2. Digital bodies

| Output Assignment |

| A 3D model scanning naked body |

| A 3D model open source |

| References |

My interests :

- technic (Scan3D/LaserCut/3Dmolding)

- research (available material low cost)

- making off (notches)

- tutorial (from 3D to 2D with rhino Fabricademy 2017)

- software (Sense3Dscanner/slicer/netfab/makehuman)

Useful links

References

Arte Digital Geek 3/10

- Arte : Fashion Geek 3/10 technology can help and can be a creative source to create and fashion work.

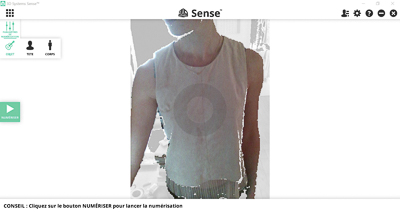

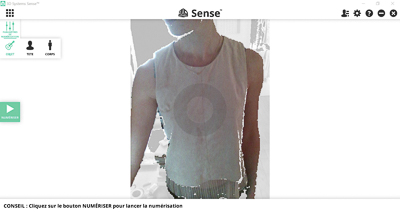

SENCE SCAN 3D

| Tools |

Observation |

|

This 3D scan is very usefull to scan object with a scale of a body or a furniture piece. During fabricademy program I use it and try to use is to scan my cristal (10cm) scan a croco leather (<1mm) an ear (5cm) and each time is doesn’t work. |

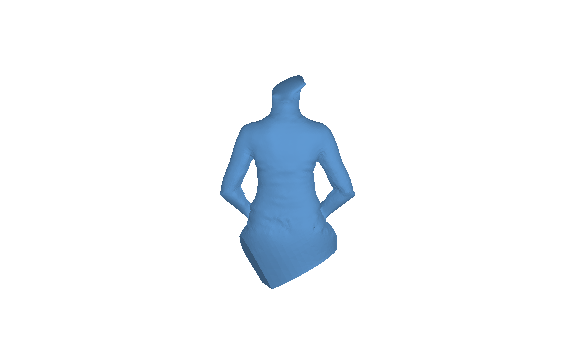

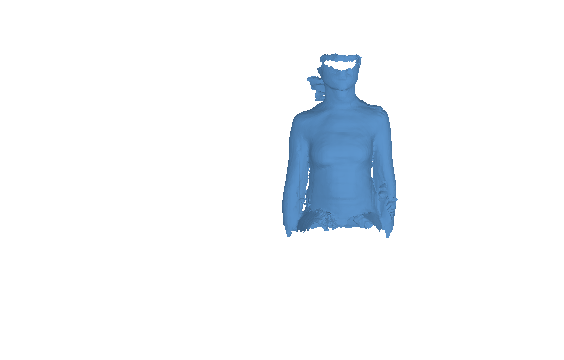

| Images A |

Image B |

|

|

observations

The scan of my body is dificult to have a good angle and a good result with the 3D axe.

I use is with out tripod.

The stability is a difficulty to take care of.

My body was good but, for a mannequin in order to work with, I choose a different technic to make my measurement.

I used Make Human.

The scan needs :

A tutorial : Sence3Dscanner

- good light

- big stability

- a very slow capture

- sometime many pass I required in order to have many good detail.

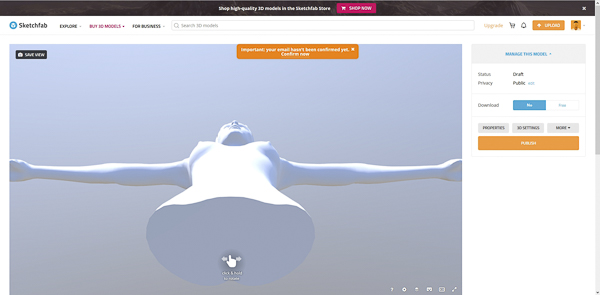

To scan my naked embody

If it’s a body for a couture tool, the experience of the real scan is very usefull.

Make clothes one by one is a nice philosophy.

The time of the scanning is a little unconfortable, because we are not use to see our own body, nacked.

A cultural practice.

I think this exercice is good to now better who we are.

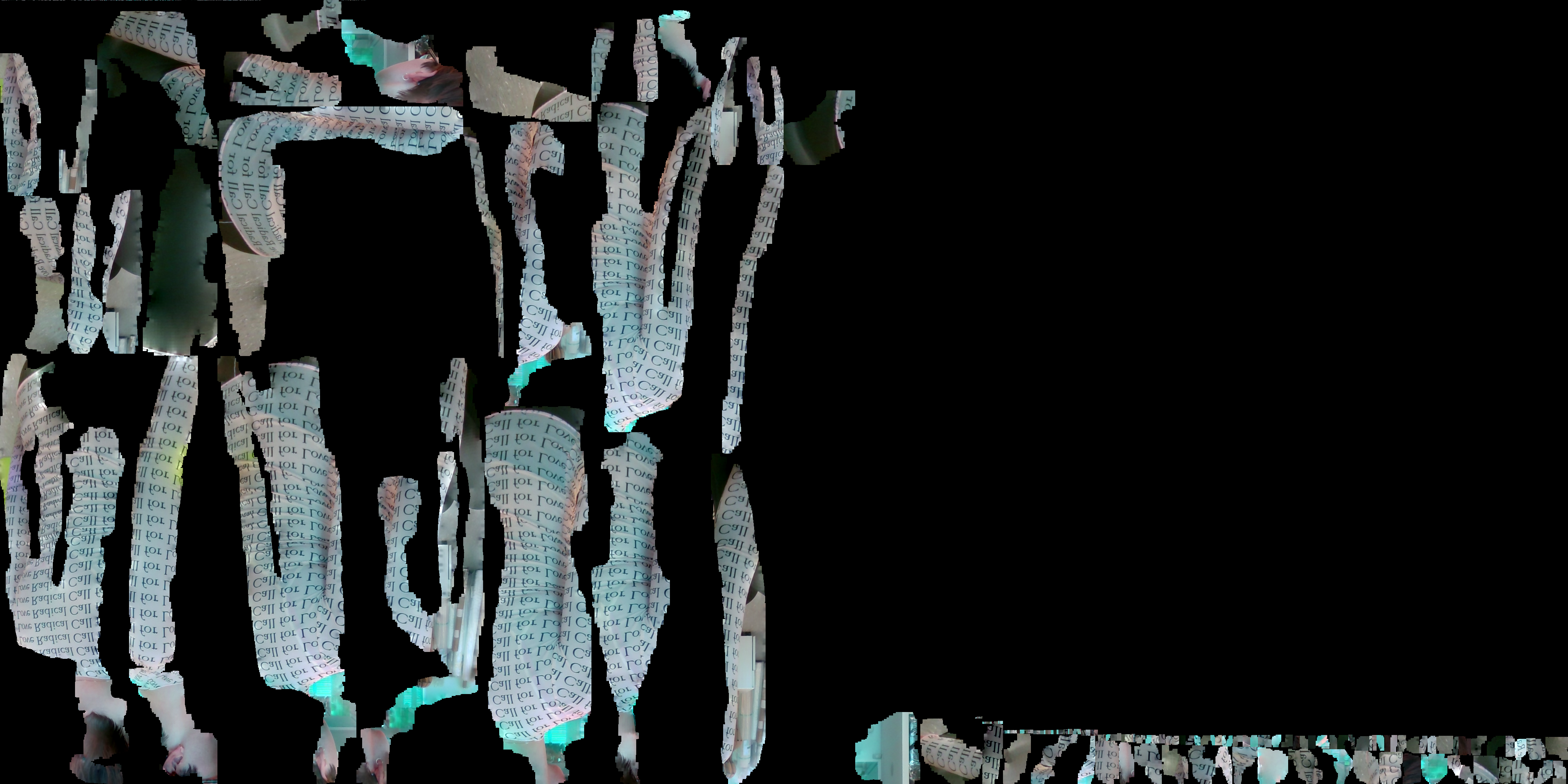

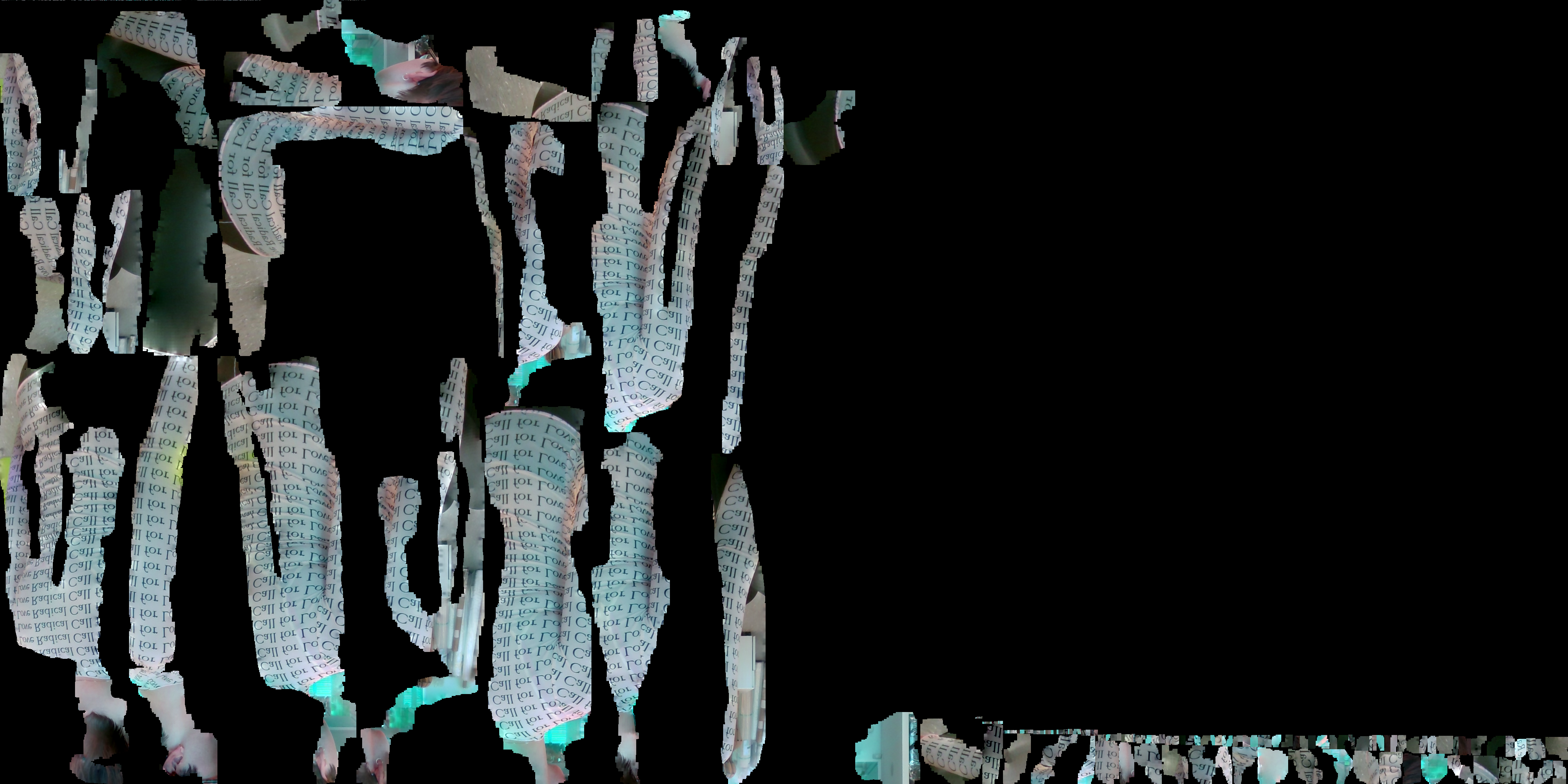

| With the 3D export I have this texture picture of myself like littles skin slides |

