This week is about either to repair, modify or build hardware machines for producing textiles. Since beginning I had in mind to work on our Brothers Knitting machine which we found in our garage. That was a breathtaking moment for us. We are three people from Zios Makerspace where harshada was doing this week in vigyan ashram. But luckily, they had same model they bought second hand few months back and needed my help to debug and repair as I repaired my own knitting machine and made it working with mahavir.

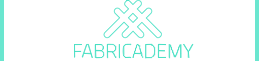

"Knitting machine KH 840 was last machine before Brothers launched its electronic version of knitting machine"

Nishtha Kaushik

Steps

Exploring Knitting Machines

After the lecture, I went through lot of projects which shares the repairs, hacks and new versions of knitting.

3D WEAVER from Zuzanna Weiss on Vimeo.

Step 1 : Assembling of knitting KH 840

We started our day by setting up and repairing our knitting machine. Our model of Knitting machine was the last manual model, after this came brother's electronic version which has lot of online hacks unlike KH 840 which has none to refer. We started by understandng if we can automate it but it wasnt possible internally but additional tool was possible.

Opening and setting up.

1. I started by assembling the machine which has been explained very well in the machine manual which you can download from here Brothers KH840 Knitting Machine

This is just a preview of the manual limited to only 15 pages.

Step 2 : Repairs

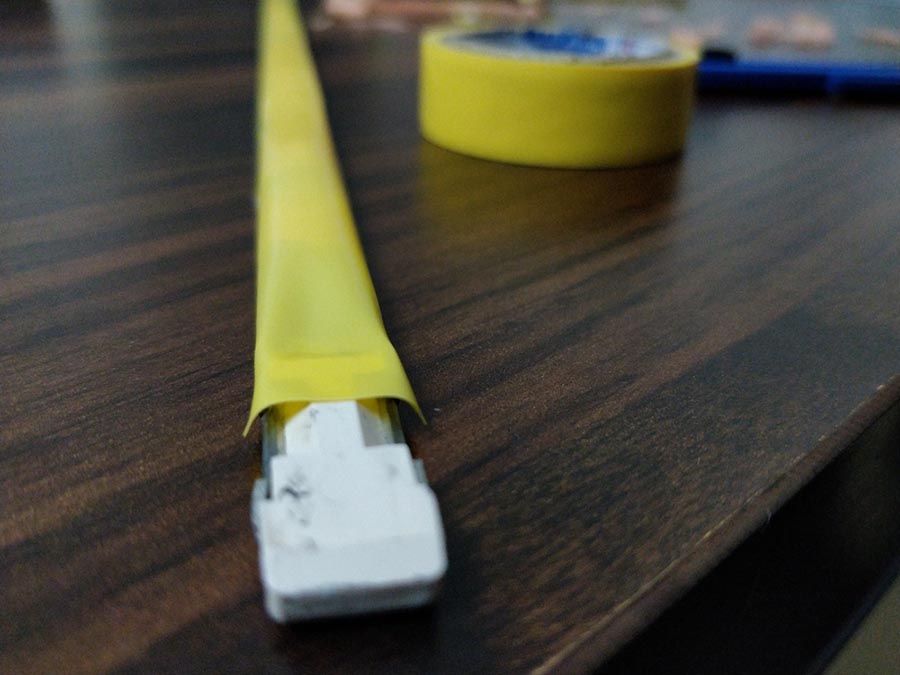

1. The Sponge of the sponge bar had disintegrated over the past 30-35 years. So we started by taking out the Sponge bar by pushing it from one side and pulling from another end of the machine. We had to remove the cloth sheet from the sponge and then change the sponge. I started by cutting the foam pieace, Ironing it for bringing it as same level. Pasted it on the plate and covered it with same cloth piece. Well, it wasnt done , after moving K carraige, my cloth came off, so we switched it with next best alternative , Insulation tape.

Below i am checking the width of the foam.

Then started ironing it and pasted it on the plate.

But after putting it back it came off, as the cloth i used was 20 year old original piece of cloth which was there before,so Mahavir and I decided to use Insulation tape.

2. The scale was heavily warped with airbubbles underneath, so we opened up completely, was tapped down precisely and reinserted back to the machine.

