Development Timeline

-

1. Design Concept

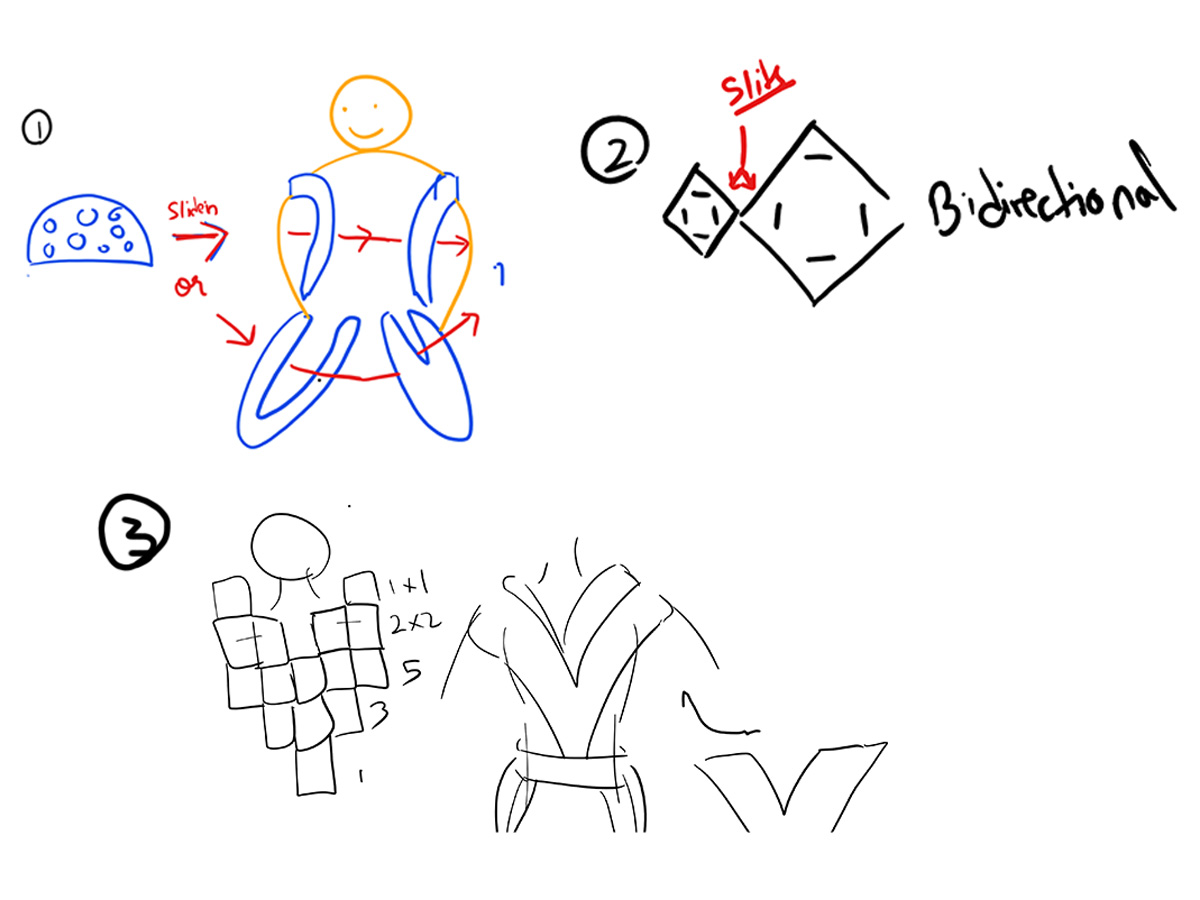

After a recitation by Zoe Romano , I started understanding what is Circular fashion and how can we work on making modular structure or connections that would allow the user to change the size or orient in different shapes.Therefore, I started thinking on the lines of the qeustion-What could be the possible joints, interlock or holds to keep the elements together without stitching?

