WEEK 4 - BIOCHROMES¶

Last Update: Nov 7, 2021

October 11-17, 2021

This week I learned the process of scouring, mordanting and dyeing natural (animal and vegetable) fibers. I also learned how to use the liquid dyes created to extract ink and powder pigments. The natural materials I used to create these dyes were avocado pits, onion skins, turmeric and blackberries.

As of Oct 18, 2021, I was only able to create natural dyes and wasn't able to get to bacterial dyes.

Keywords: natural dyes, mordanting, scouring, alum, sodium carbonate / soda ash, arabic gum, avocado pits, onion peels, blackberries, turmeric, inks, yarns, muslin, linen, fibres

Quick Summary¶

Tools Learned:

Tools Learned:

- The process of mordanting, scouring, dyeing, ink making and pigment production

Tools Refined:

Tools Refined:

- Numbers: - Mac's version of Excel

- Adobe Illustrator Version 2021 - a photo editing program

- Adobe Lightroom Version 2021 - a photo editing program

- Canva: a graphic designing platform

- DSLR Camera: Canon 5D Mark II*: - the camera I used to take final photos

What I still want to learn better:

What I still want to learn better:

- how to use arabic gum properly

- how to create inks more properly

Research and Inspiration¶

Huge shoutout to instructor Cecilia Raspanti for her class notes, informative tutorials and mind-blowing knowledge around this topic of colours. Her class notes/slides served as my bible this week as it was primarily my source of inspiration and guidance for all the work I was able to do.