|

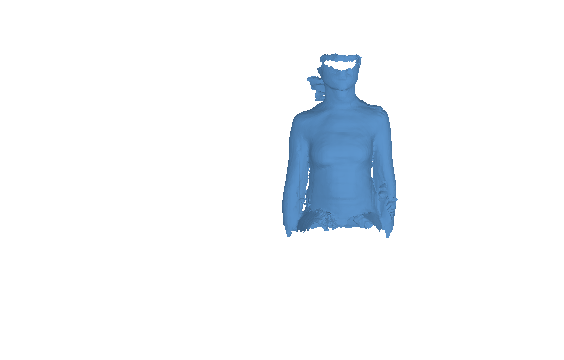

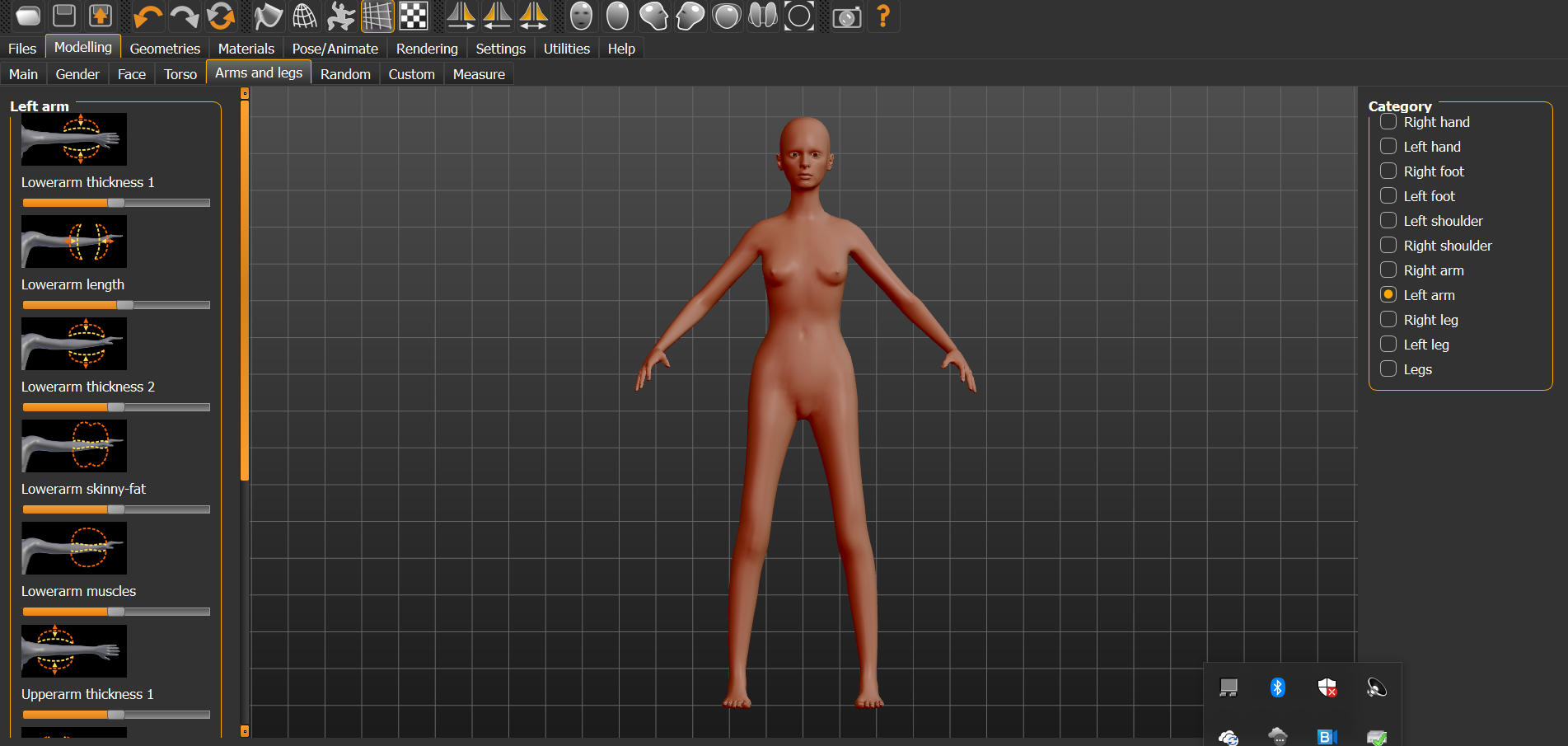

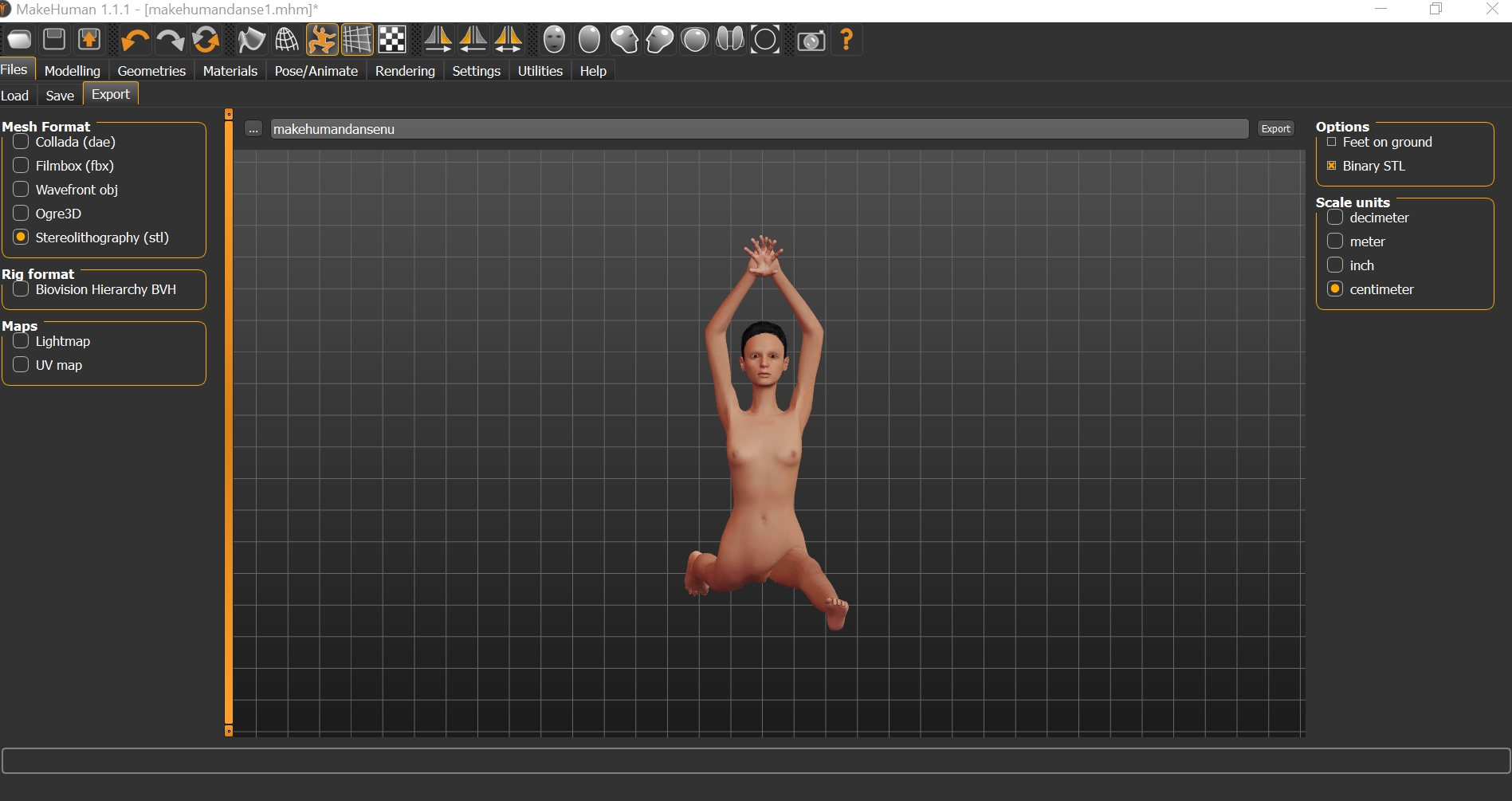

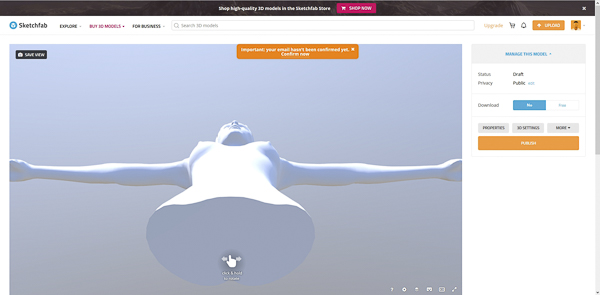

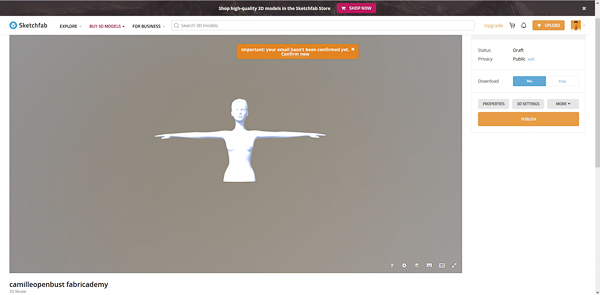

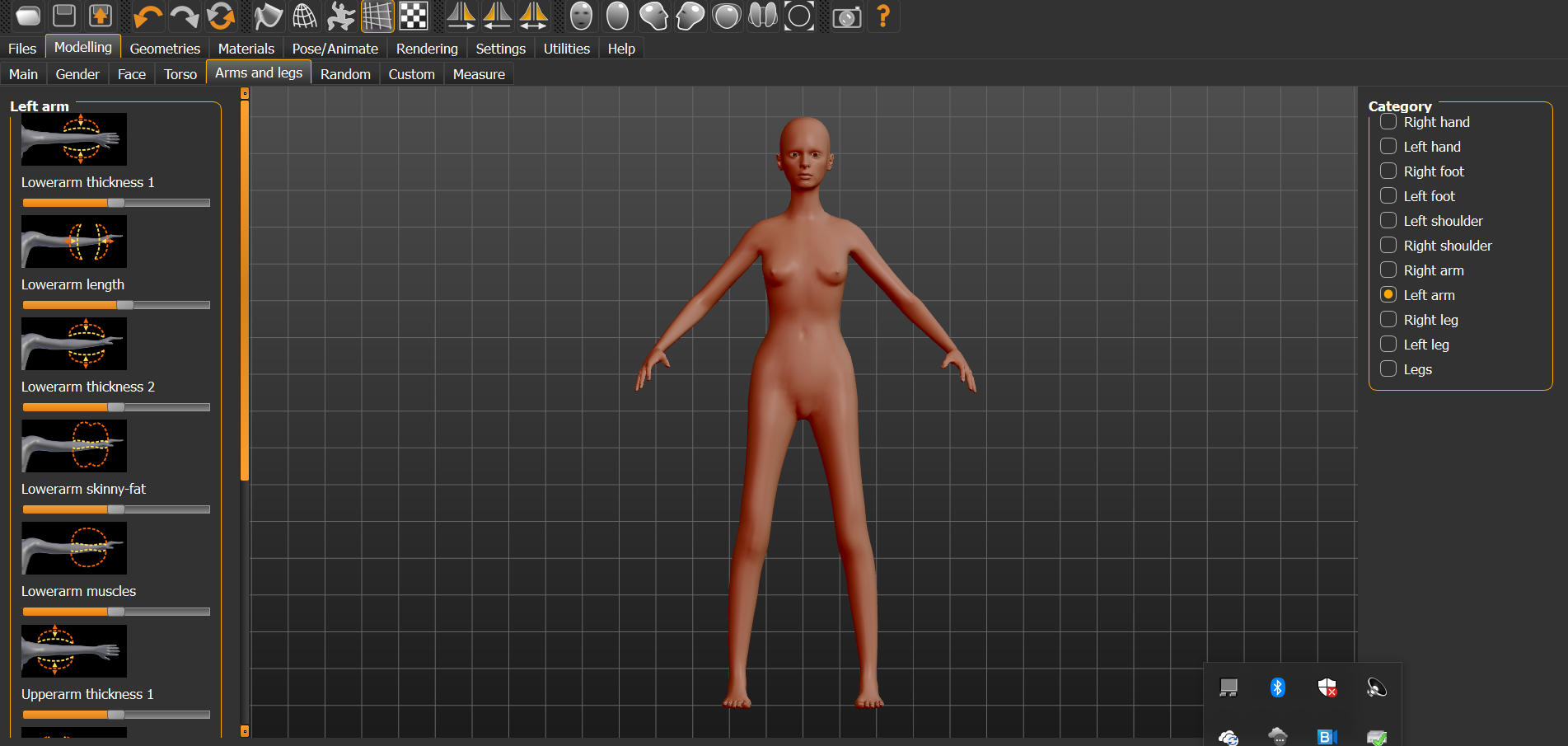

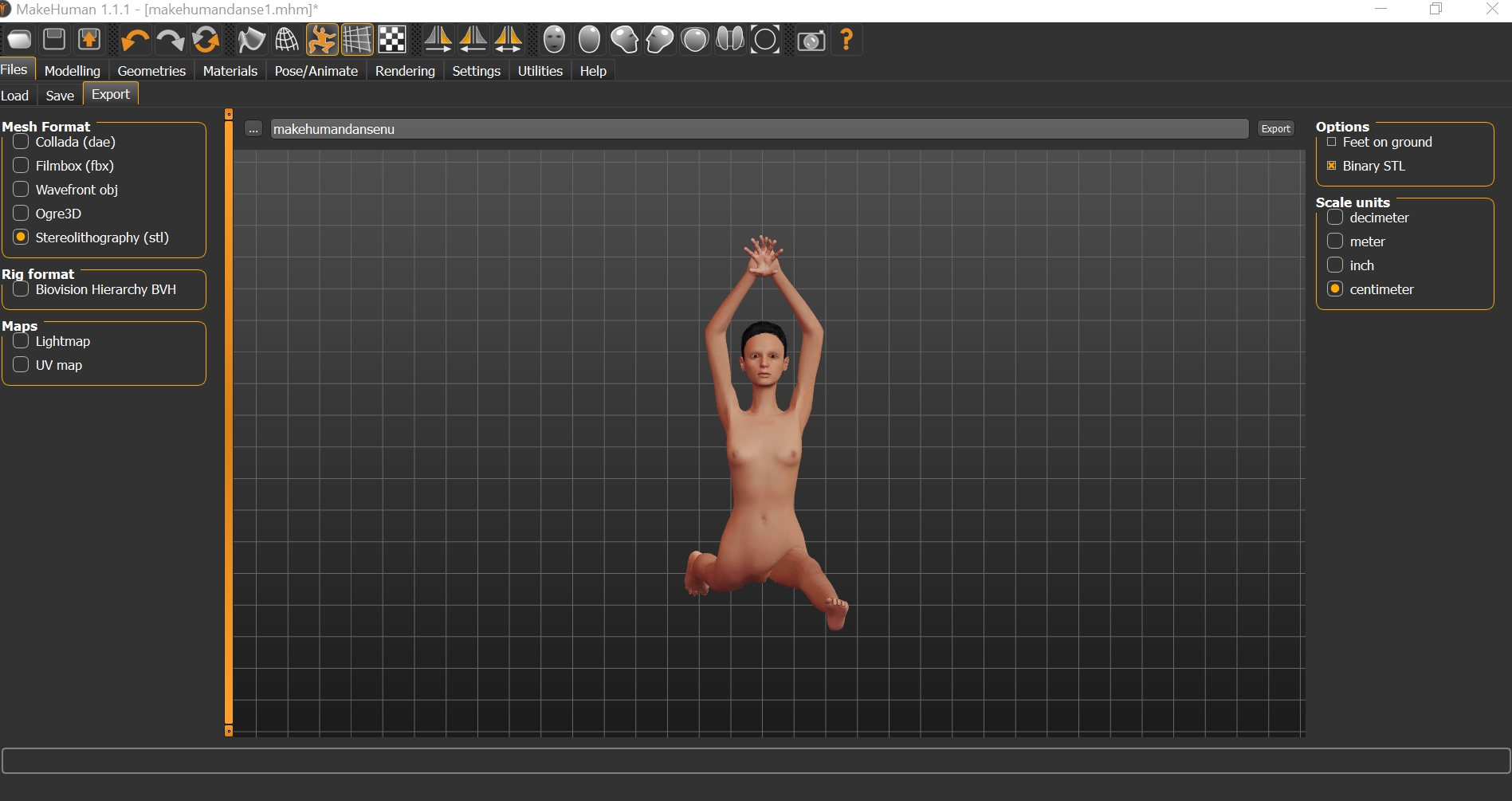

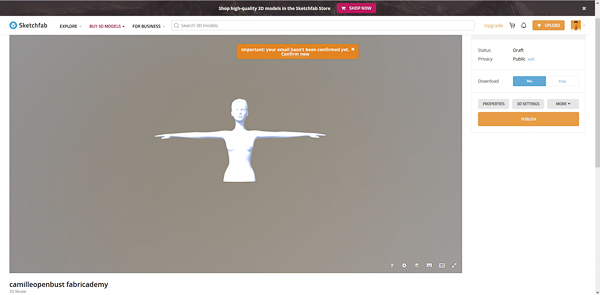

Make Human : size of my own body

With this software you can change the size of the body.

And try different attitudeor position of the body .

| Make Human |

Make Human |

Observations |

|

|

this software have many good parameters and to make quickly one mannequin is very usefull. |

