4. Biochromes¶

| Biochromes |

|---|

|

This week I worked on textile dyeing and studied the effect of chemical dying on the environment.

Assignment¶

Study and understand the chemical dyeing methods that currently used in textile industry. Then purpose eco-friendly natural dyeing techniques and also find the way to fabricate them.

4.1. Introduction¶

The enormous usage of synthetic dyes in various industries, chiefly textiles and paper industries, has posed a considerable health and environmental hazard. This dictates the need for amendment in the textile coloration technology by using natural origin pigments to replace the existing toxic, mutagenic and teratogenic dyes. Therefore, the scientists have recently focused their attention on applications of natural pigments for fabric dyeing as they depict eco-friendly, biodegradable and environmental compatibility properties. Furthermore, the application of biochromes in textile dyeing is free from disposal problems as well. Several micro-organisms, plant systems as well as some animal sources have portrayed the potential of production of biochromes that can be extracted with ease and be used for coloration technology including textile dyeing.

| Chemical Dyeing | Natural Dyeing |

|---|---|

|

|

The process of extracting color from plants via steaming, beating, heating is called natural dyeing.

4.2. Fabrication of Chemical Dyeing¶

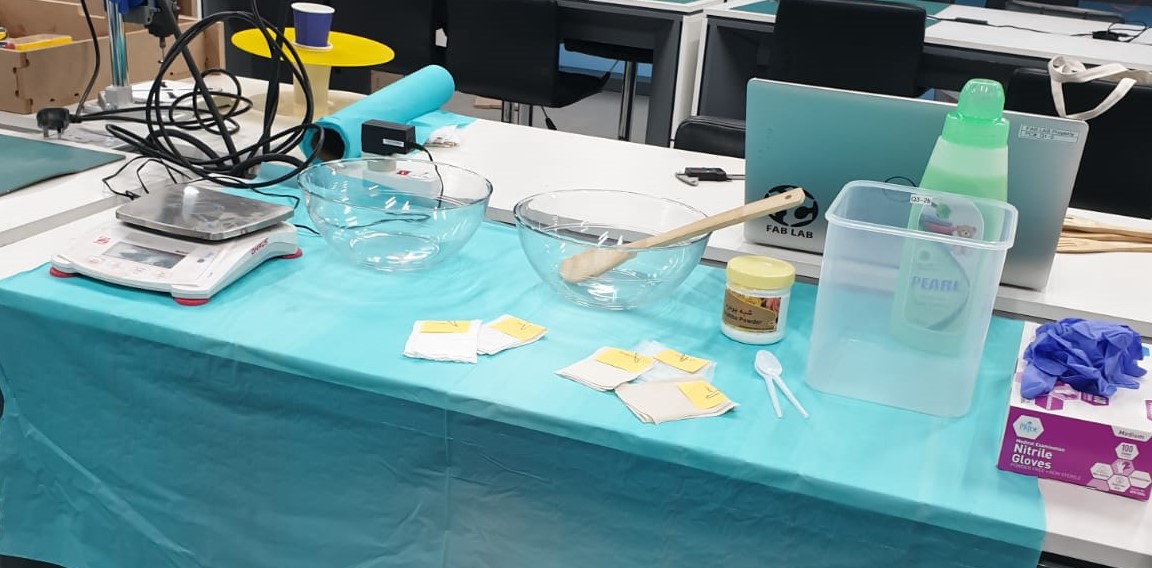

Required Equipment with Specifications¶

| Equipmet and Tools | ||||

|---|---|---|---|---|

| Vinegar, Baking Soda | Cooking Tools | PH Modifier | Vegetable Fibres | Measuring Cups |

| Beet Root, Blueberried | Fabric Conditioner | Spoon, Wooden Sticks | Plastic Container | Glass Bowl |

| Fabric Pieces | Tumeric Powder | Lemon, Salt | Safety Gloves | Digital Balance |

The Process of Scouring¶

Scouring is deep cleaning of fabric or fiber. Scouring helps assure even color and good penetration of the dye. Proper scouring is absolutely essential to good dyeing. Improperly scoured items do not dye evenly, the dye does not penetrate well, and the dyed item may not be fast.