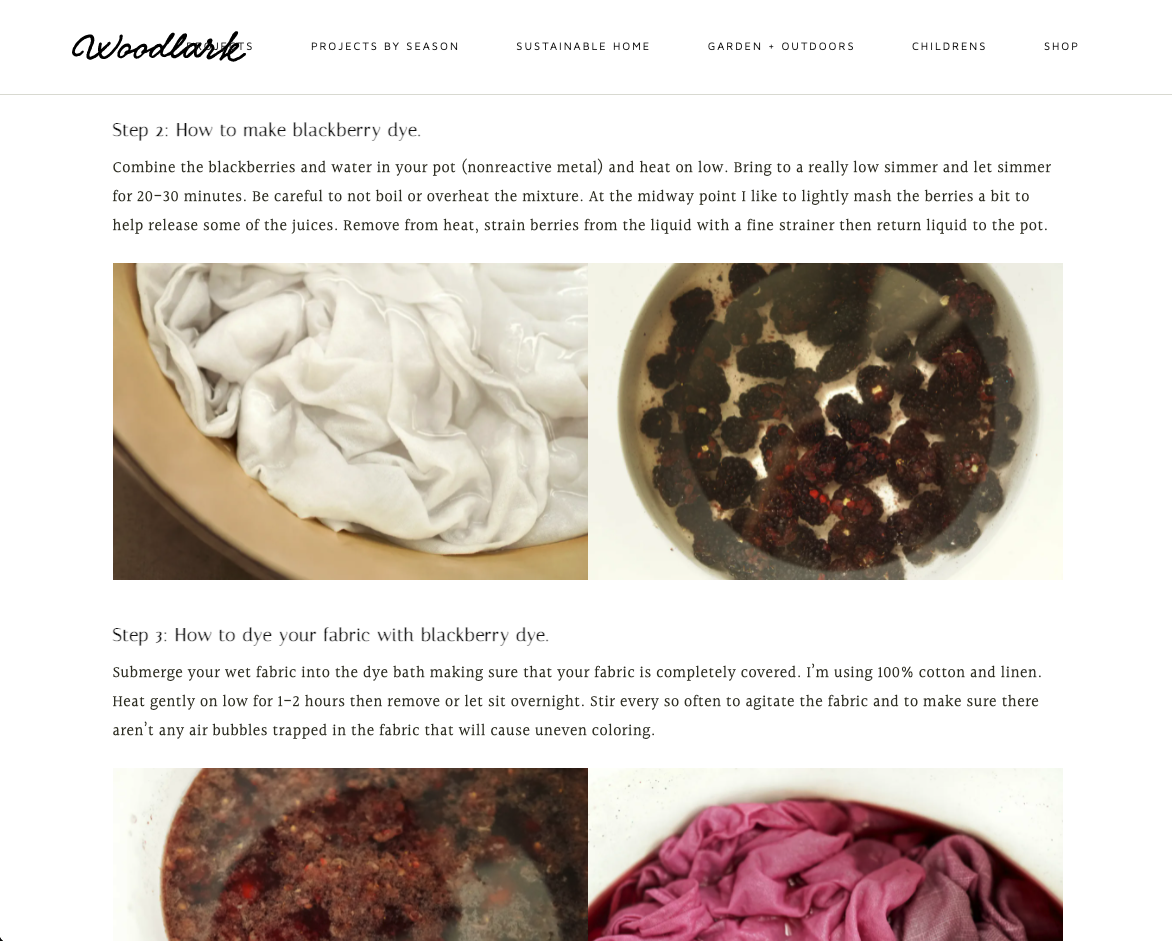

In addition to her notes, I did online research for the dyeing process using blackberries. I found a blog called Woodlark that provided step-by-step suggestions on this.

To be honest, most of my process was made possible

Preparation Process¶

Obtaining/Searching for Materials¶

As I listened to the global lectures and tutorials I continued to learn new terms I had never heard before such as scouring, mordanting, alum, and arabic gum. I realized that half of these terms were actual materials I needed to obtain. After a couple hours of visiting multiple local supermarkets near me (I'm in Boston, USA), I found out that there weren't any alum, sodium carbonate or arabic gum local to me and that I had to purchase them online on Amazon. These are the links I used to do so:

I also had to purchase a new digital scale from Target to weigh the fibers I was going to use and even get started with this week's assignment.

In terms of fibers themselves, I decided to use 3 different types:

- wool yarn (animal fiber)

- cotton muslin fabric (vegetable fiber)

- linen fabric (vegetable fiber)

