9. Textile as scaffold

I'm very excited about this assignment. First of all I have to confess this one is one of the most complex for me, because here I see some of the techniques that are not very usual in the life of the fabrication, or at least, speaking from the perspective of a Fab Lab's manager. The most complex process we have done is more about developing machines, but of course I like it.

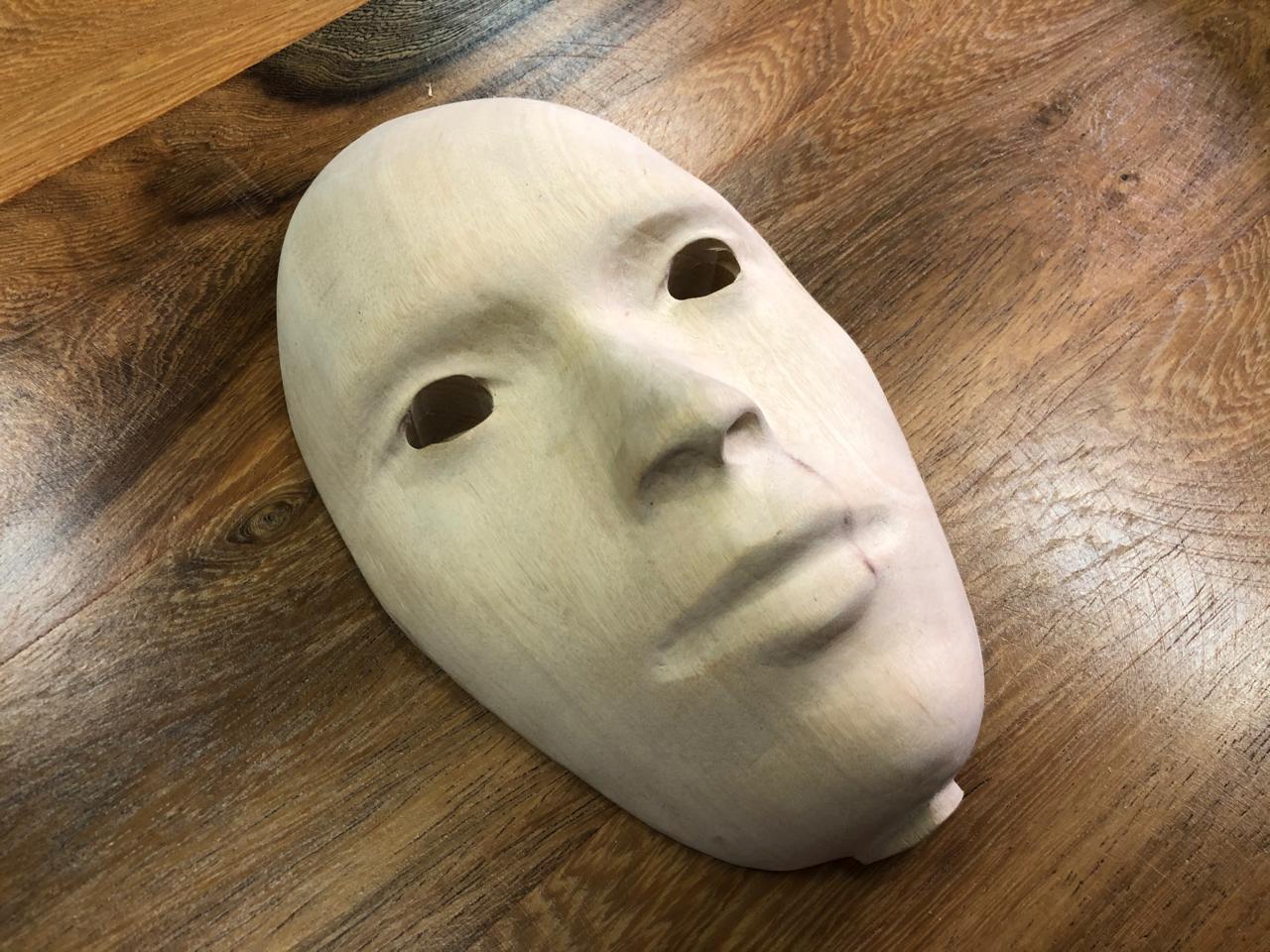

