Development Timeline

-

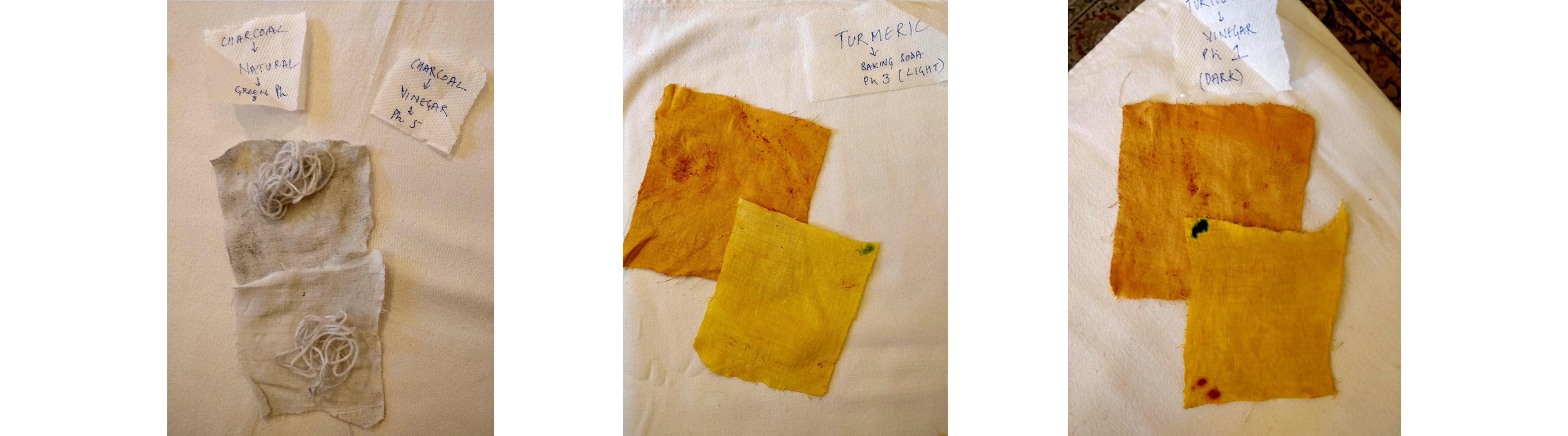

1. Scouring and Mordanting

In biodying, there are two pre-processes before dyeing, Here I took Pieces of white cotton (Vegetable fibre) and white wool (Animal fibre). In scouring process, cotton was washed in boiled water and baking soda and wool was dipped in warm water and detergent. As wool is sesnsitive to temperature so we prefer warm water over boiled. This process is to clean fibres very well. Next process is mordanting, which is important to make sure fabric is able to absorb the colour permanently therefore I used alum where I dipped the pieces of cotton and wool in mixture of water and alum. I started understanding what is Circular fashion and how can we work on making modular structure or connections that would allow the user to change the size or orient in different shapes.

-

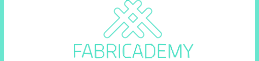

2. Bio Dyeing

After the above process, I chose natural ingredients for making my dye. I chose Turmeric powder for Yellow, Charcoal for Black, Coffee waste for Brown from coffee machine and Pomengerate for Red. After grinding, boiling and filtering. I took my mordant pieces of wool and cotton and dyed them for minutes till I was sure that they are ready. The colours were really different and beautiful. The fibers also got unfiletered particles on them making them look natutal designs.

-

5. Bio-Plastic from Milk

Executing a Milk bio-plastic is probably the fastest recipe to make and cast but probably one of the slowest curing recipes. I added vinegar to hot Milk. Quantity of vinegar added was very less that complete liquid became semi-transparent with the squishy particles settled below. I rinsed them, squeezed out whatever little moisture I could using a cloth and my hand. Thereafter pressed it down onto a thermoformed mould and let it sit for about 4 days. The result was a super hard fawn-white plastic which was hard and brittle.