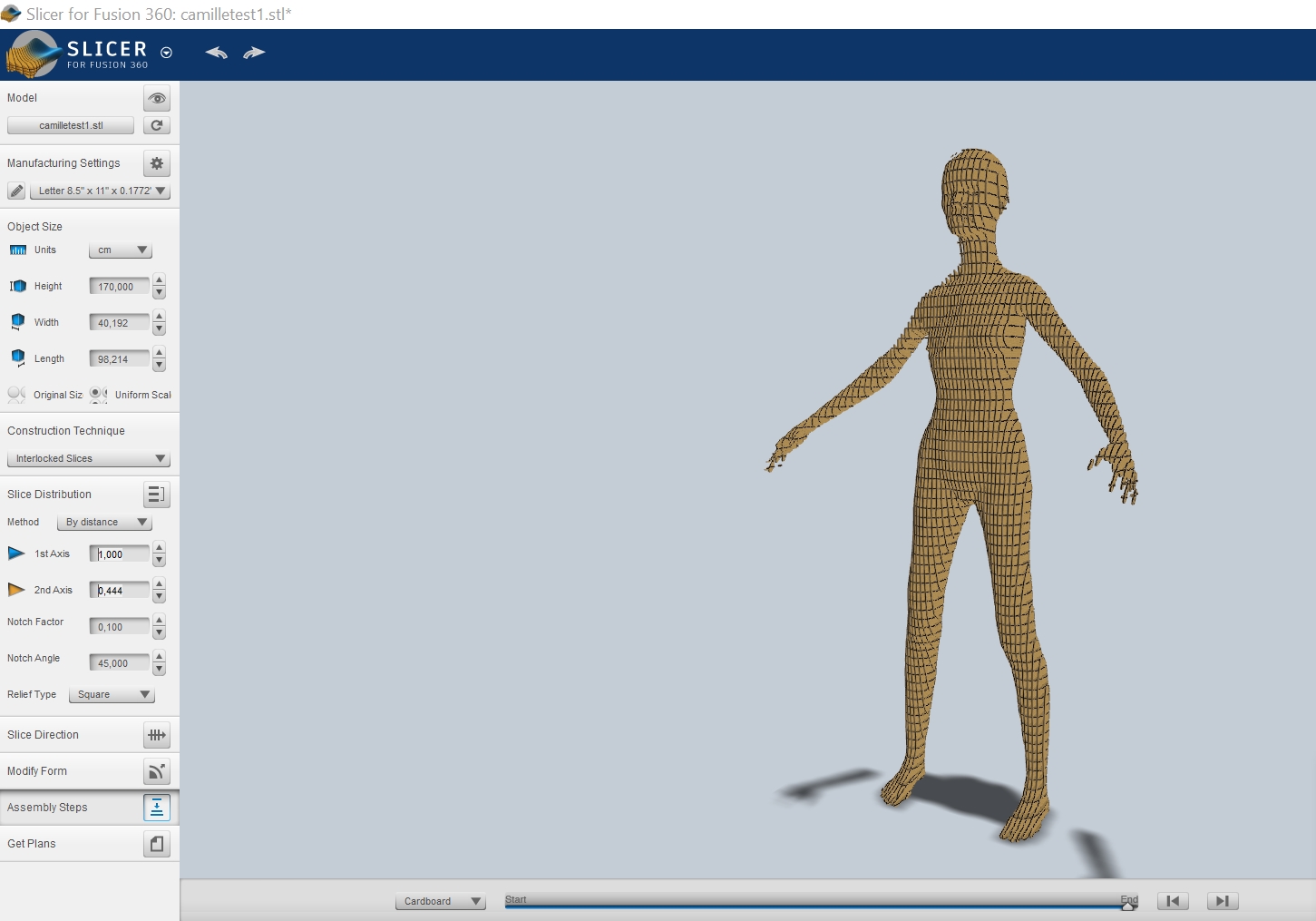

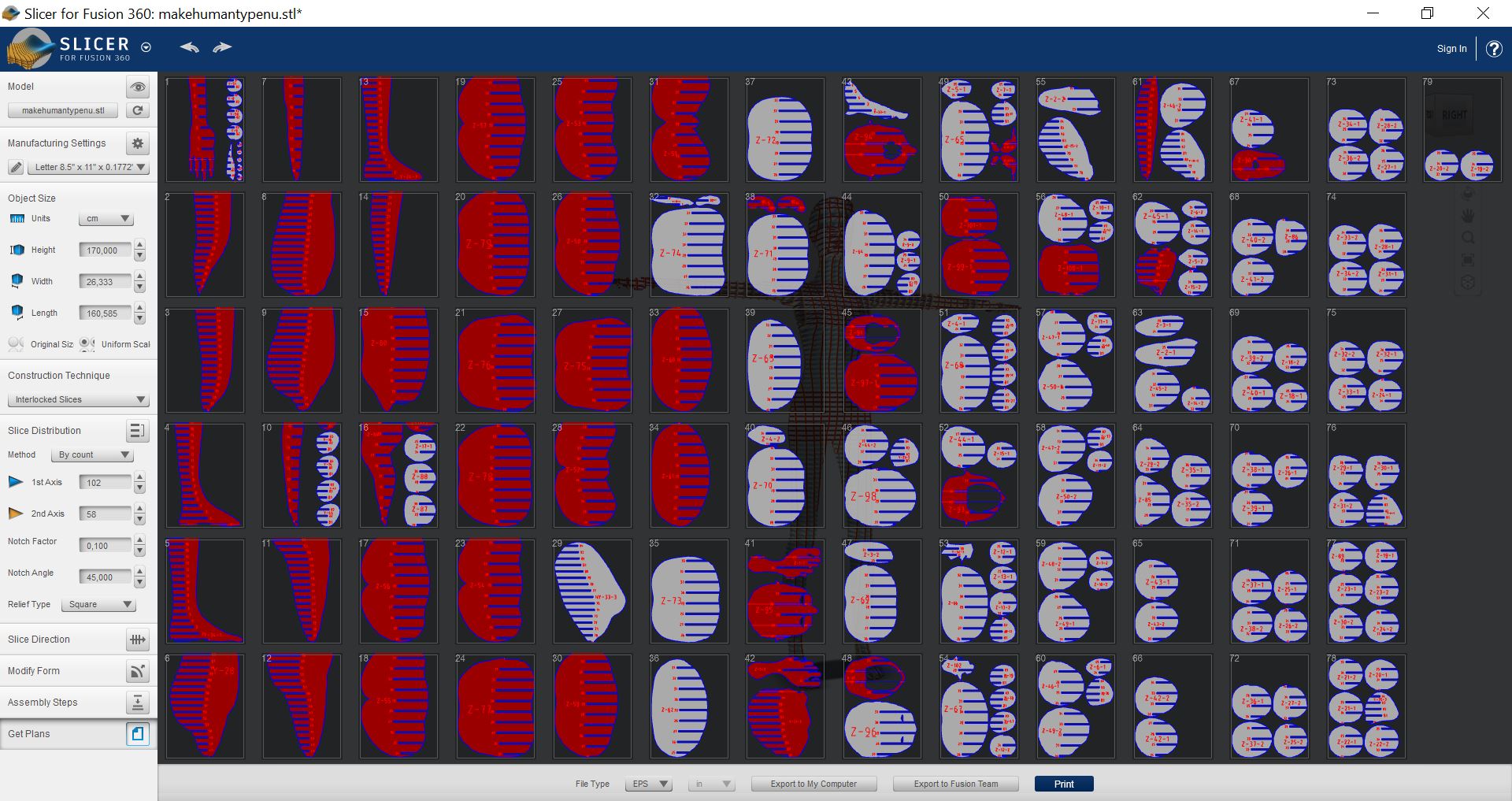

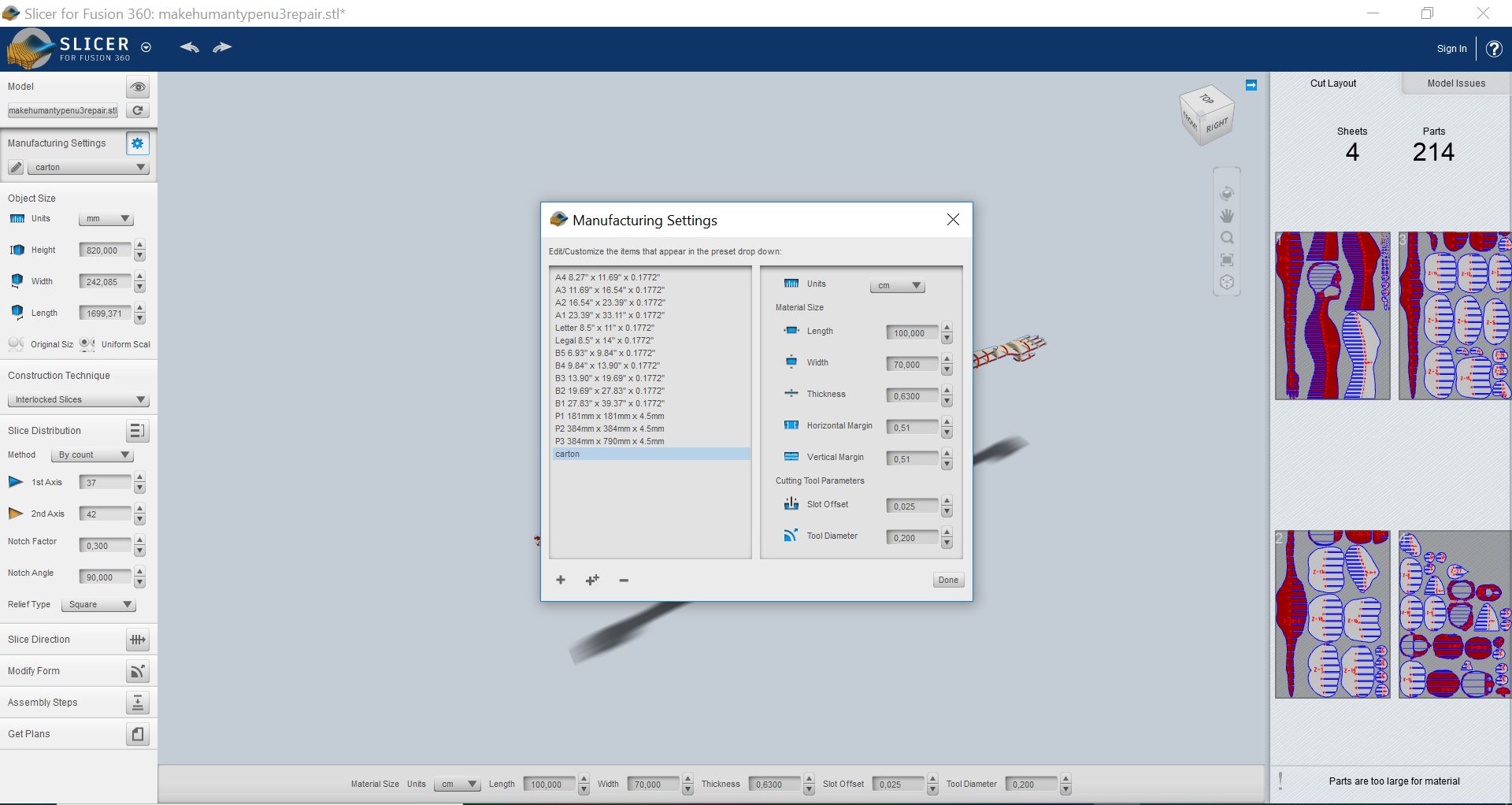

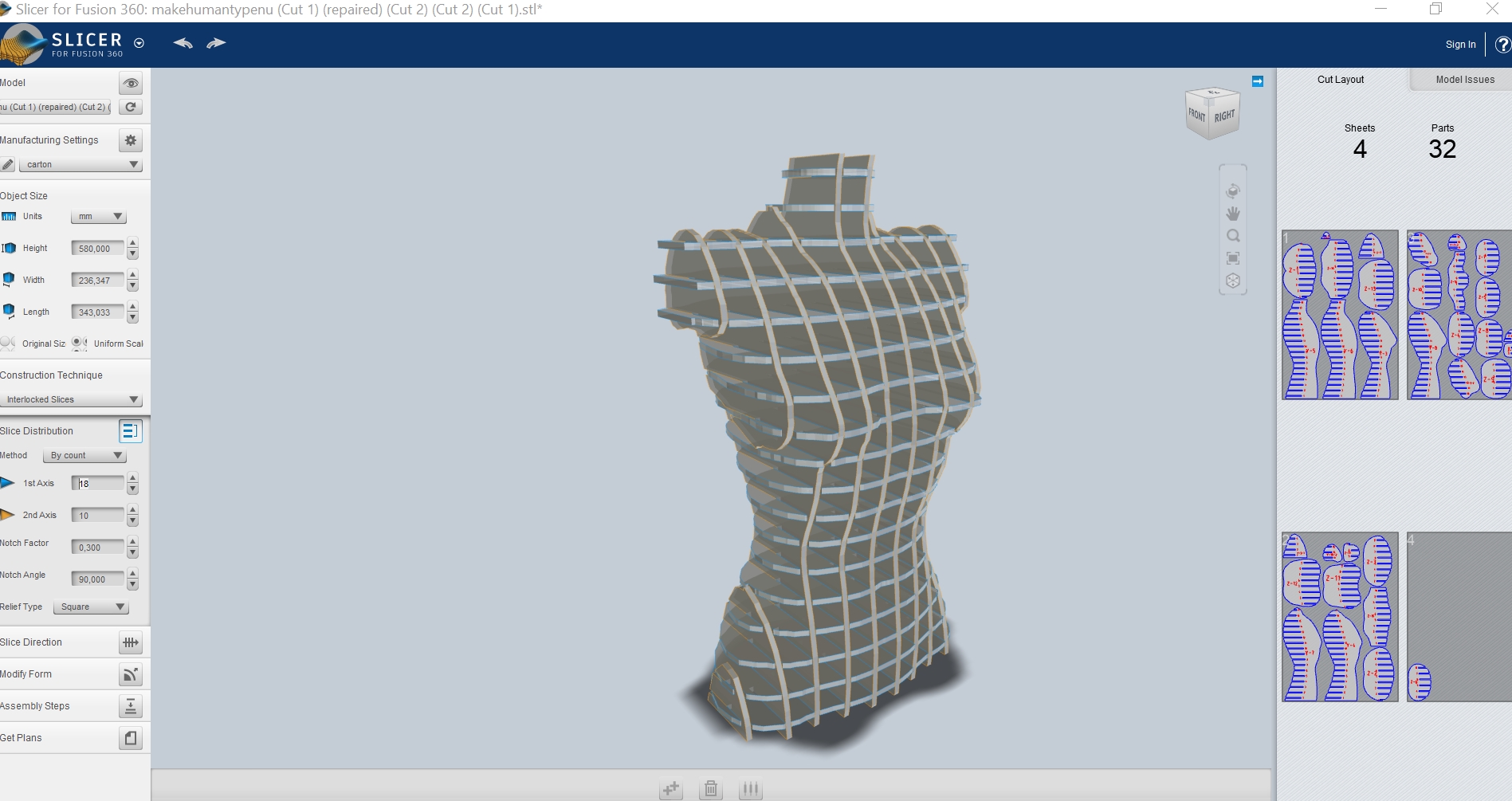

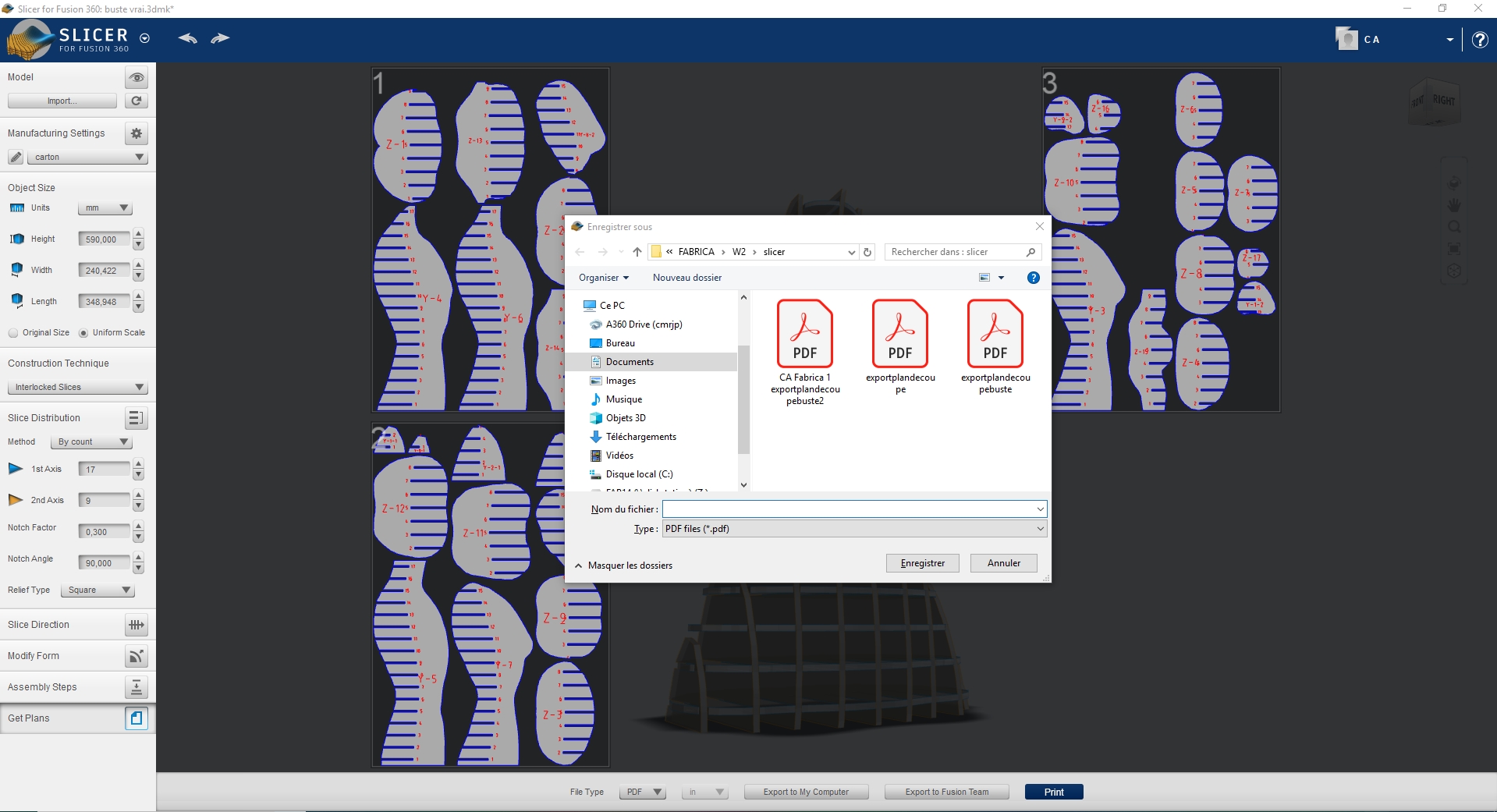

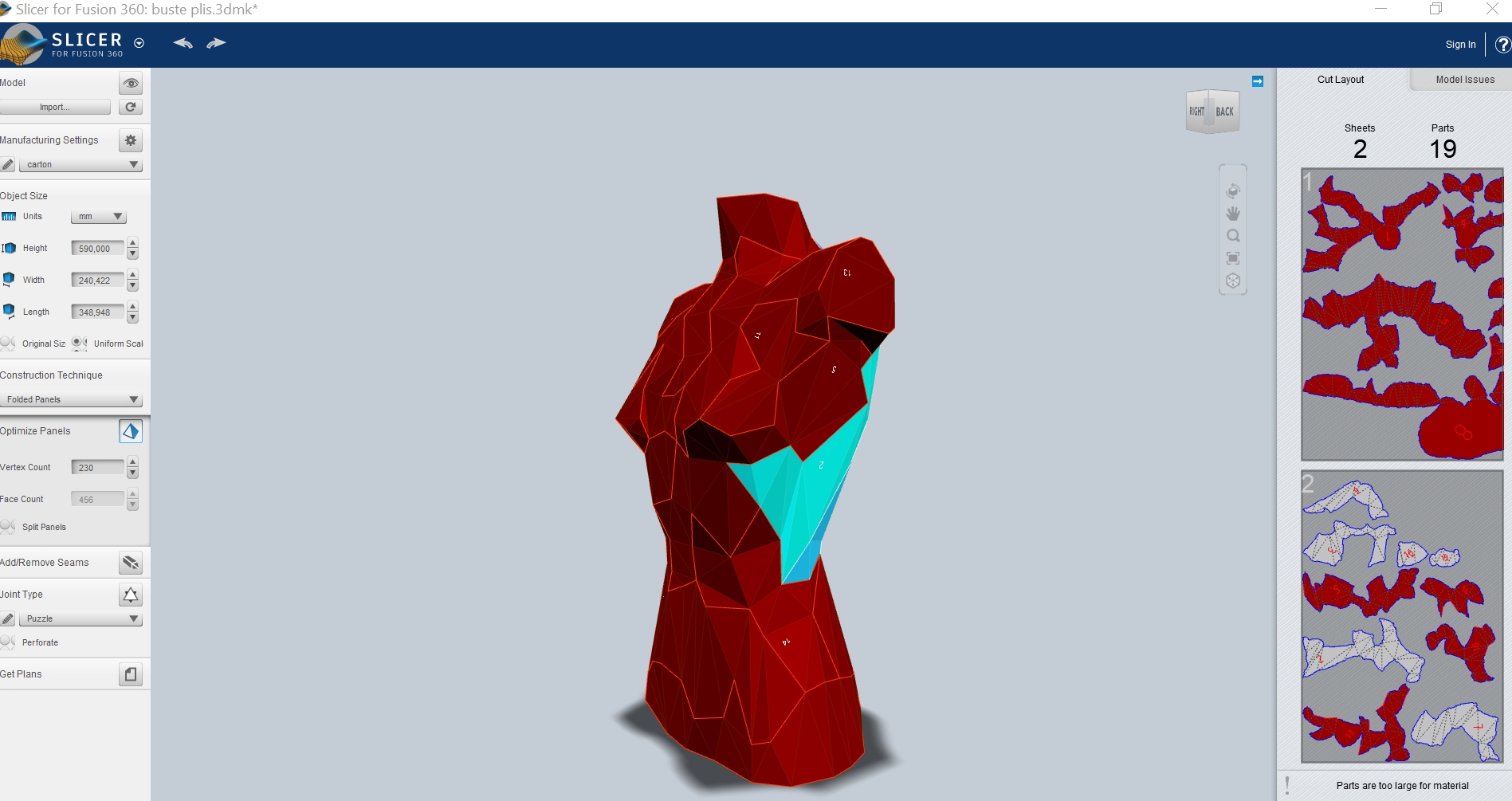

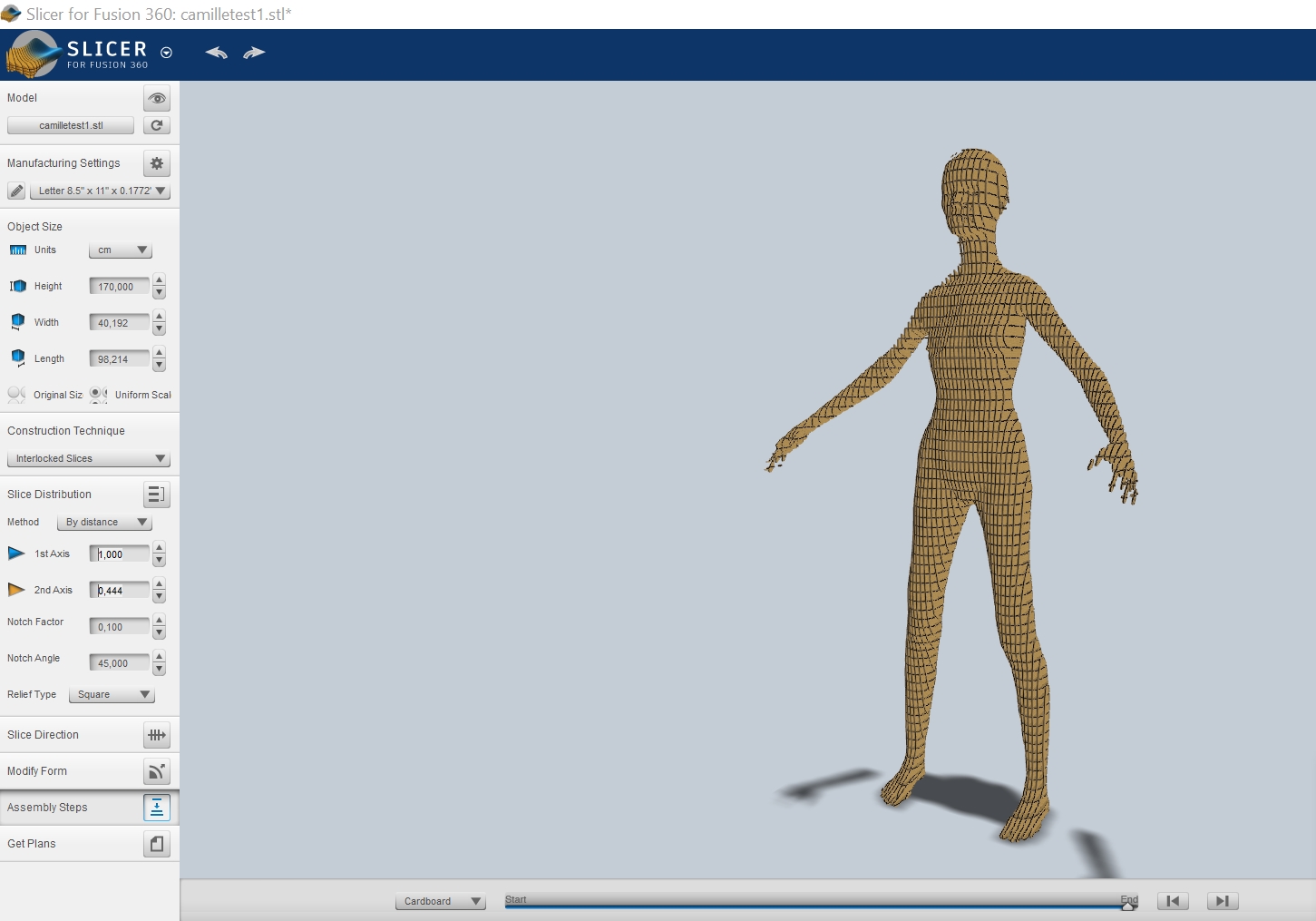

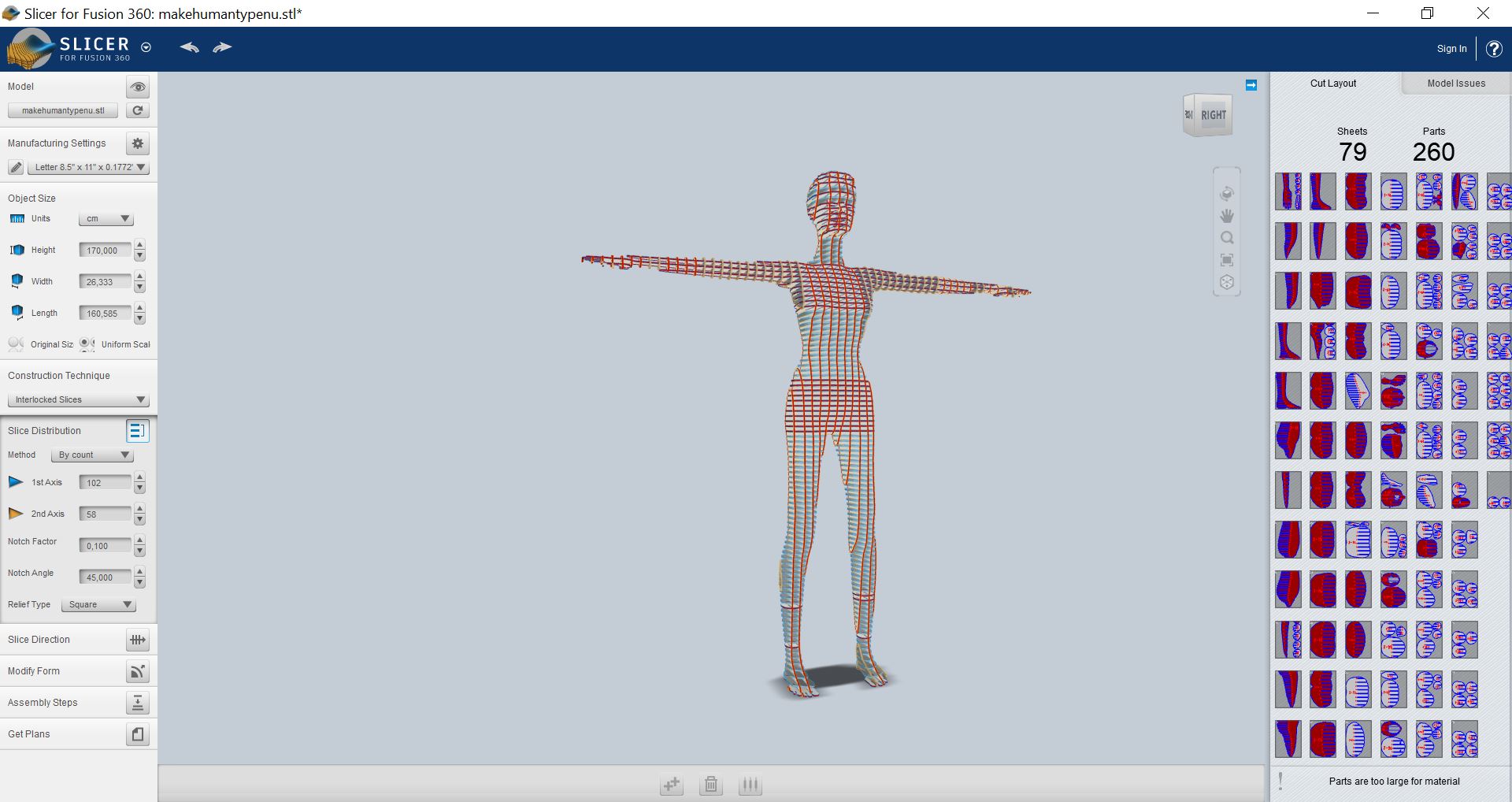

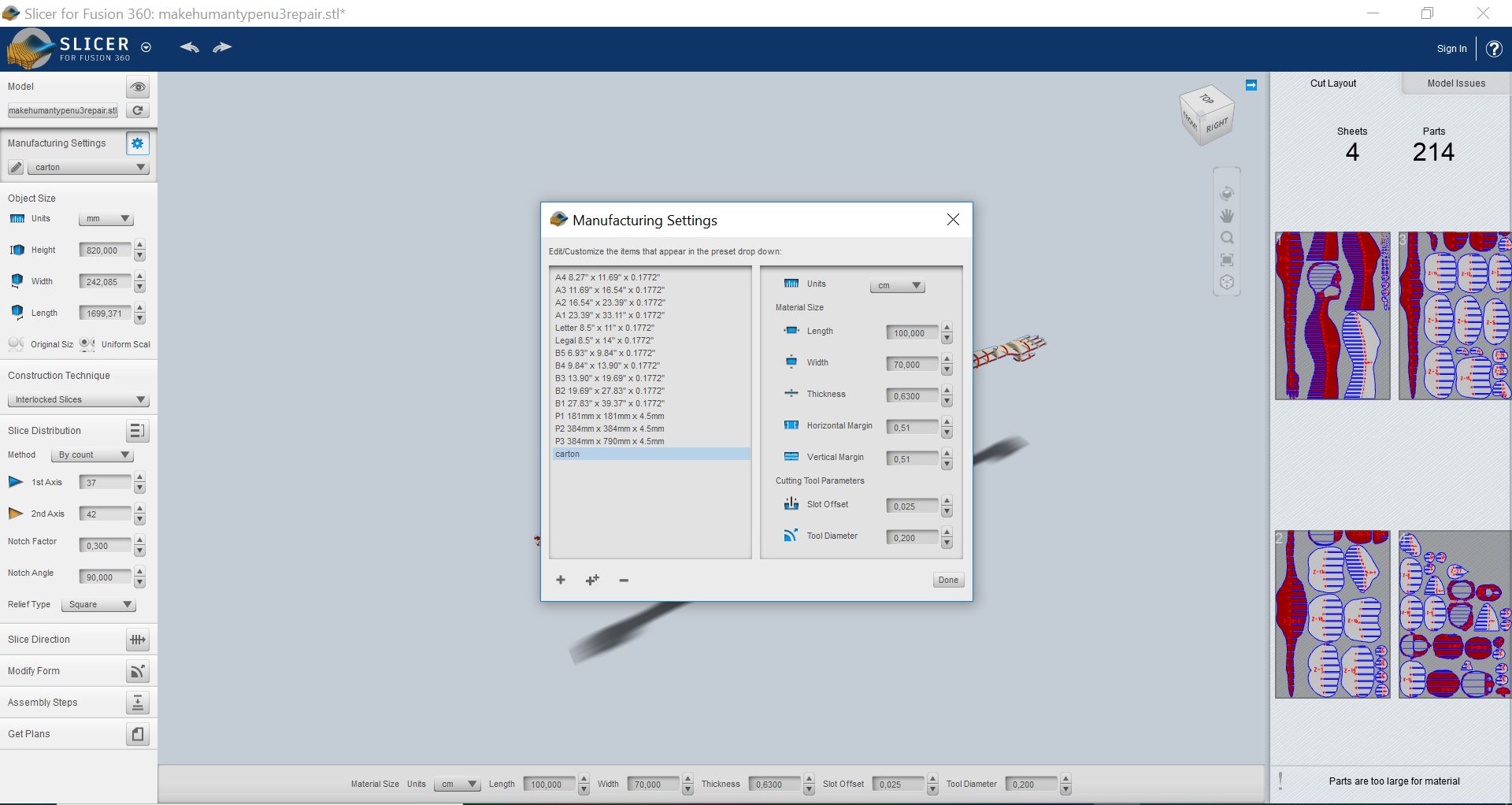