I eventually settled on a 'Poncho' as the garment to make, divided into 4 quads-Front, Back, Left and Right shoulders and integrated it with a semi-circular accesory lace design which I would eventually cut and fit into each module that would seamlessly crossfit the adjacent module.

P.S. Pretty happy to have explained the design on the left the way I just did above. Made such a simple design sound so Poshh and Geeky with a sprinkle of SWAG!! To be honest, this is the simplest design I was able to come up with. -

2. First Module test (Head portion)

So, the first step to the design post the main module design was to figure out the Incan Chief's head. Still stuck with AUTOCAD remember!! Settled for a merged boolean of two concentric spiral circles as my perfect Head. Immediately tested it out on a 2 day old Newspaper lying in the boot of my car to find out if what i visualised actually looks nice or whether there is any design error i might need to correct.

The settings on the laser of newspaper was very less. About 10 % power on a 40w tube (=4W) and 100 Speed. Will explain the Laser cutting process in detail below. For now, just penning down that newspapers to test designs meant for fabric and cardboards to test designs meant for acrylic/wood/metal is alsways a economical and more enviornment friendly way of testing designs before fabrication. -

3. Design Development

Living in the Corbusien city-Chandigarh and as an architect, it was only natural I try my luck with incorporating the Fibonacci Series as one of the design principles the proportions of the module would revolve around. For some reason, the webm(left) doesnt play at times. Better just click the image (left) to have it play a video showing the steps on how obsolete a way I used to design this module. After having figured out the head(above), incorporating it into the form of a flat design that would fold to an organic looking dancing Incan was worth a lot of brainstorming (roughly 2 days) of thoughts that went into this. Cherry on the cake was the amount of time recollecting all the commands of Autocad which i revisited after quite a huge gap (4 years). Surprised to see the software hasnt changed much since the time it was launched in MS DOS ;-)

