9. Textile as scaffold¶

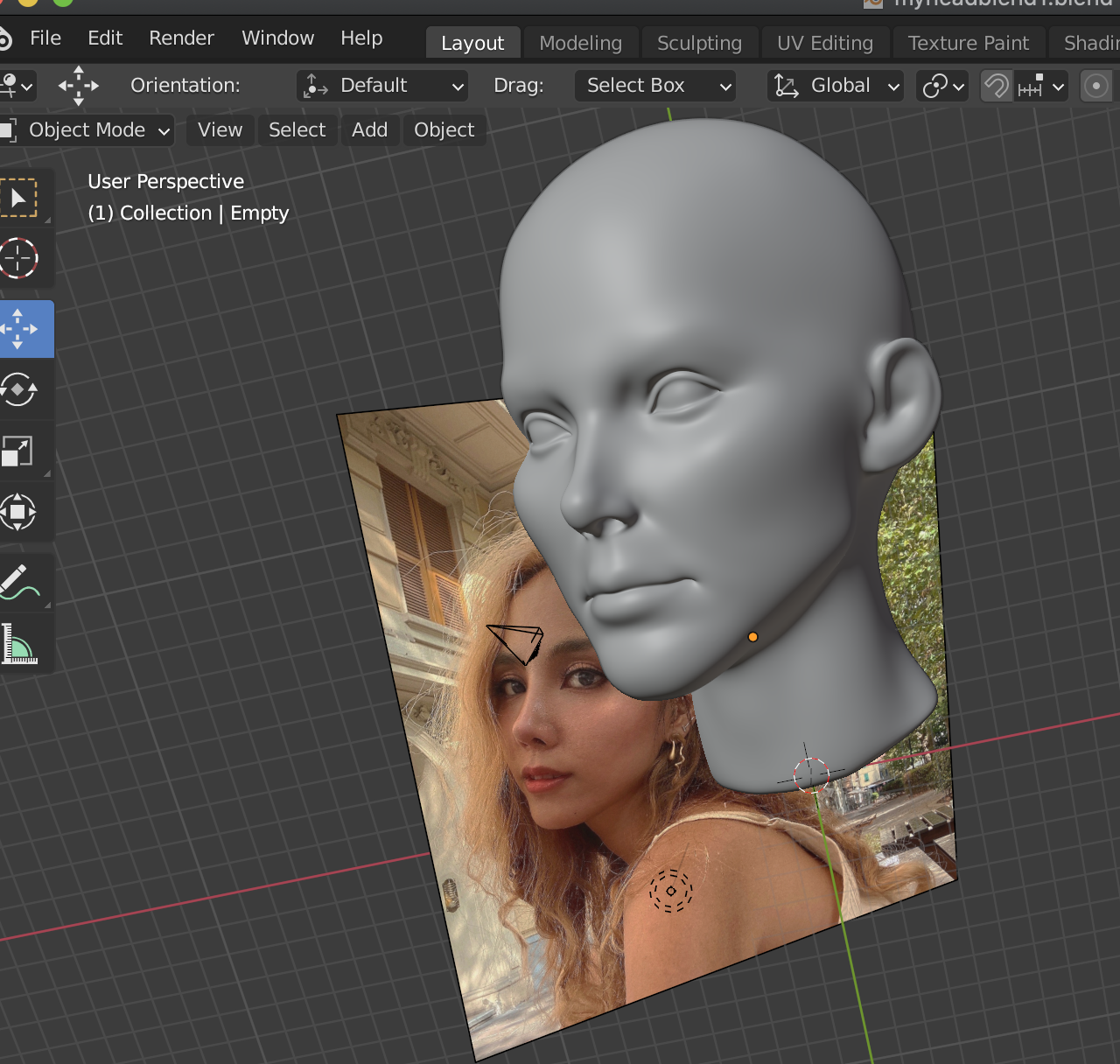

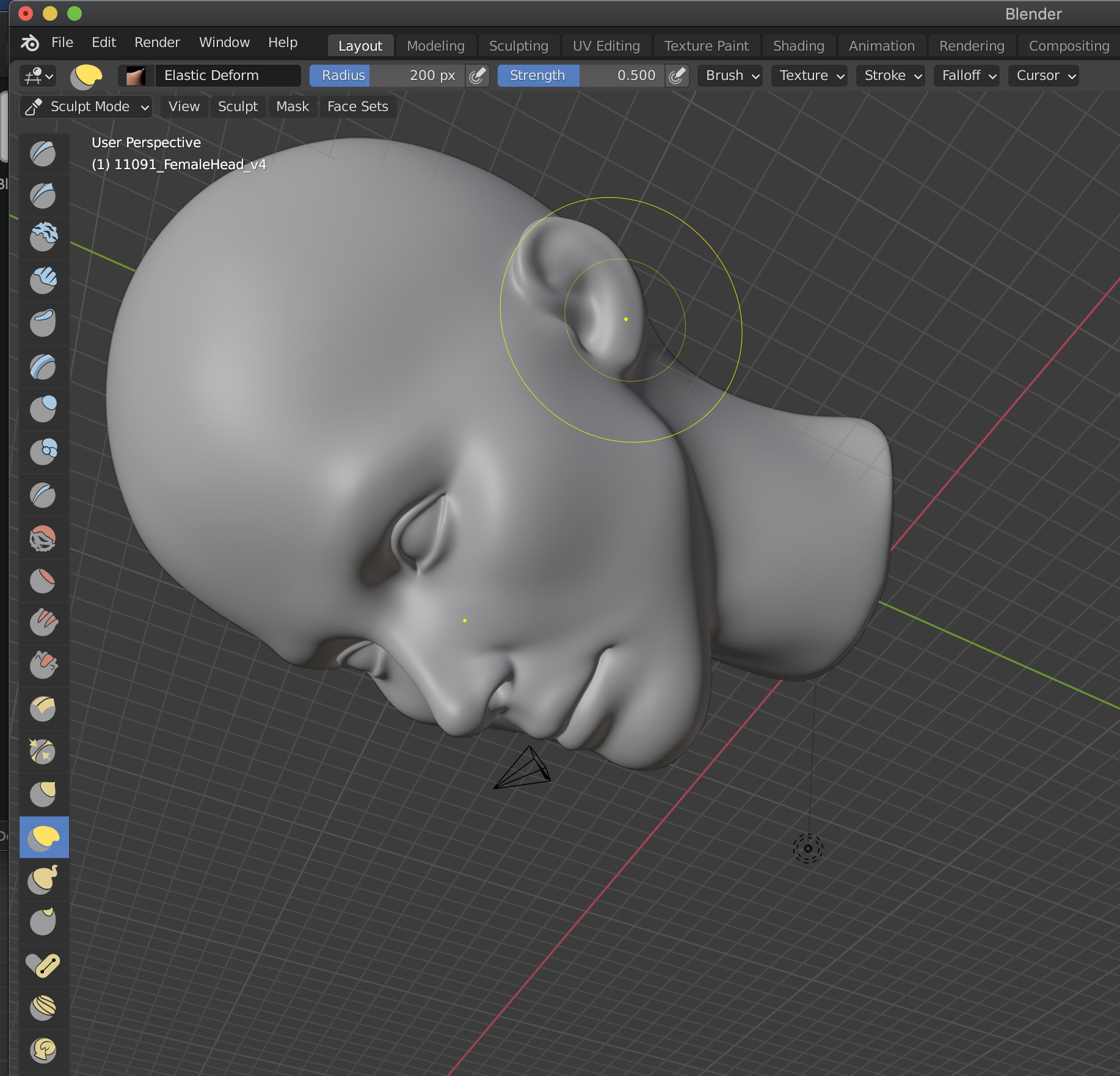

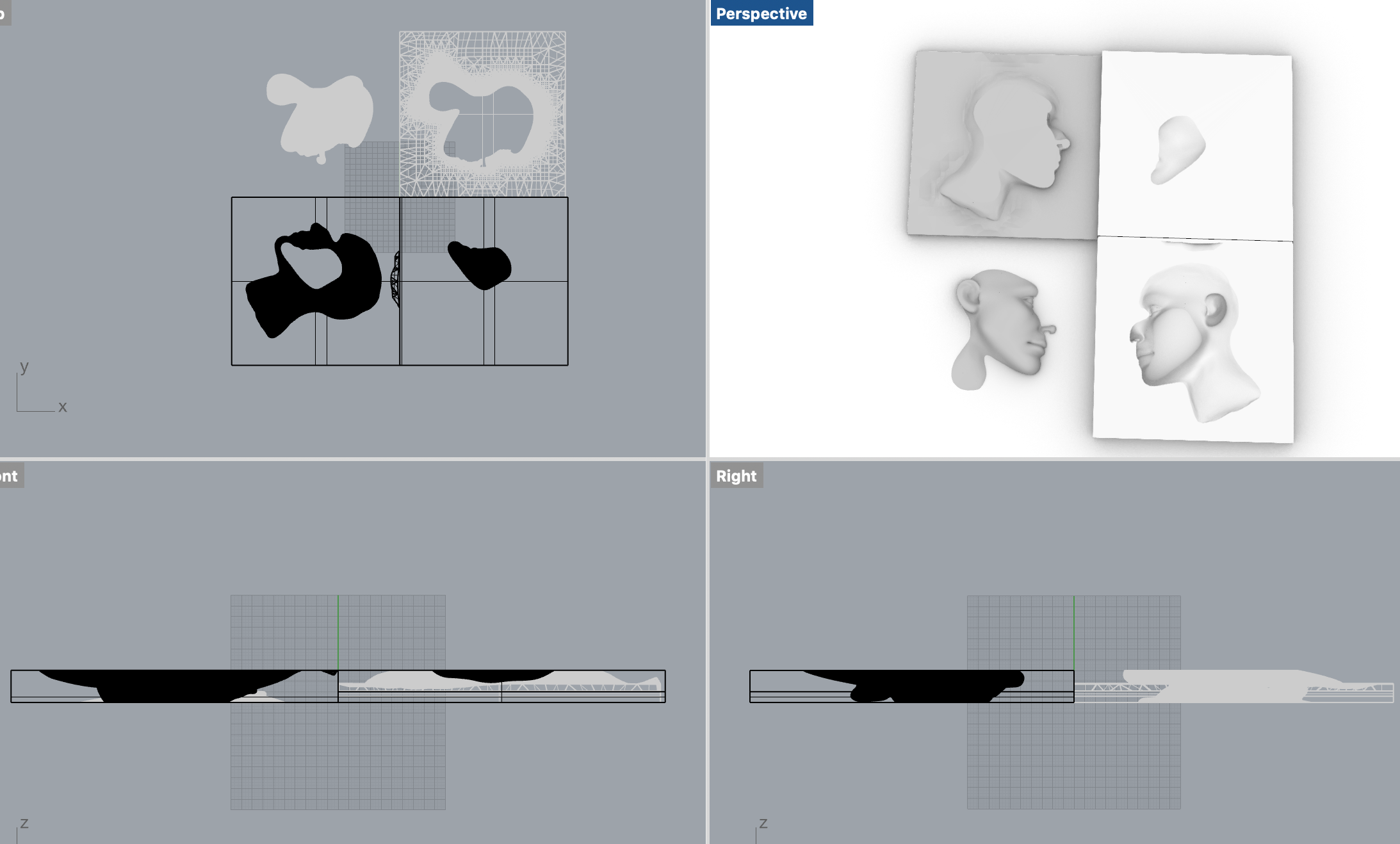

I used my own picture to sculp my jawline with Blender. I followed this video as tutorial. I found blender is very east to use.

I first found a basic head model without strong facial features on internet, you can start from scratch. turn on sculpting mode in blender, you can sculpt the shapes and details.

I first found a basic head model without strong facial features on internet, you can start from scratch. turn on sculpting mode in blender, you can sculpt the shapes and details.

