6. BioFabricating Materials¶

This week I experimenting creating bioplastics and bioleathers.

What does it means biomaterial?

- Biobased (organic in the nature)

- Biodegradable (not natural ones)

- Biocompostable (eatable by miocrobes,less impact, full assorbly by the environment)

-

Bioplastic are renewable resources, you can replace high pollution products, you can use them like 3d filament. They are Compostable, it means that can it decompose only on certain conditions. Bioplastics follow the same process of plastic making, . You need a Polymer (Algae, Alginate, Gelatine, Starch..) . a Plasticizer (glycerin) . a Stiffening (Fibers, Natural debri) . Expanding (greensoap, emulsifiers) . Color (natural pigments, ink) We need to think of the material in all stages: Production, Application, Use, Reuse, Repair, End of Life -- RECYCLE Gelatine even if is animal based is reusable and reshapable.

-

Biodegradable Plastic Home compostable (wheat bran, coffee, orange peels) . Grown collagen instead of the Gelatine.

For colors can be used: Aromatic fabric, cacao, mika powder, hibiscus and vinagre(useful against moulds, paper and starch, charcoal and fibers)

For additive: Orange peels, eggshell, avocado

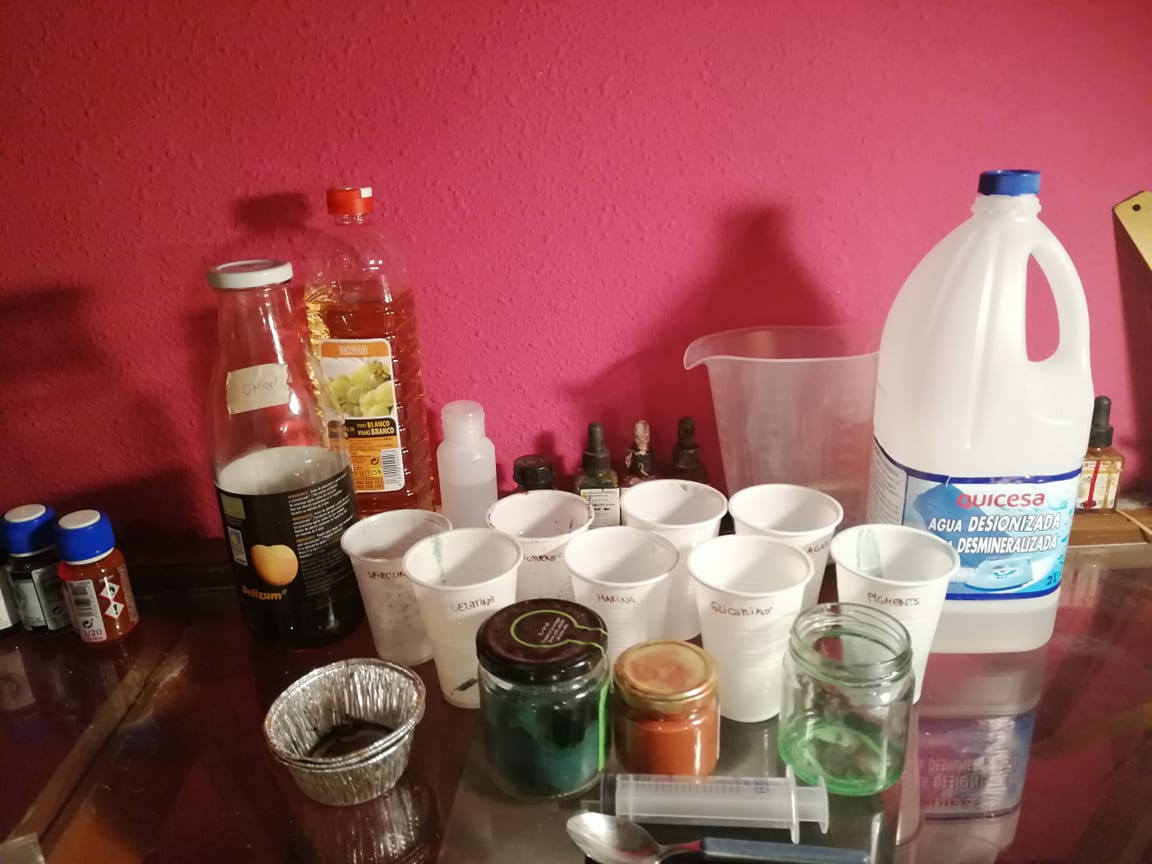

Preparation & tools¶

Tools:

