Development Timeline

-

1. Understanding the Machine

The first step forward was to locate the manual of this machine. Luckily Nishtha found one online (linked in refferred links). We read through it trying to understand exactly what this machine takes to run smoothly. Each component was analysed, touched, felt, moved around the machine.We went through videos to see how this machine works in normal circumstances.

The knitting machine was the flaghip of Brothers in the 1970s-80s and very popular in households at that time. We were surprised by how amazingly well kept this machine was when it came to the FabLab. But yes, it was in a non-working state. We sat and went through what we felt could be the consumables that need replacement/repair. -

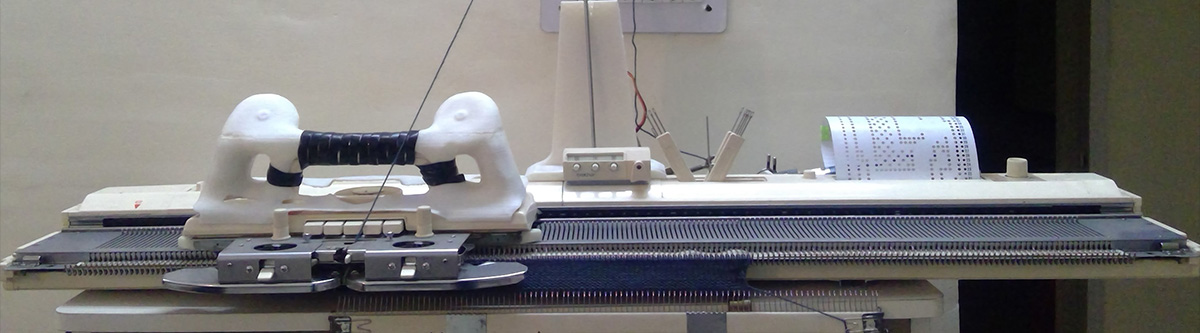