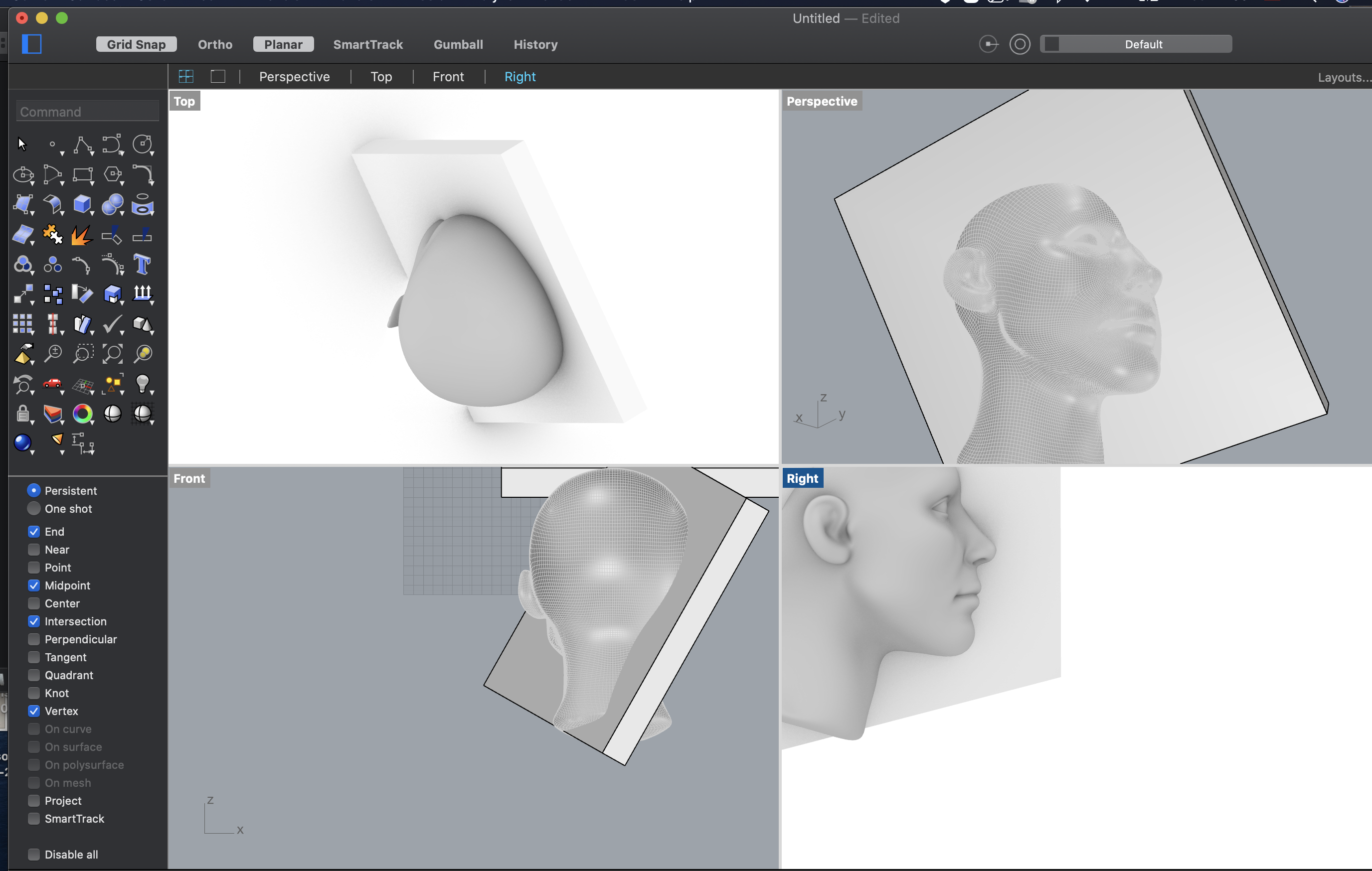

I exported the model to Rhino to do accurate sizings, I measured my own head and scaled it on Rhino to make it 1:1 to my head.

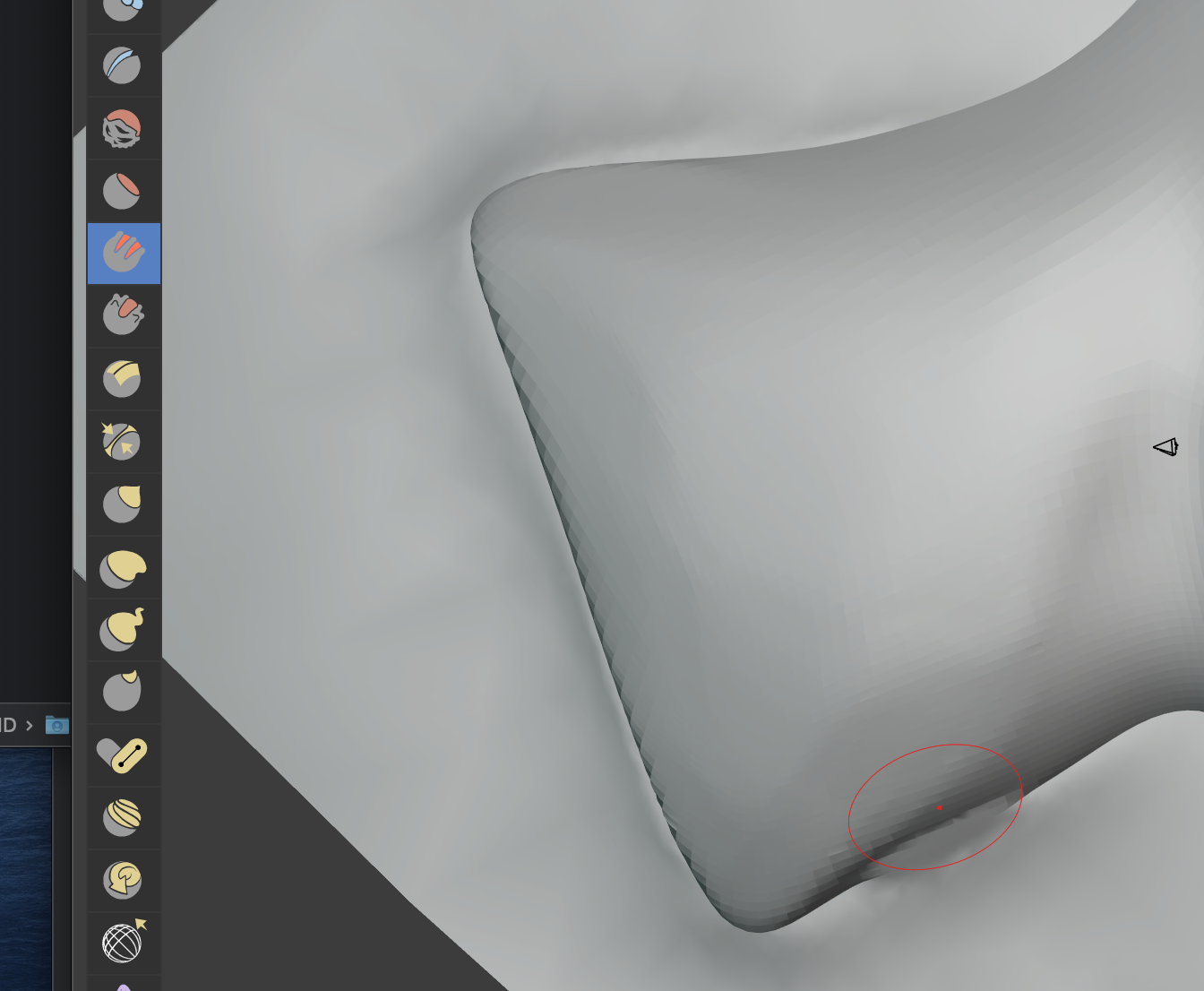

I use Rhino to smoothen the hard edges and the areas I want to blur out. In order to do that, I used the flaten tool on blender.

