Development Timeline

-

1. Photogrametry + IR + T.o.F 3D Scanning

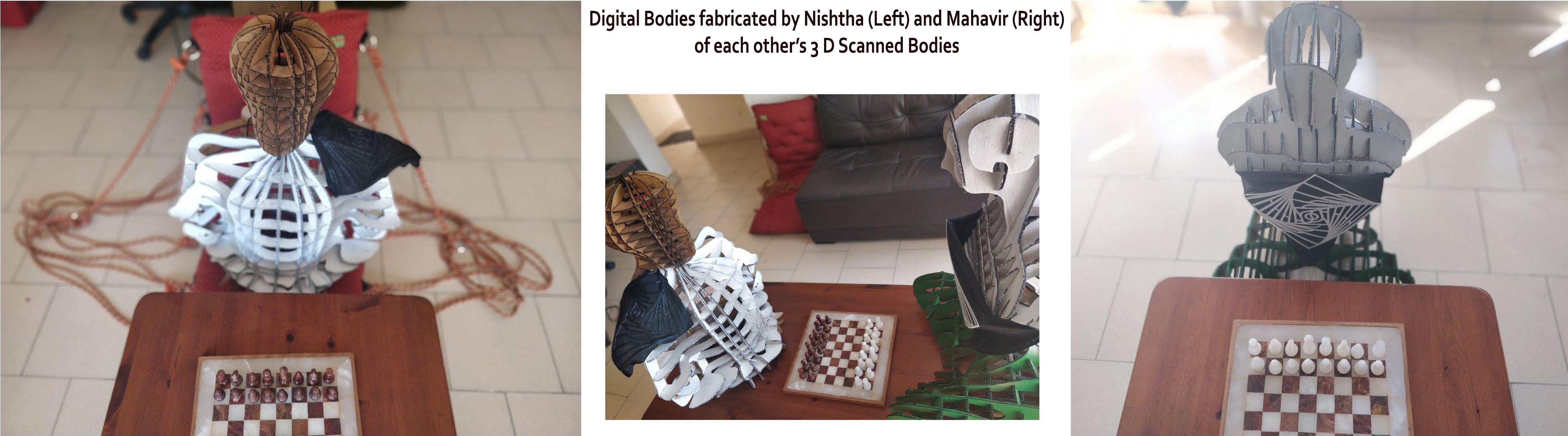

The Kinect One is a very underestimated scanning solution. Within this piece of fantastic Microsoft Genius, is a Time-Of Flight tech, IR, Pointcloud data optimisation and photogrametry arrangement along with a very high def camera for capturing color data. There are multiple scanning softwares that integrate with Kinect as an input Device. Brekel, IpI, Rhino|Grasshopper, 3D Scan, KinectStudio are just few of those that one can use to capture data in a variety of ways, Motion data included. We have done several Mocaps with this but for now, the assignment is a simple one and so the I proceeded with requesting Nishtha to bear with me till we could collectively figure out how to scan an interesting Lotus pose of a Human. Between the two of us, she has a much fitter physique to keep sitting with a straight spine till i keep repeating the scans in different ways. What worked best for us eventually an armless chair in the lab. I was personally pleased with the outcome and was excited to start proceding with the next steps.

-

2. Pointcloud to Mesh

The best advantage I see to a pointcloud scan data is your ability to keep or ignore objects you would like to retain or omit from a scan post data scanning. The current scan was scanned using both Scan 3d and Brekel through Kinect studio. I finally settled on the Scan 3D scan as its mesh quality was comparable and descent to post process. I thereafter segregated my focuse area from the extra scans of the room. Am now ready to export this to meshmixer to edit and optimise the mesh.