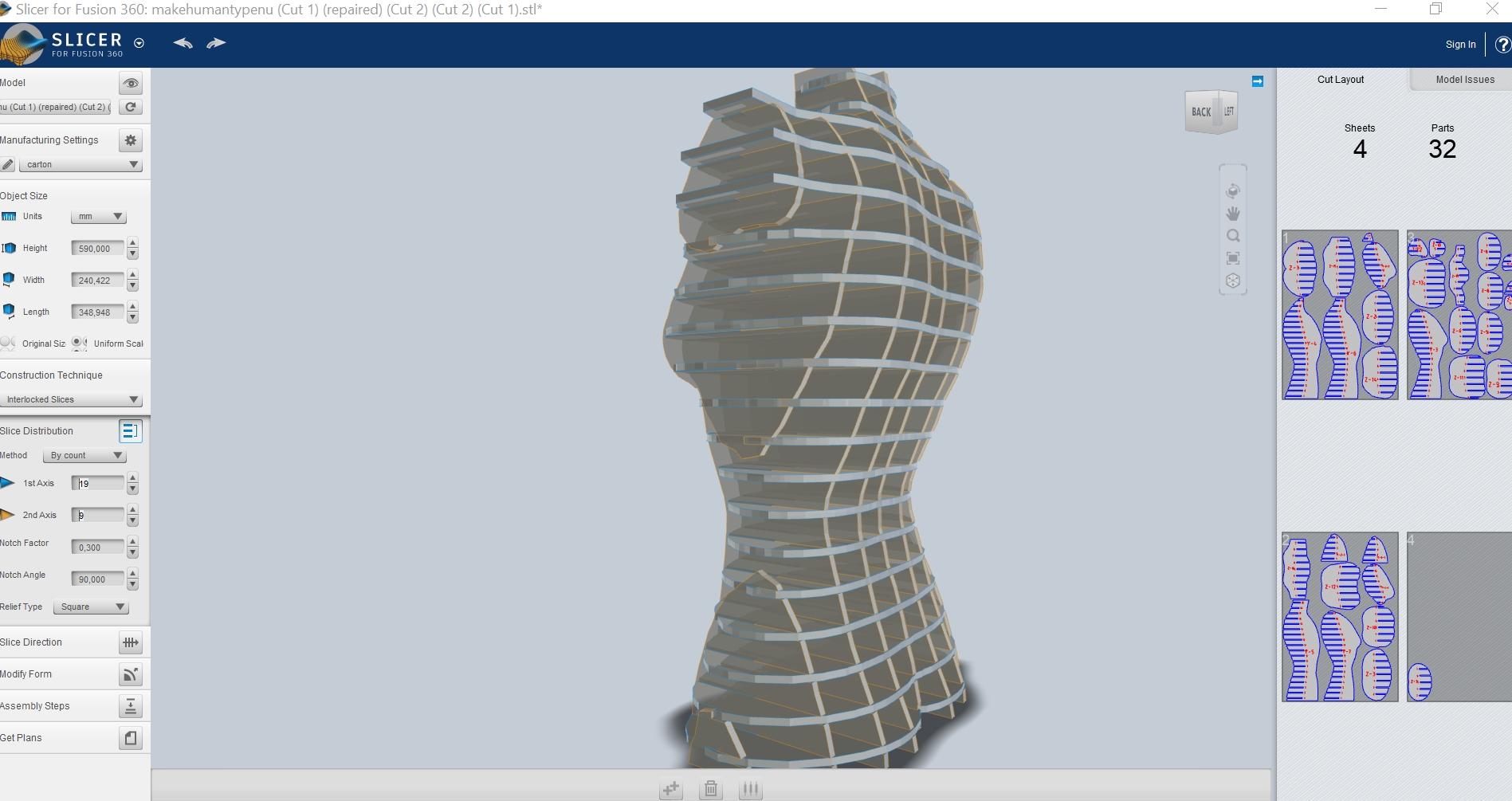

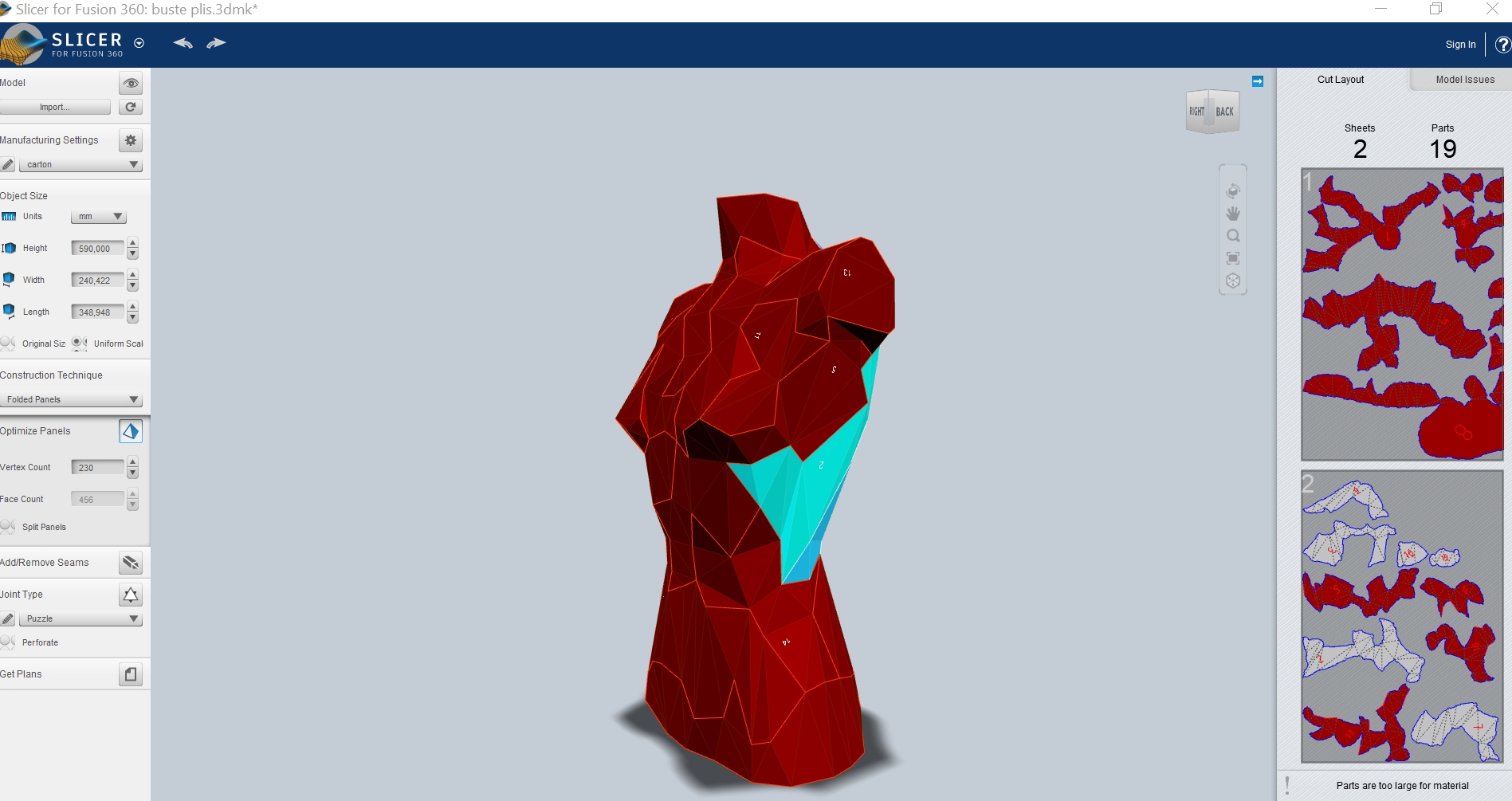

Slicer

Slicer by Autodesk : Download

| Silcer |

Process |

|

I use this body to understood quickly how it work. |

|

|

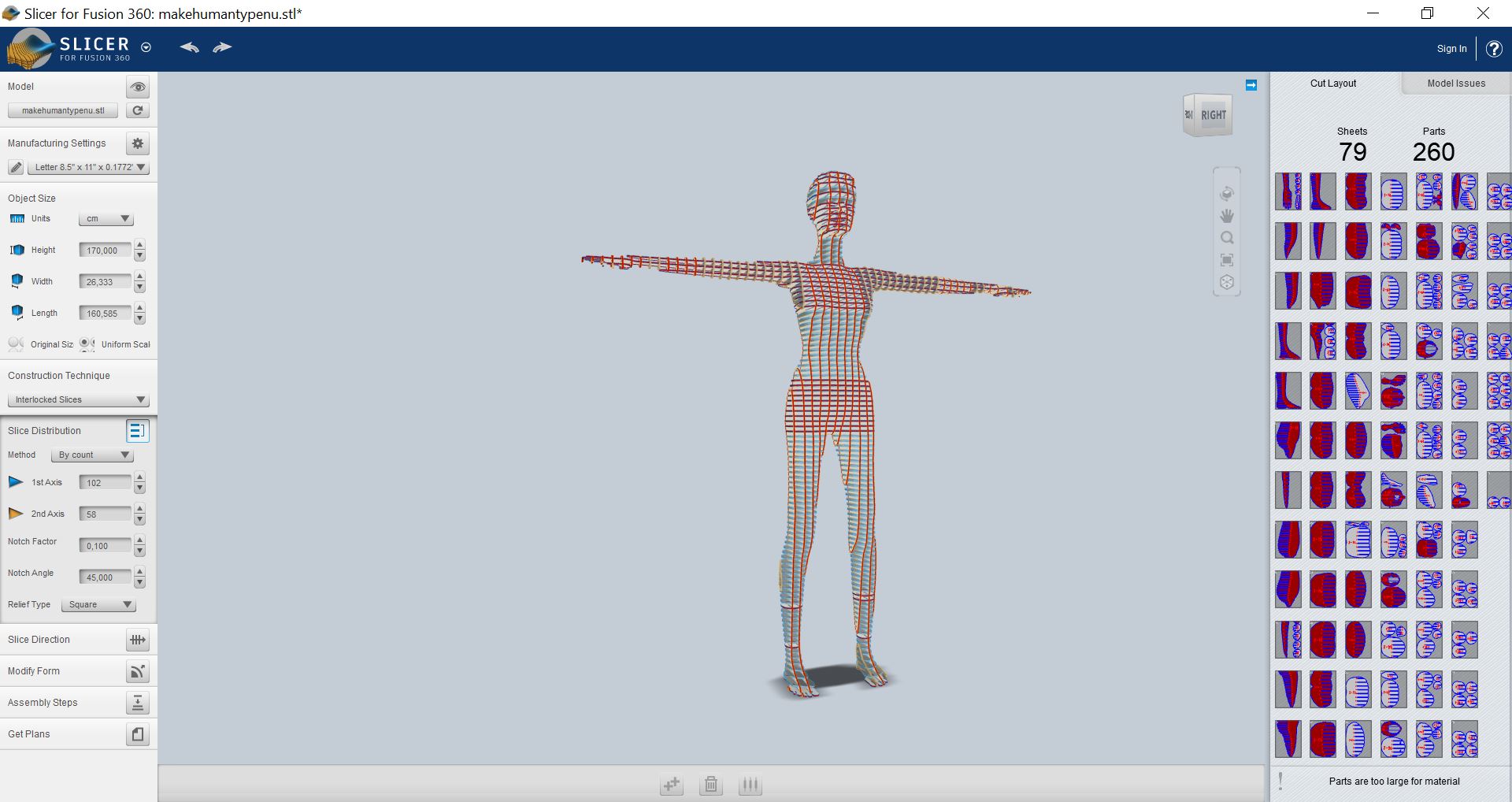

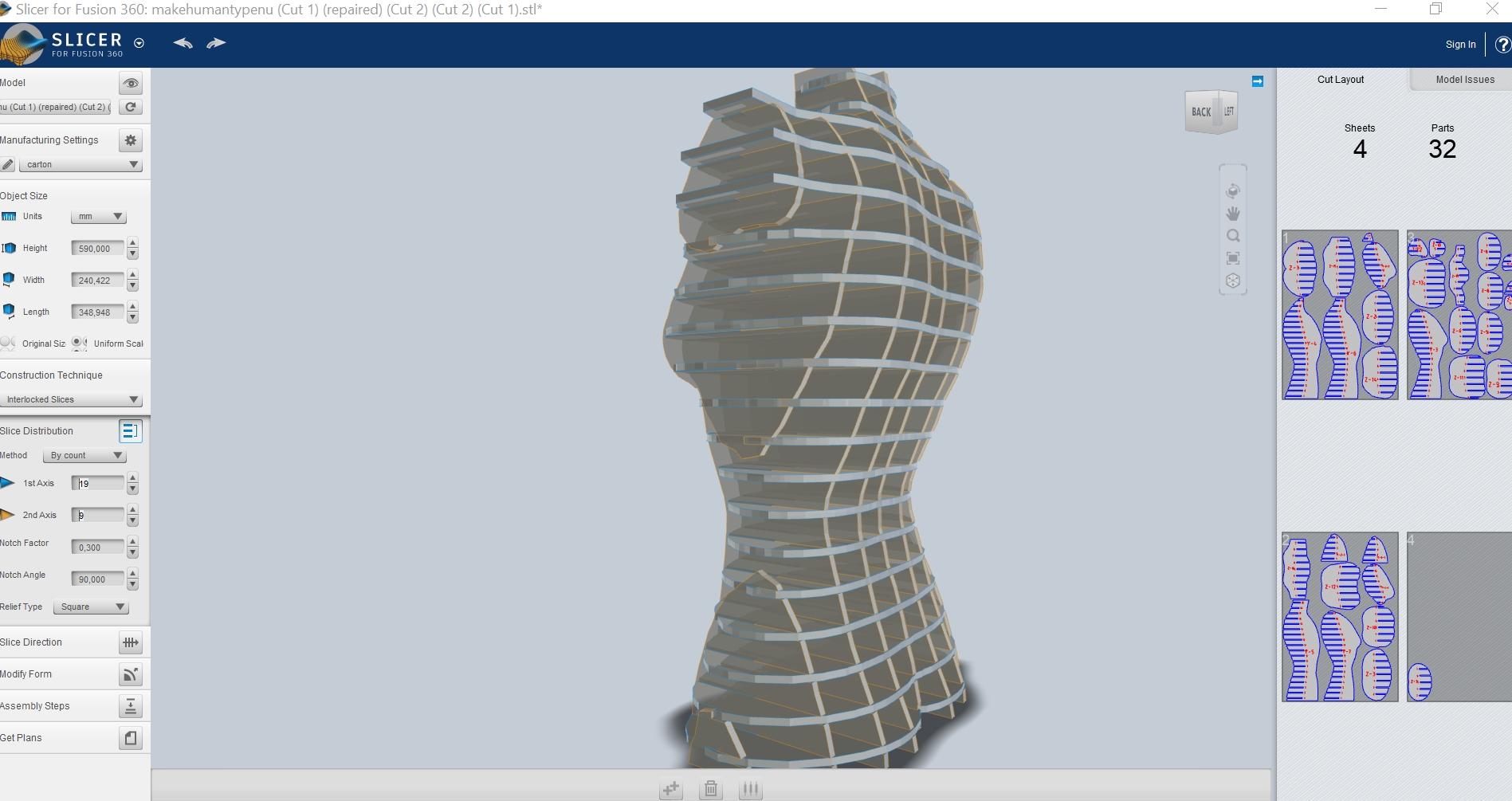

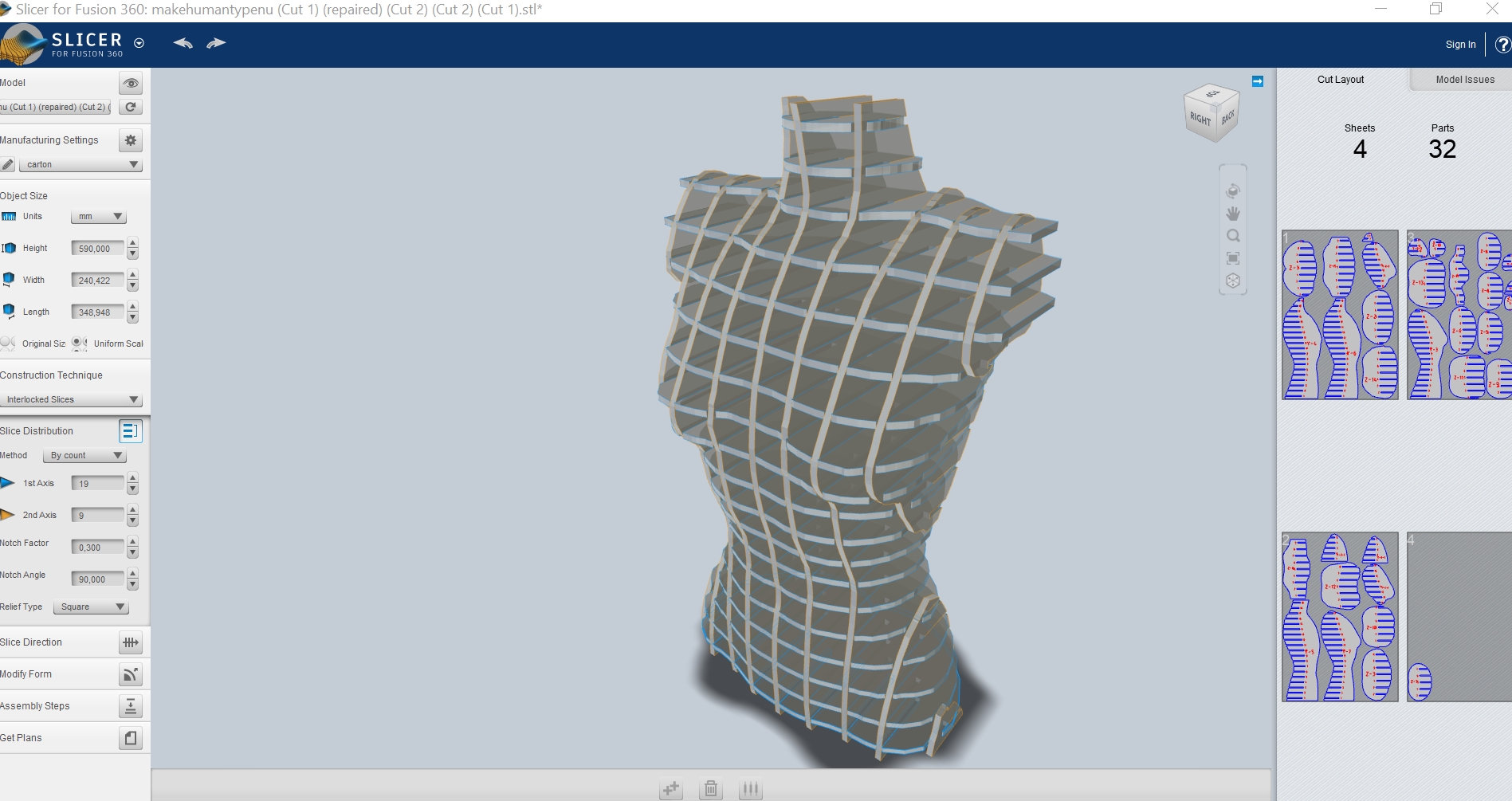

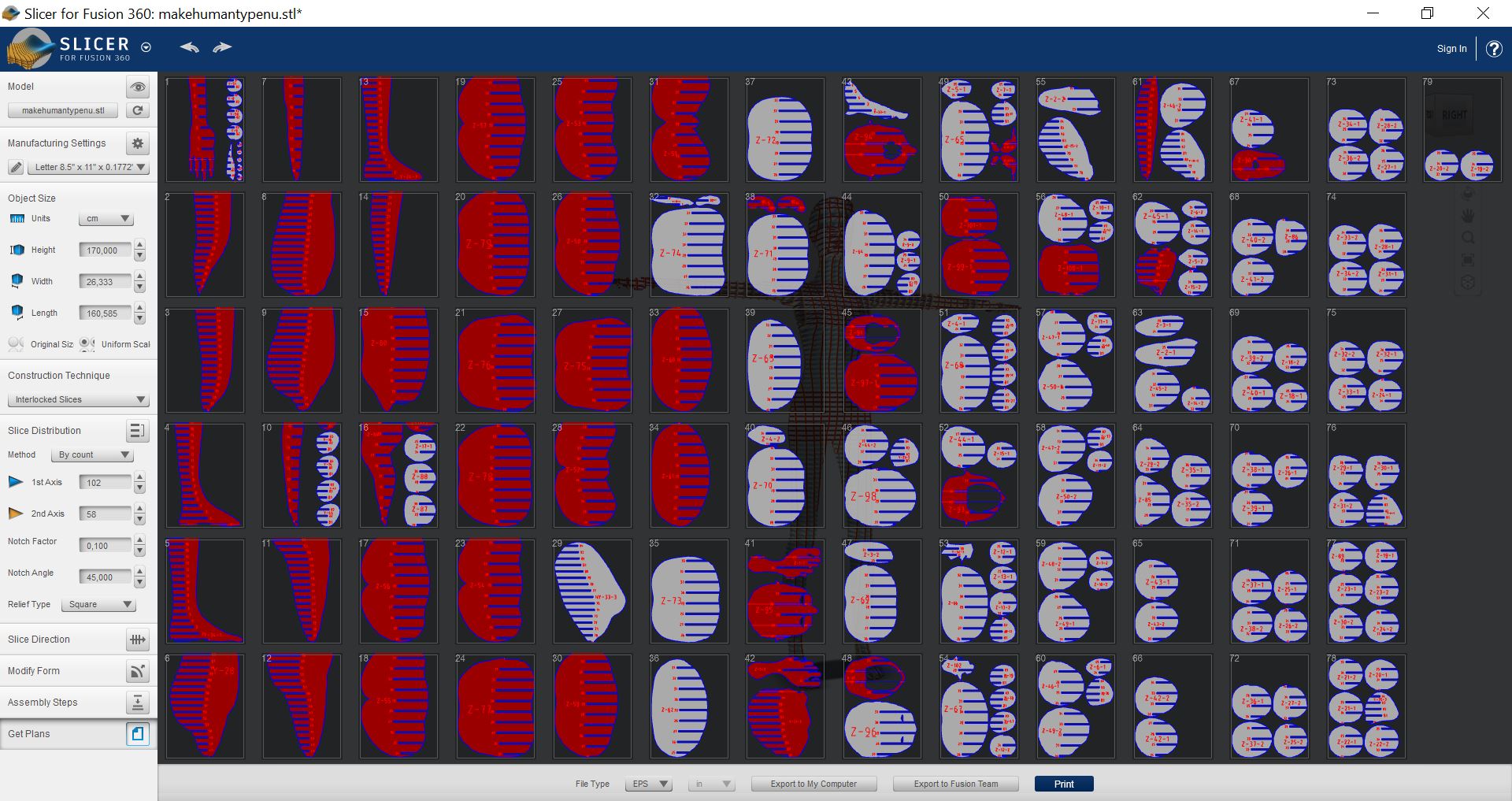

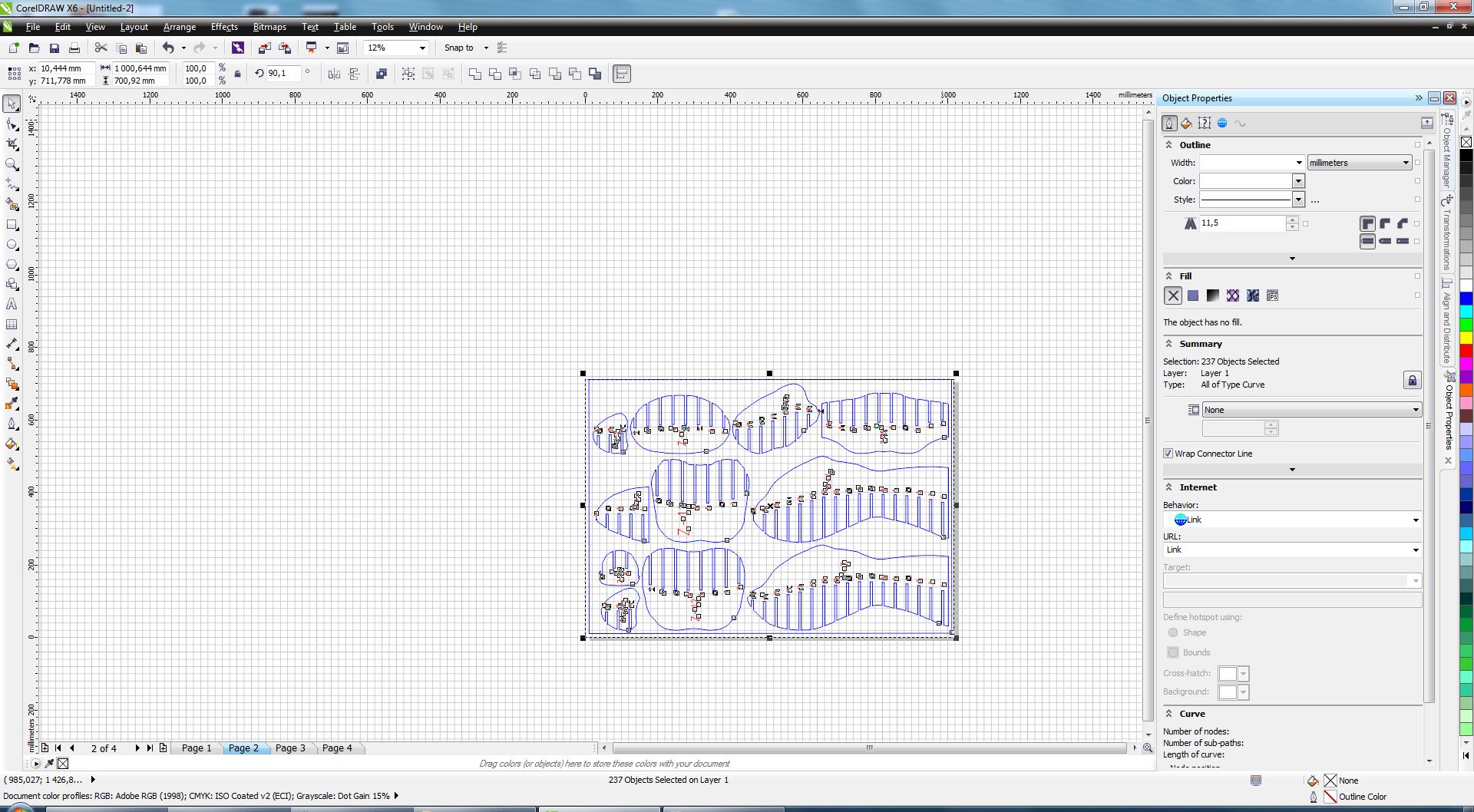