I use Rhino to smoothen the hard edges and the areas I want to blur out. In order to do that, I used the flaten tool on blender.

My notes for how to use shopbot milling machine are not perfect, I found this video very helpful.

This glue is very good for gluing foam together without causing uneven hardness and ruining the shape of foam.

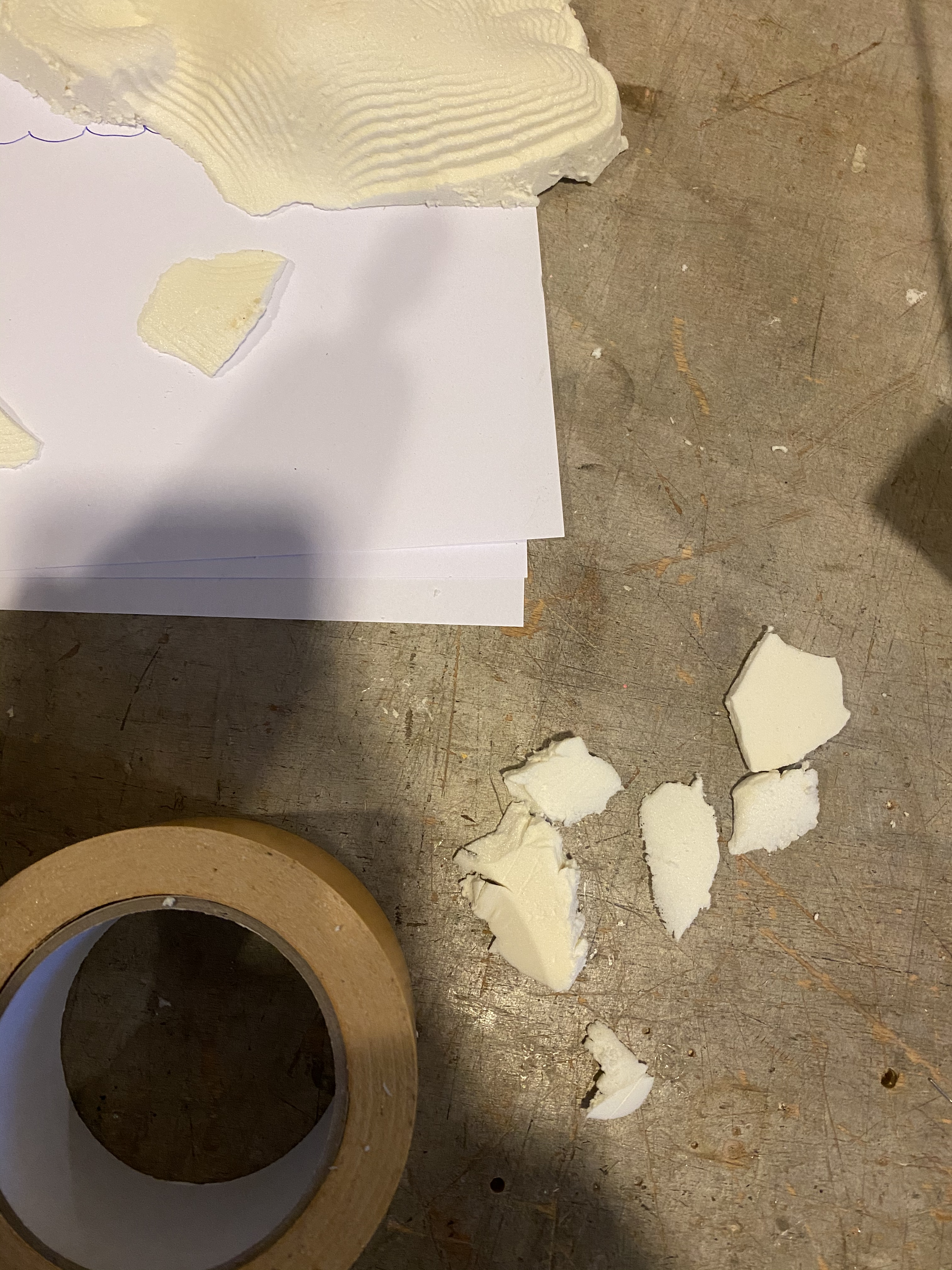

I made mistake: I put tape directly underneath the shapes that i want to cut. I wanted to do cut out shape with machine, it became really thin and it broke when i peel the tape. I made two molds, for the second one I put the tapes only at cornors.

I made mistake: I put tape directly underneath the shapes that i want to cut. I wanted to do cut out shape with machine, it became really thin and it broke when i peel the tape. I made two molds, for the second one I put the tapes only at cornors.