| Scouring Process Image - 1 | Scouring Process Image - 2 |

|---|---|

|

|

| Scouring Process Video |

|---|

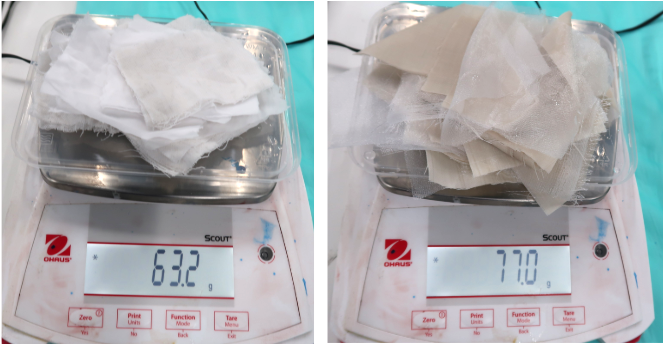

I have used Digital Balance to weigh the vergetable fibers (2-potions) and protien fibers (3-portions).

| Vegetable Fibre | Protein Fibre |

|---|---|

|

|

Scouring Steps:¶

1 - I used a container and fill with enough water so that the yarn or fabric may be well covered and not crowded.

2 - I added 1 teaspoon (5 ml) orvus paste soap (conditioner) for each pound 450 g of dry fibre/fabric. Hence, 0.27 ml conditioner will be used for 24.5 g of vegetable fibre and similarly 0.4 ml conditioner will be used for 36.6 g of protein fibre.

3 - I waited to simmer for approximately 1 hour and then rubbed and scoured the fibre so that they are clean.

4 - I noted the weiht of fibres again.