| Total of the slices PROTOCOL TEST |

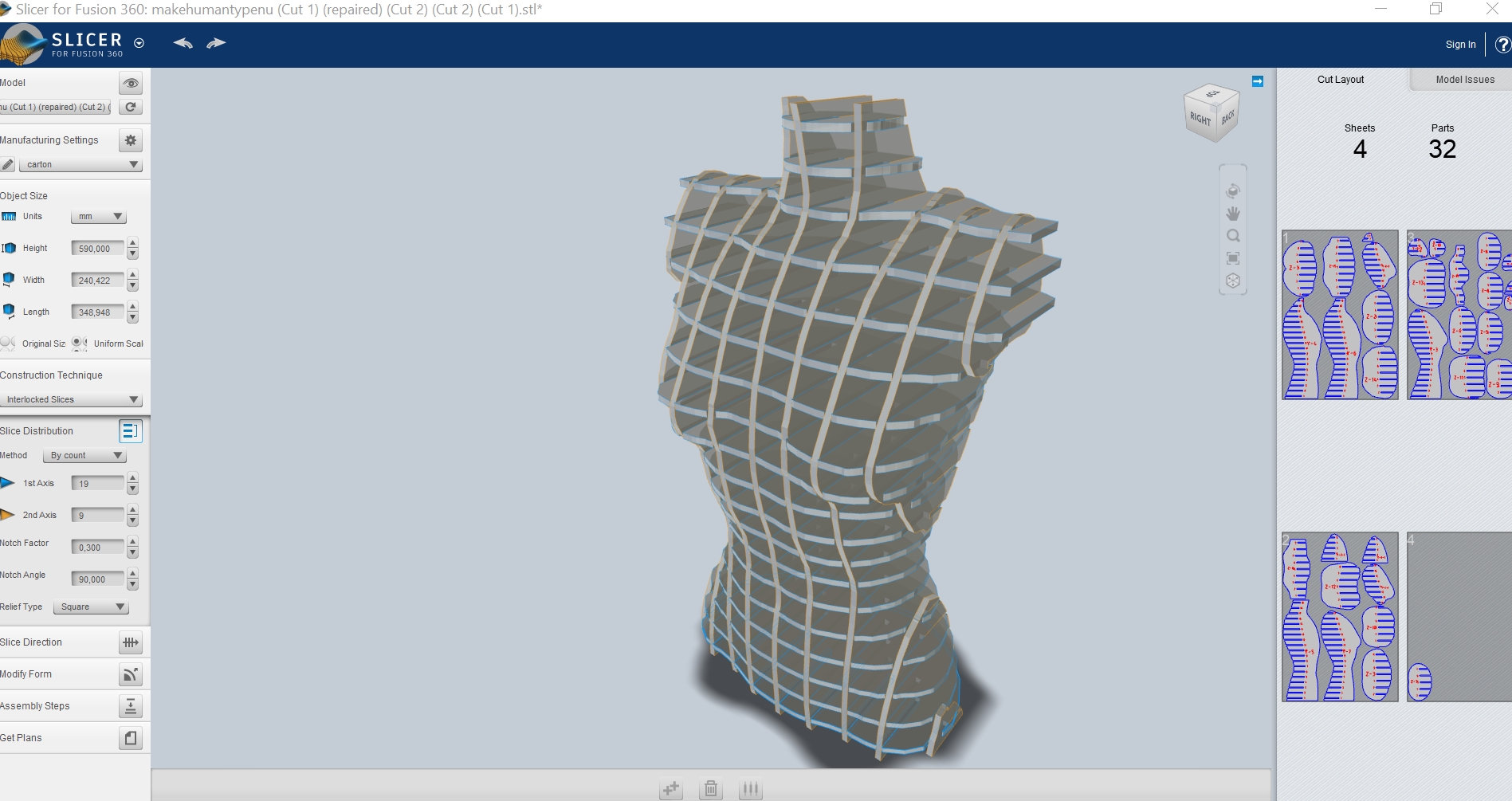

Change the settings PROTOCOL TEST |

|

|

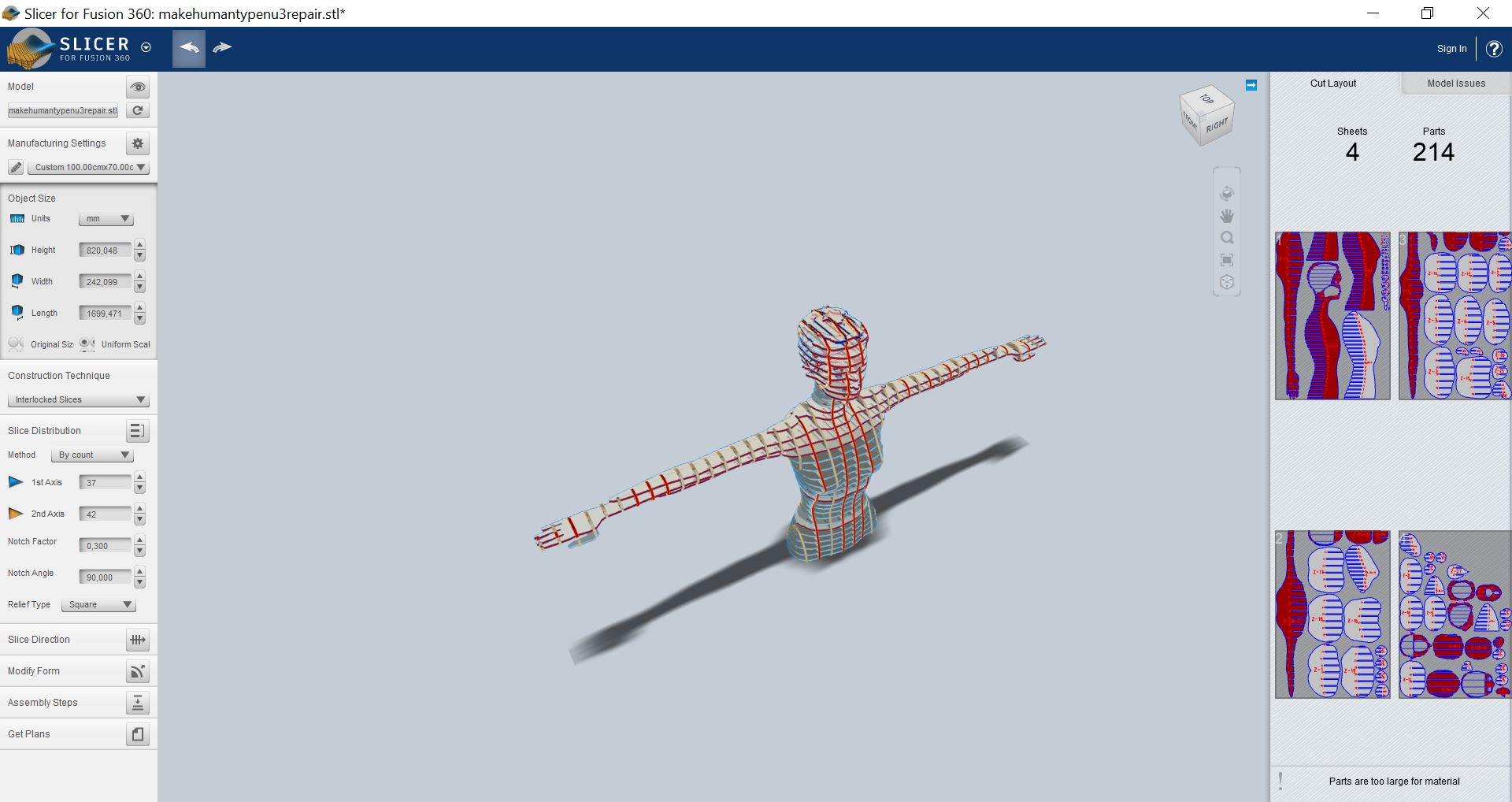

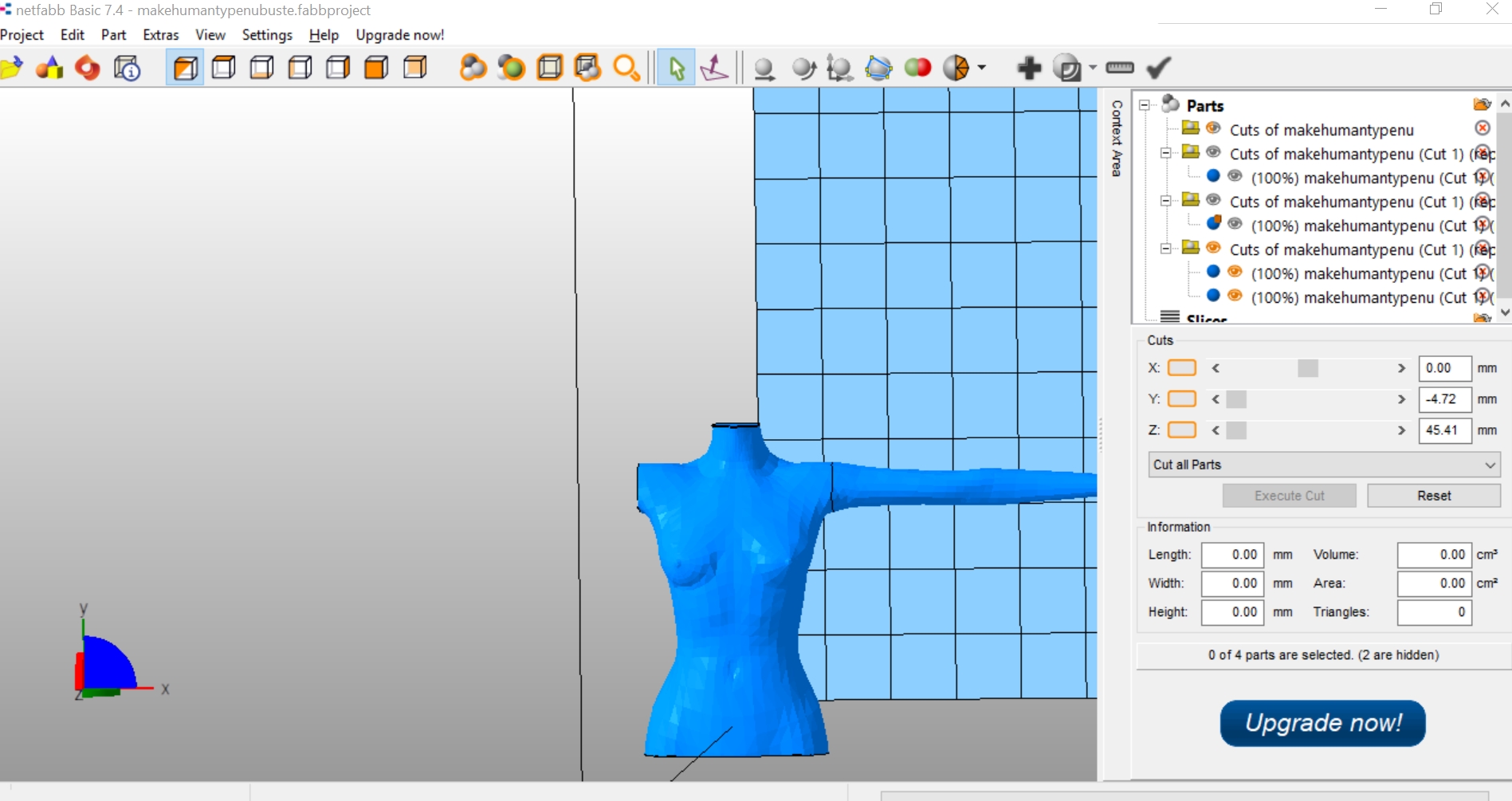

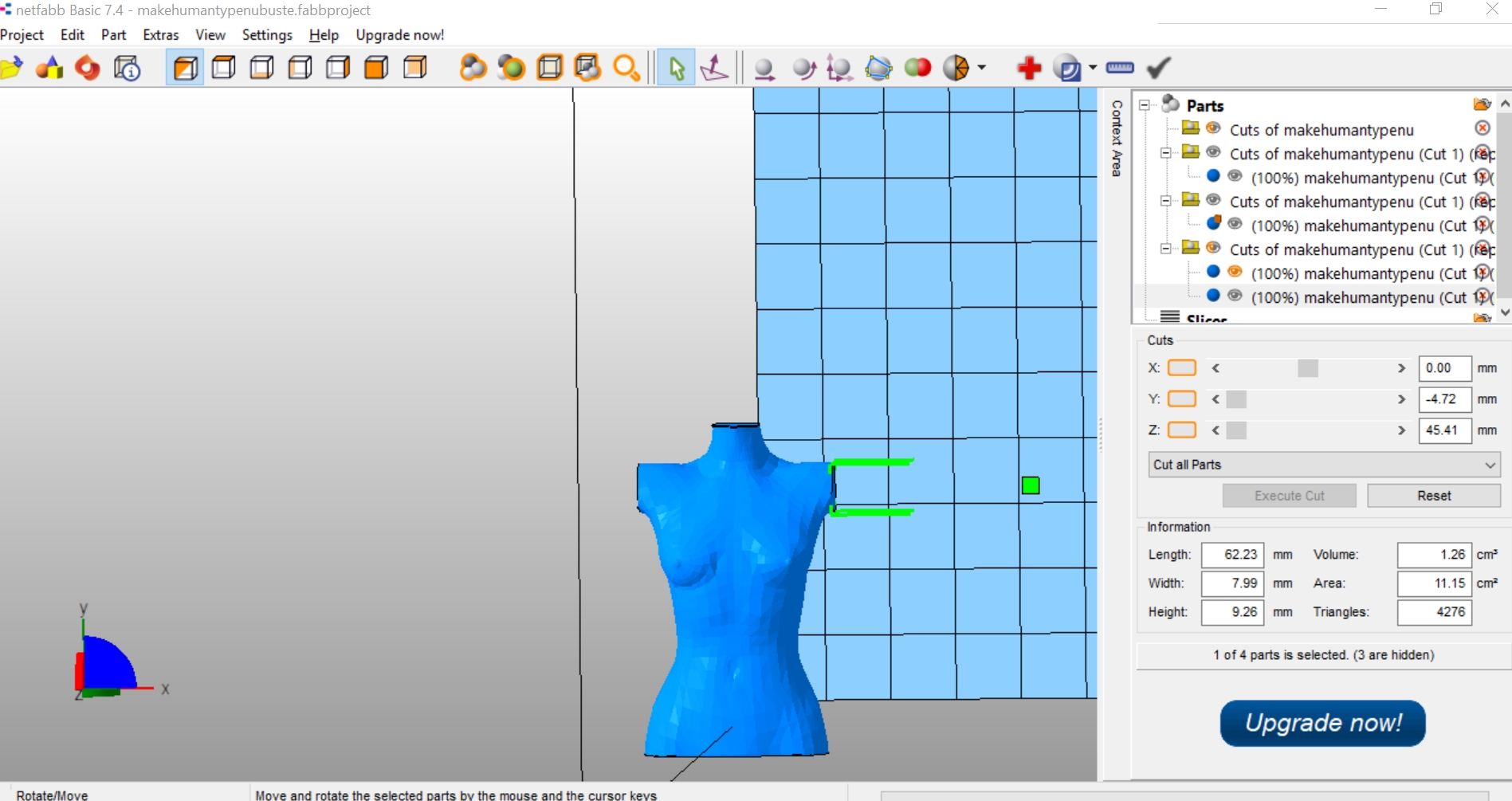

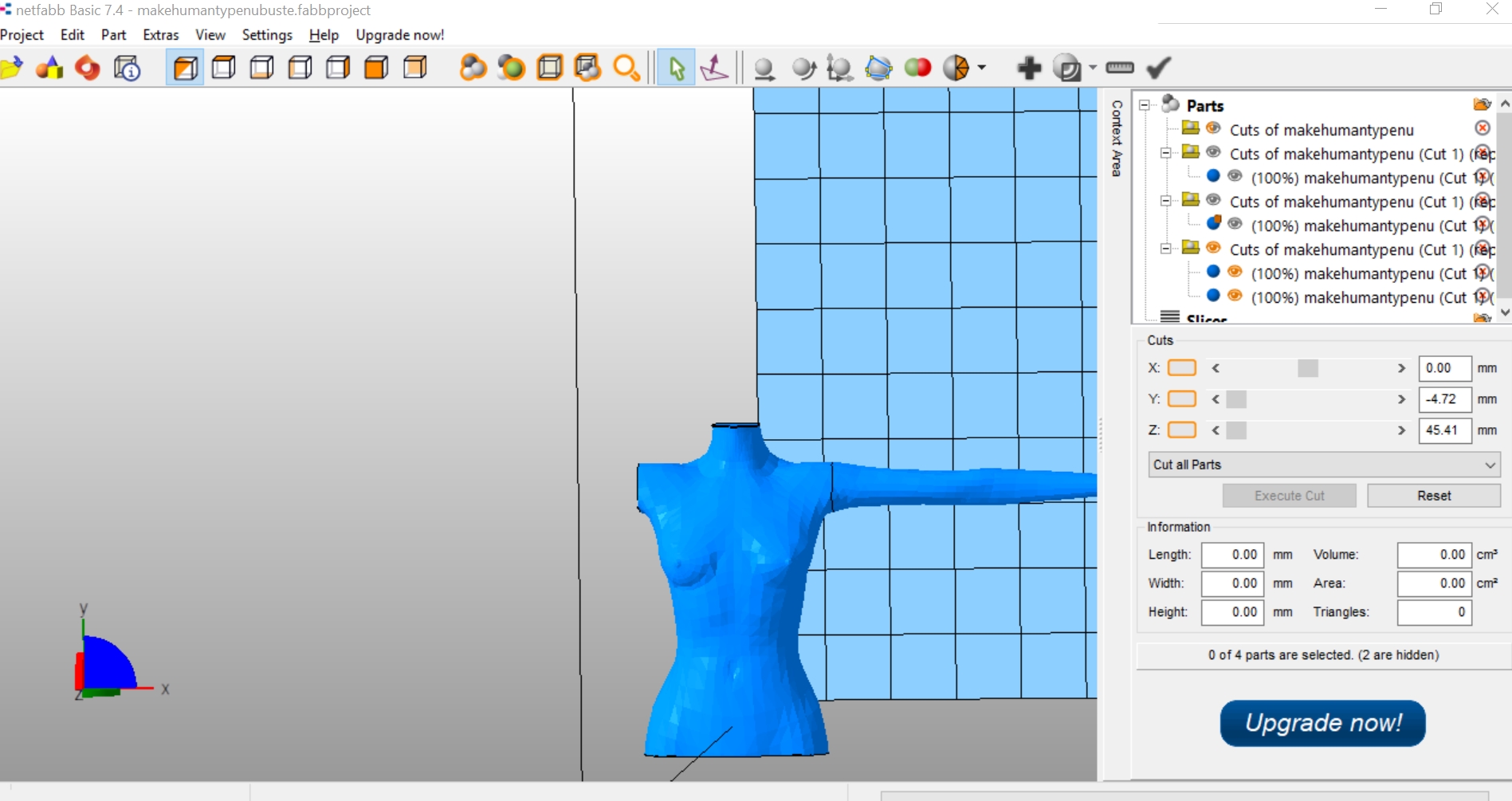

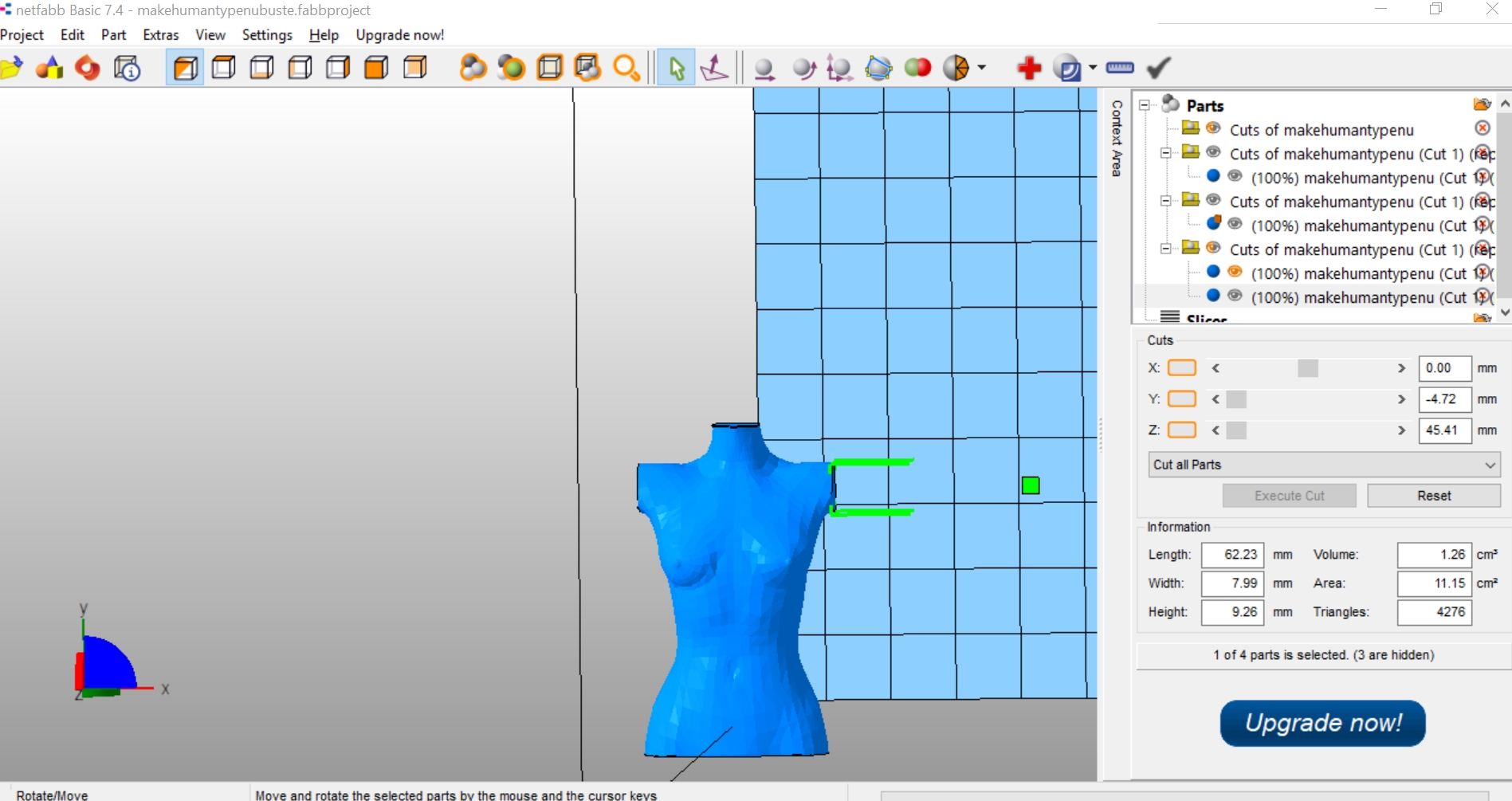

Netfab change the body 3D model

I use Netfab