-

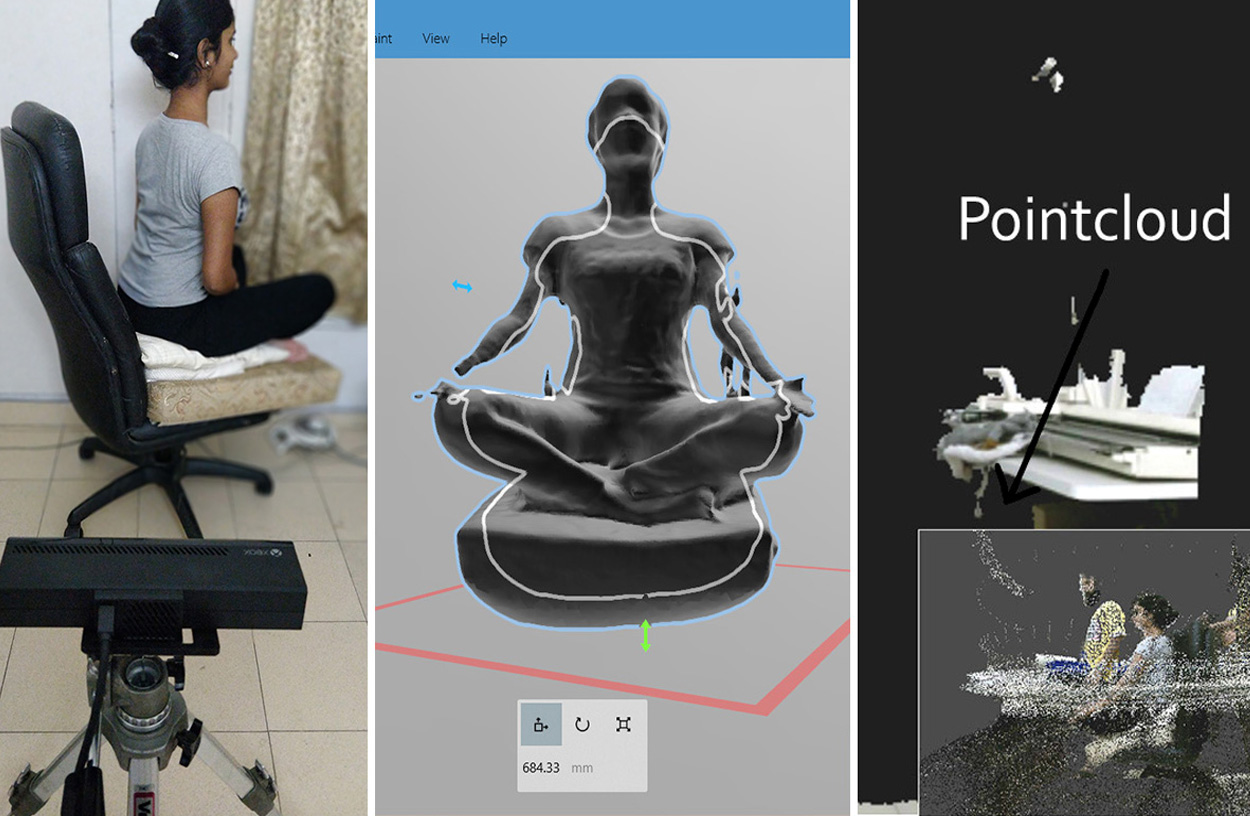

3. Mesh editing and optimisation

So for the mannequin, I need to modify Nishtha's scan in such a way that it is fabricable without compromising on the integrity of the structure. I also need to retain information within the mesh and remove certain mesh spots that have no consequence on the scan thats beeing tried towards fabrication.

I downloaded Meshhmixer, its a very simplified version of softwares like Zbrush or Mudbox. At the same time, it does the job needed and retains al scultping functions one needs to do an intermediate 3d Modelling sculpt work. As you can see from the image on the left, I removed the hands, cleaned up the pectoral region, slightly smoothened the mesh to take out inconsistencies that point cloud triangulated meshes are prone to. Post sculpting few things here and there, making the mesh a solid and uniforming the mesh, I proceeded to the next step-Slicing. -

4. Slicing Software

I havent used Slicer before,got introduced to it through last year's tutorial/review. The download link to the software can be found HERE and Yes its free. Thanks Autodesk.