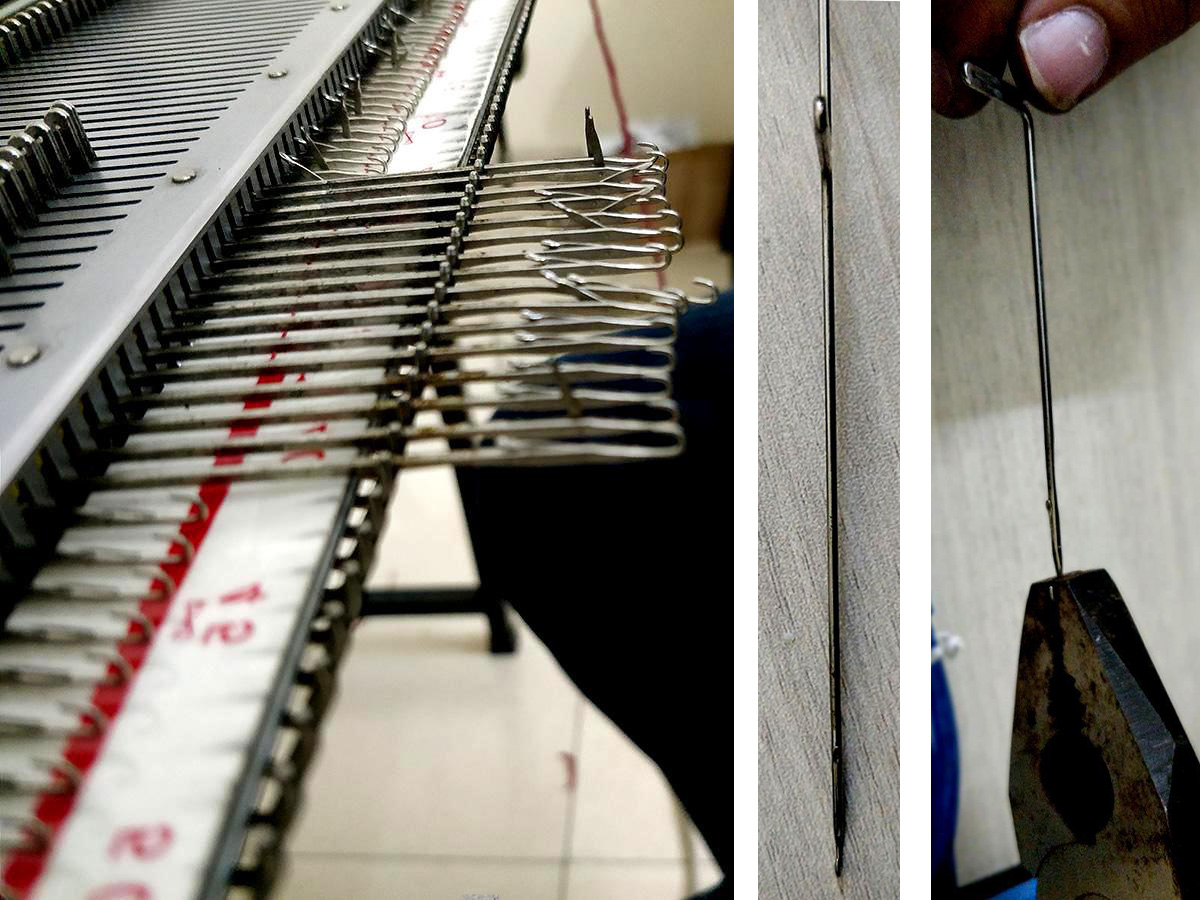

2. Throwback needles misaligned and bent

We found the needles have a big job role to play and so one by one slid out each pin. The pins we felt are bent, we later removed and straighened before putting it back. There were other pins whose mouth would not open or close smoothly, those we replaced with ned ones that came as spares with this machine.

-

3. Repair Work

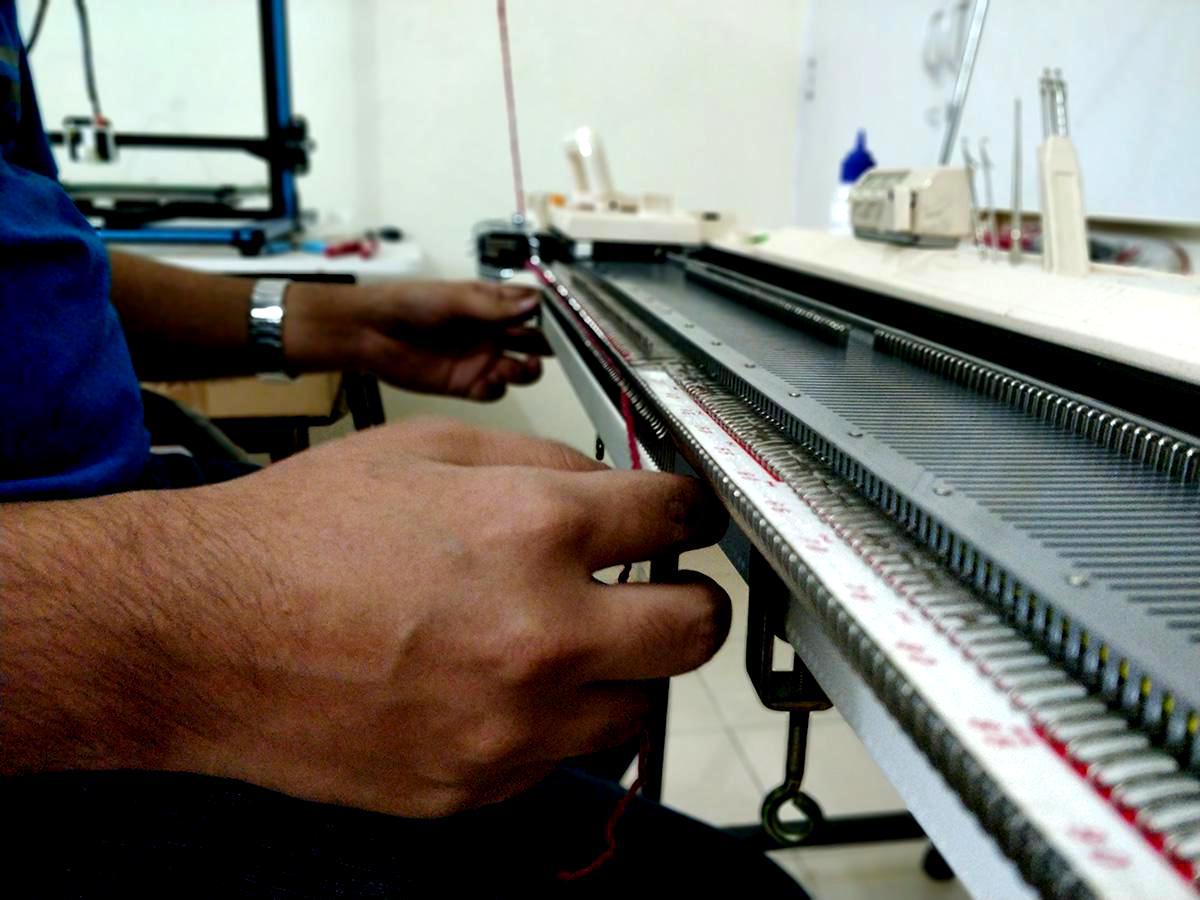

To remove the needles, one has to slide out a sponge bar from the left side of the machine. Nishtha did a splendid job, removing and repairing that sponge. When it was removed, the pins came out easily. Once she put back the repaired new sponge bar, the pins were springy as brand new and even throughout.