-

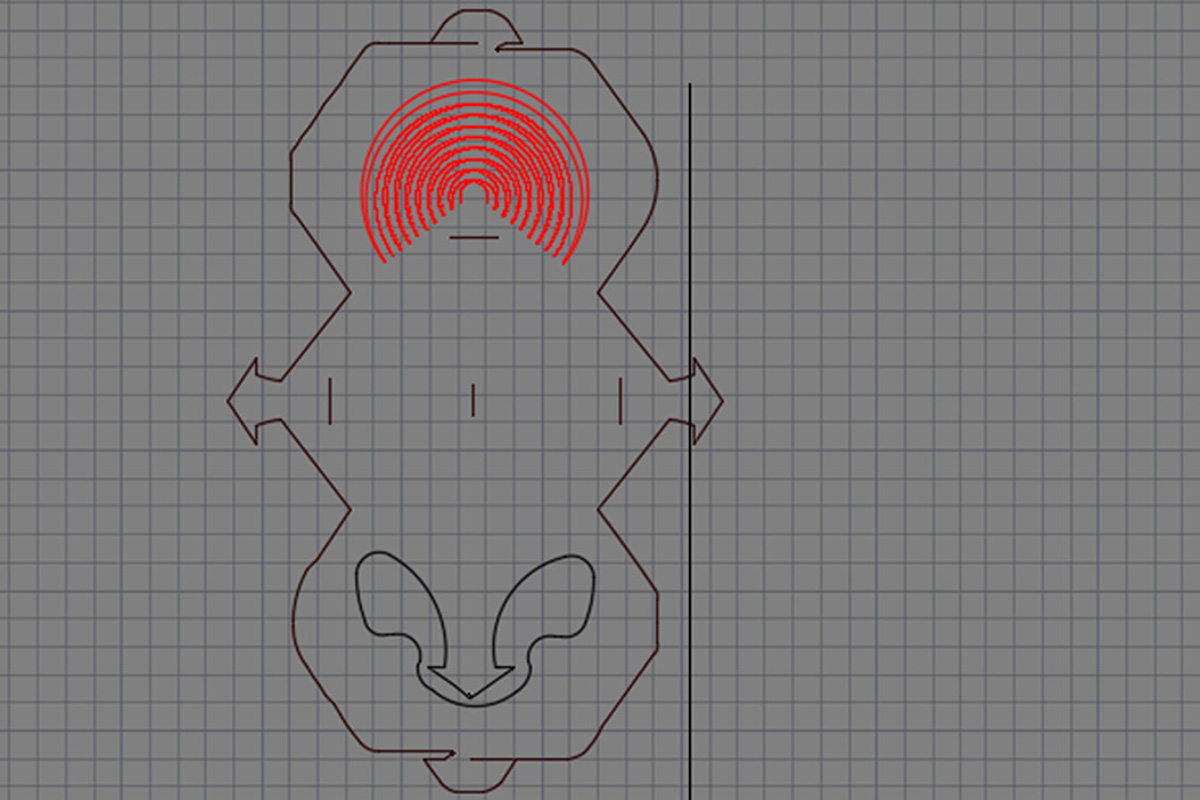

4. 2D Design Ready for Laser Cutting

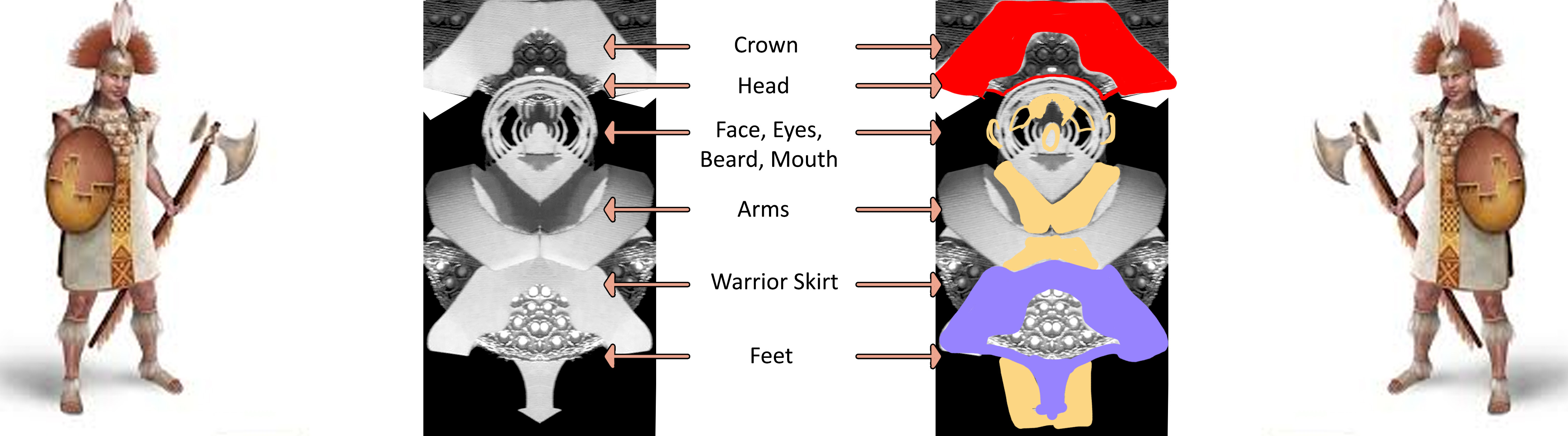

The piece you see on the left is the final design derived which will fold into the Arms and legs of an Incan Chief along with his/her headgear.