3. Then everytime you start to knit first layer of knitting, the thread stucks on carraige lock, so you need to unlock the carraige knob and clean the brushes.

4. We also repaired the pins of the cast on comb, so that its able to hold the needles in right position.

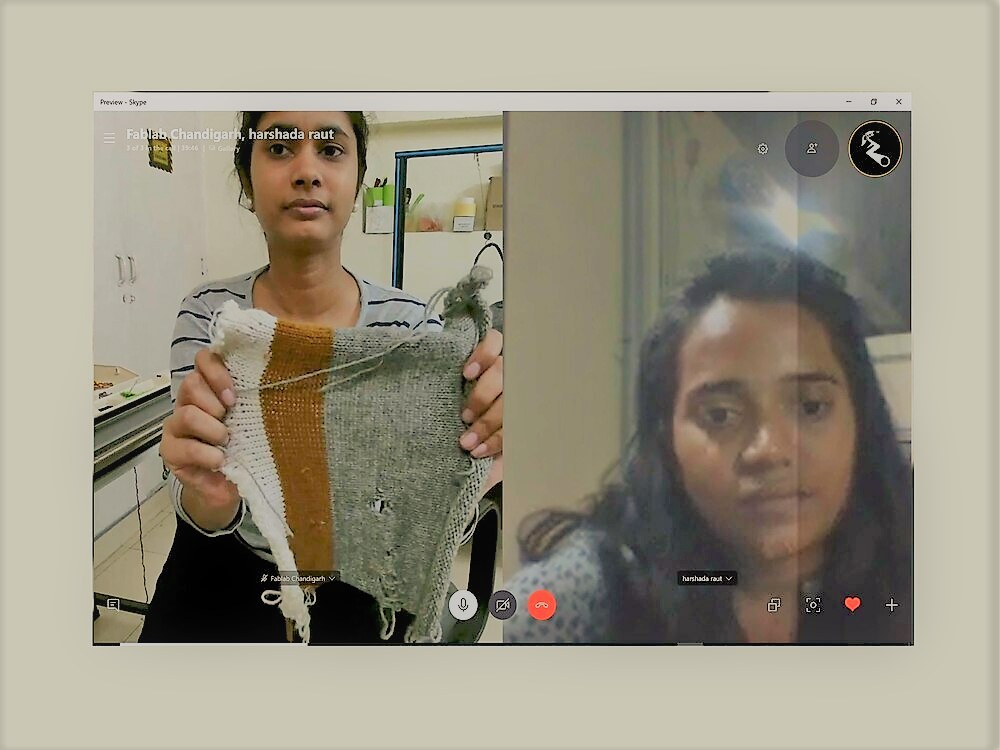

Then later , I and Mahavir had a skype conference with Harshada to guide her through the assembly and working of machine, share our mistakes and suggestions so that she could fix her machine.