In terms of hard disk space, the software takes roughly 221Mb of hard disk space post installation(64 bit). One needs an autodesk id to sign in and use the ir feautures. The software is supposed to help slice your intended waterproof models along a couple of slicing and stacking techniques, generating you cut files as a pdf or dxf and also lets you set in your laser kerf parameters among other parameters. Quite a nfty and easy to understand sotware by Autodesk. Not bad !! -

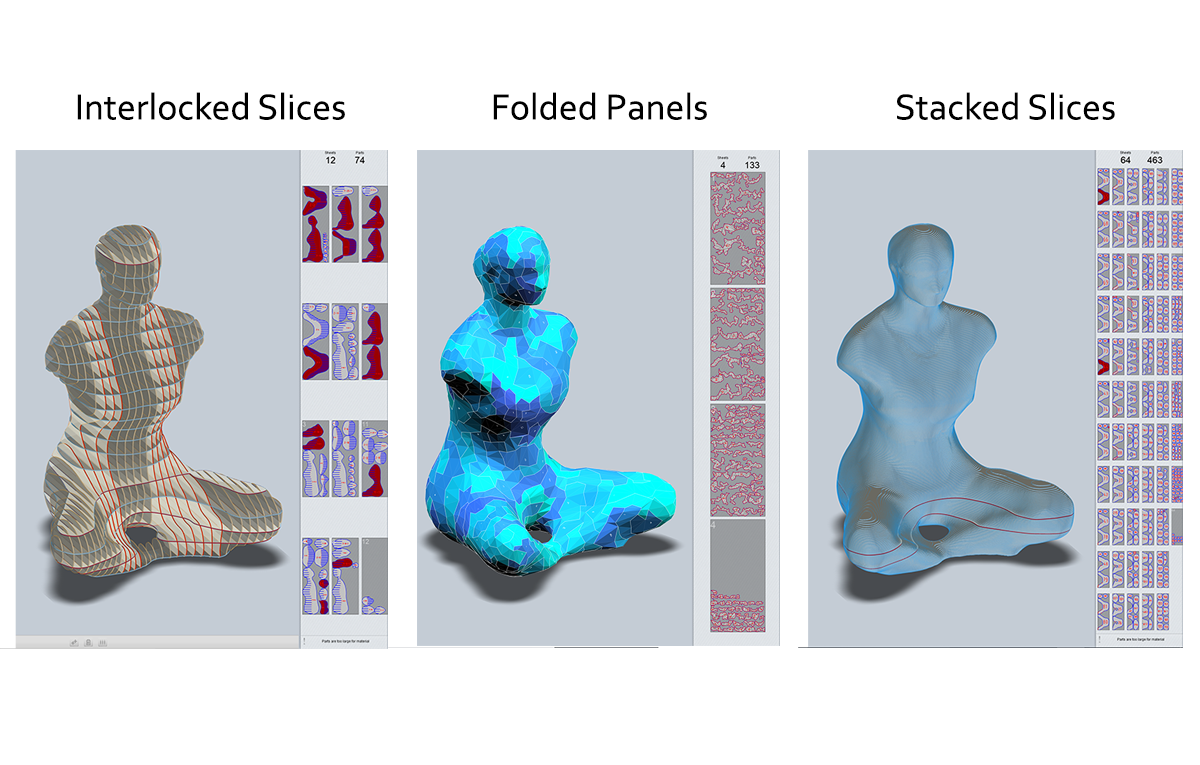

5. Slicing techniques

There are numerous ways of assembly and slicing. The ones I considered besides the one I used finally to fabricate the lotus pose were Interlocked Slices, Folded Panels and Stacked Slices. I finally settled for a Radial Slice Technique once I compared the pros and cons of all 4 types of fabrication.