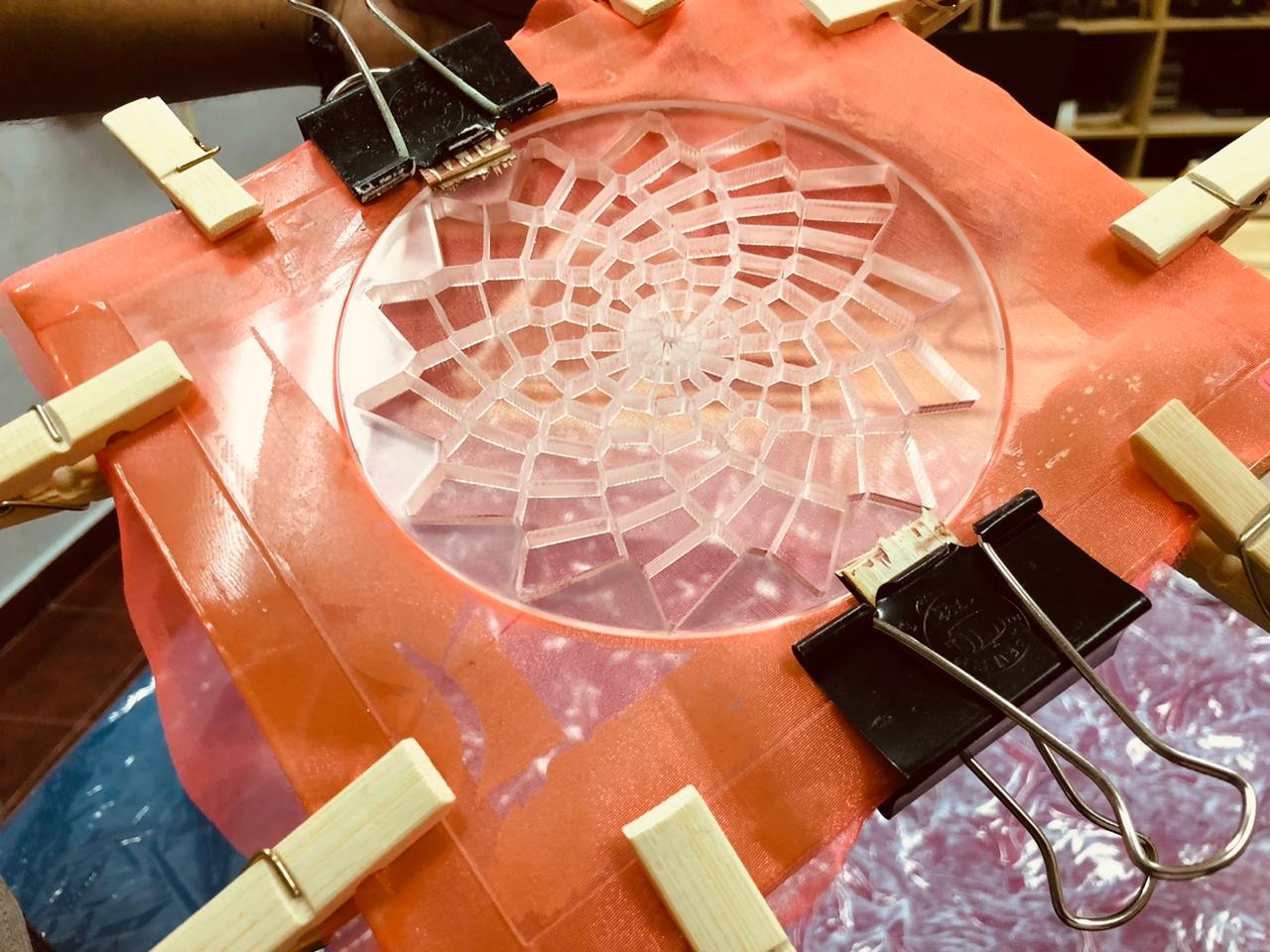

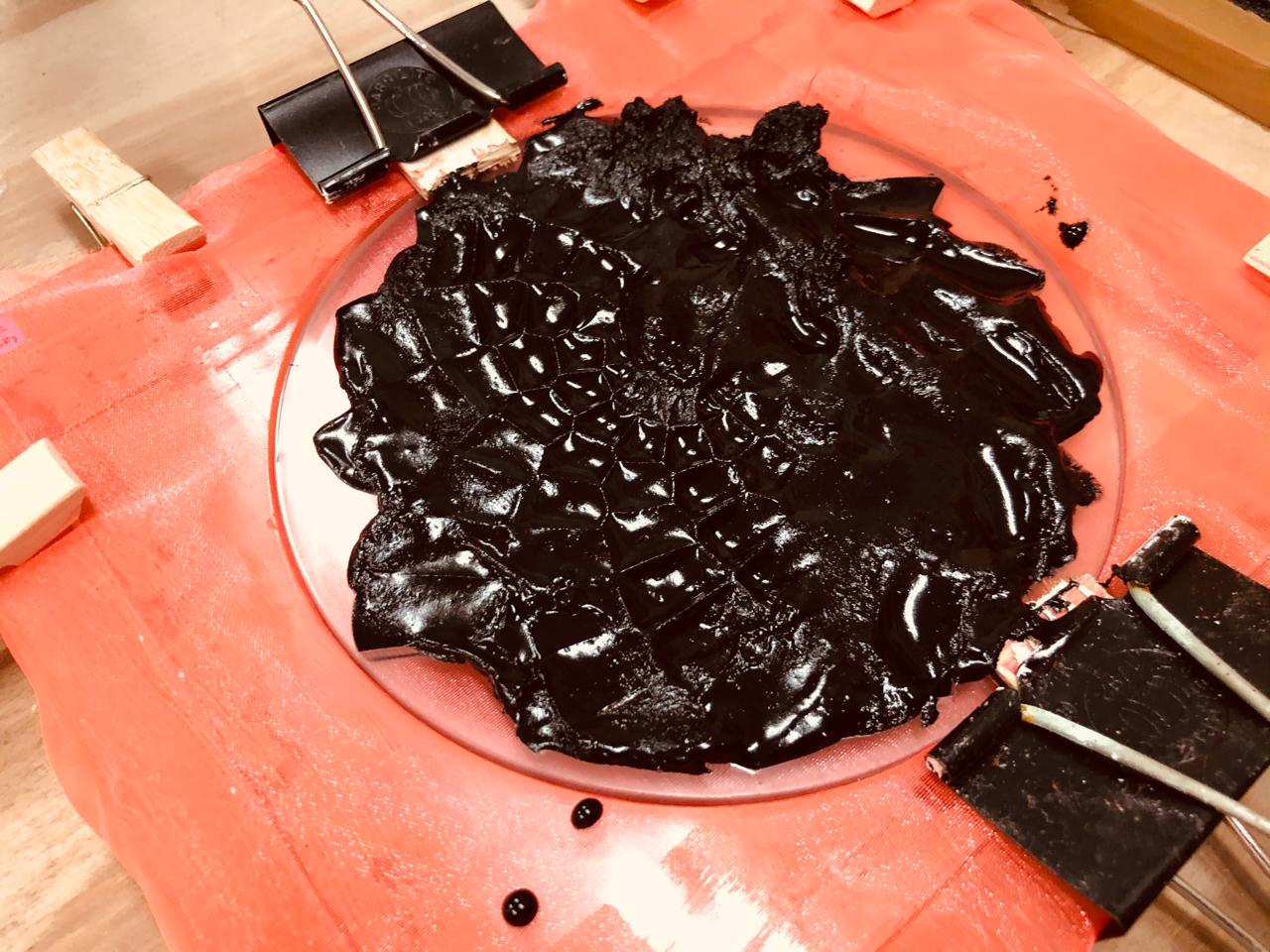

I chose this project that I found on pinterest, I have this idea of creating a different mask for every technique that we learn in Fabricademy so, for this one I would like to make a mask with the scooby of the kombucha from a wood mold. I like the concept of extending some of the parts from our bodies with the color of our skin so I think using kombucha for this is perfect.