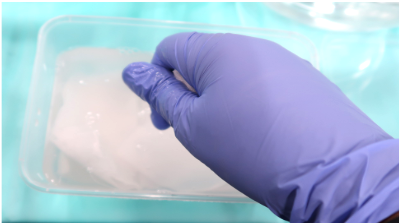

| Fibers Packed in Container | Rubbing and Scouring | Weight After Scouring |

|---|---|---|

|

|

|

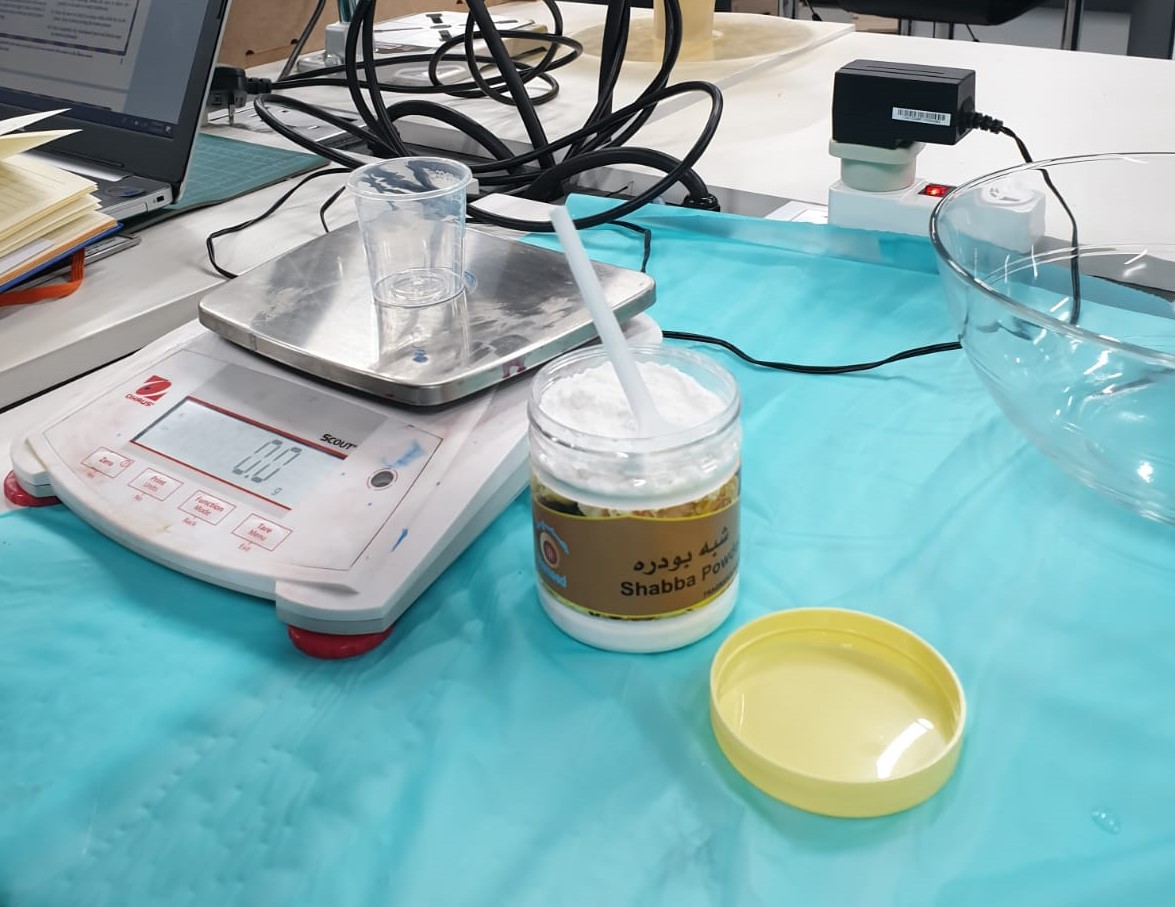

Mordanting the Fabric¶

Many natural dyes require the use of a mordant to achieve the most durable and long lasting colors. Mordanting prepares the fibers to bond with natural dyes and is typically a separate immersion bath for the fibers. The technique is simple: measure the mordant, dissolve in water, and add to a dye pot or bucket or tub filled with water. Add the fibers and hold them for a period of time, then remove and proceed to the dye bath. Although many substances have been used in the past for mordanting, I prefer alum as a mordant.