Process Planning¶

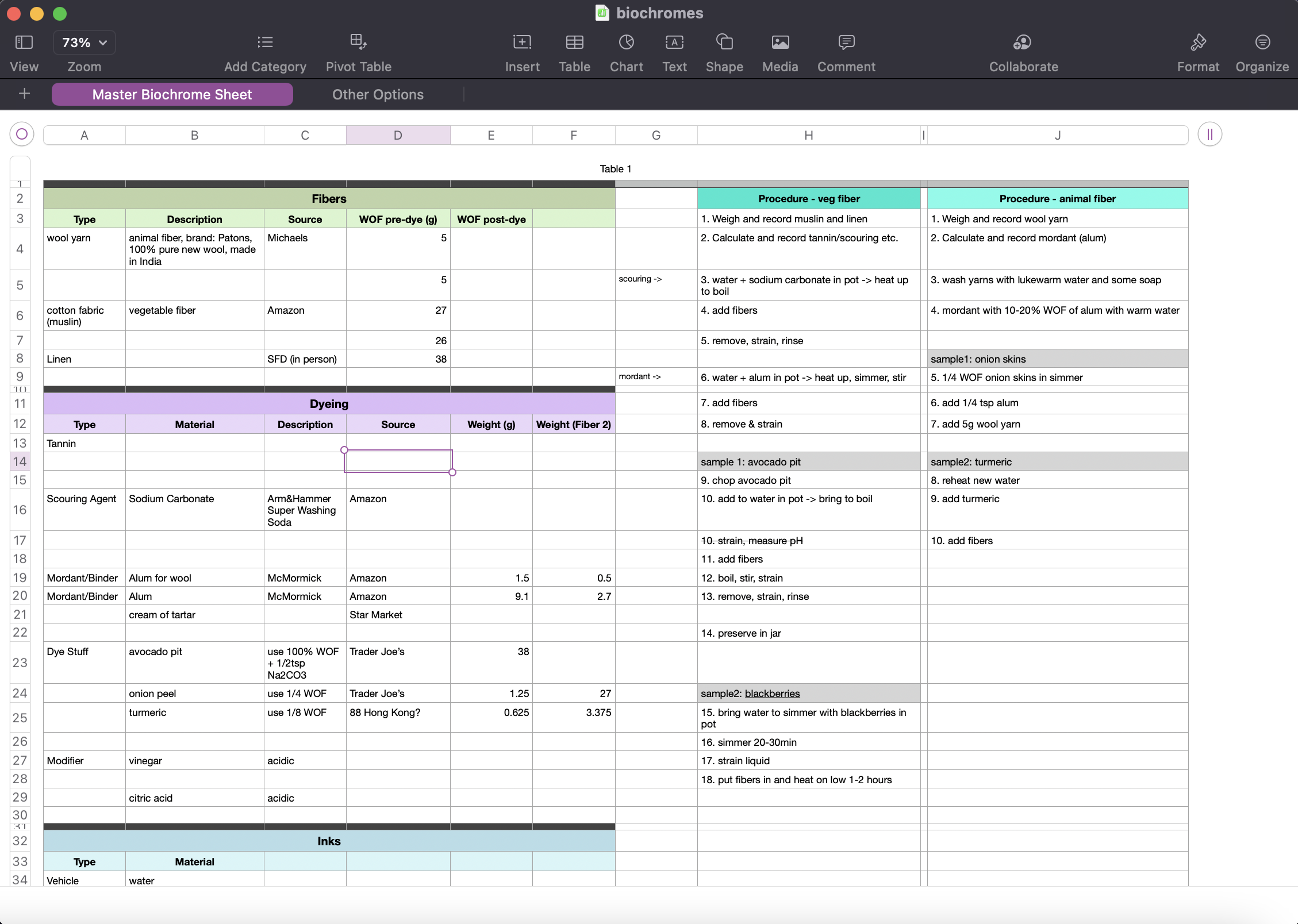

While I was waiting for the shipping of the above new materials, I created a spreadsheet that outlined the details of my dyeing process so that I was ready to go right from the start.

Note: this screenshot is as of the morning of Oct 16 and may need to be updated.