INSPIRATION

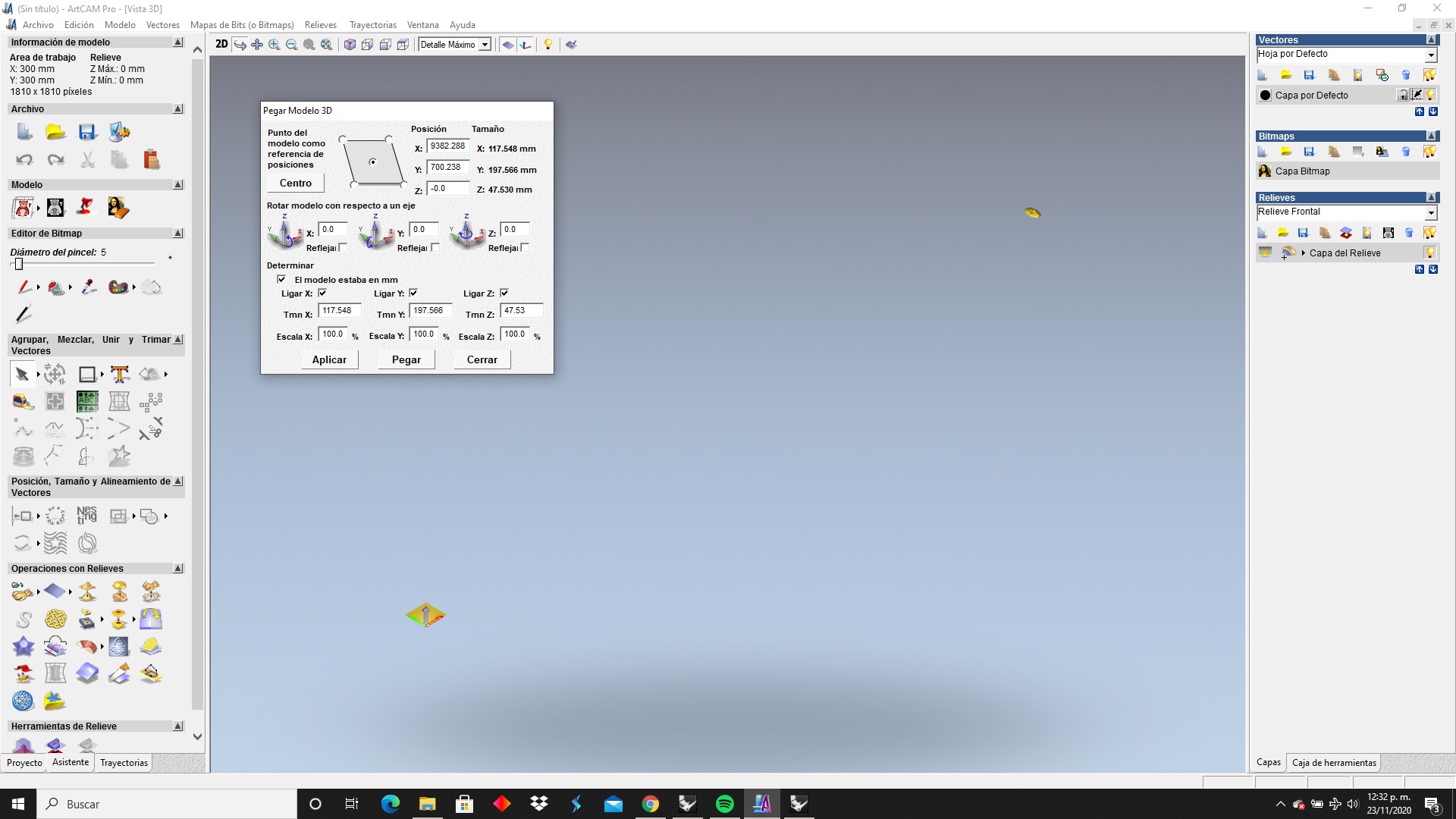

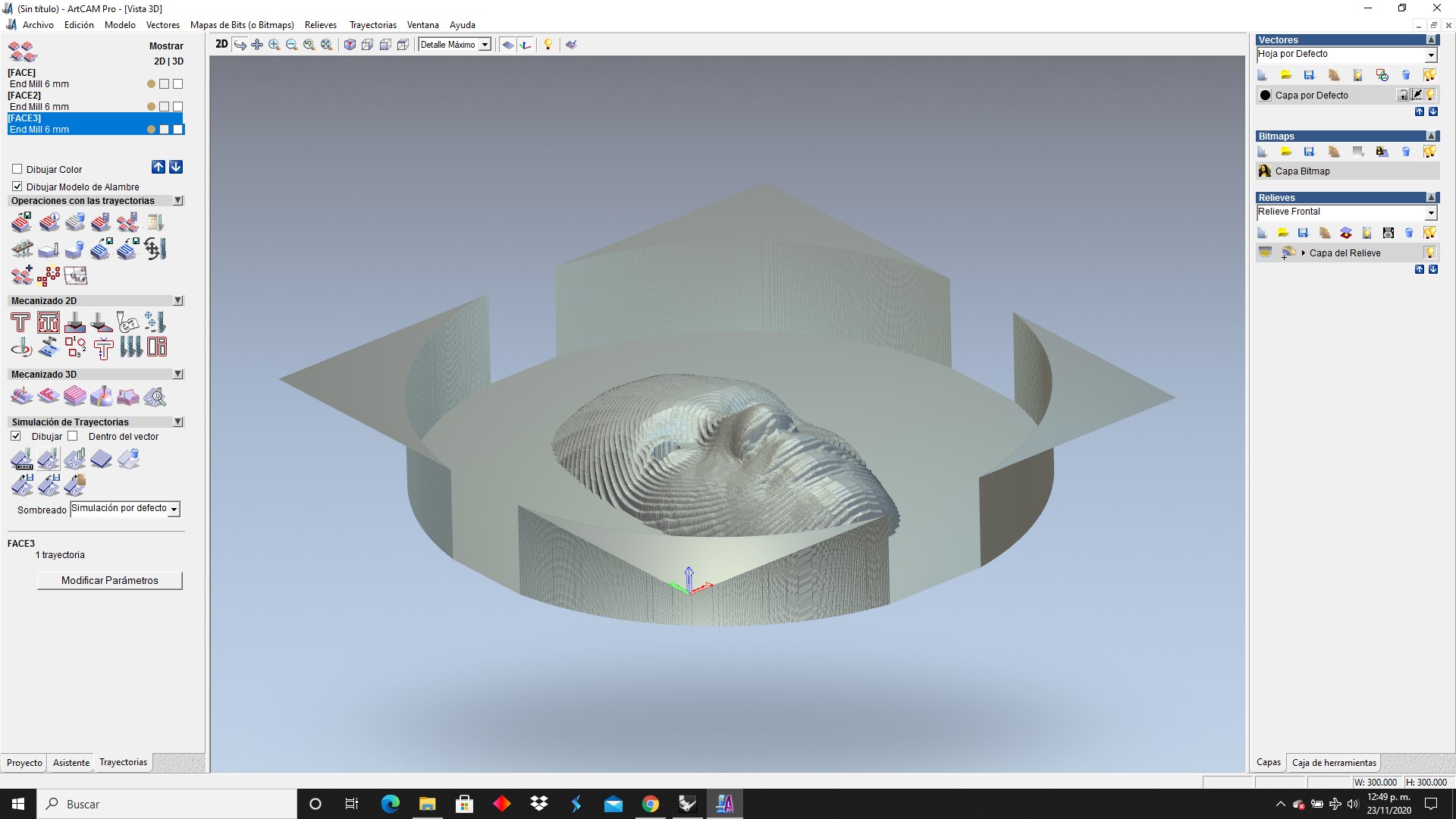