I kept in mind 3 factors majorly:

1. Time taken towards assembly;

2. No. of Full Sheets it takes to assemble;

3. Nesting efficiency (learnt from circular design week) -

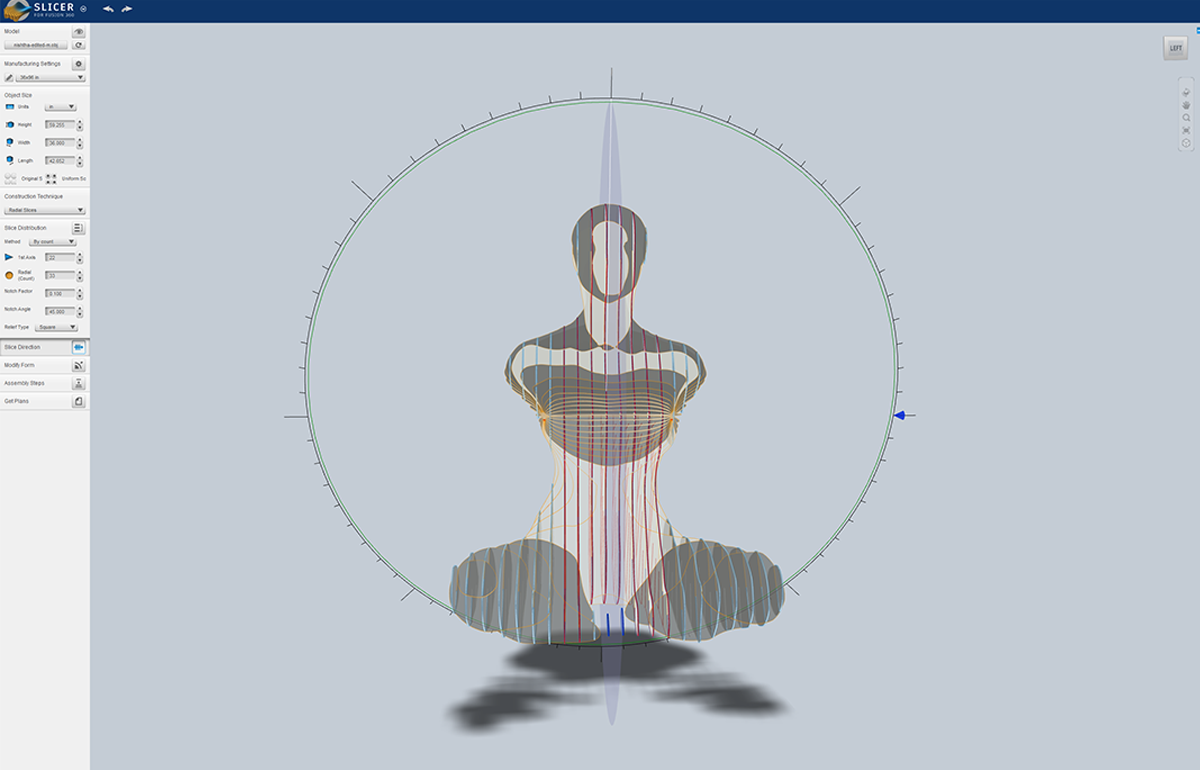

6. Optimal Slicing Orientation and Design Development

I recollected that a Lotus pose was attempted to be fabricated by another student too which had run into problems. Its my personal opinion that it had a lot to do with the orientation and technique of slicing. The radial technique seemed efficient to me if only I could find the right orientation. I ended up changing the orientation of slices in all three directions to get one which I saw most probability of assembly. Although a few pieces are marked Red, its solvable by making precise cuts to open the close loops that the Lotus pose generates.