I took the pins and straighened them with a Plass. Its the only tool i felt could do a good job. -

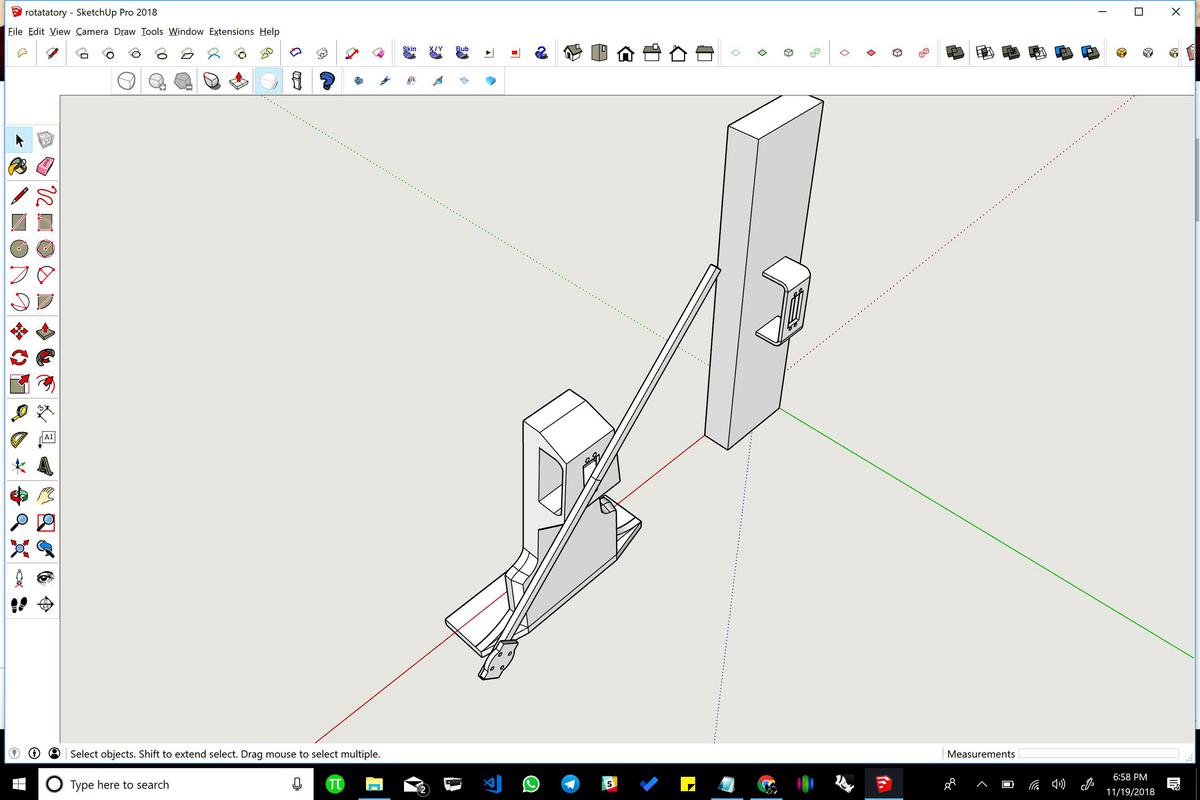

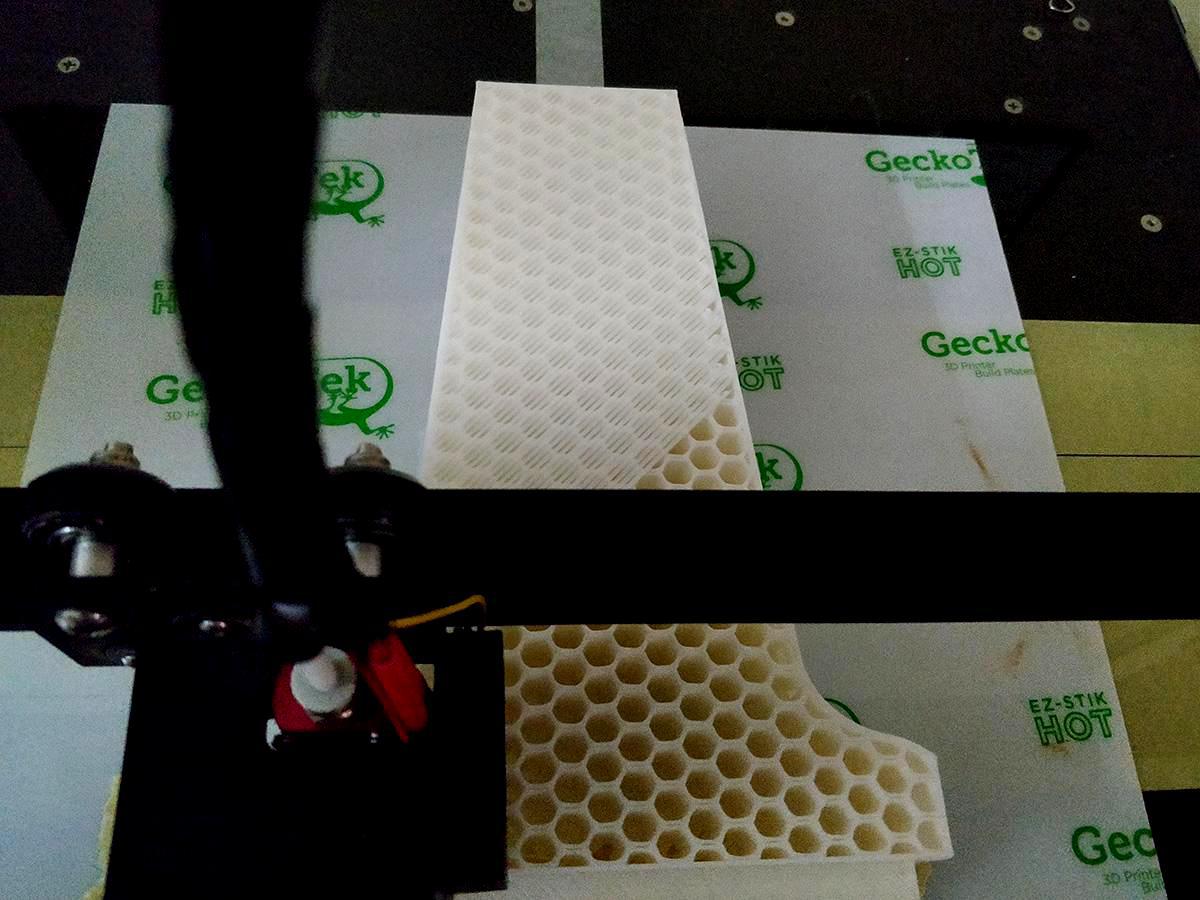

8. Digital Fabrication | 3D Printing

Zios Makerspace has two Laser cutters. One is a 60*50 cm bed size 40w Laser with a Z of 45 cms and a 4th axis rotary. The second is a 4 feet*8 feet 150W Laser cutter that has been upgraded inhouse to now cut at 240W of CO2 Laser cutting.

The small laser cutter is pretty fun as you are kind of dealing with about 10-25% power only and within that range always manage to cut neatly and cleanly with a reasonable speed.

From a fire safety concern, I switched of the air assist to prevent any chances of the fabric catching fire specially since fabrics do not need a deeper penetration which the air assists contributes to. -