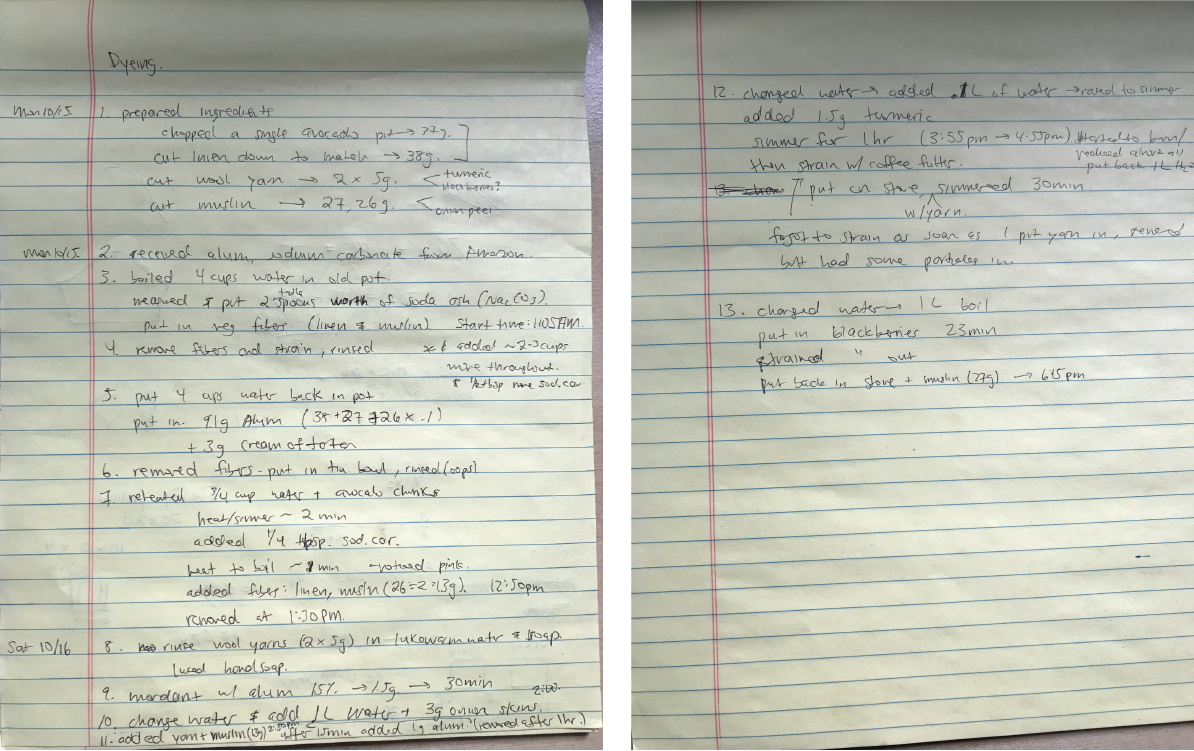

During the actual process itself, I geared towards hand written notes to keep track of the actual procedure I followed (because as we all know, the perfect scenario doesn't exist).

Preparing Ingredients¶

While I was waiting for the scouring and mordanting agents to be delivered, I prepared my first dyeing ingredient: an avocado pit. I started the process by chopping it using a kitchen knife, which was suprisingly and pleasantly much easier than I thought it would be! After receiving my digital scale, I weighed the chopped bits, which totaled 37g.