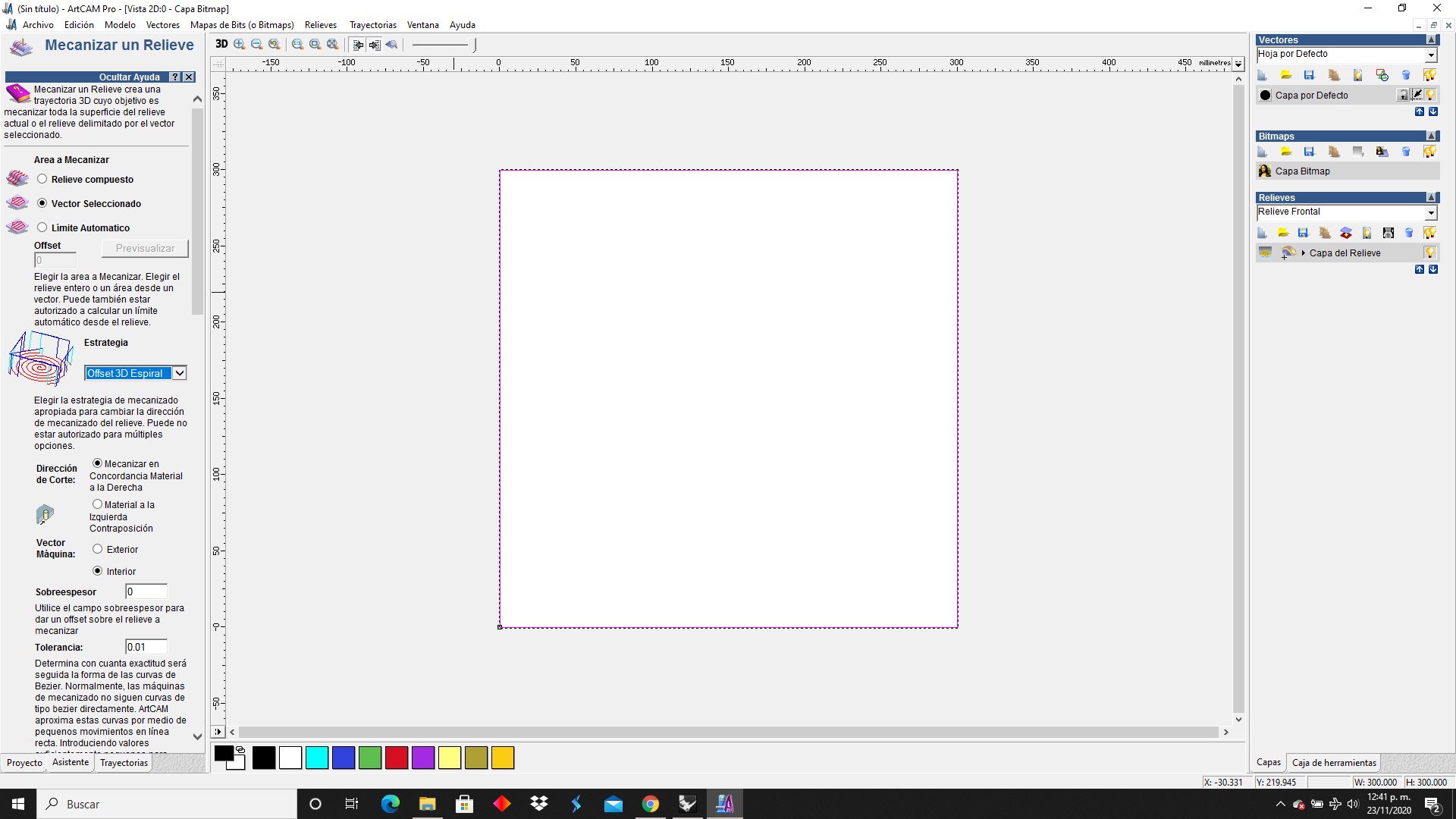

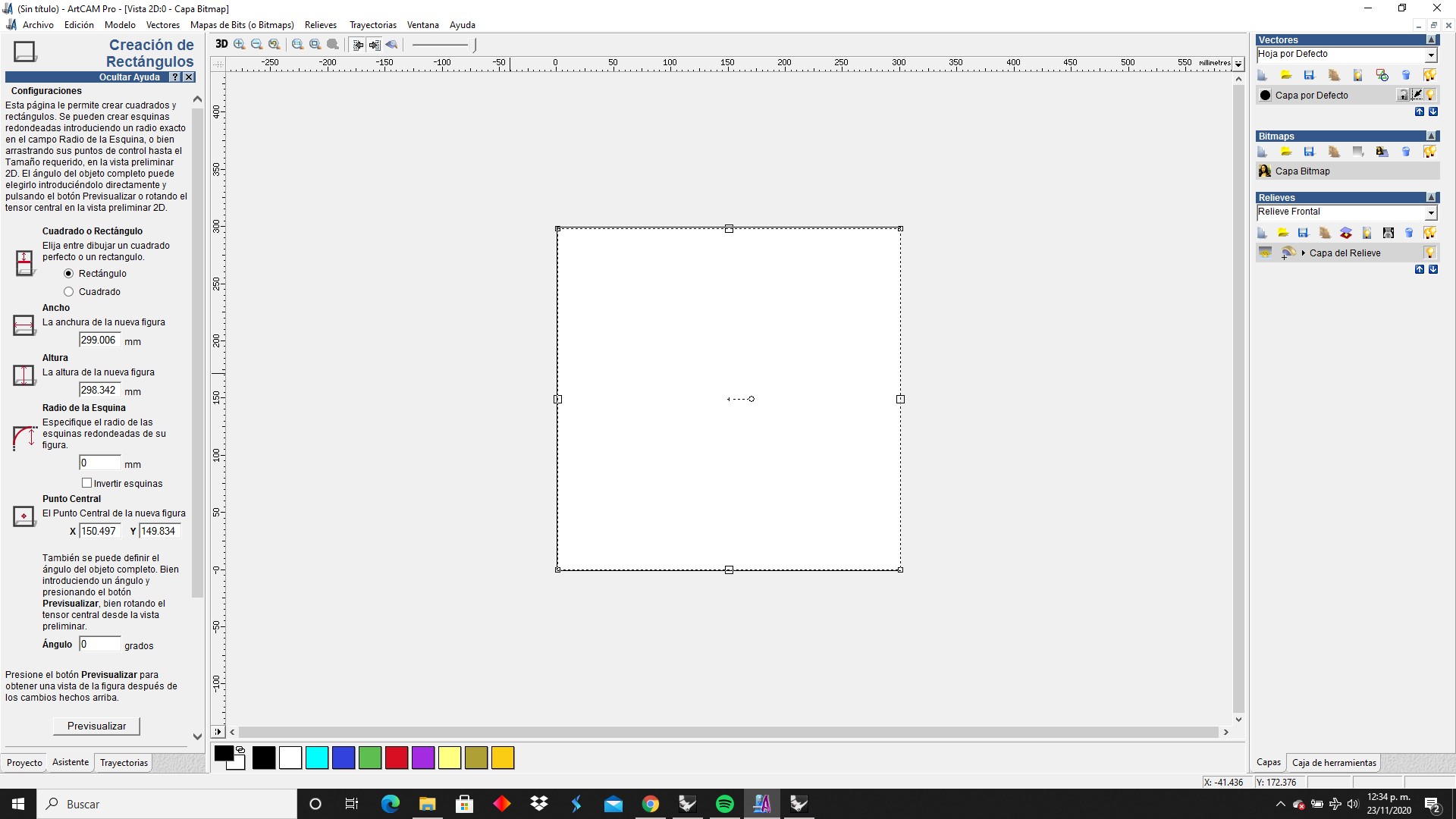

CNC MOLD