As per the original concept, the plan was to use 2 seperate colored cardboards-White and Black. Our board manufacturer had run out of the two color sheetrolls and we did not have that big an order that e purchase 2 full rolls of that color. So we settled for a cardboard lot comprising of 5mm thick 6 layer criss-crossed cardboard sheets of size 5*4 feet each. -

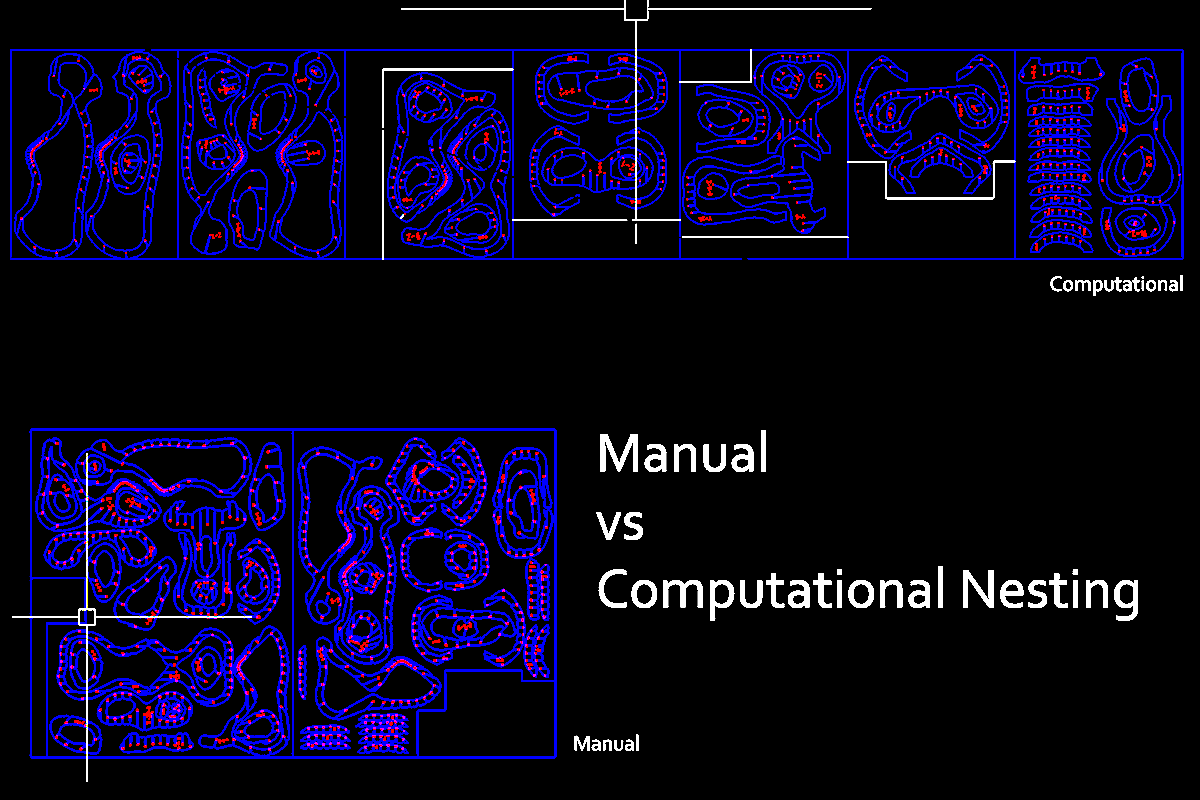

7. To Manually or Computational Nest?

So, I never came across an honest test to see whether computational nesting is as efficient as Manual ones. But what I do realise the more and more I have been nesting for the past 6 years is that its a combination. Let the software nest for you, and then you nest further with logic that is defined by your current machine information that you have access too.