Quick Trivia :

Guess the hands of the Incan chief in the design. If your answer is the Left and Right facing arrows, you are wrong. Watch the assembly video to see the answer. -

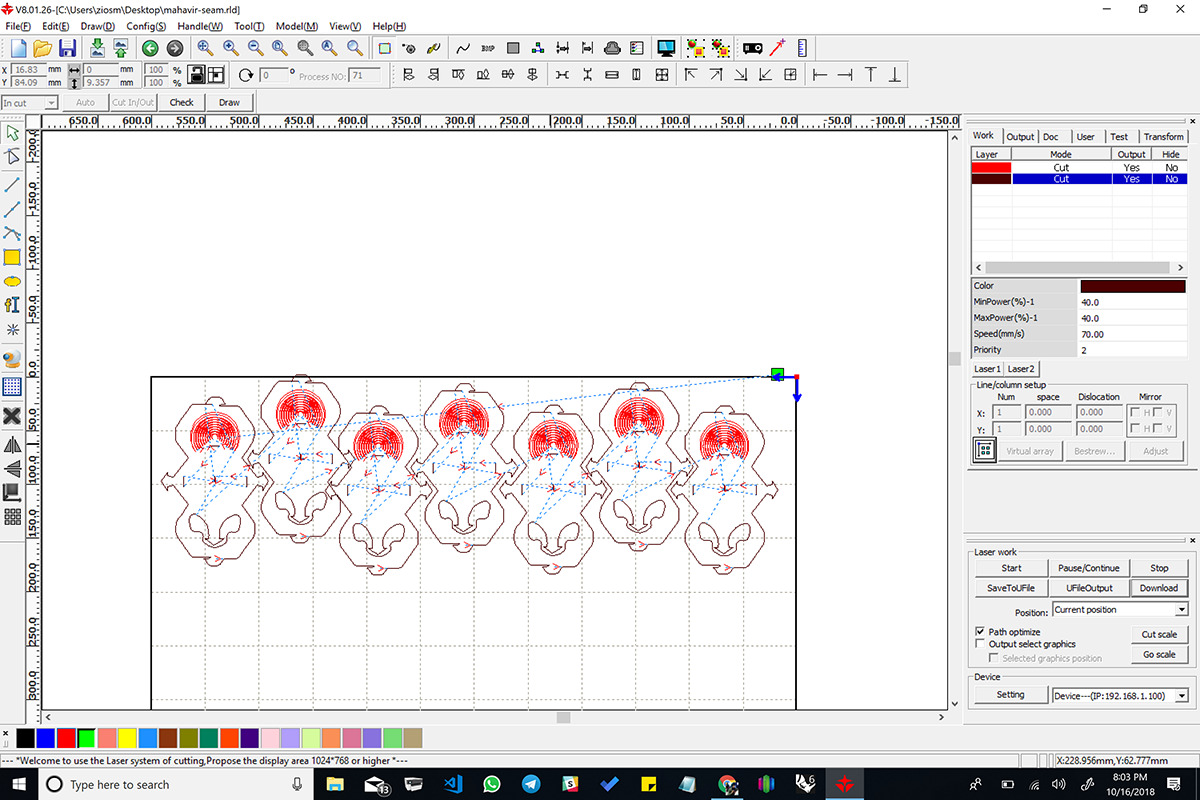

5. Nesting | RD Works | Laser Cutting

I nested it manually in RD works itself as I tried to cut on already cut fabric pieces. Would have loved to cut on a bigger piece all at once but if you can get pieces from leftover reasonable fabric, why not use it then.

The RD Works settings were 40% Power(=16W) and 70mm/s Speed for the Starch Fabric

You see two layers in the CAM software as I wanted control over which part of the design gets cut first. Settings for both remain the same. -