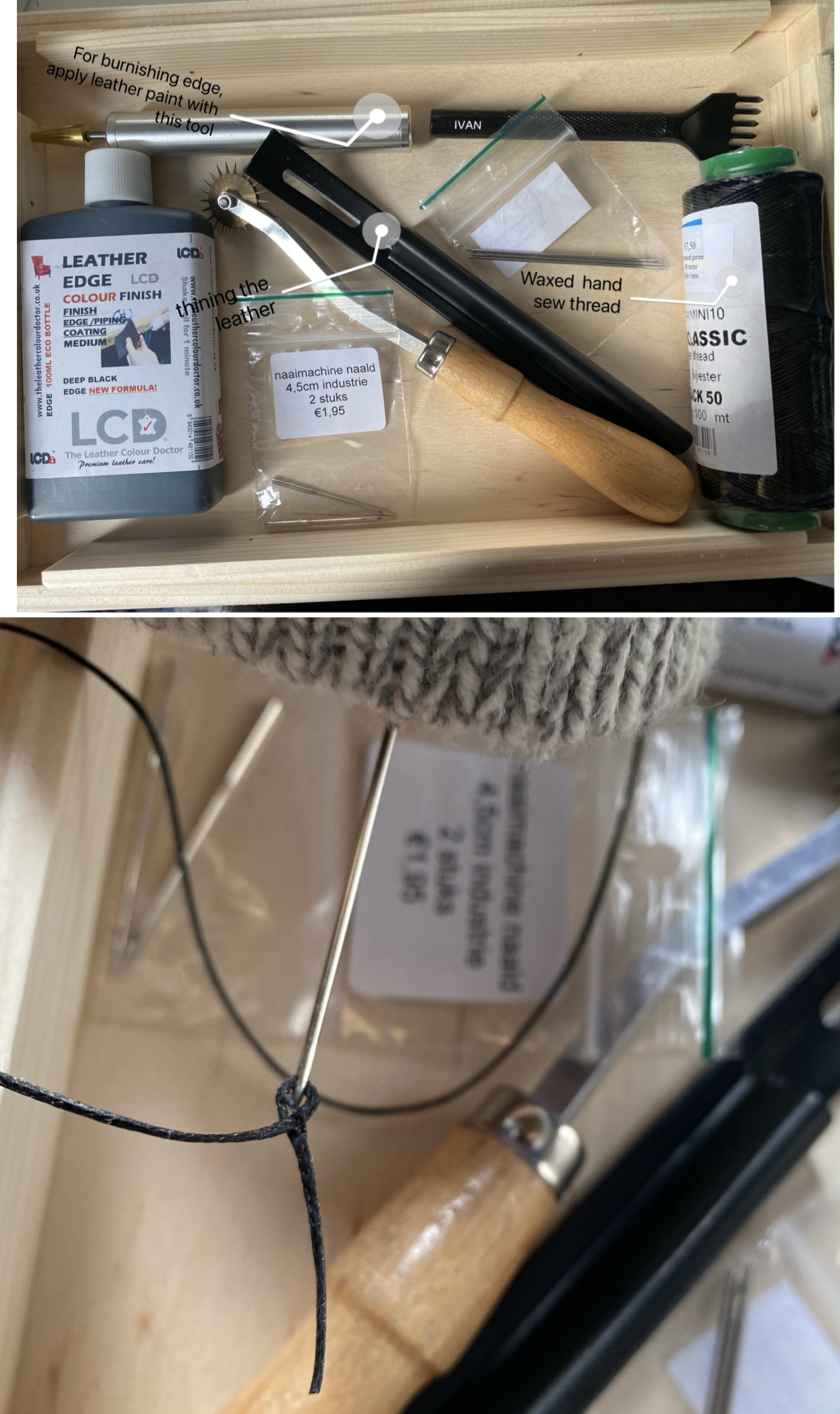

I see it as prototype. I didn't use intended hard leather because I want to test patterns and the mold first. I think the pattern for the bag is ok, I like the size and shape, but need some inprovement on the corners. and the mold looks slightly awkward because it was meant to be a jawline purse, but it came out looks like a full head with super tiny forhead. I will imrpove the shape of the mold. I have contact the milling service that I worked with, they say they can do a mold with copper fot me. I think it will look nice with really thick leathers.

I see it as prototype. I didn't use intended hard leather because I want to test patterns and the mold first. I think the pattern for the bag is ok, I like the size and shape, but need some inprovement on the corners. and the mold looks slightly awkward because it was meant to be a jawline purse, but it came out looks like a full head with super tiny forhead. I will imrpove the shape of the mold. I have contact the milling service that I worked with, they say they can do a mold with copper fot me. I think it will look nice with really thick leathers.

I made two versions with faux leather: one cut out the shape and leave the foam inside to maintain the shape. It works well if you want defined edge. another one is harden the faux leather with silicon textured glue, press the faux leather until it is hard, then move one to the next part. I kept my hand on until the gel is hard, then remove the mold. the shape stays well and have a smooth edge.

I did crystal with KAl(SO₄)₂·12H₂O Potassium aluminum sulfate. just add boiling water to the Potassium Alum, the leave the fabric in, it grow really well just over night. The crystal grow really well on alluminum foil. I left fabric and aluminum foil in the solution around the same time, and the crystal that grow on aluminum is much larger in size.

