put our textile + petri dishes in the pot and leave them during 15 minutes.

Then, Pauline put a little bit of the bacteria in cecllulose petri dish to cultivate them again.

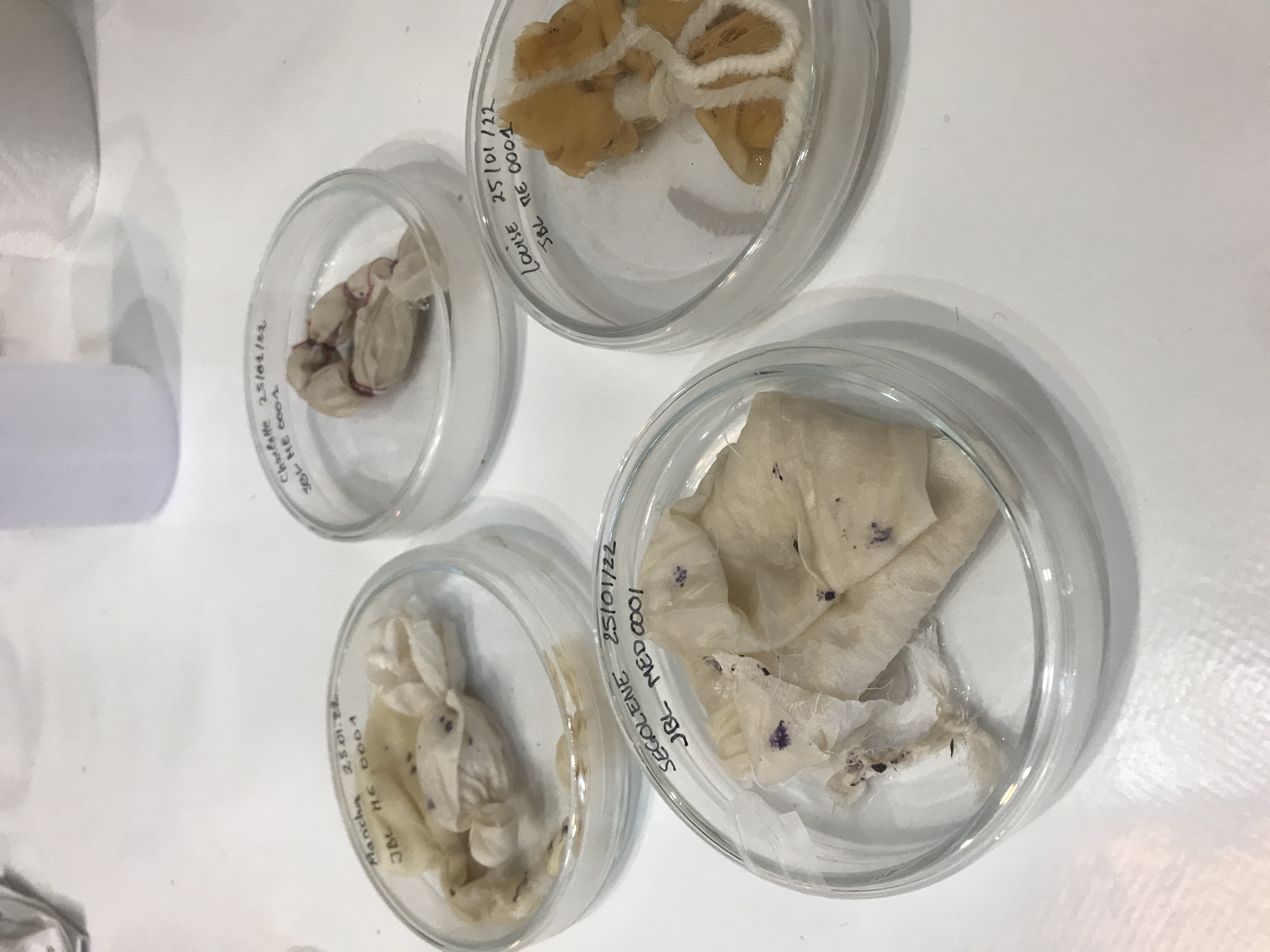

One by one, we removed our textile from the sterile bag and put it in the petri dish with bacteria. Be careful to be super precised and meticulous with the material and manipulations.

All the video process with MC :)

Waiting for the bacteria dyeing result....................

My textile with bacteria :))))

Link to the tuto of Cecilia

Useful links¶

Key words of the week/reflexion¶

I trully loved this week. I'm sure I want to creat something with natural dies for my final project. Maybe something with recycled paper (last year tuto) and light. I think this kind of recipes are perfect for my artistic vision because you don;t need to be (too) precised. Dies come from nature we it will end up different at each time and for different reasons. It's MAGIC, AUTHENTIC and ALIVE <3

BOOKS : Teinture vegetales from Aurelia Wolff