Step 3: Handle Design

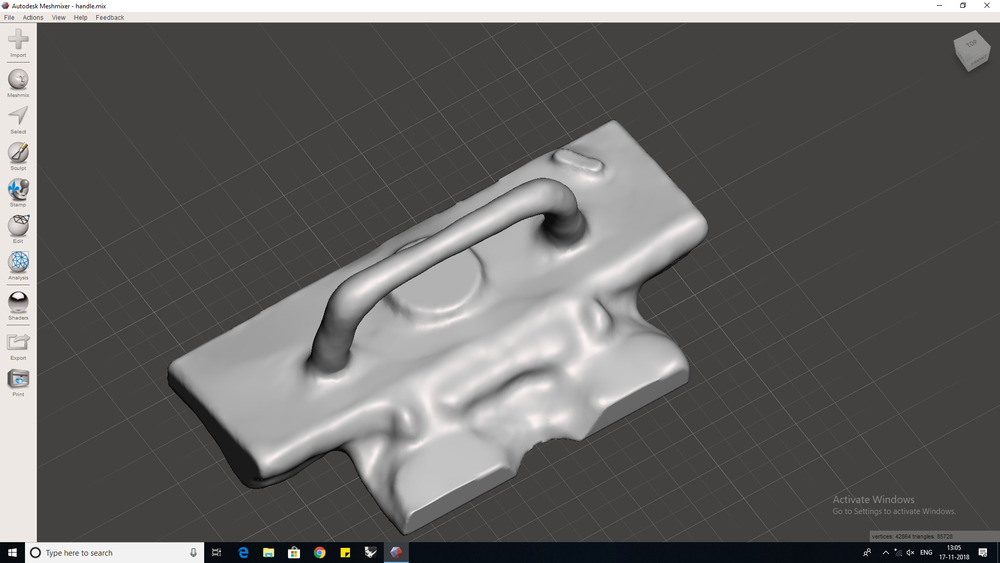

Mahavir suggested me to explore work of Antoni Gordi and it inspired me to make something which is neither CAD generated organic nor symmetrically accurate but something which feels like made out of clay and is an comfortable and interesting experience to hold. The design software I chose was Meshmixer as it keeps me away from symmetry and still lets me make design. The urpose of this piece was to bring comfort while holding and moving, but also to integrate soft buttons later.

Steps for Design:

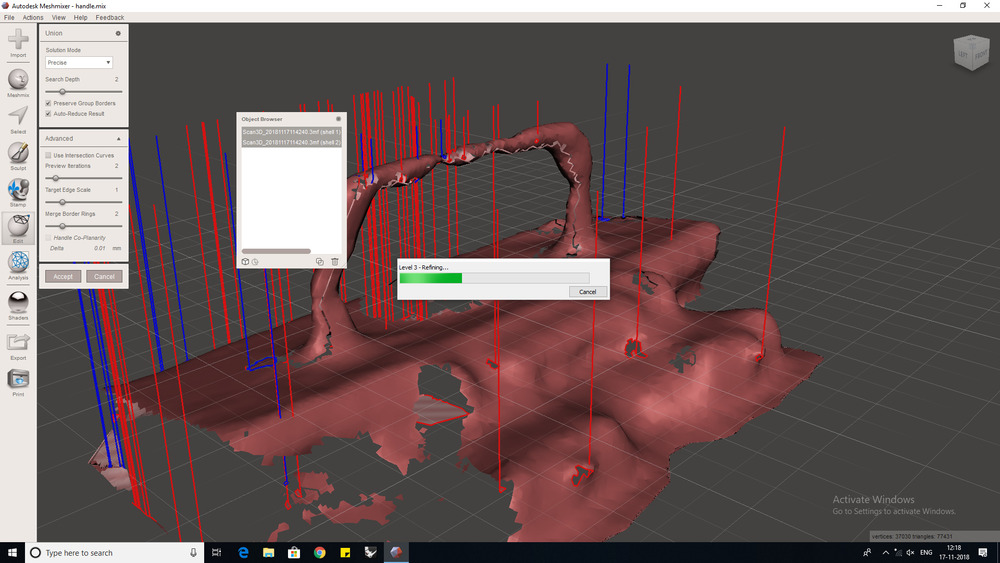

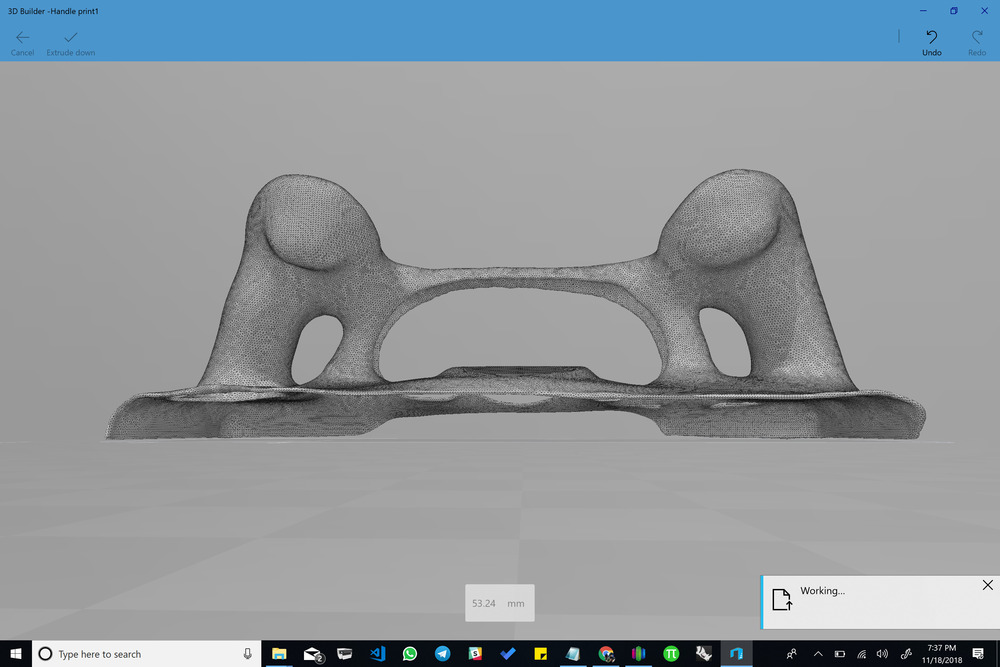

1. First I 3D scanned the K carraige with the help of Kinect 1.0 which I then opened in 3D builder to do some basic repairs and dispose off extra parts.

2. Which I later imported to meshmixer to work on the piece

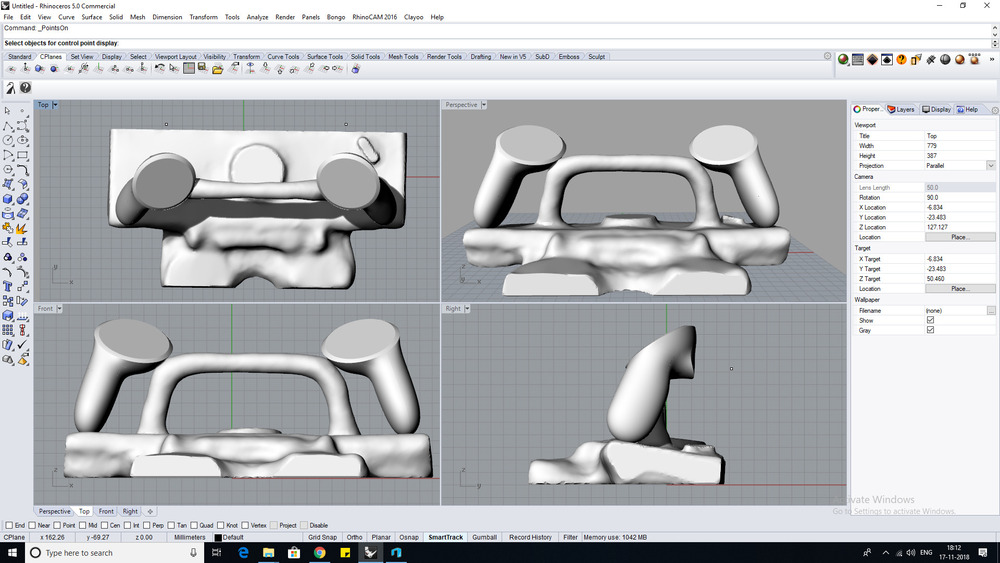

3. Then I imported it in Rhino and taking Design inspiration from Oculus where in wanted something to be organic as well as to change handle from One Hand to Dual hand which helps balance force required for sliding the carraige, it also gies feel of game controller which is futuristic. And the purpose of not press fitting is because I wanted to give a gear effect to it by bending it front and back.

i compiled these two designs together as follow in Rhino.

I further took my design to Meshmixer to fix any holes, or make it more non structural.