This happens as I read the Milk contains a protein called casein, which is negatively charged. Vinegar contains hydrogen ions, which are positively charged. Both react and this curdles the milk. Though not too fit for consumption the way cottage cheese traditionally is. -

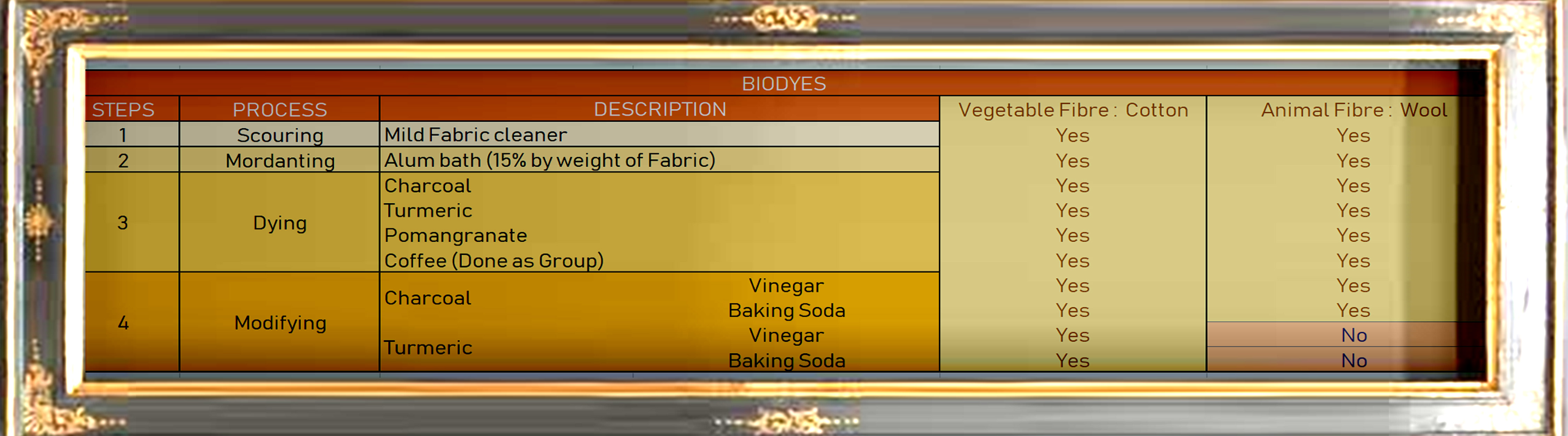

6. Bio-Plastic from Mango

This was by far the most fun part of the assignment. I simply took mangoes, made pulp from them using a Blender, squished it till I had a descent mix which was not too wattery nor too thick. Thereafter I vacuum it using a Vacuum Chamber, and baked it in an oven at 200 Degree Celsius for about 30 minutes using Convection. Once baked, I let it further dry for one day. There it is, a non recipe needed Bio-Plastic.

-

7. Bio-Plastic from Gelatin

This is the recipe made with Gelatin, Water and glycerin where amount of glcerine will decide the hardness or softness of the Bioplastic. There can be multiple applications of this Bioplastic but the ones where it doesnt have a contact with water as it can dissolve in water. I started by bioling gelati and water and added glcerine, then used vaccum chamber for degassing and removing bubbles, removing bubbles is an important aspect as it can make or break your bioplastic. For this recipe, I took Zios logo, Laser cut it and used thermoforming for making its mold. Next I spread a layer of photoluminescent powder and poured bioplastic, after 24 hours, my bioplastic was ready and glowing so its GLow in the dark bioplastic. ;-)

Tips and Tricks

Info Panel

Warning Notes

2) Dont overvacuum as curing speedens up under vacuum.

Danger Panel

2) Though recipes are food safe, better to keep lab seperate from the pantry.

Success Panel

2) One should also understand effect on color with use of acids or basis( pH variations)

F.A.Q.

I usually ask the Global team or myself questions relevant to the week's task.I plan to use this section to help me document for our lab's next batch of students important questions and their answers discussed during Global review/Recitation.

1) Shift + F5 (Prefer viewing in Chrome) to load website completely again rather than relying on caches.

2) Make sure you are connected to the internet. As few GIFs are present online so would require the internet to load.

Objectives | Tasks at hand

For this week, I have tasked myself of shortlisting Turmeric, Pomengerate, Coffee and Charcoal as my Bio dying ingredients and Milk and Mango as my Bio Plastic ingredients.

Reffered Links

Oct 17, 2018

Oct 17, 2018

Oct 18, 2018

Oct 18, 2018