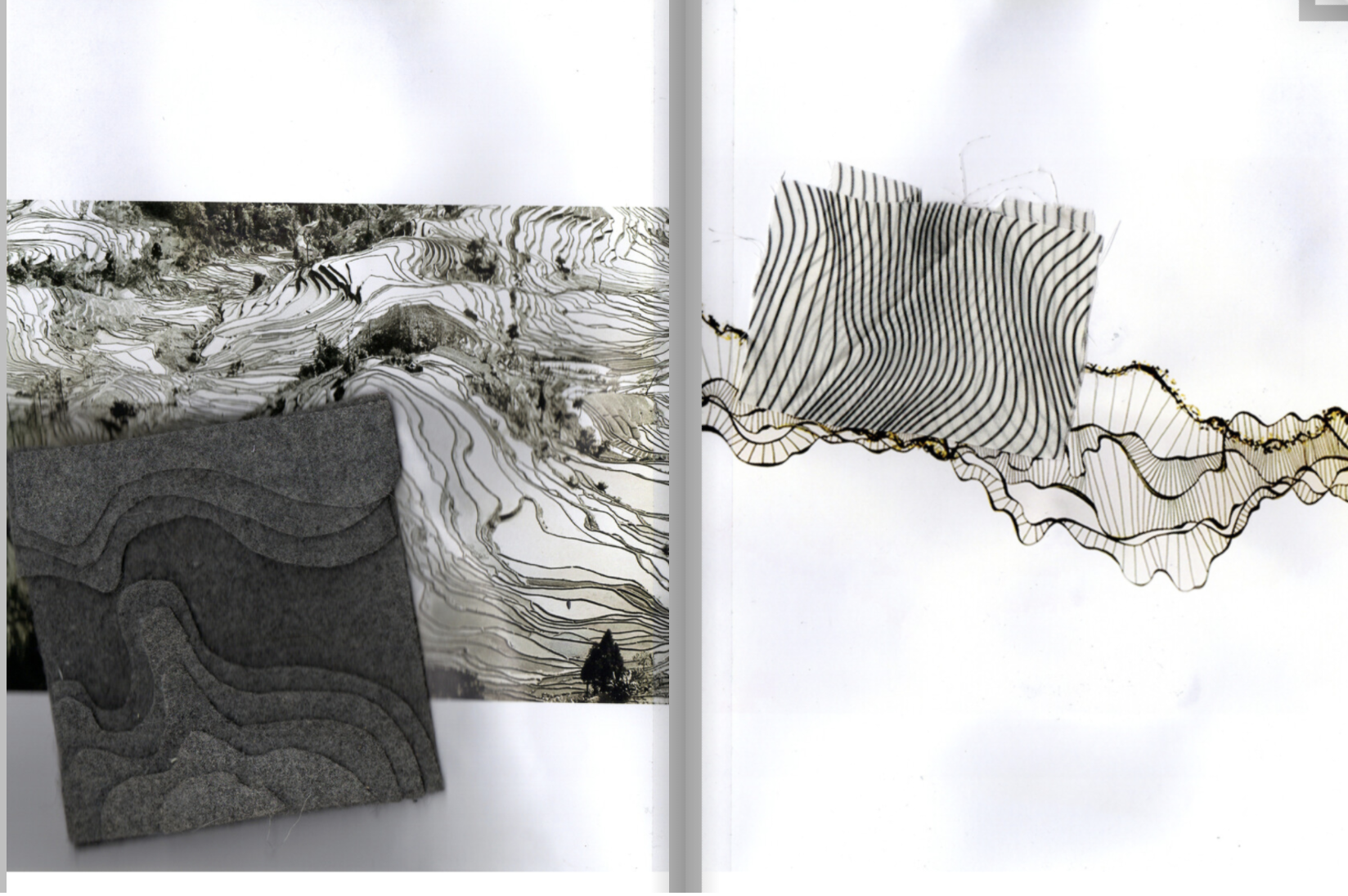

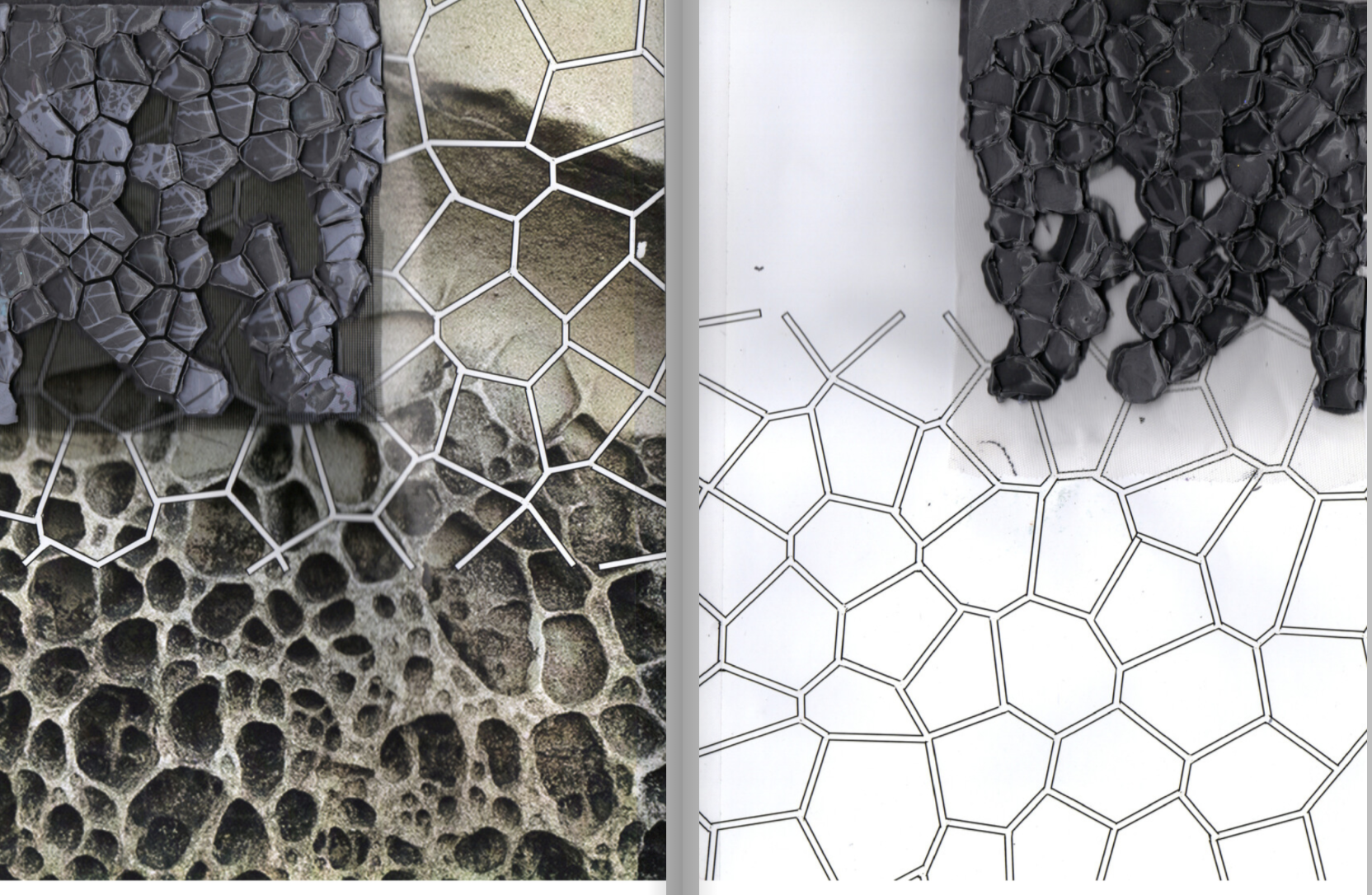

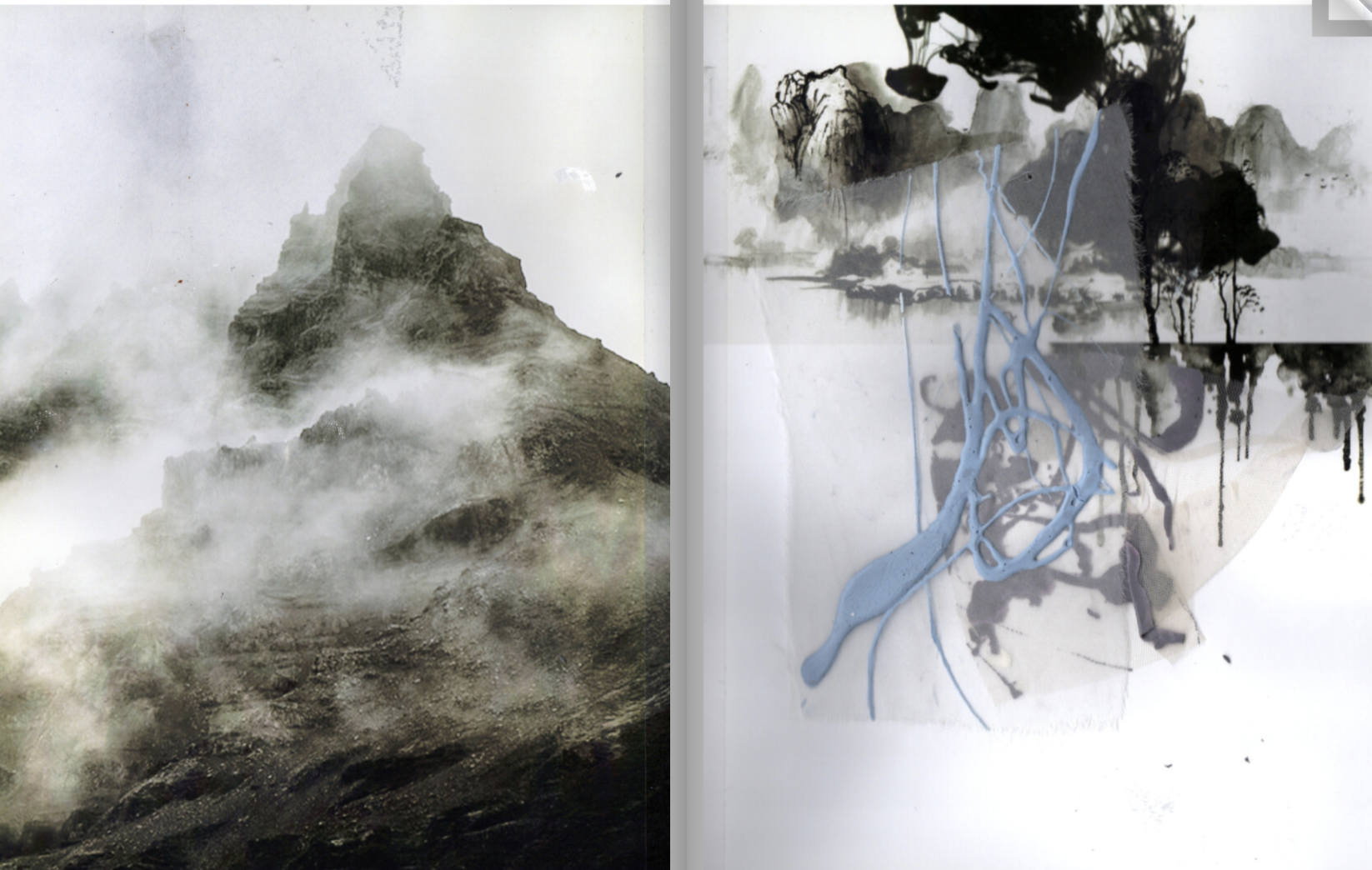