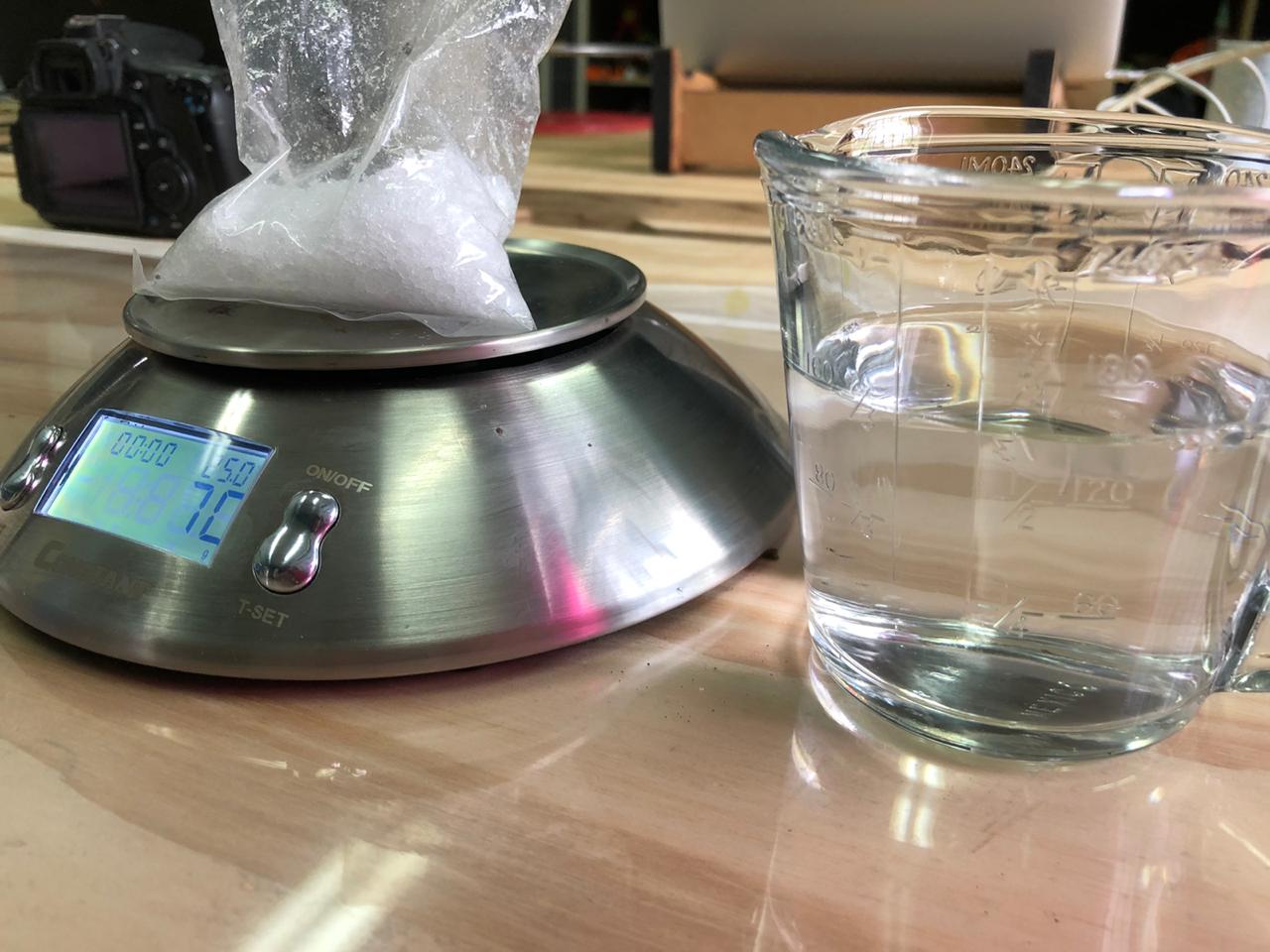

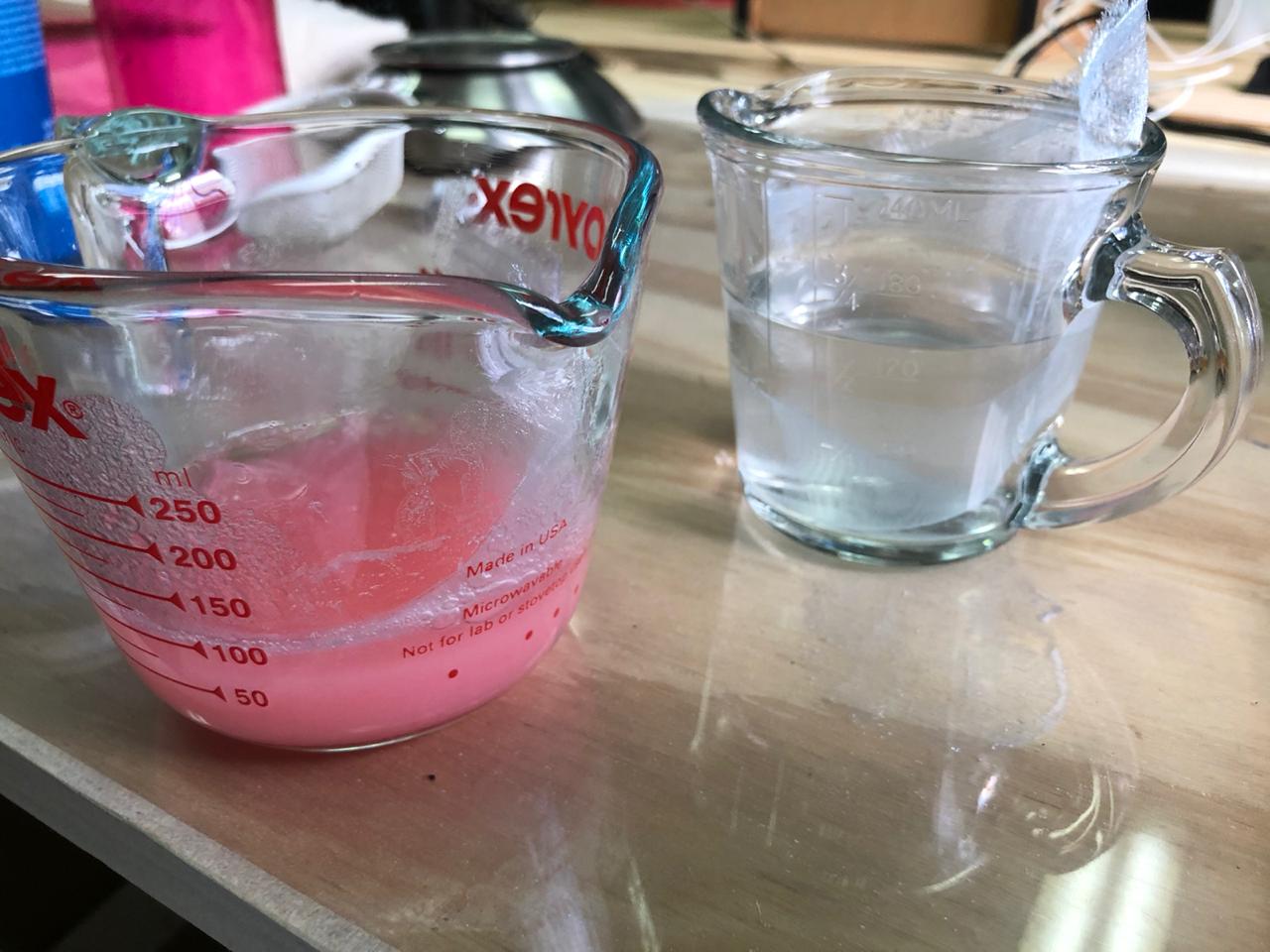

KOMBUCHA MASK

GROWING CRYSTALS ON LEDS AND FABRIC