I open my body from Make Human in order to change the 3D model for the lasercut machine protocol.

I don’t need arms, then I need to delete the arms of the 3D model.

| The netfab software |

The netfab software |

|

|

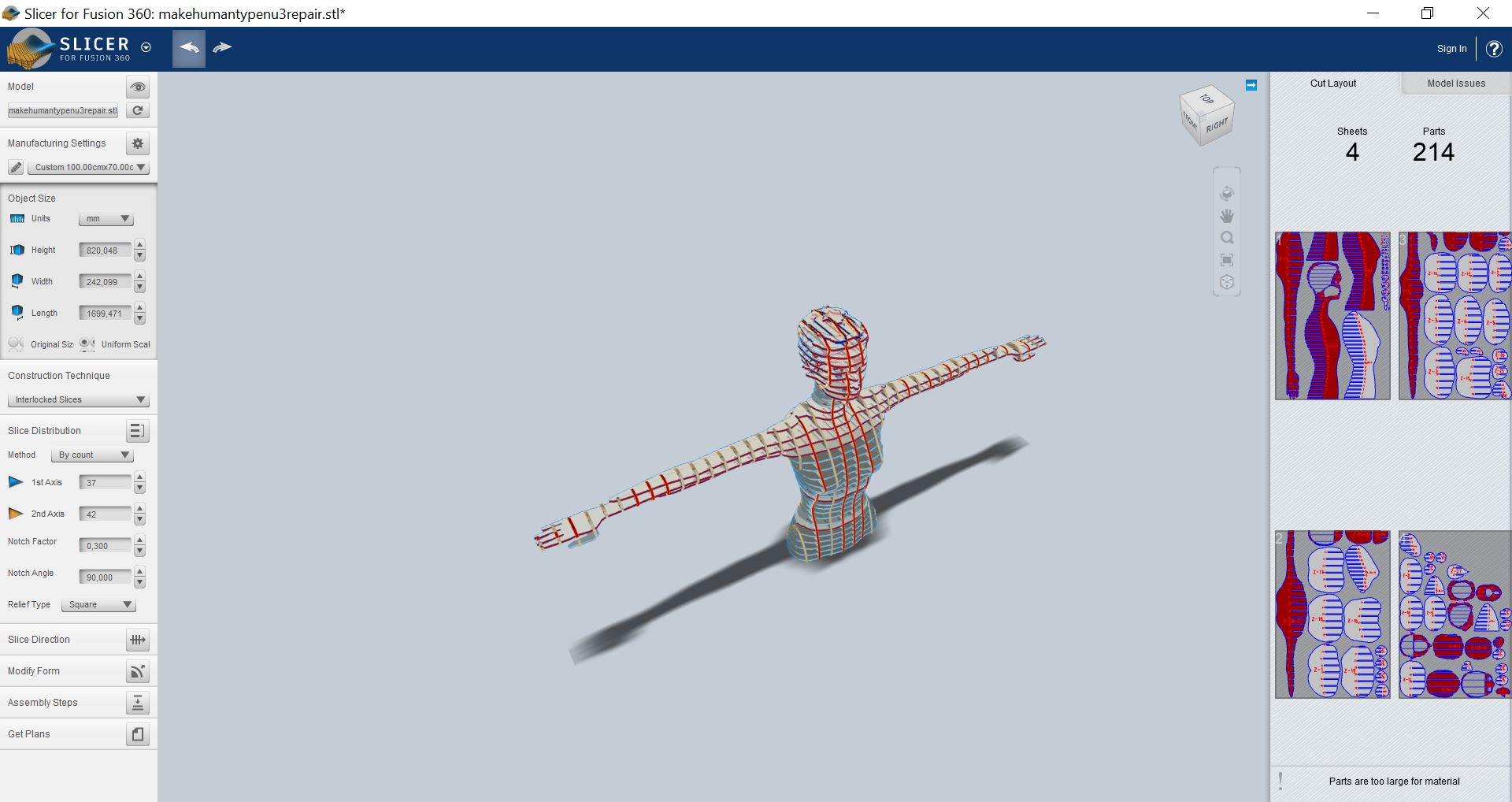

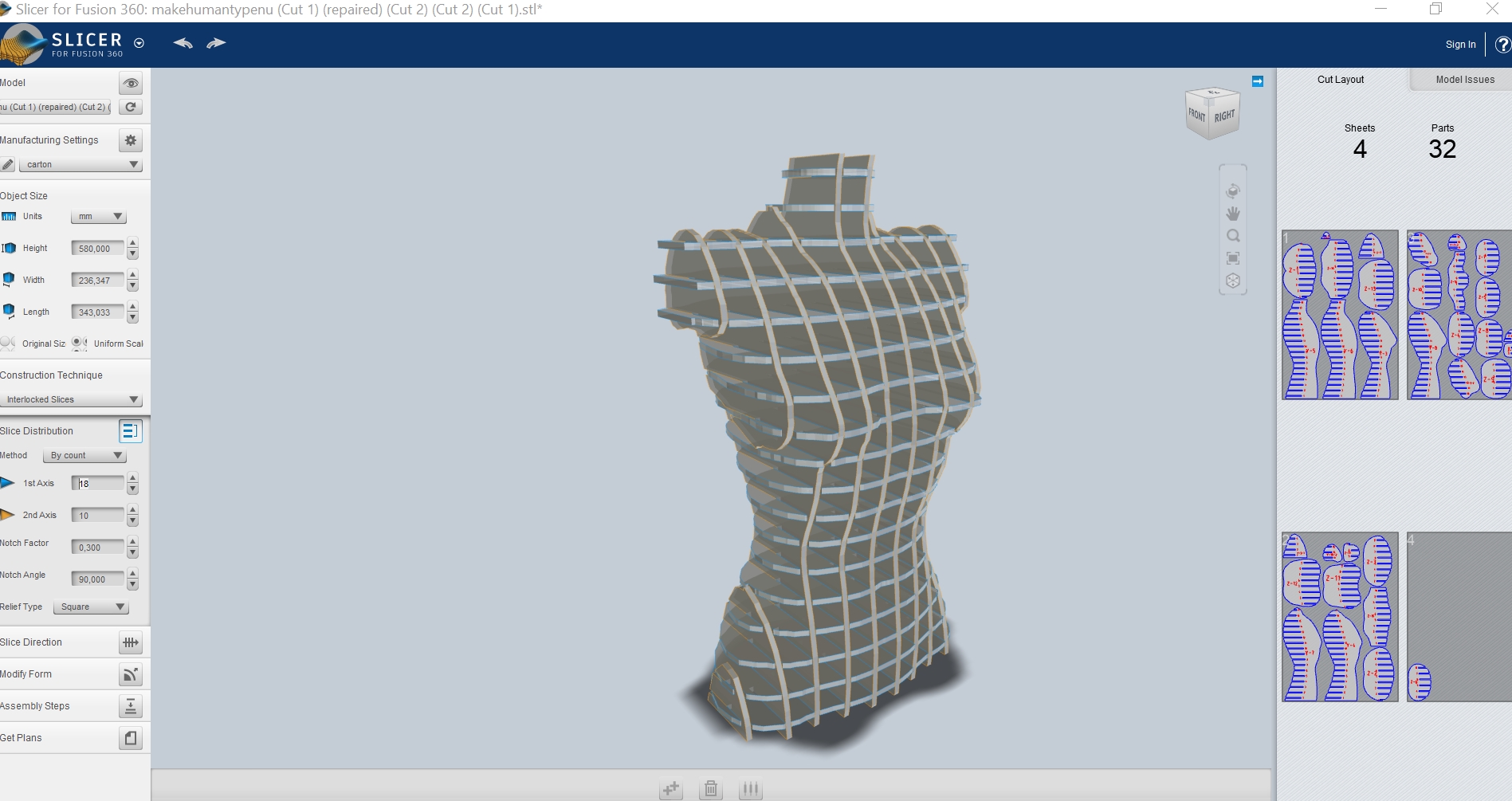

After this operation I have opened again the 3D model in Slicer and work on my final file.