Ingredients:

Gelatine (you dry in vertical) Agar (in the oven)

CRAFT MATERIALS¶

SODIUM ALGINATE¶

Water 525ml Alginate 14gr Glycerin 42g CLoruro 30g +Pigments +Flowers If you add oil to any of your receipe will mantain the liquid.

- Mix the Alginate in the pot

- Add fibers or pigments and Glycerin

- Rest for few hours to let the bubble disappear

- Spray the surface with Cloruro (30g Cloruro x 100ml Water)

- Add the Alginate mix

- Spray again and press, and rest

- Wash it

Glycerine: Makes the composite elastic or stretch Sunflower: make it more white Cloruro: Is the cure to make the alginate harder

GELATINE¶

Water 75ml Gelatine 15gr Glycerin 7g + coffee waste + Avocado pits

Boil the Water, add the gelatine, stir it, then add the glycerin and the pigments, and continue stir it for 10 min and put into the mold.

AGAR¶

Water 100ml Agar 1gr Glycerin 1,5gr + Seashell + Fibers

Mix the Agar with the water and boil it, stir it til is not dissoved, then add the glycerin and the pigments, and continue stir it for 10 min and put into the mold.

Bio Resin Recipe¶

127g Pine Resin 127g Ethilic Alcohol + Tea and Mica Pigments

Put the pine resin inside the pot, heating up and wait till the resin start to melt, don't mix it When the Resin is liquid add the alcol and the pigments. Mold it and wait to dry.