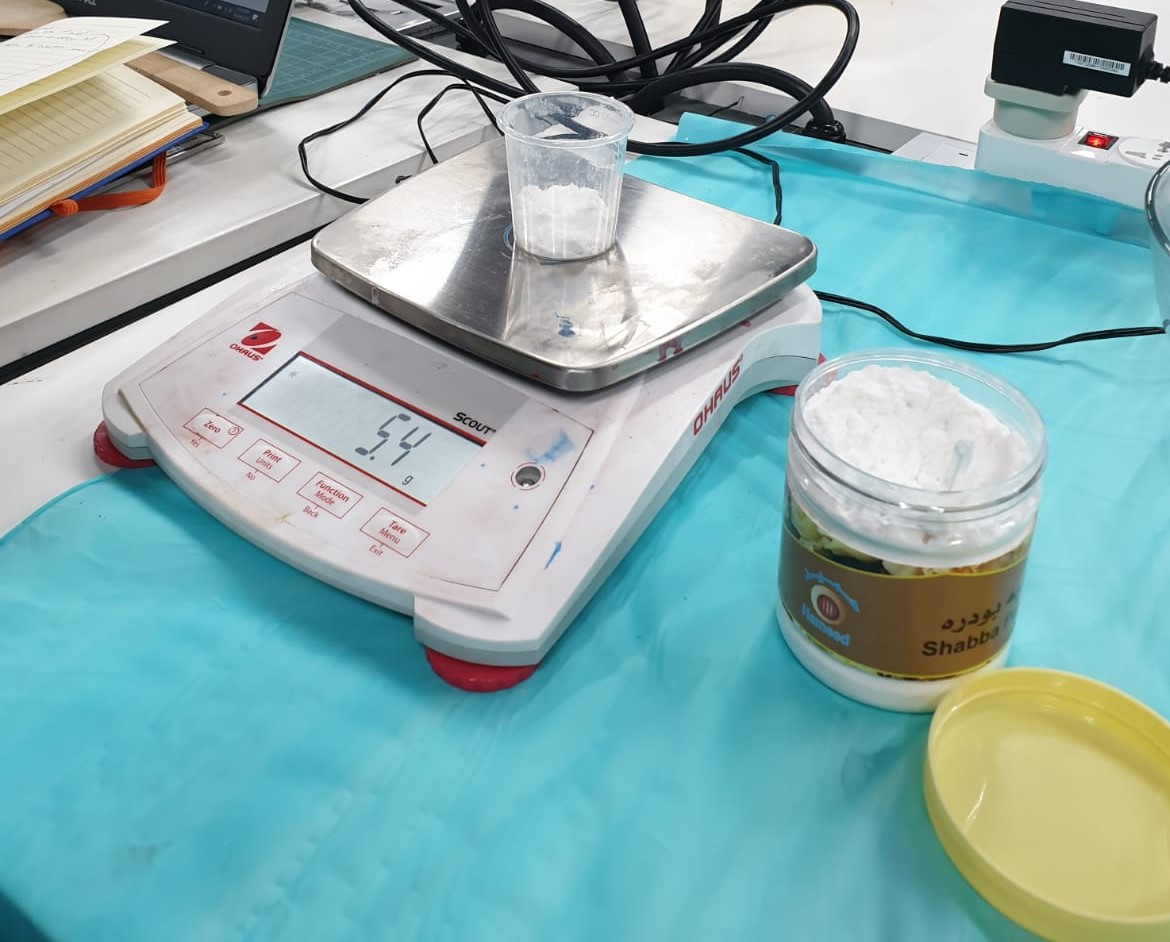

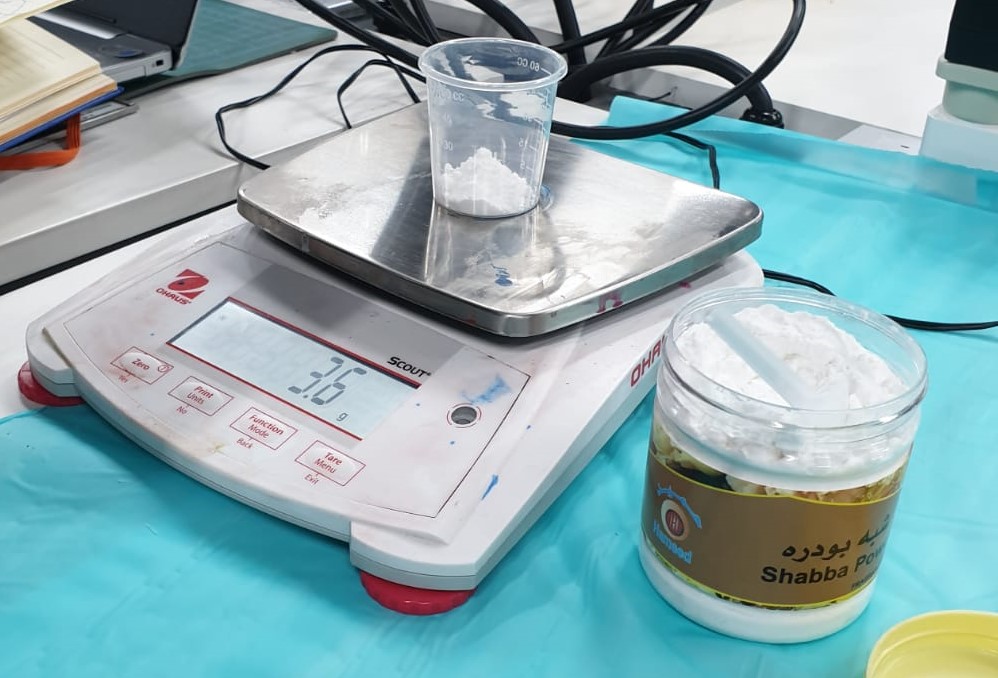

Weight of Modrant should be 15% of the fibre. So, for the vegetable weight of 3.675 g mordant will be used fo vegetable fibre and similalrly, 5.49 g modrant will be taken for protein fibre.

| Keep Balance at Zero Before Weighting | Weighting the Modrant for Protein Fibre | Weighting the Modrant for Vegetable Fibre |

|---|---|---|

|

|

|

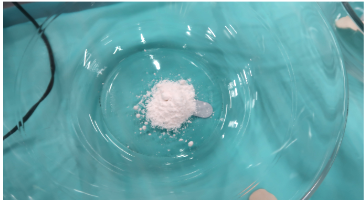

I put this mordant into the bowl filled with boiling water with the ration of 30:1. I used two bowls: one for vegetable fibres and other for protein fibres. So, i filled one bowl with 735ml of boiling water to soak the vegetable fibre and similarly i filled other bowl with 1098ml boiling water to soak protein fibre.

| Puting Mordant in the Bowl | Mordant and Bowl | Solution of Hot water and Mordant |

|---|---|---|

|

|

|

Now, for 20-25 minutes I left it to simmer gently, with occasional stirring, I dimped and soak the fabrics in the solution of mordant and hot water for 30 minutes. Then, I removed them from hot solution and hanged them over wooden stick for the pupose of dry.