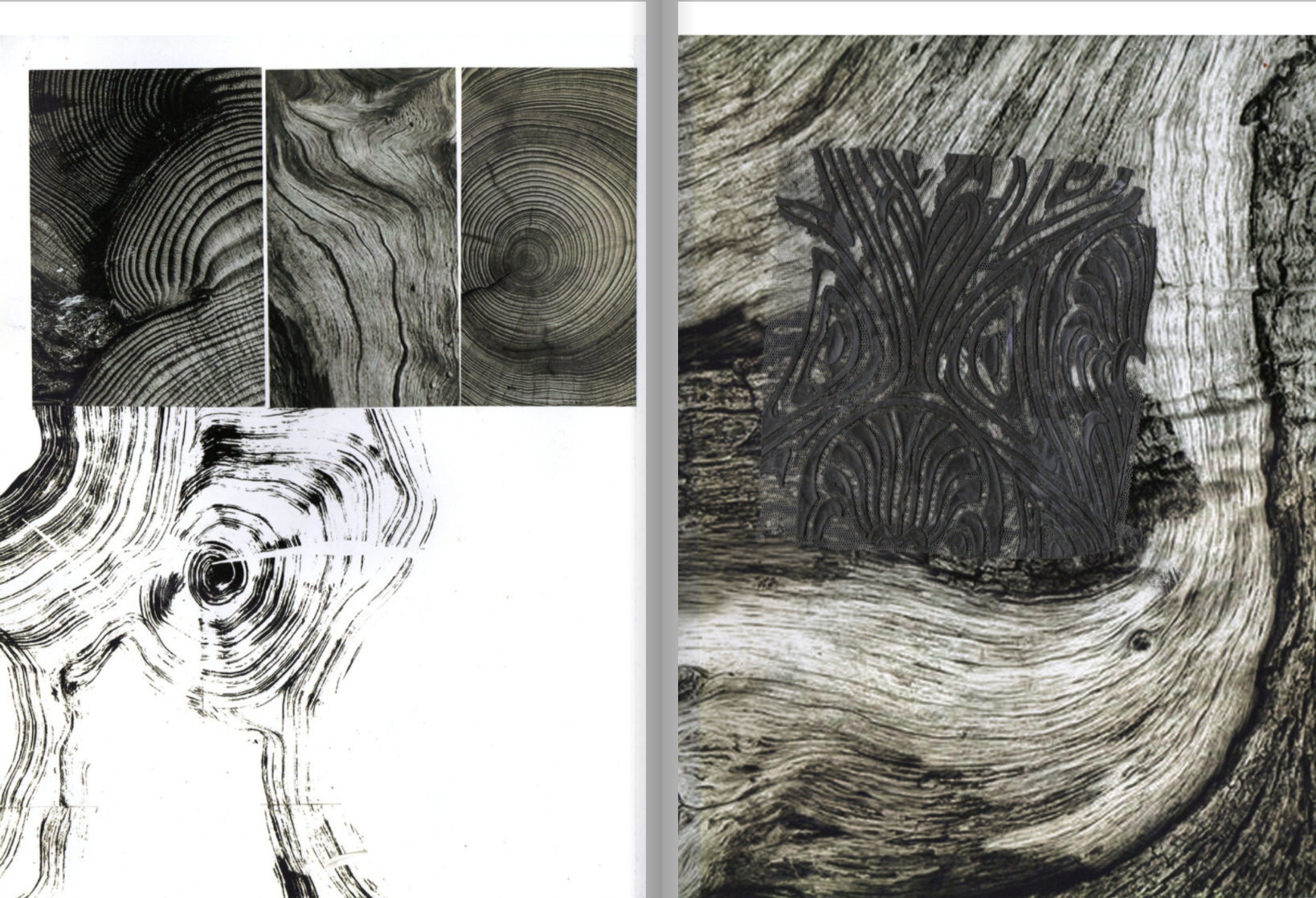

Here is some previous textile samples I did.