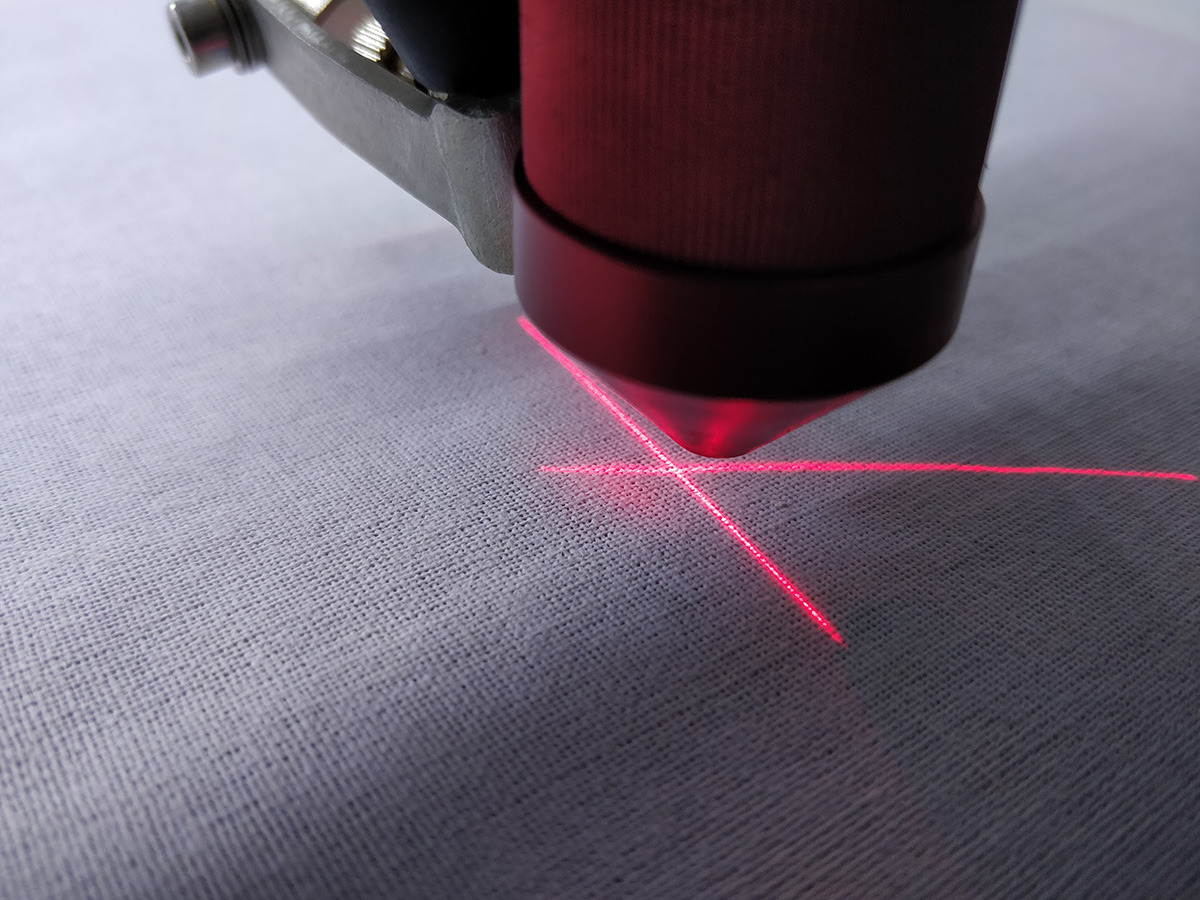

8. Digital Fabrication | Laser Cutting

Zios Makerspace has two Laser cutters. One is a 60*50 cm bed size 40w Laser with a Z of 45 cms and a 4th axis rotary. The second is a 4 feet*8 feet 150W Laser cutter that has been upgraded inhouse to now cut at 240W of CO2 Laser cutting.

The small laser cutter is pretty fun as you are kind of dealing with about 10-25% power only and within that range always manage to cut neatly and cleanly with a reasonable speed.