Scouring¶

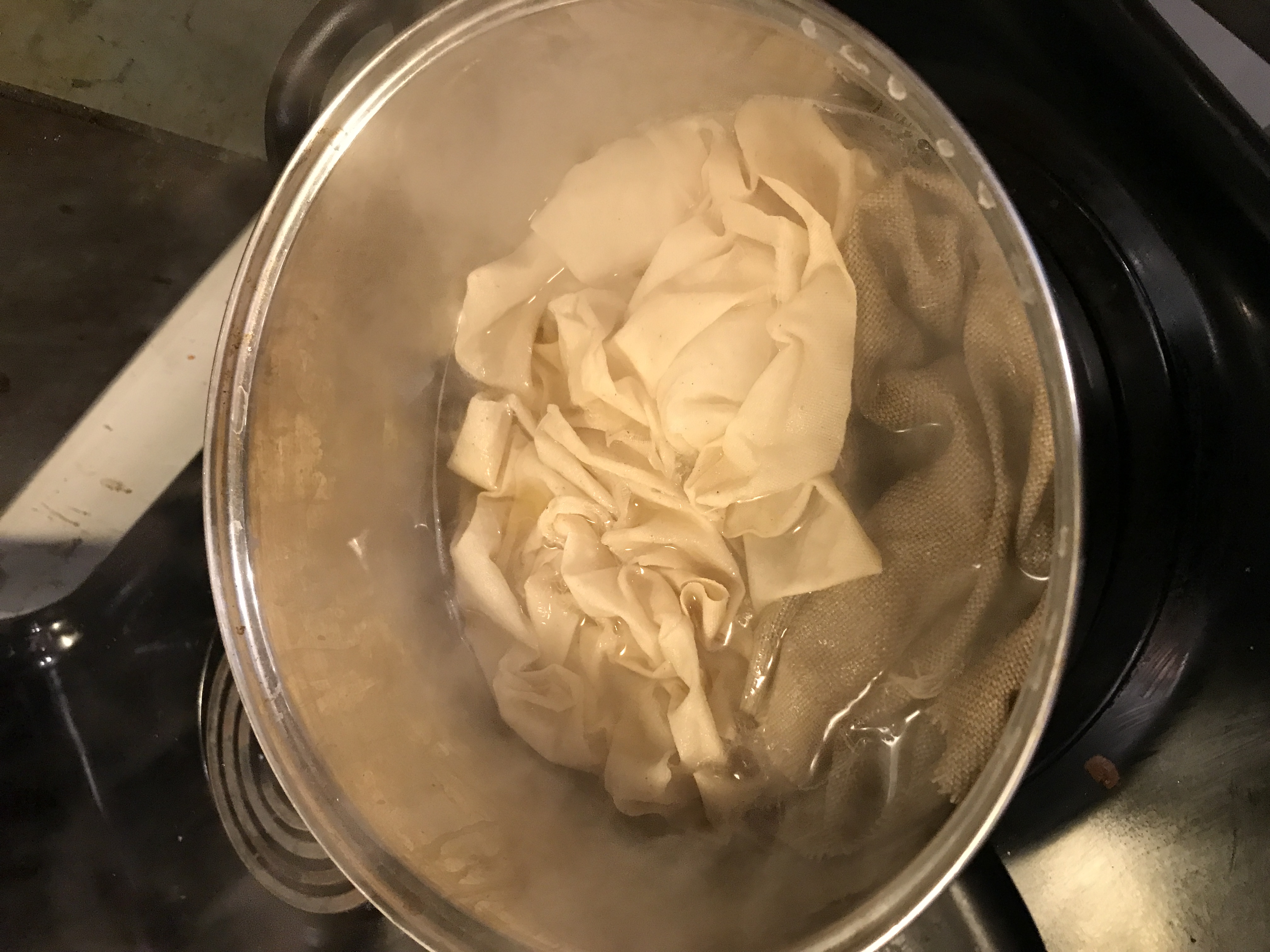

I started scouring by boiling 4 cups of water in an old stainless steel pot and put 2 tablespoons of the soda ash (sodium carbonate) in.

|  | |

| |

Halfway through this process, I noticed a lot of the water evaporated away so I added 2-3 more cups of water and ½ tbsp more of soda ash to continue the process.

Halfway through this process, I noticed a lot of the water evaporated away so I added 2-3 more cups of water and ½ tbsp more of soda ash to continue the process.

After an hour, I removed the fabrics and rinsed them in lukewarm water.

Mordanting¶

Before mordanting, I rinsed and cleared the pot I used to scour the fibers and re-added 4 cups of new tap water into the pot. I then turned the heat up until the water started to simmer before adding 9.1g alum and 3g of cream of tartar. I gave the pot a stir and then added the linen and muslin. I let this mixture simmer for about 30min.

Dyeing¶

1: Avocado Pits¶

After the avocado pit was chopped, I added the pieces into some boiling water (enough to cover the bits) and let it simmer for about 2 min.

I then added ¼ tbsp soda ash to see if the color would shift to pink. Fun fact: it didn't. But it may just not have been enough soda ash. Anyway, I added the linen and muslin into the water and let it simmer for 40min.

After the 40min, I took the fabrics out carefully by placing them in a mason jar (one for each fabric) and then pouring the remaining liquid into the mason jars with the fabrics to continue fermenting for at least 24 hours.

2: Onion Skins¶

Once the pot was emptied and cleaned after the avocado pit mixtures, I re-added about 3 cups of water into the pot and reheated it to a simmer. Then, I added 3g of onion skins. Almost immediately, the color of the water started changing into a orange-yellow hue. After simmering this for about 30min, I removed the onion skins and added a 5g skein of wool yarn and a sample of muslin (13g).

I let these fibers sit in the pot simmering for about 45min, re-adding water when it was starting to evaporate too much. I then removed the fibers along with the liquid and let it ferment for almost 24 hours.