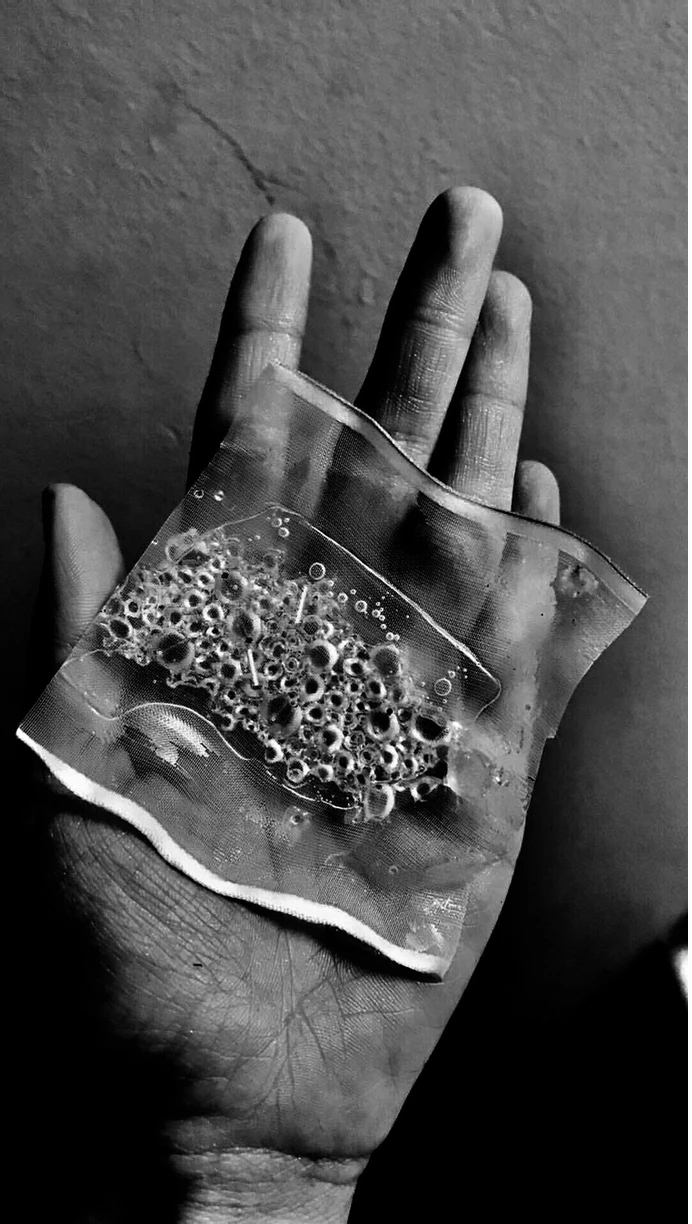

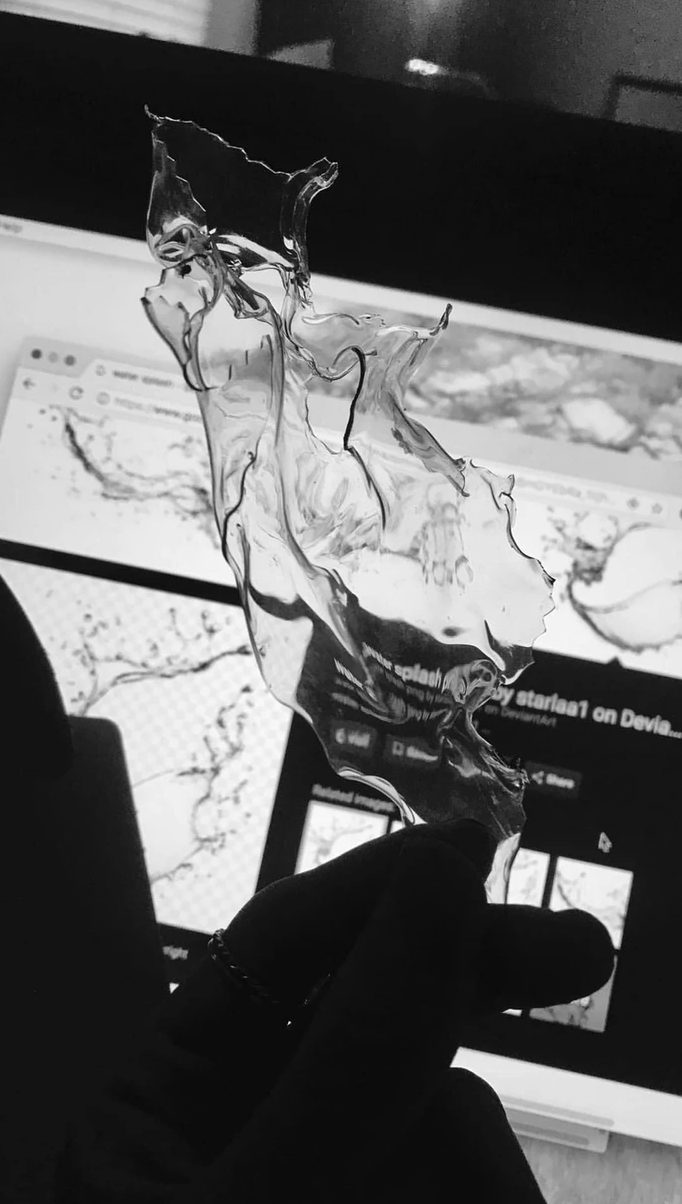

I casted the fabric with resin. I did this few years ago, the resin became a bit yellow now.

cast with silicon, mold made with laser cut.

cast with silicon, mold made with laser cut.

heatgun on polyster.

heatgun on polyster.

stiffen by layering up..