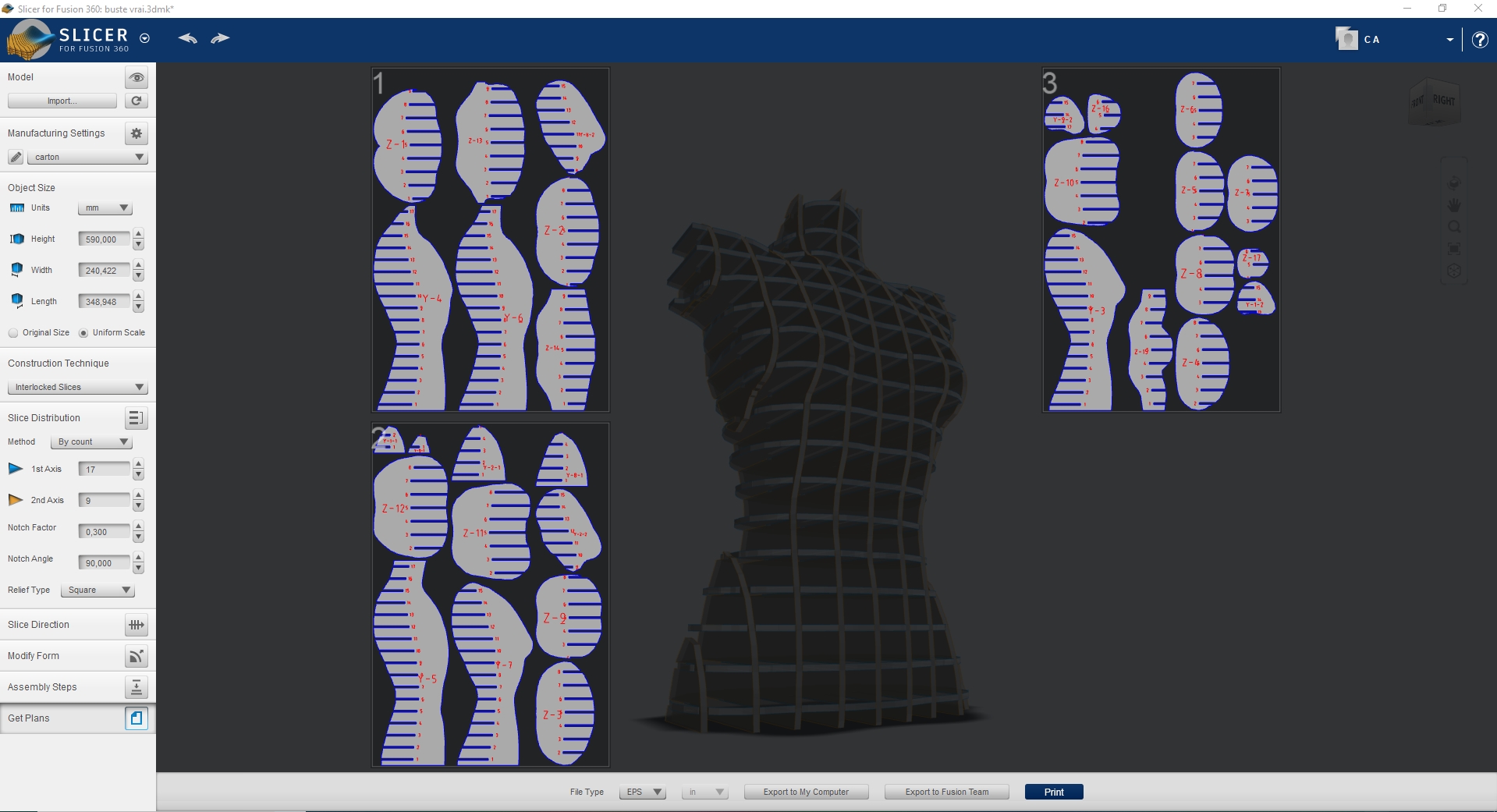

Slicer

| 3D model back |

3D model front |

|

|

|

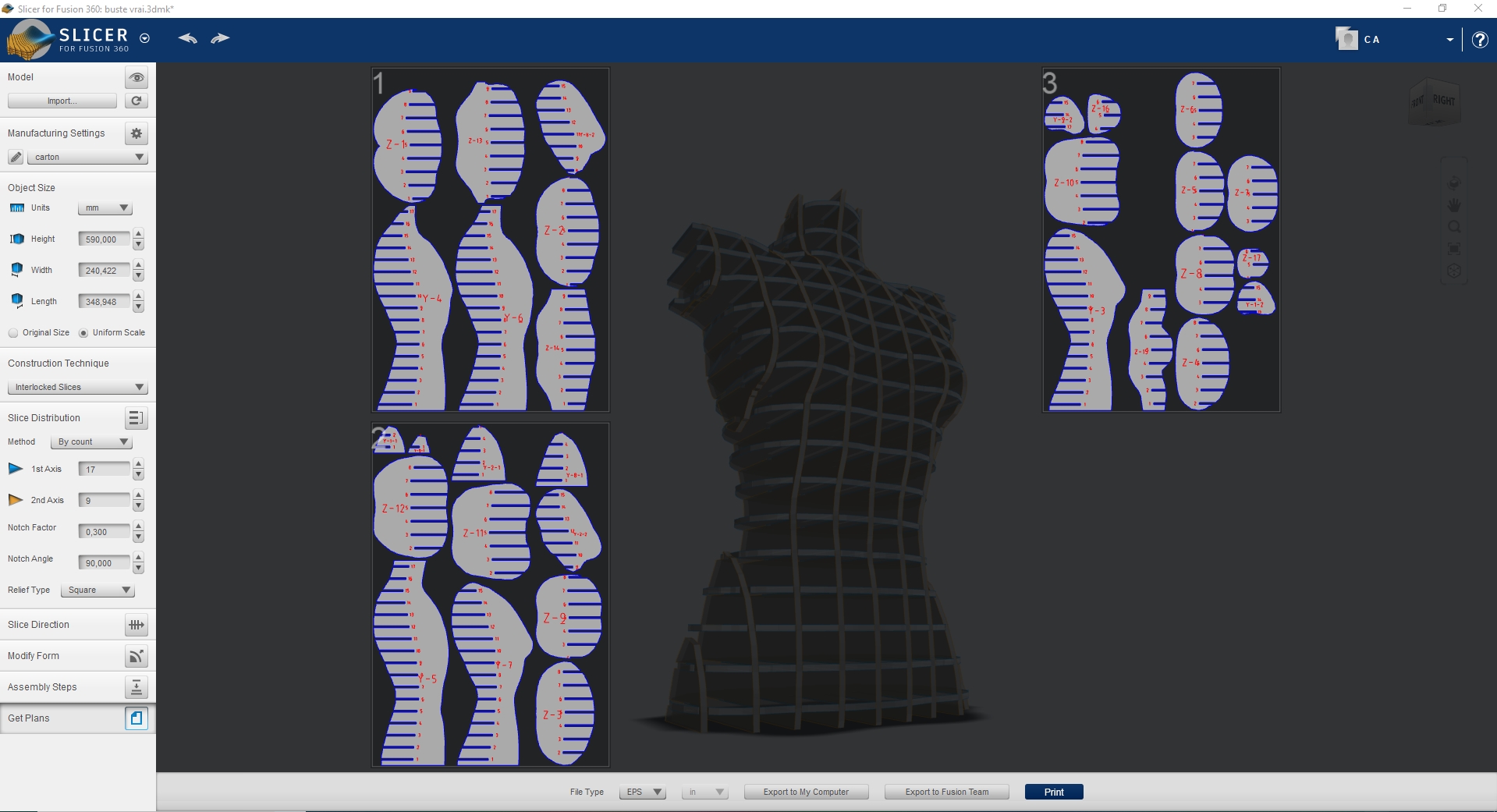

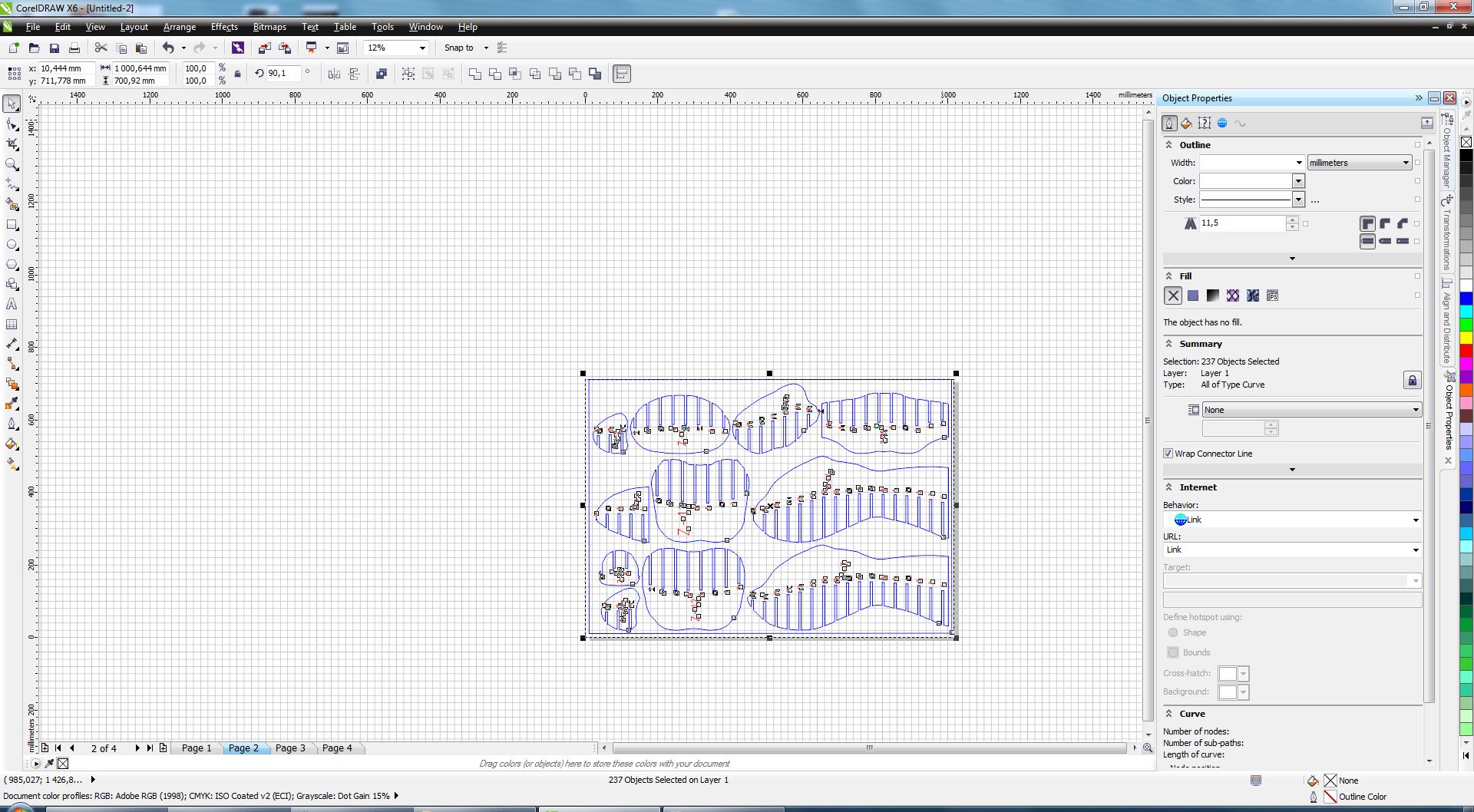

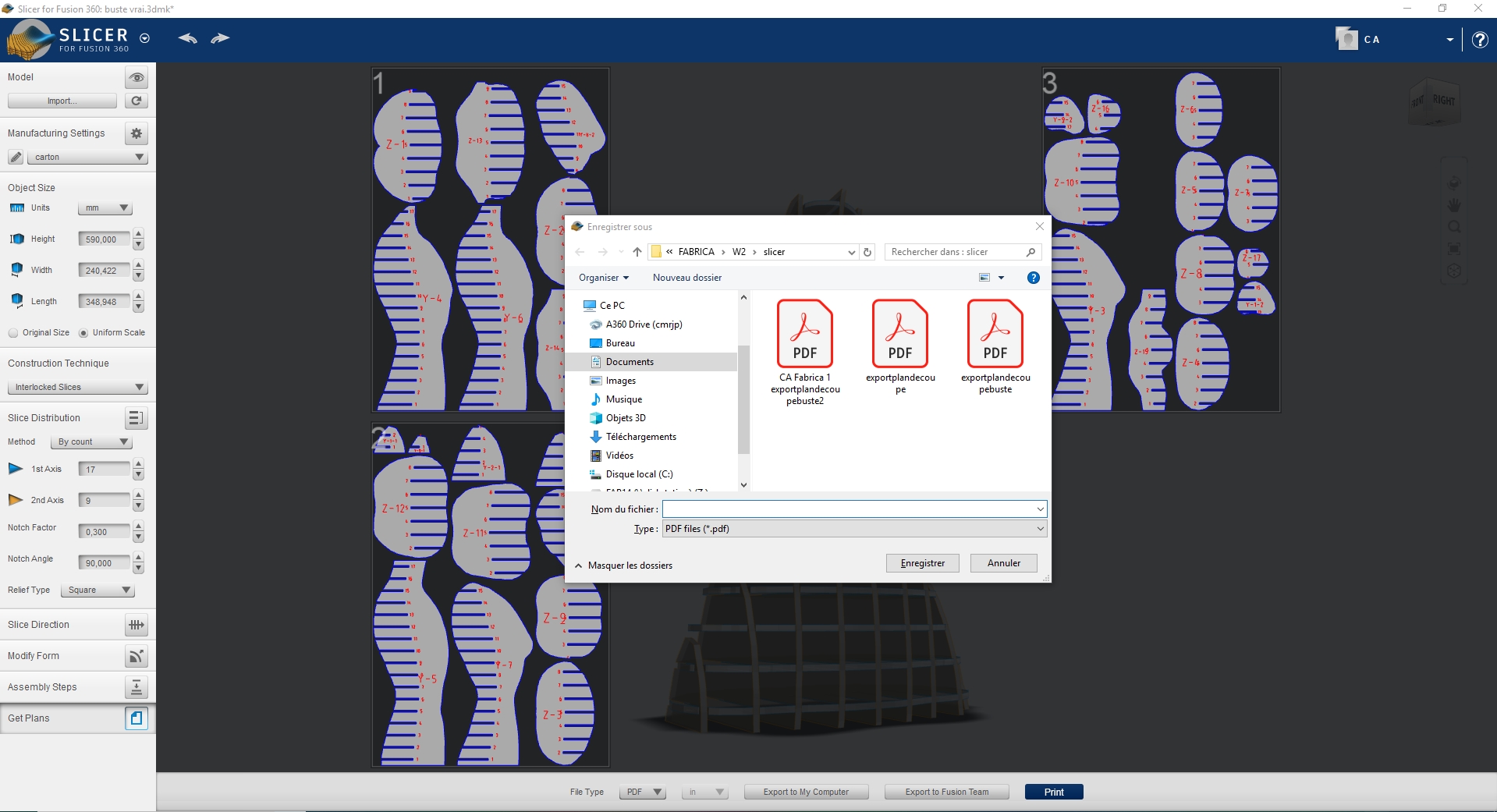

I download my 3D model and slicer change the 3D slice by slice. |

| Total of cardboard 3 panels |

Export as possible as .dxf / .pdf / .eps depends of the machine, I choose .pdf because corel draw work with |