I always manage to reduce the no. of sheets used post computational nesting by manually nesting it further. And often than not, its close to a 60-70% reduction. It might take more time to manually nest, but if you rather approach it as more of an after nested step, the more efficient it becomes and saves you a ton of material. This Mannequin was fabricated using only 2 sheets post manually nesting compared to the 4-6 that various softwares gave results to me of. -

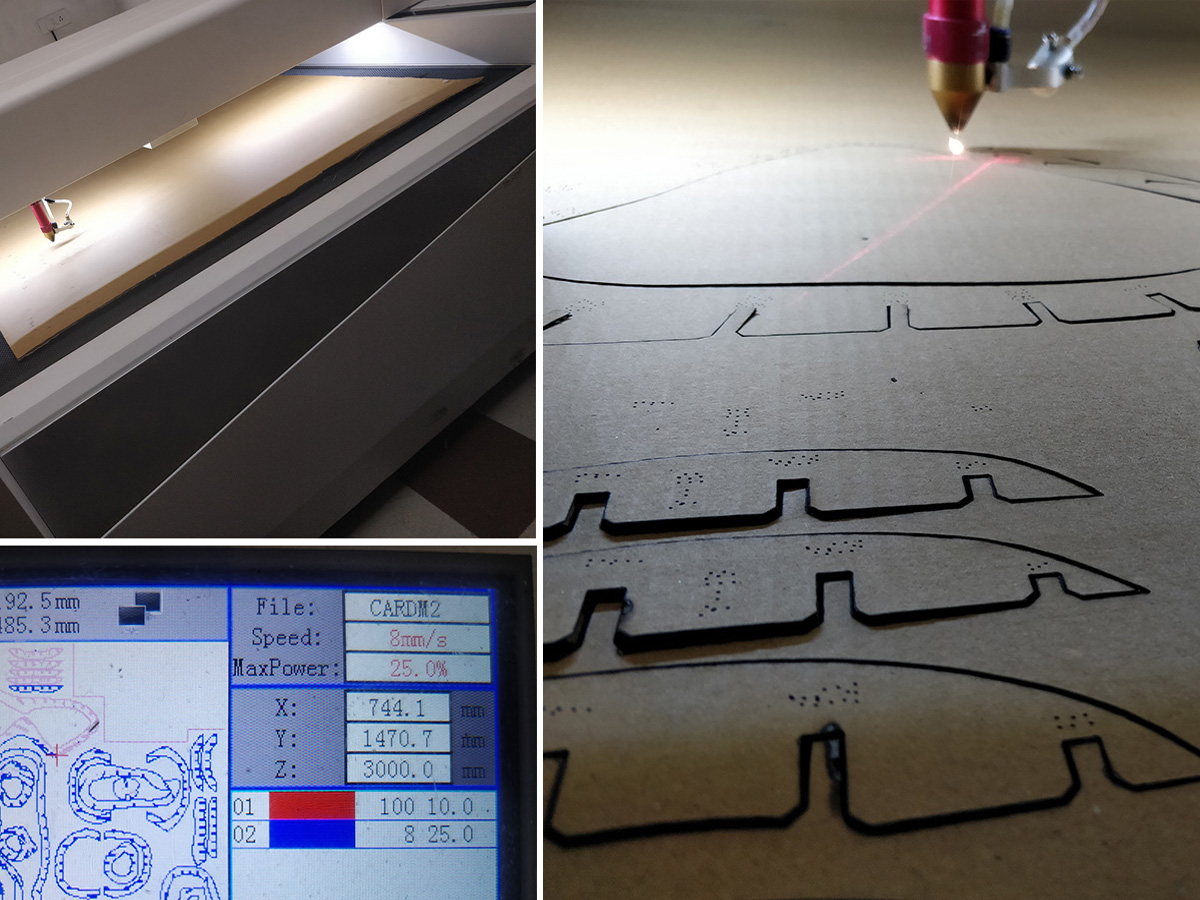

8. Digital Fabrication | Laser Cutting

Zios Makerspace has two Laser cutters. One is a 60*50 cm bed size 40w Laser with a Z of 45 cms and a 4th axis rotary. The second is a 4 feet*8 feet 150W Laser cutter that has been upgraded inhouse to now cut at 240W of CO2 Laser cutting. We never found a justifiable cost to a fibre laser specially since down the line such lasers are upgradable to fibre ones through special kits should the need arise. From that context, cutting cardboard or fabric on this laser cutter is pretty fun as yo uare kind of dealing with about 10-25% power only and within that range always manage to cut neatly and cleanly with a reasonable speed. We however dialed down our cutting spead due to just one reason. We wanted more conrol over the pieces that were getting cut as the moisture content of cardboards is an issue for us during the Winter Season and more importantly for CO2 tubes, higher power cutting leads to a bigger difference in temp. between the tube when it is hot and when it cools down in the 5-10degree celsius ambient temperature which can lead to substantial loss of a laser tube's life. A slower speed with a very low power ensures us a neater cut and saves the tube life too. However this would not be true for any other time of the year for us as we switch on our air assist.

-

9. Manual Assembly

This involved some skill, as the slicer animation does not consider one factor during assembly:

'The Phenomenon of Gravity'

There were a few places at the start and mid timeline of the assembly where we saw a need to insert pieces that were not recommended to be put first by the animation of Slicer.

Overall the assembly took close to 2 hours between the two of us-Nishtha and myself. I am definate that this task is not meant to be done alone. It requires two sets of hands at least.(two sets of feet too).

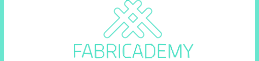