Biomaterial recipes¶

GELATINE BASED

Water 100ml

Gelatine 20gr

Glycerin 1gr

Spirulina 3g

+ Hemp fibers + palm tree

STARCH BASED

Water 16gr

Tapioca 16gr

Vinegar 1,6gr

Wholewheat flour 50gr

+ Flowers

ALGINATE BASED

Water 525ml

Alginate 14gr

Glycerin 42g

CLoruro 30g

+Pigments +Flowers

GELATINE BASED

Water 75ml

Gelatine 15gr

Glycerin 7g

+ coffee waste + Avocado pits

AGAR FOAM

Agar 1.6gr

Glycerin 2.7gr

Water 40ml

Soap 4gr

+Charcoal + avocado pits

AGAR BASED

Water 100ml

Agar 1gr

Glycerin 1,5gr

+ Seashell + Fibers

AGAR BASED

Water 100ml

Gelatine 4.8gr

Agar 1gr

Glycerin 1,5gr

+Banana peels powder

AGAR BASED

Water 100ml

Gelatine 4.8gr

Agar 1gr

Glycerin 1,5gr

+Banana peels powder +palm tree

GELATINE BASED

Water 100ml

Charcoal 16gr

Gelatine 26gr

Glycerin 10g

AGAR FOAM

Water 40gr

Glycerin 2.7gr

Agar 1.6gr

Soap 6gr

ALGINATE BASED

Water 525ml

Alginate 14gr

Glycerin 42g

CLoruro 30g

+Pigments +Flowers

Bio FOAM

Water 100gr

Glycerin 5gr

Gelatine 20gr

Soap 4gr

+Blue ink

CONDUCTIVE AGAR

Agar 2gr

Glyc 1ml

Water 210ml

Salt 5gr

+wine for the color

+flowers

GELATINE PAPER

60ml water

Gelatine 12gr

Glycerin 14ml

+ recycled paper + mika pigment +onino skin

GROWN MATERIALS¶

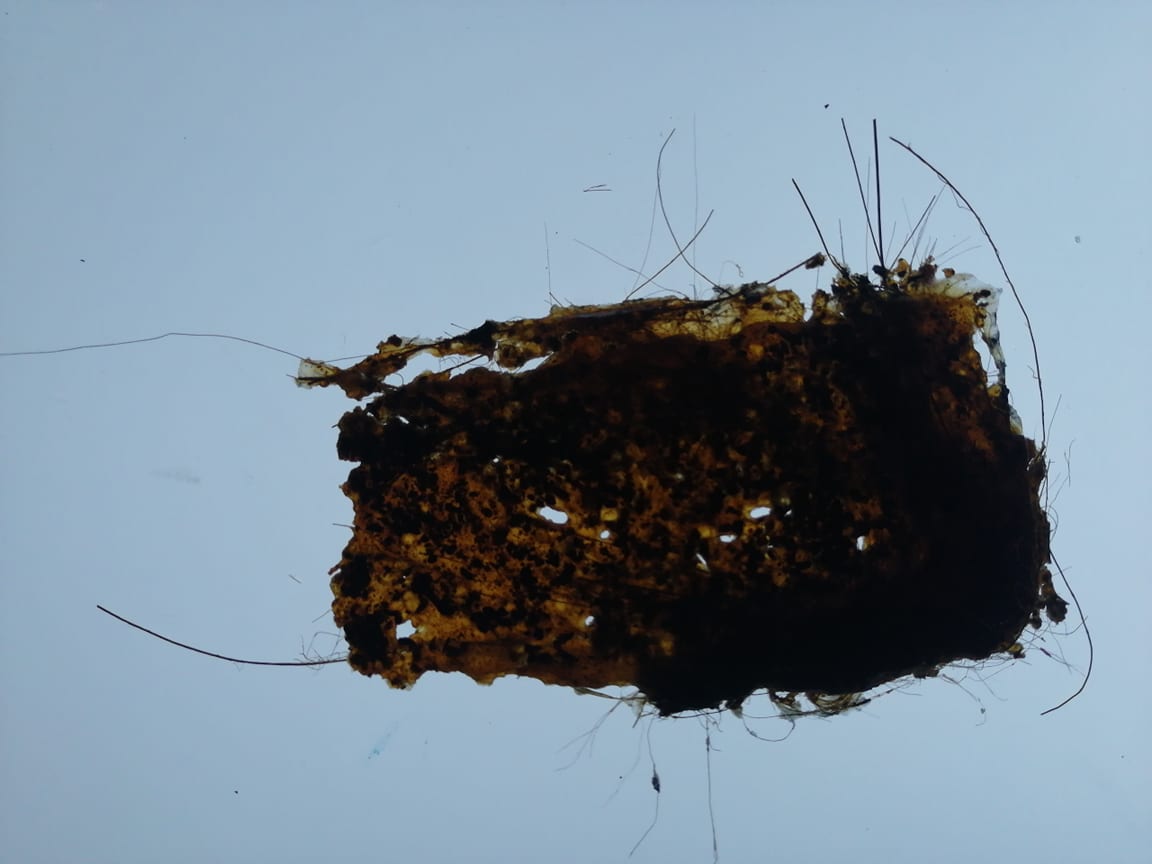

Kombucha Leather Recipe¶

Fermented tea, or tea fungus. Recipe for 5l water:

- 5l water

- 10 teabags

- c. 600g sugar

- 1 Kombucha Scoby

- Vinegar (until the Ph turns 2.5-3.5)

- clean container

- natural dyes or food dyes

- Ethanol 96%

-

Gloves

-

Boil tea with sugar and let it cool down

- Disinfect the containers

- Control the PH and add vinegar until the Ph turns 2.5-3.5 (In this case, we added about 500ml)

- Add Scoby

Mycelium¶

vegetative part of a fungus or fungus-like bacterial colony Use with mycelium: - hemp fibers, hemp compressed fibers, iuta, allowing to circulate air. -Rise processed and mixed with other fibers. - different materials from agriculture waste 1.Sterilize everything 2.Put into a mold to let it colonize for 2 weeks. Smooth surface and plastic over the mold. 3.Wrap it with plastic and make breathy holes. 4.24-25° incubator Different mycelium has different properties. 5.In 3-4 days remove it from the mold 6.Put upside down protecting with plastic without touching it 6.When is white inside you leave it solidifying on the sun.