After waiting atleast 24 hours, then both fibres can be taken for the process of dyeing.

Natural Dying¶

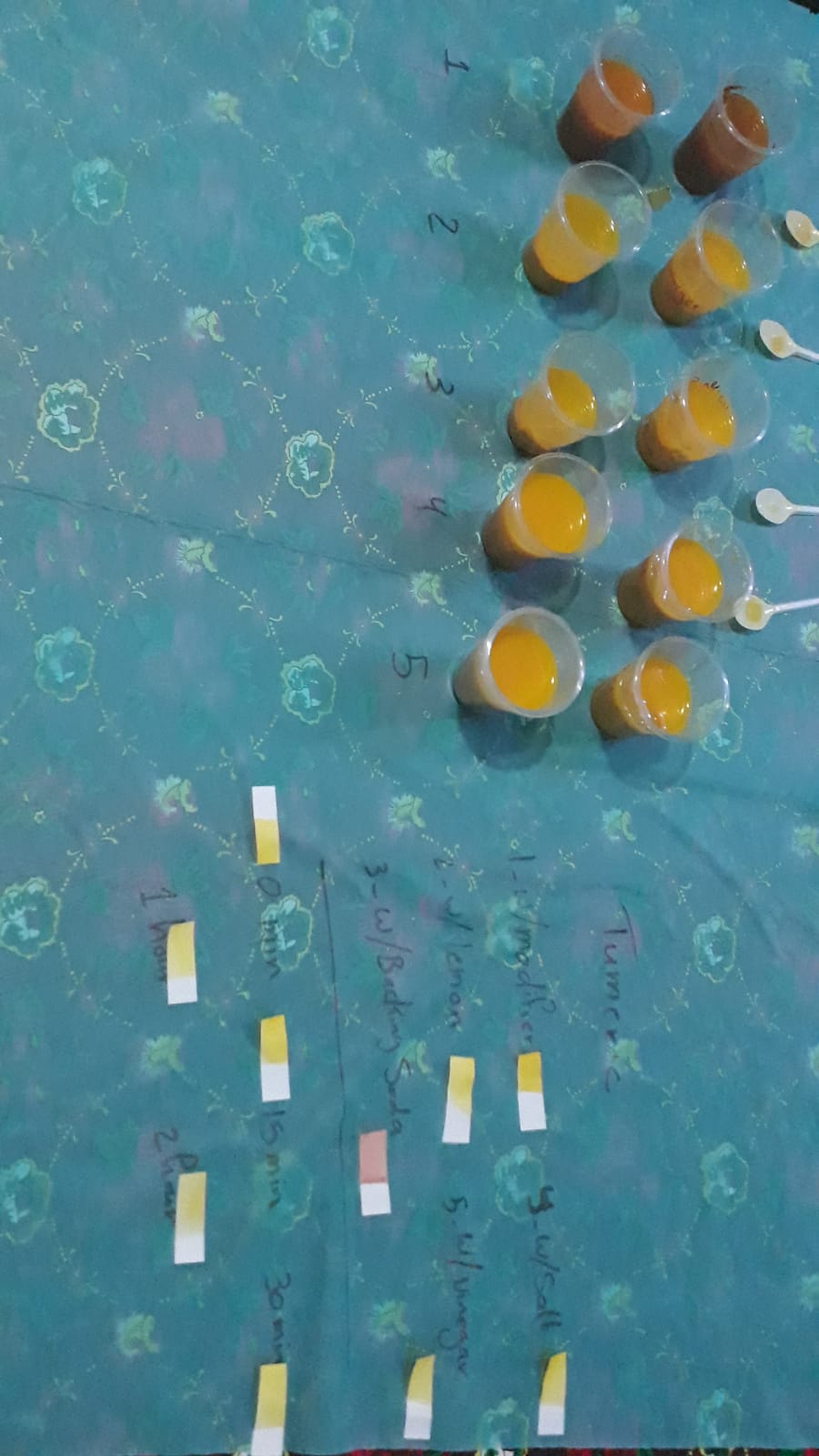

| Experiment Setup | Natural Sources of Dye | Sources of Natural Dye |

|---|---|---|

|

|

|

| Experiment Setup | Natural Dying |

|---|---|

|

|