It was hillarious to see how tiny the manequin seemed but once Nishtha sat next to it, I realised the true nature of what digital bodies actually consets for the current and future applications. It seemed so accurate to the nearest details of Nishtha's ergonomic measurements. -

10. Digital Body: Lotus Pose

Yay, Something in the lab that amalgamates seamlessly with our landscape! As an architect, thats one possible interesting application towards Landscape Architecture.

The more I saw it for a few days, the more I fell in love with this raw look. If only this had been done in a more waterproof material. Sad that am going to ruin it by painting it (Thanks to a weird idea and risk I have in mind for this piece.)

Command Line used to Push Documentation for Week 02: Digital Bodies

ziosm@SurfaceBook MINGW64

$ cd

ziosm@SurfaceBook MINGW64 ~

$ cd fabricademy_website

ziosm@SurfaceBook MINGW64 ~/fabricademy_website (master)

$ git pull

Enter passphrase for key '/c/Users/ziosm/.ssh/id_rsa':

ziosm@SurfaceBook MINGW64 ~/fabricademy_website (master)

$ git add --all

ziosm@SurfaceBook MINGW64 ~/fabricademy_website (master)

$ git commit -m "week02 updated"

ziosm@SurfaceBook MINGW64 ~/fabricademy_website (master)

$ git push

Enter passphrase for key '/c/Users/ziosm/.ssh/id_rsa':

Tips and Tricks

Info Panel

Warning Notes

Danger Panel

Success Panel

F.A.Q.

I usually ask the Global team or myself questions relevant to the week's task.I plan to use this section to help me document for our lab's next batch of students important questions and their answers discussed during Global review/Recitation.

Objectives | Tasks at hand

The goal for me this week is to 3D Scan via Photograpmetry and Pointcloud data capture of a Kinect One someone in LOTUS pose. Why Lotus-Becuase its challenging to scan an unorthodox pose. I plan to utilise the bigger laser cutter of the fablab-a 1.3m *2.5 150W Laser Cutter to cut 5*4 feet 5 layer cross pasted cardboard sheets. Lets see how it goes.

UPDATE: Glad the end outcome(shown on the left) came out well. Was amazed to see how well it merged into natural landscaping. It came out so well that I visualised my country's National flag within this figure and used this same mannequin to wish our network India's Republic Day wishes whose poster I have attached in a slideshow below in 'Final Weekly Result' Section.

Reffered Links

Oct 03, 2019

Oct 03, 2019

Oct 04, 2019

Oct 05, 2019