BIO-PLASTIC COMPOSITE

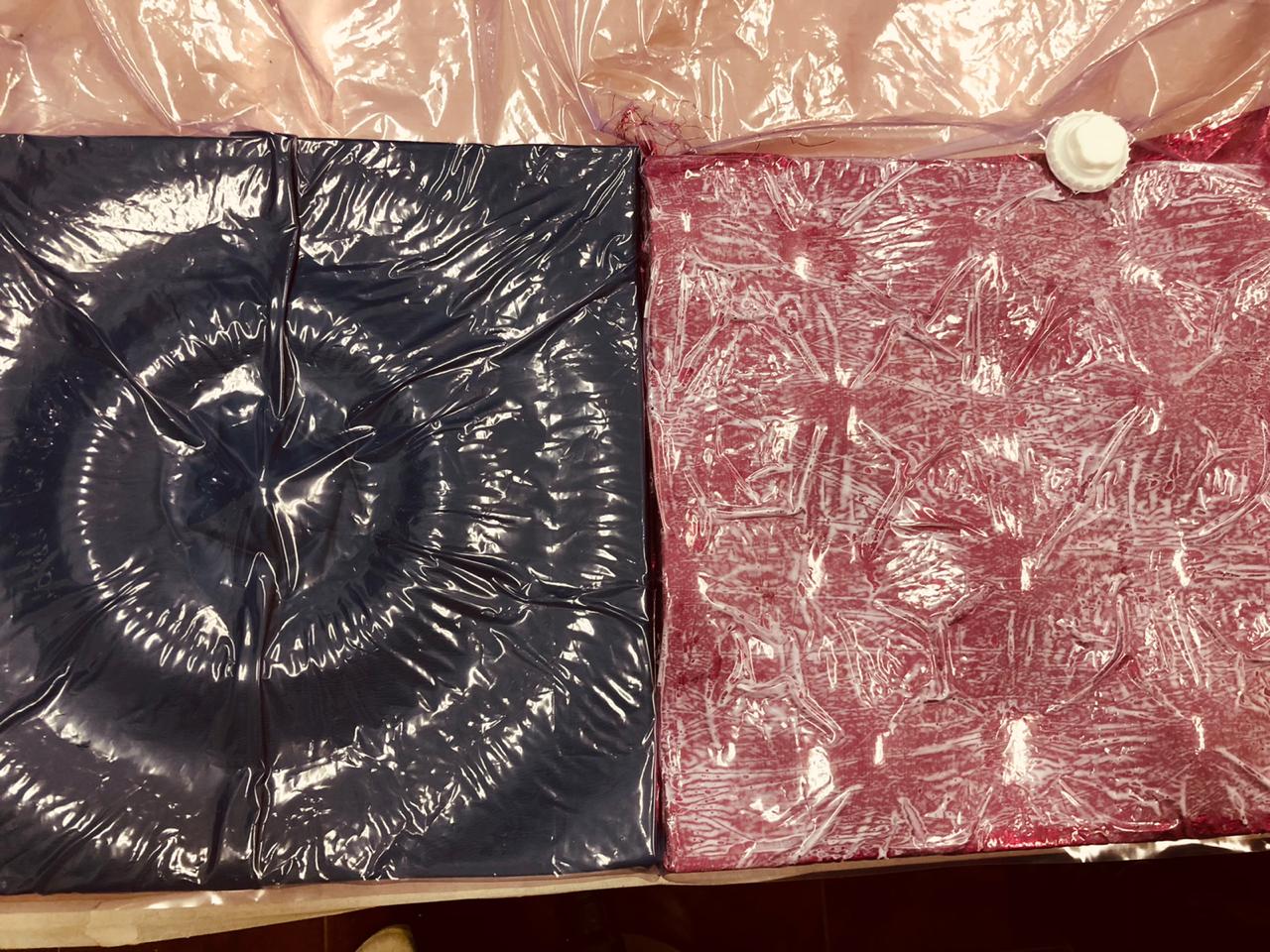

VACUUM MOLDING