|

|

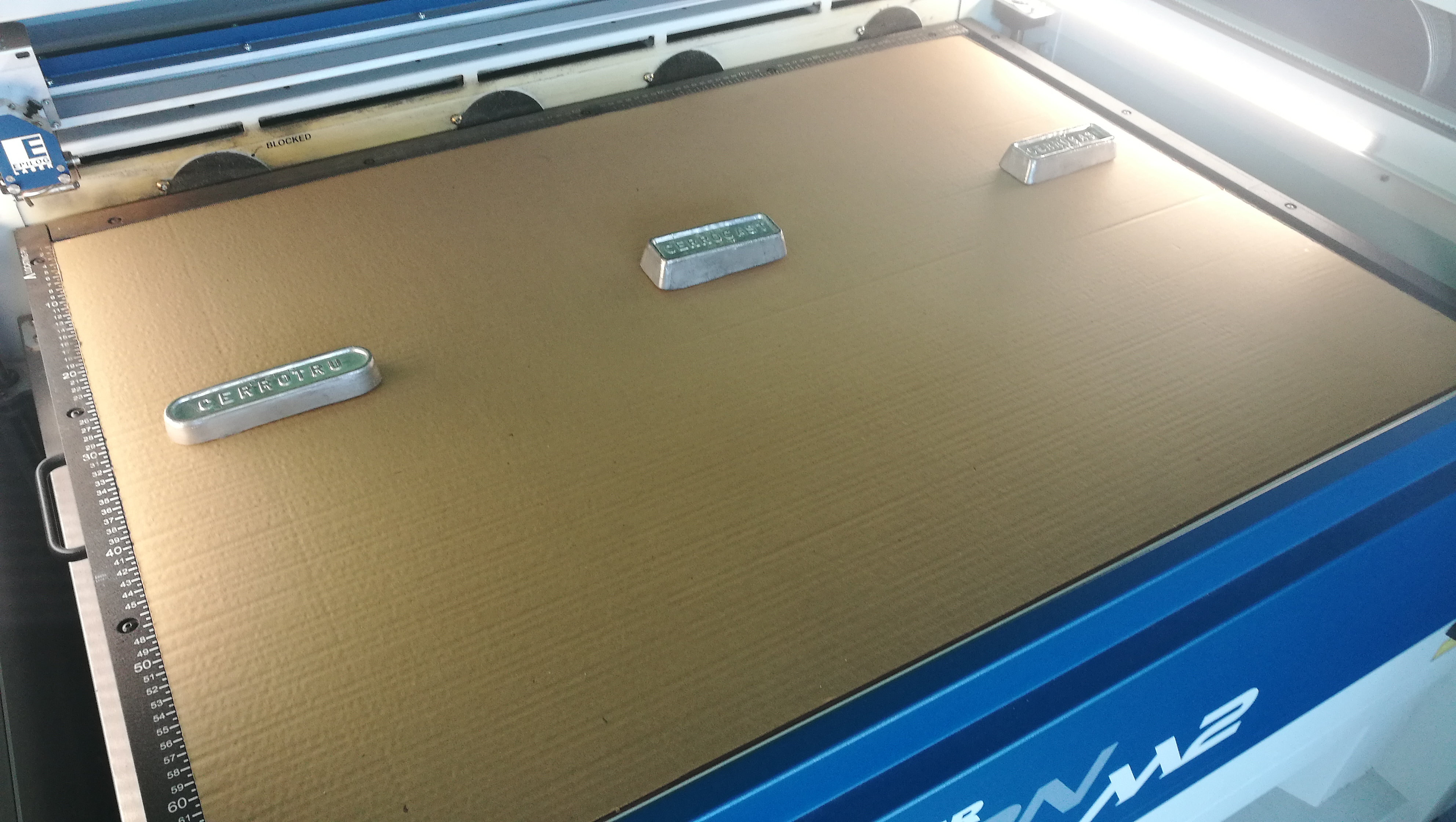

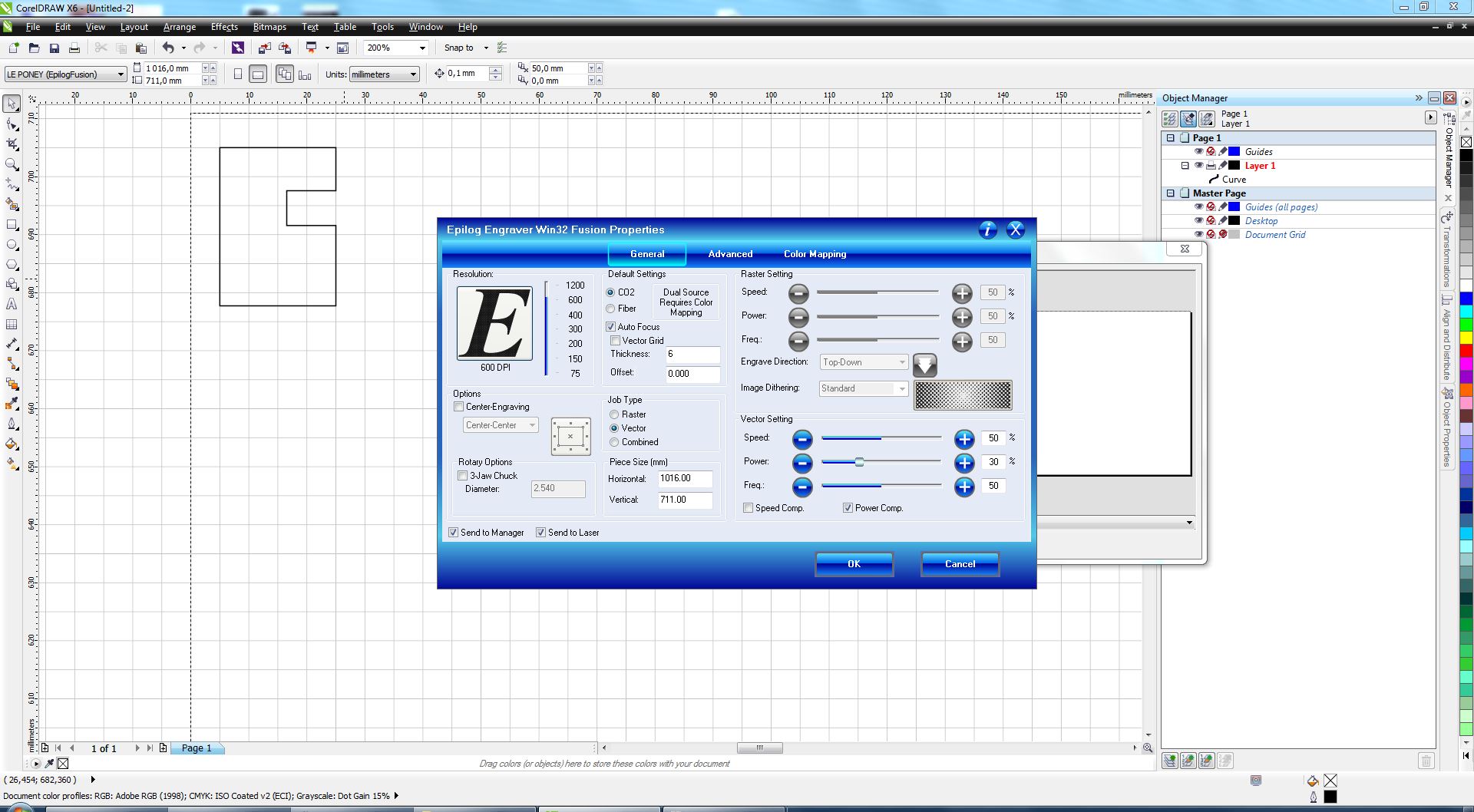

LaserCut

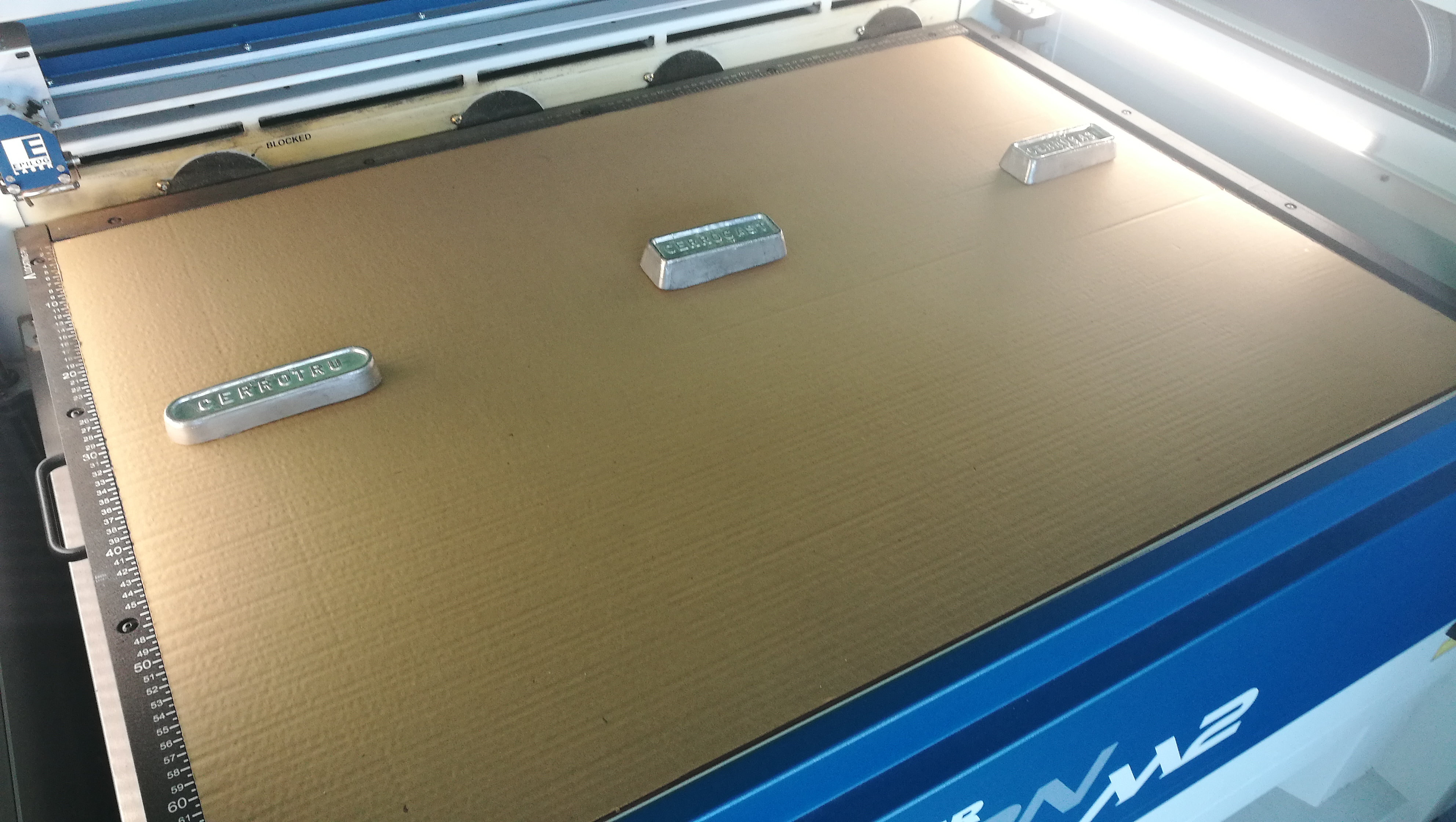

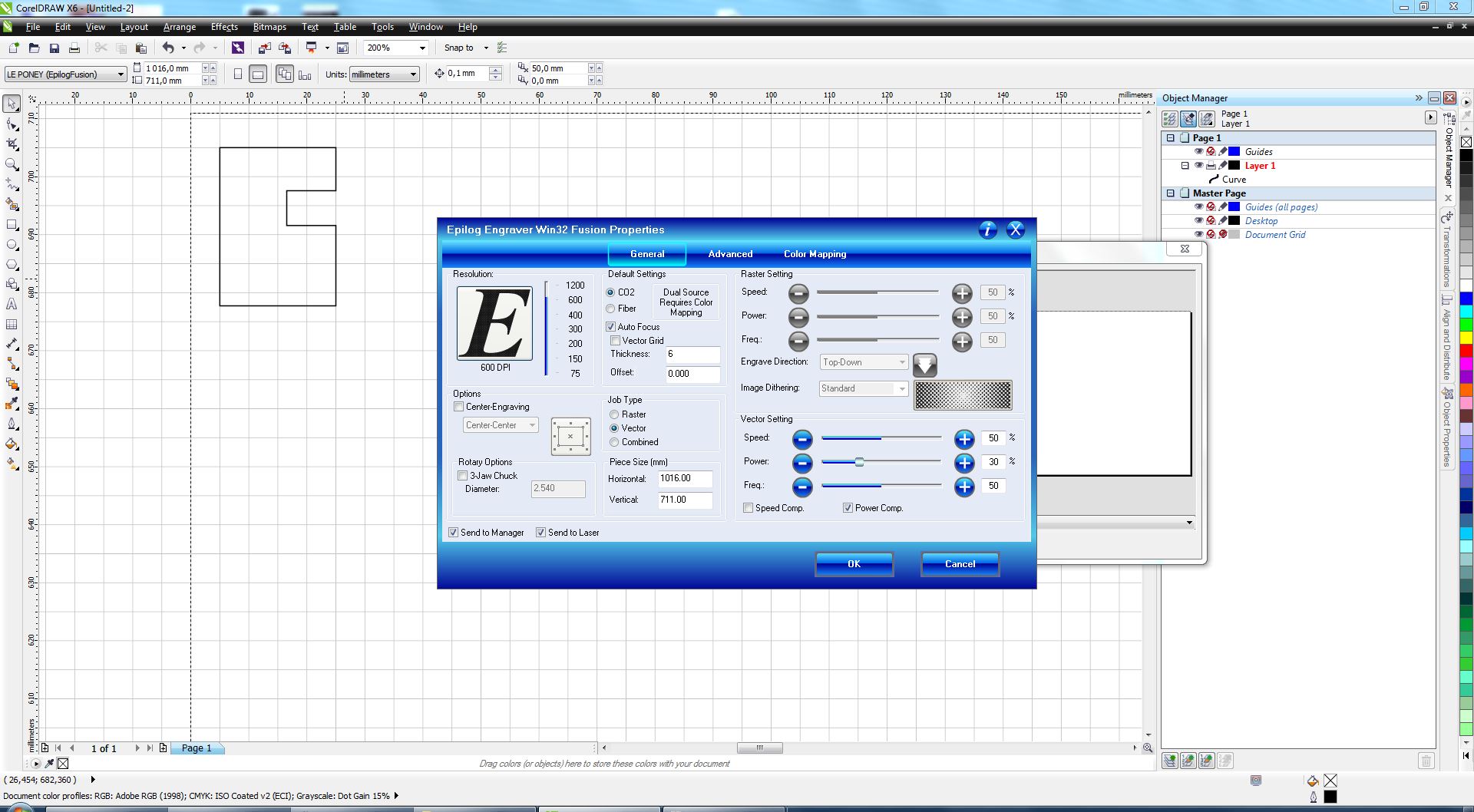

| Epilog Fusion |

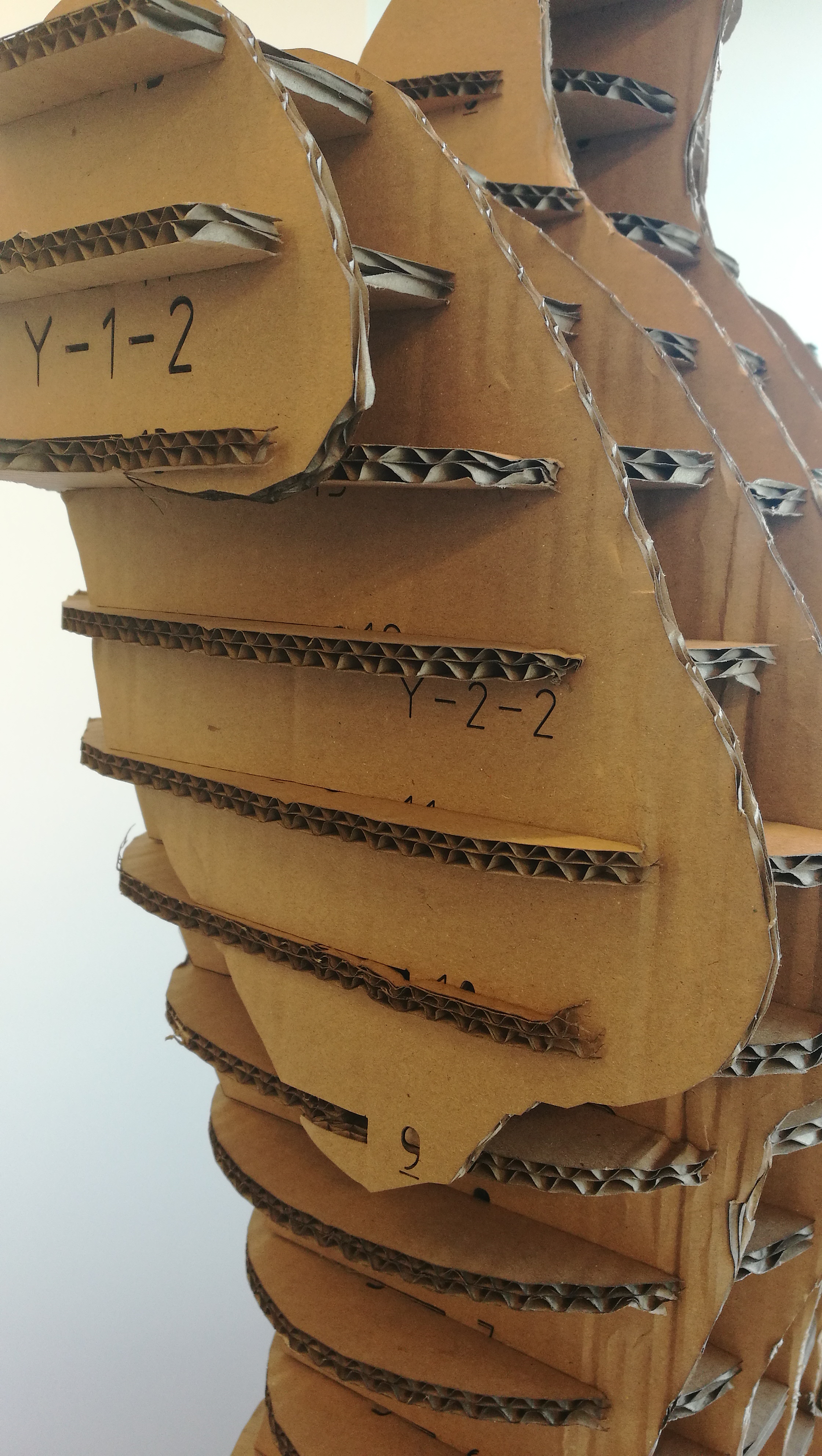

Notches process |

| My set-up, I use blocks because the carboards wasn’t flat. |

size of the cardboard pannel to make the good choice for the notches |

|

|

| Notches |

Observation |

result |

|

Testing the tolerance of the assembly 3 tests for 6.0 / 5.9 / 5.8 thickness |

* 6.0 notch was too easy 5.8 notch was too strong 5.9 was the good one for my cardboard with 6mm of thickness |

| Settings |

Epilog Fusion 50 30 50 |

|

|

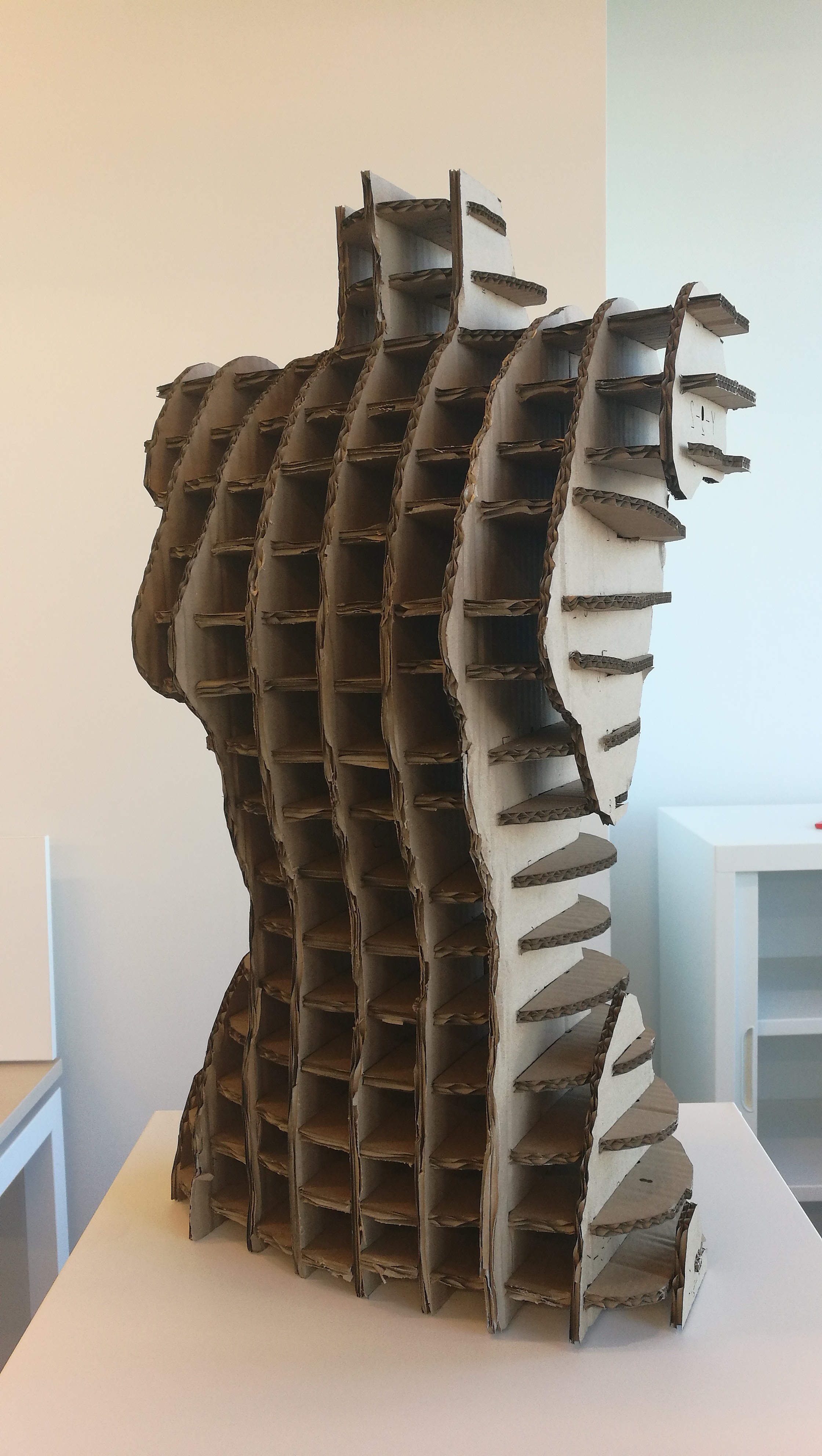

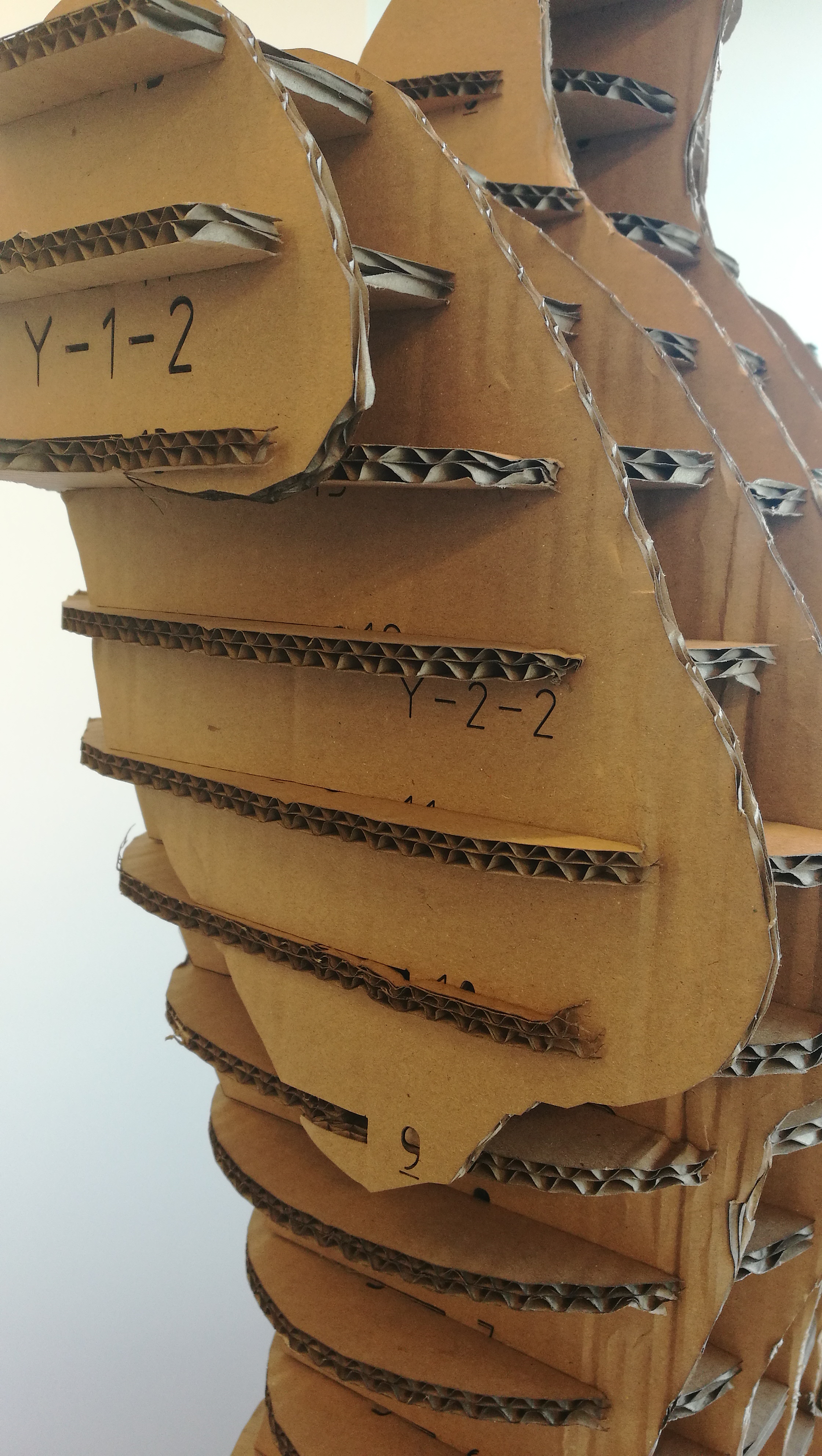

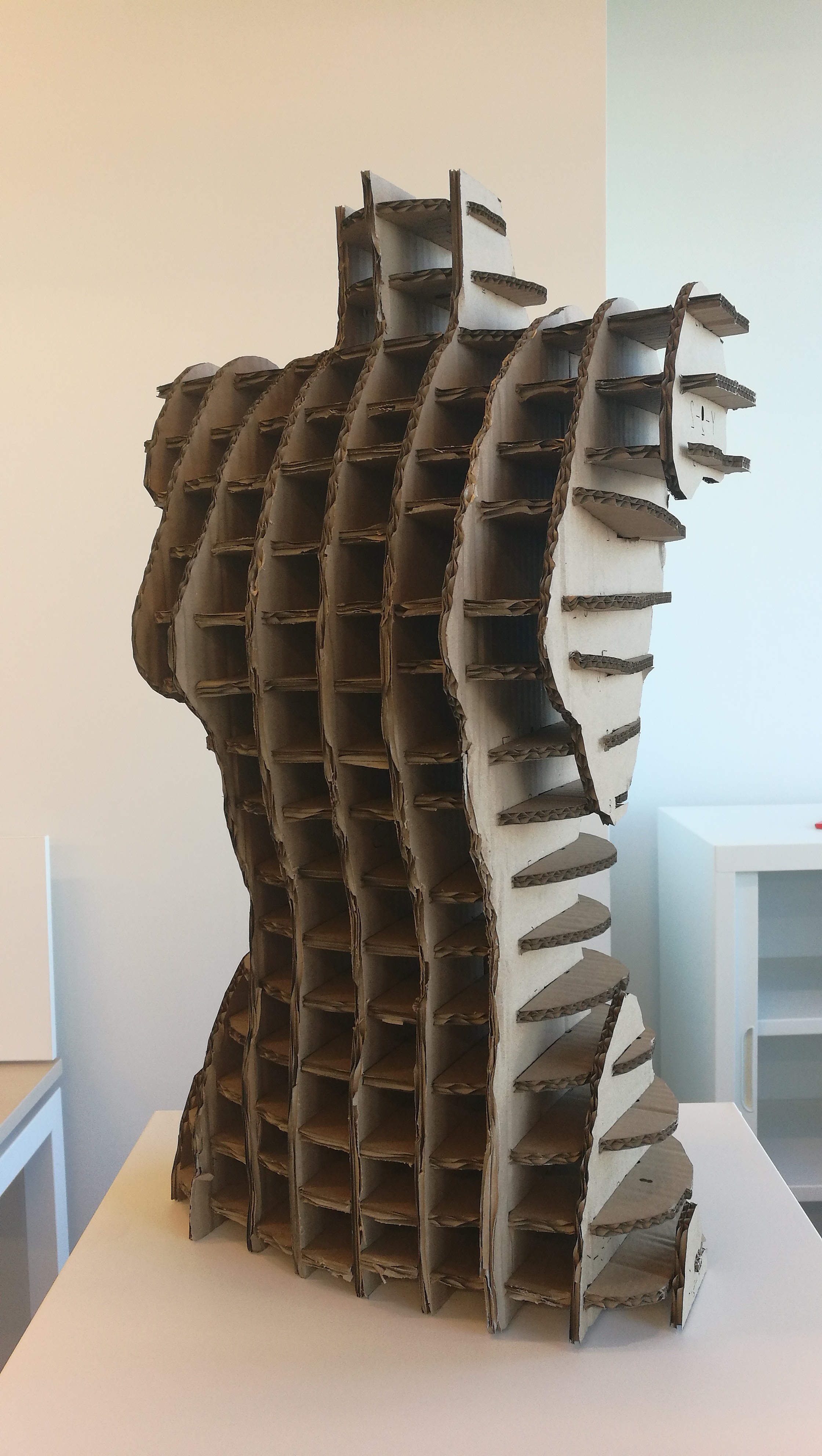

Assembly

| Face A |

Face B |

|

|

Add a 3D skin

| Expectations |

Slicer different option |

| I have tried to make a little skin, this needed more expertize |

|

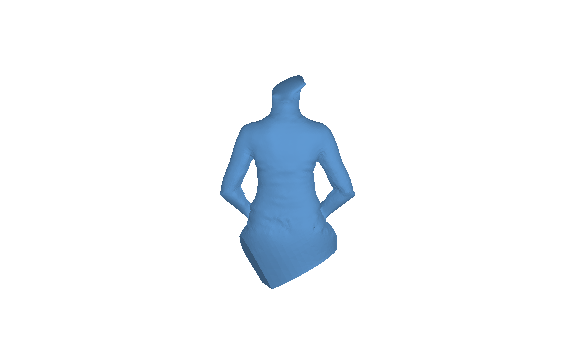

Second test for my nacked skin 3D model

| Library device |

A 3d scan like a book |

|

Put a scanner between Foucault Surveiller et Punir is like, put an eye like a security camera device at your own home. |

| Device 1 |

Device 2 |

Device 3 |

Device 4 |

|

|

|

|

I have not a good light but the scan works.

Result with the production latter (work in progress).

I have my own body in 3D model

Yes, my scanning process work, very well.

But I’m not sure that I would like have a little me in 3D data model on the network.

Let me think about it.

| Test |

Crash |

|

|

Fashion in 2060 :

I go to the H&M shop at Chatelet les halles infact it’s like a device production shop, the 3D scan on a kukka harm replace the dressing room, it’s a private luxury salon. I can go there, scan my body. At the showroom, I see different kind of fabric, I shoose my pants template (or whatever) choose my fabric, and go to the checkout.

Pruposes :

1. Economic issue

2. Eco-friendly methodology

3. Funny Fabrication

IF in the real world we do that :

If I have that device at home, I won’t go to the H&M shop ever and I will make my own garment.

3D Models

Link of my model : 3D mannequin model

| Sketchfab |

Sketchfab |

|

|