3: Turmeric¶

Similar to the previous processes, I made sure the pot was clear of previous liquids and cleaned before restarting the next dye process, which was the turmeric. I added about 3 cups of water and let to come up to a simmer before adding 1.5g of turmeric into the water. The solution continued simmering for about 30-40min (during which an unsettling but not dangerous smell began to arise).

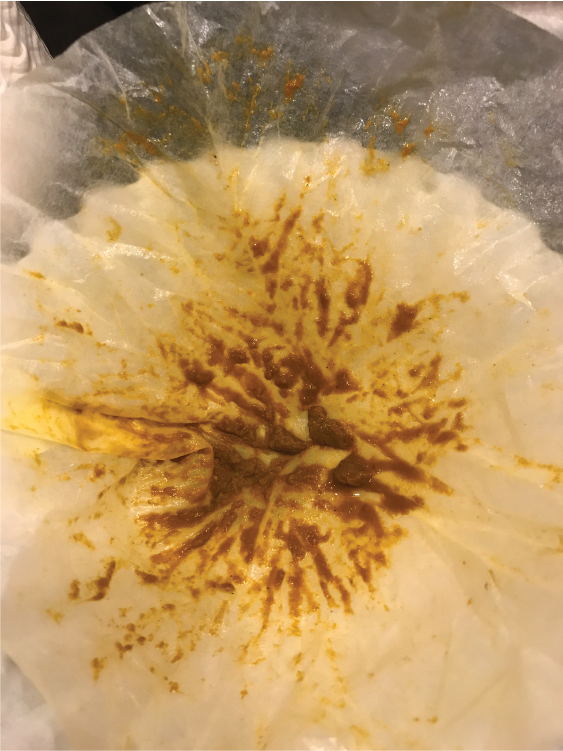

Then, I took the solution and began filtering it through a coffee filter. This filtering process turned out to be longer and more difficult than I expected as I originally started with holding it in an ordinary strainer, but then wanted to double the setup but adding a funnel filtering system next to it too.

I used multiple coffee filters because it seemed like it was getting easily "clogged" and filtering was taking longer. Regardless, by the end of filtering through one filter, some residue was leftover in the filter.

silly me thought this was going to be useless material so I ended up tossing all of these filters including the residue... however, as I learned later on it was actually important to keep this residue to create powder pigments.

silly me thought this was going to be useless material so I ended up tossing all of these filters including the residue... however, as I learned later on it was actually important to keep this residue to create powder pigments.