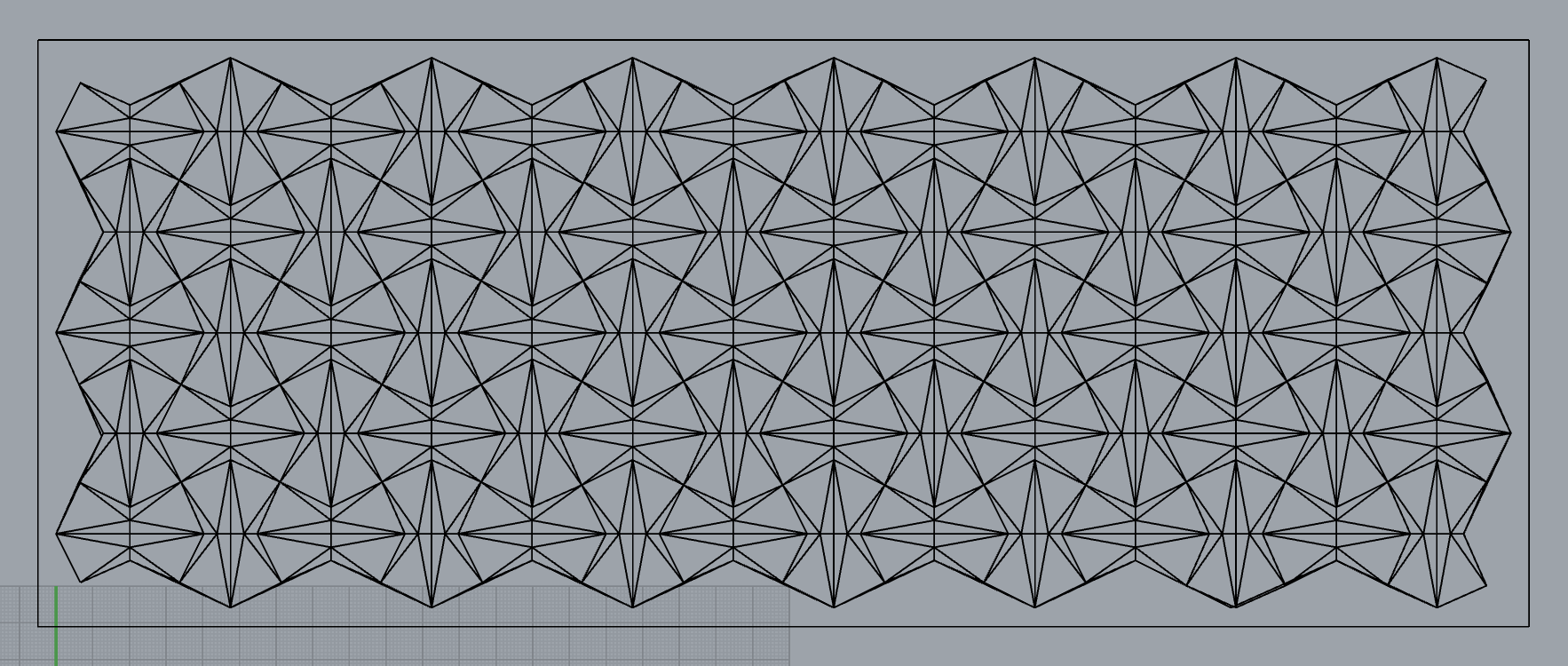

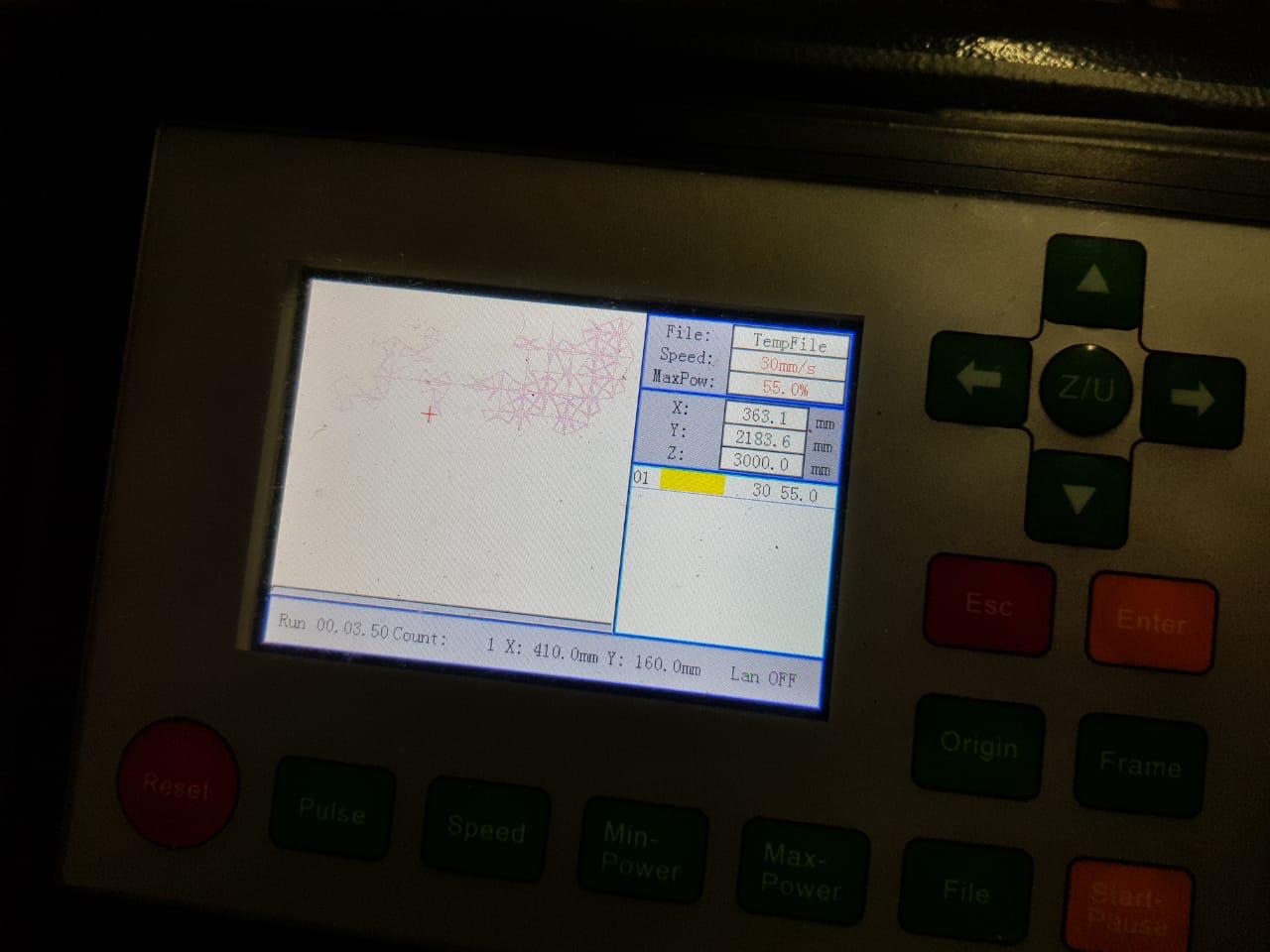

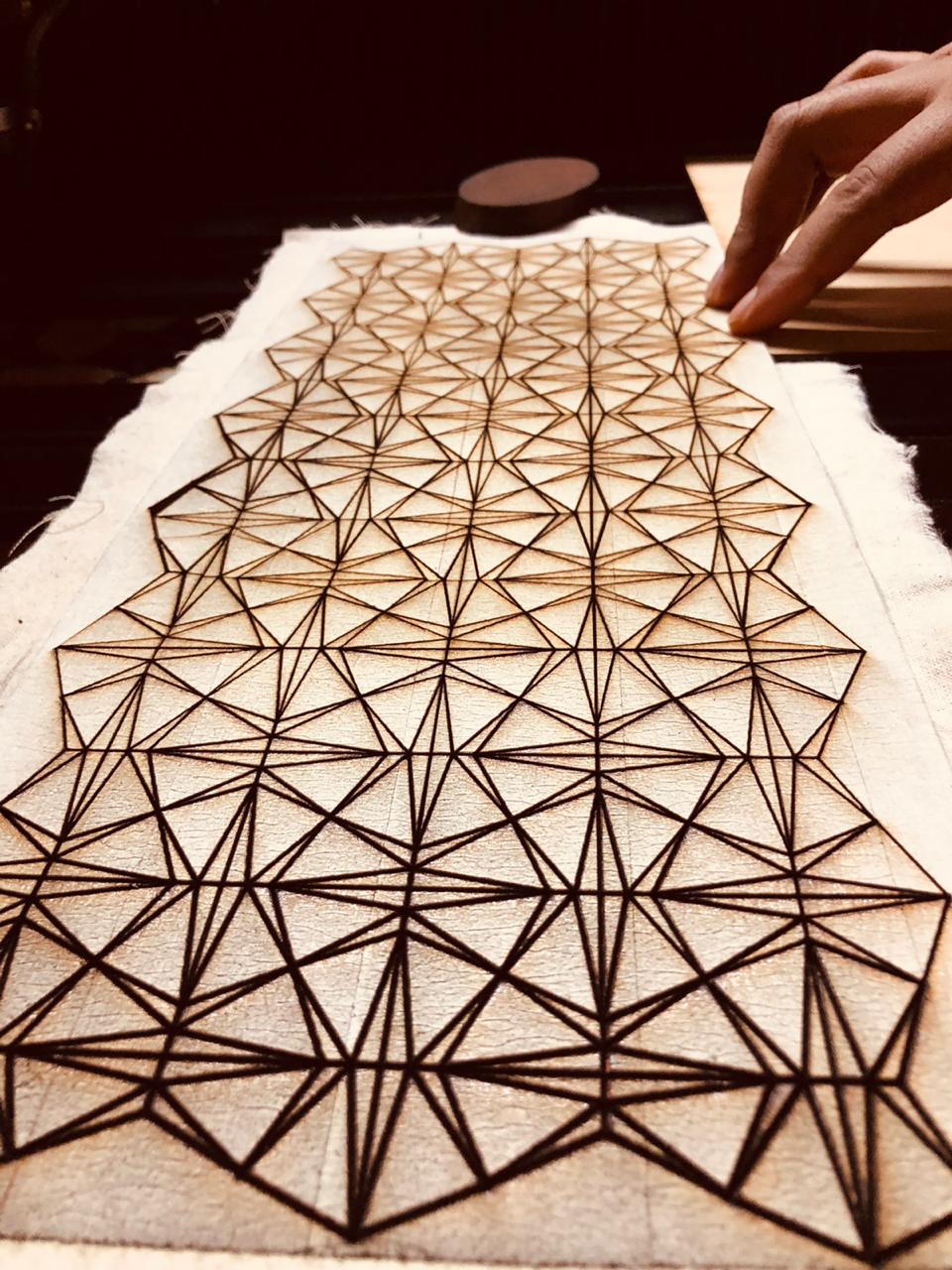