From a fire safety concern, I switched of the air assist to prevent any chances of the fabric catching fire specially since fabrics do not need a deeper penetration which the air assists contributes to. -

9. Manual Assembly

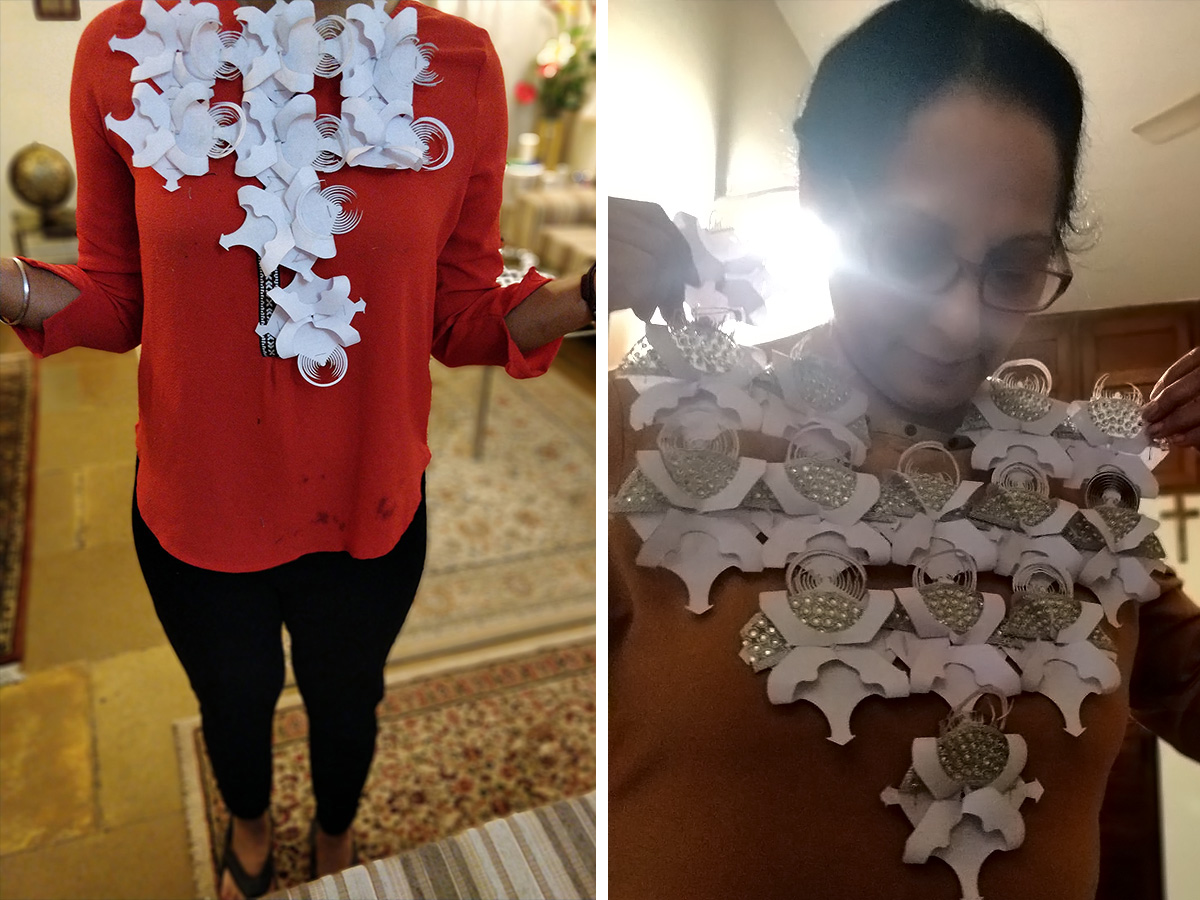

To the left, is Nishtha wearing the first assmebled set of laser cut pieces.

Assembly time: 4 mins (Thats right, very quick to assemble)

Towards the right, my Mother trying on a sample side of the same with the correct orientation as per the concept I had drawn.