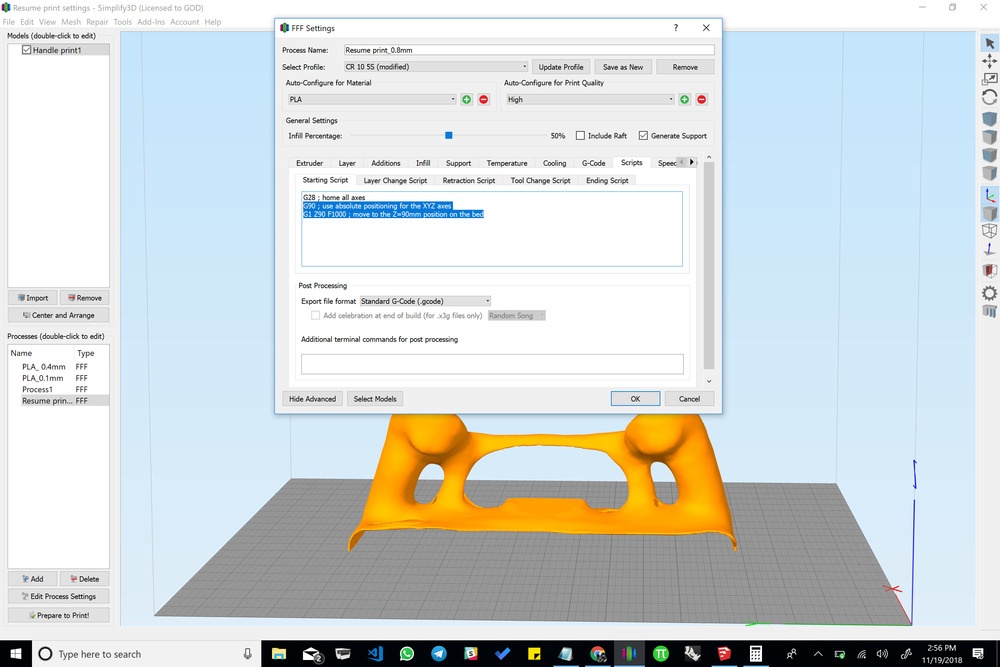

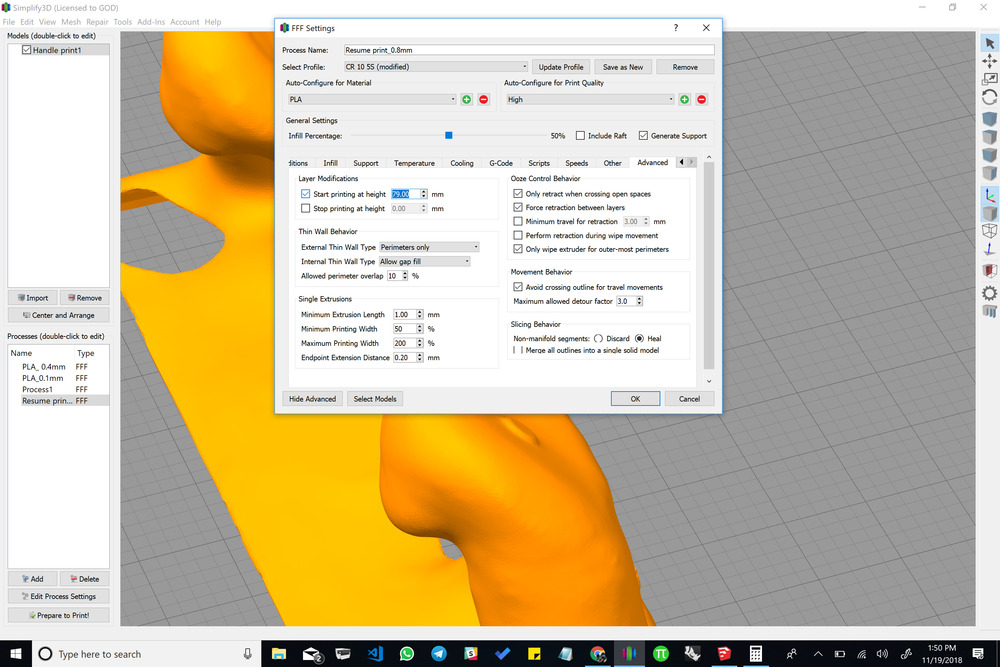

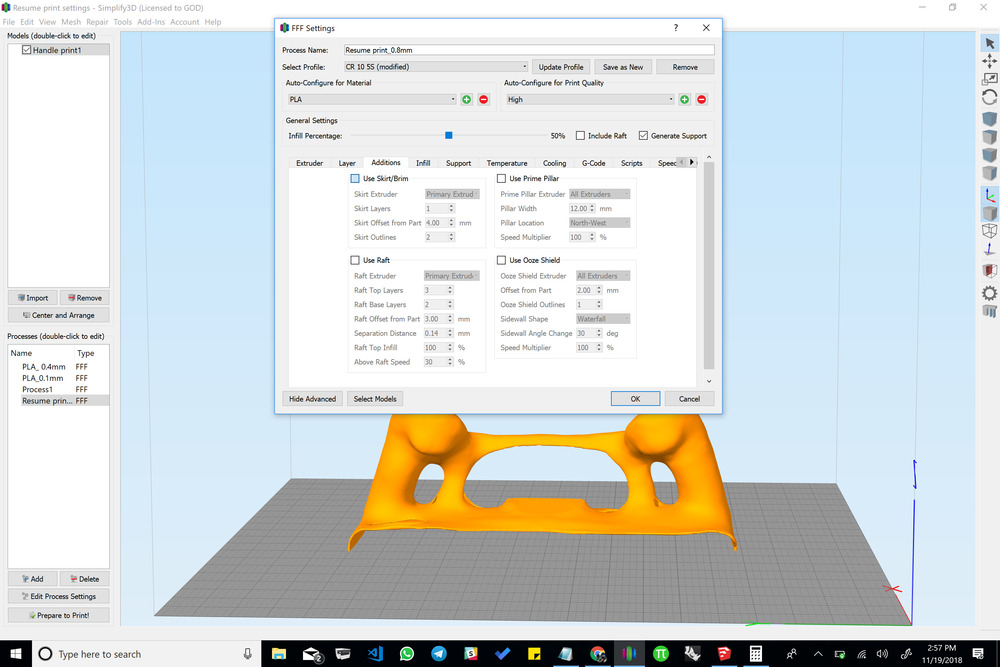

I am using Simplify3d for 3d printing, this sftware gives an edge over others by providing lot of settings possibilities and helps incalculating cost as wellifyou feed in the defining components before.

4. Then I started 3D printing my piece on 50x50x50 Bed size 3D printer, where i had to first wait for bed to get hot at 70 degree Celcius and check if bed is levelled perfect with the help of Dial gauge attachment we designed and fabricated or not. Also, i chose honeycomb pattern for printing as its strength is stronger than other patterns.

Then while printing i came across an error i.e my printer stopped extruding as filament broke mid print so it lost its track of layers,

So I explored that we can resume the print from any layer we want or exact the layer where it left by following these steps: -I added these lines to the Script tab :

"G28 ; home all axes

G90 ; use absolute positioning for the XYZ axes

G1 Z90 F1000 ; move to the Z=90mm position on the bed

"

-In Advanced tab-> Layer Modicfications-> Start printing at 79 mm (enter current height which shows under 'Z' in 3d printer's X,Y,Z cordinate display)

-Also, you need to switch off Additions tab-> use skirt Brim

-Layer-> Bottom solid layer=0

STL file can be downloaded from here at SKetchfab:

Carraige Handle Print by nishtha on Sketchfab

Assembly and electronics

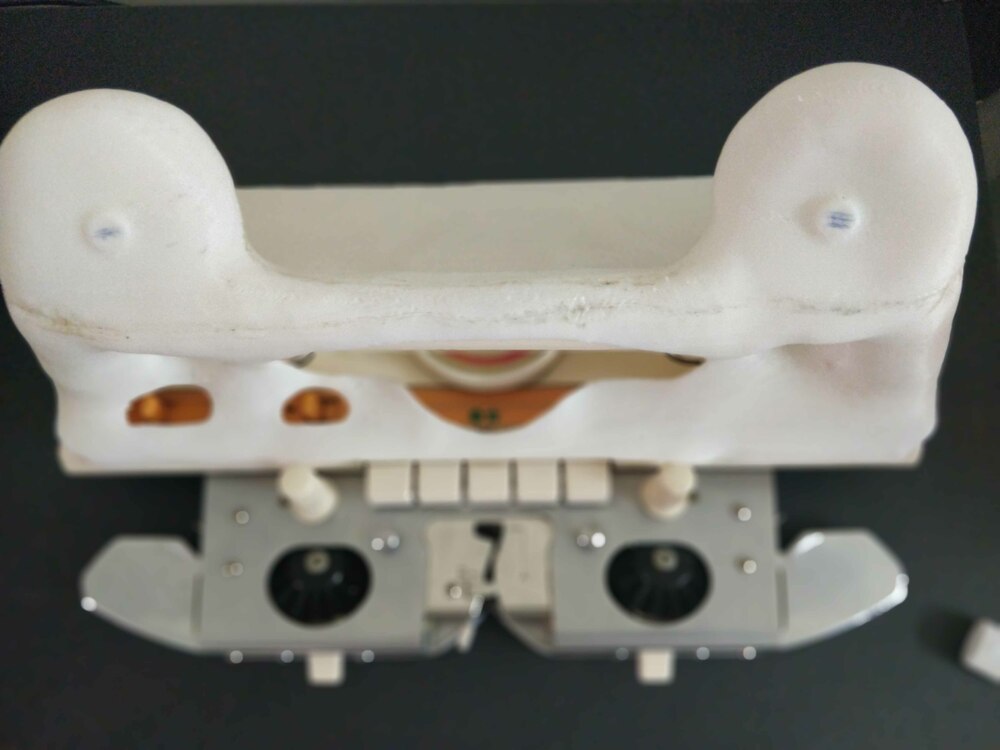

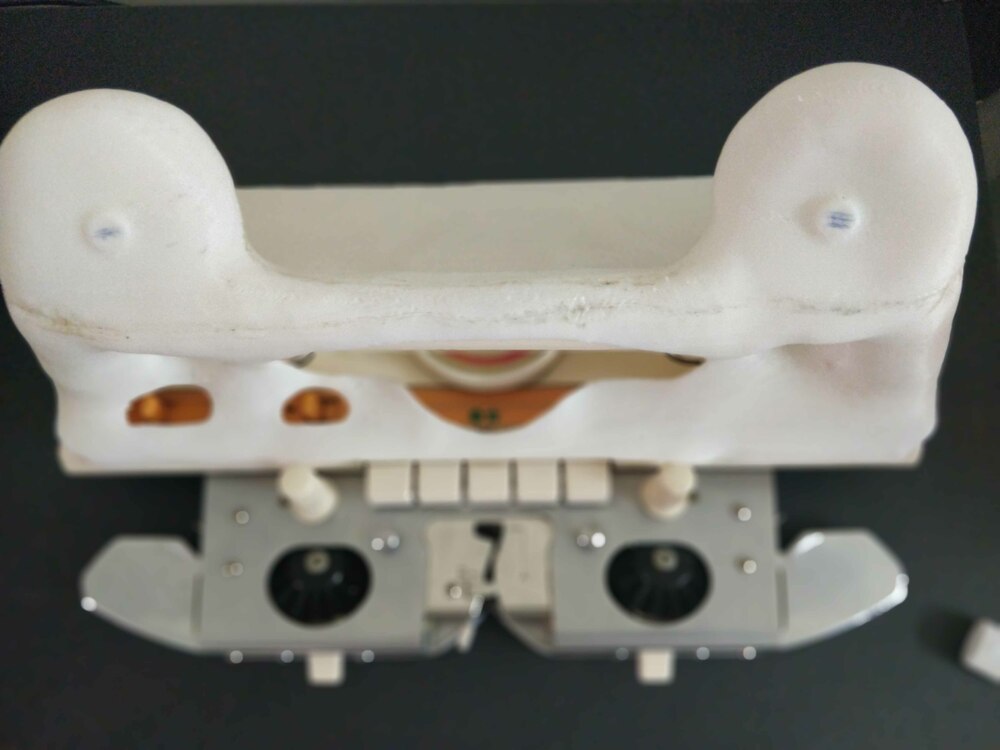

Besides designing I helped Mahavir assemble his design of Rotatory and my design of Handle.

Those are becase i was try to sand it but then it got dirty so i left it.

I made an arduino code for the servo motor which we installed on the Rotatory. This code basically rotates and slides the thread from one point to another so that it pulls wool and it doesnt get stuck while we are sliding the carraige

Final assembly

We started by fixing the tension controller Mahavir designed on the Knitting machine frame integrated the yearn tension unit in the controller. Putting servo motor MG 996R on the guide rail and did basic coding to check if it works. We integrated Handle for easy usage but as well to open possibilities to add button on its two holes to contol servo, which we thought can done later and nt include for now.