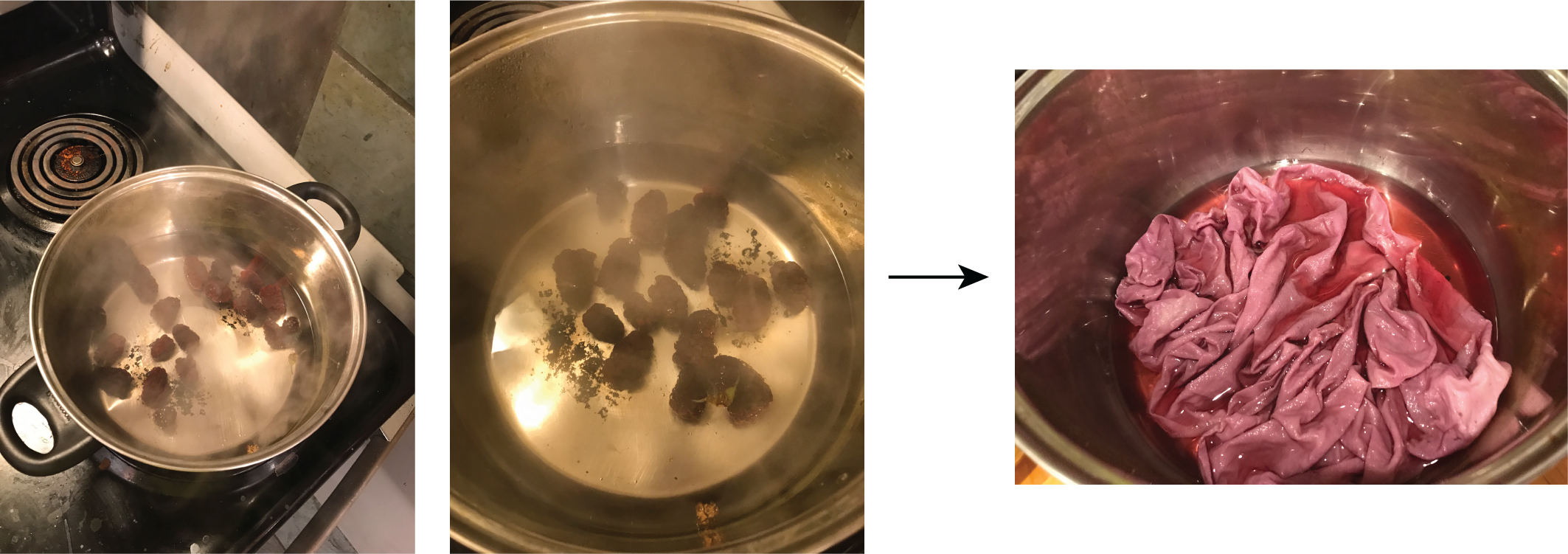

4: Blackberries¶

Out of all the dyeing processes undergone this week, I think the blackberry one was my most anticipated one. I started by filling up the pot with 3-4 cups of water and heated it to a simmer. Then I added about 5g of blackberries into the pot. This simmered for about 20-30min before I added a 26g piece of muslin. The muslin simmered in the solution for about an hour.

All samples¶

In the end, all samples fermented in their respective containers for 12 hours (blackberry sample) to 48 hours (avocado pits). Before moving on to the modifying phase, a portion of all the liquids were removed into little plastic containers for further play and experiementation.

Modifying¶

To play around with the dyes I made, I used a painting palette to easily compare the differences. However, the first time I did it I didn't document the exact modifiers I used and how much for each. And then due to time constraints, I wasn't able to revisit the modifying stage until 3 days later.

When I revisited the modifying 3 days later, I re-documented the actual modifiers used and how much of each. The precipitates of the dyes were also much more visibile.

Creating Inks¶

Making inks was a tricky process for multiple reasons - the primary one is not having access to any pure ethanol locally. At my local pharmacies they only had isopropyl alcohol, not ethyl alcohol. My next closest option was using Tito's vodka which contains 40% ethanol. Just to see what would happen, I tested out some drops of vodka in some of the avocado pit dye.

Creating Pigment¶

I created some pigment out of the turmeric, blackberry, and onion skin dyes by running them through coffee filters repeatedly and then saving the precipitates leftover in the filter.

Update Oct 20, 2021: the powders in the filter are still drying

Final Fabrics¶

After air drying the fabrics outside overnight, there were still some bits and pieces stuck on them. So, they were then lightly hand washed with some soap and quickly dried again in the dryer for 30min. After that, I took an iron to lightly press out wrinkles.

Some interesting observations I had about these samples were:

- the turmeric and onion skin yarns were very similar in yellow-ness

- the turmeric yarn was lighter in color than the onion skin one

- the linen and muslin dyed with avocado pits weren't as dark as the dye itself hinted, though this may have been due to accidental rinsing after mordanting

- the blackberry muslin turned out to be my favorite

Problem Areas¶

Rinsing after Mordanting¶

Problem

I didn't realize until the moment I started doing it but I started rinsing the fibers for the avocado pit dye after the mordanting process. As a result, the fibers didn't bind with the dyes as well as it could have.

Solution

I shouldn't have done it. It was pure human error and the moment I finished rinsing the linen and muslin and put it in the avocado pit dye stuff, it was too late. As a result, the dyes weren't as deep as it probably could have been.