Assembly time: 12 mins

The design seems to be coming together. Hopefully it ends up looking elegant rather than too flashy. Might end up with neither. Either way, am pleased with the results. This week was more enjoyable than what I had envisioned it to be. -

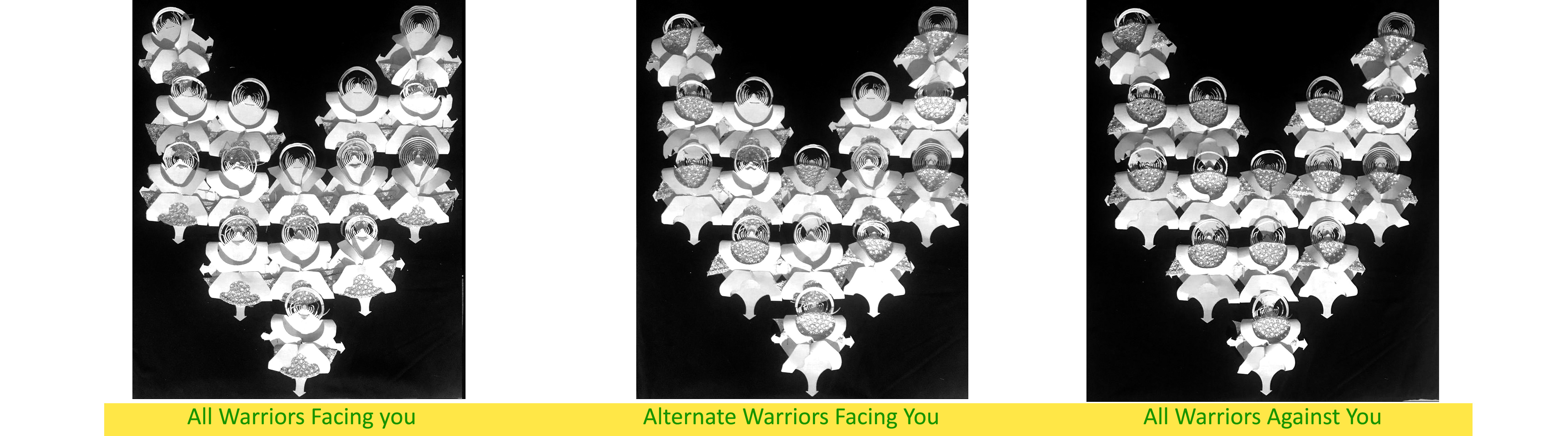

10. Reconfigurable

As you can see (left), there are quite a few ways to arrange the garment to be and styles it can be used as. The fabric is currently not dyed, but can be dyed to different shades and combinations to bring more variety.

The assembly process is intuitive and since the fabric can be disambled with ease and post assembly take about 20% stretch horizontally and about 10% vertically, Its reconfigurable to some extent.

To the left, I have put together a few configurations I could think of given the time available. There was a version of it where it even fit my pet dog as a stylish dog soft saddle/coat (given the small size of the Indian Spitz), but I seem to have misplaced that image somewhere.

Tips and Tricks

Info Panel

Warning Notes

Danger Panel

Some fabrics (Course and dry) are prone to catch fire. Always stay alert Laser cutting.

Success Panel

F.A.Q.

I usually ask the Global team or myself questions relevant to the week's task.I plan to use this section to help me document for our lab's next batch of students important questions and their answers discussed during Global review/Recitation.

Objectives | Tasks at hand

For this week, I am referring to the Incans one of the more ancient civilisations with the 7th wonder Machu Picchu built by them. From the books I have read on their history during my earlier graduation days long back, I was interested to see how could i take elements of their culture and laser cut a modular design from that. I referenced an Incan Warrior for this.

UPDATE:

I managed to make a modular bi-directional piece of an Incan Warrior in a Dance pose. This has been the most hillarious week for me. WIll write about it if I get the time to post my documentation first of all assignments. Otherwise would love to discuss it in Fab 15, Egypt

Reffered Links

Oct 10, 2019

Oct 11, 2019

Oct 11, 2019

Oct 12, 2019