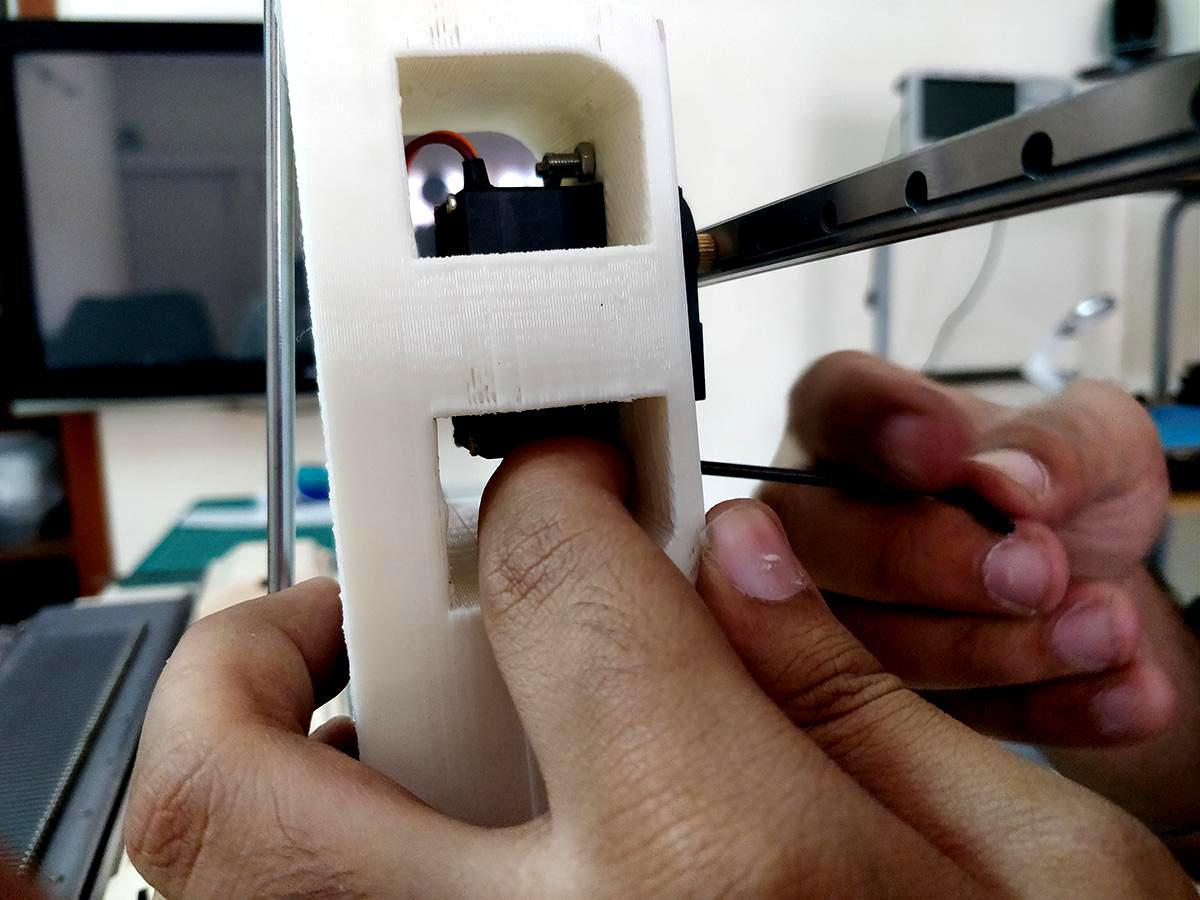

9. Assembly

To the left, is us finally using the M bolts to tighten the servo and test our tolerances

Assembly time: 2 mins (Thats right, everything was press tight and perfect)

The design seems to be coming together. Hopefully it ends up looking elegant rather than too flashy. Might end up with neither. Either way, am pleased with the results. This week too was more enjoyable than what I had envisioned it to be. -

10. Press fit Servo and its carriage mount

After having debated a lot, I finally settled on a mounting design for the machine. We would use the machine-s handle to have a press fit joint -one form underneath that would raise the machine from backside towards the user and other from above. This way, we achieve an ergonomic position for the user's arms to move to and fro with the machine at an inclination towards him while at the same time mounting the servo bang in the centre of the machine's tension rods. Even the tension rods go through this 3d printed carraige mount case.

Code by Nishtha

SERVO code

#include

Servo myservo; // create servo object to control a servo

// twelve servo objects can be created on most boards

int pos = 0; // variable to store the servo position

void setup()

{

myservo.attach(9); // attaches the servo on pin 9 to the servo object

}

void loop()

{

for(pos = 0; pos <= 180; pos += 1) // goes from 0 degrees to 180 degrees

{ // in steps of 1 degree

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(10); // waits 15ms for the servo to reach the position

}

for(pos = 180 ; pos>=0; pos-=1) // goes from 180 degrees to 0 degrees

{

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(10); // waits 15ms for the servo to reach the position

}

}

Tips and Tricks

Info Panel

Warning Notes

Danger Panel

Success Panel

F.A.Q.

I usually ask the Global team or myself questions relevant to the week's task.I plan to use this section to help me document for our lab's next batch of students important questions and their answers discussed during Global review/Recitation.

Objectives | Tasks at hand

For this week, we chose to do a group project but had our individual tass to achieve. We started by repairing our old knitting machine Brothers KH 840, we planned to take it apart and repair it. Also, we came up with a modification to solve tension problem, wherein I designed the piece and assembled it.

Reffered Links

Nov 13, 2018

Nov 13, 2018

Nov 14, 2018

Nov 14, 2018