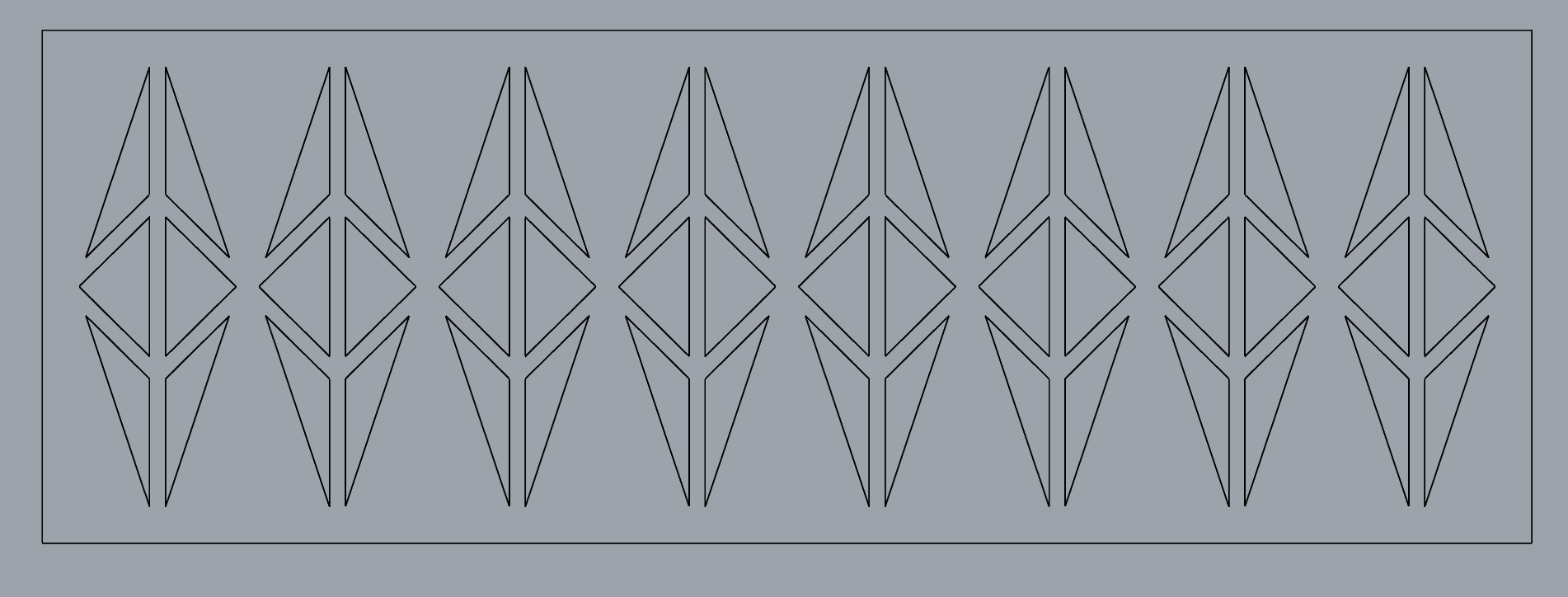

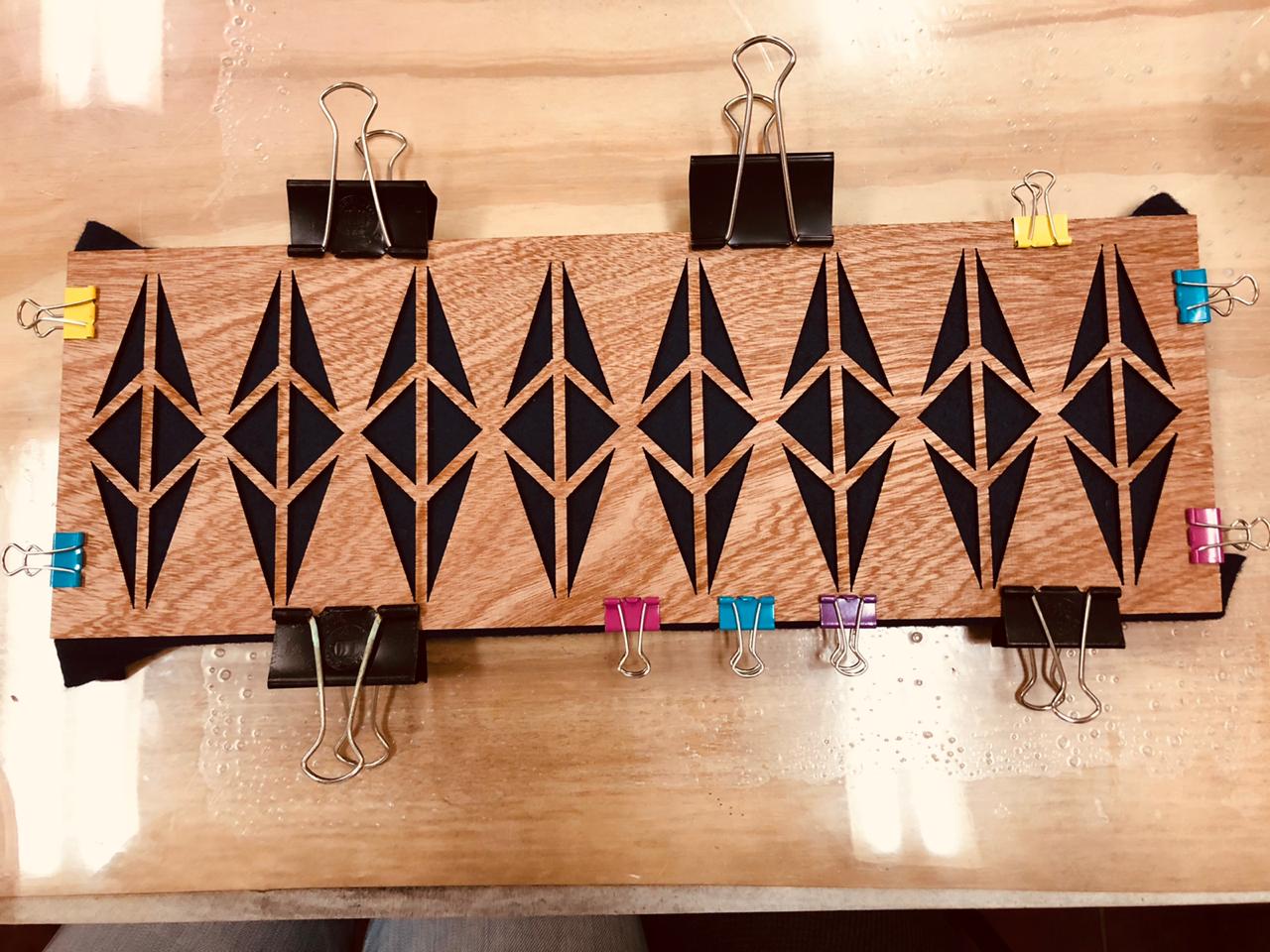

WOOD FABRIC

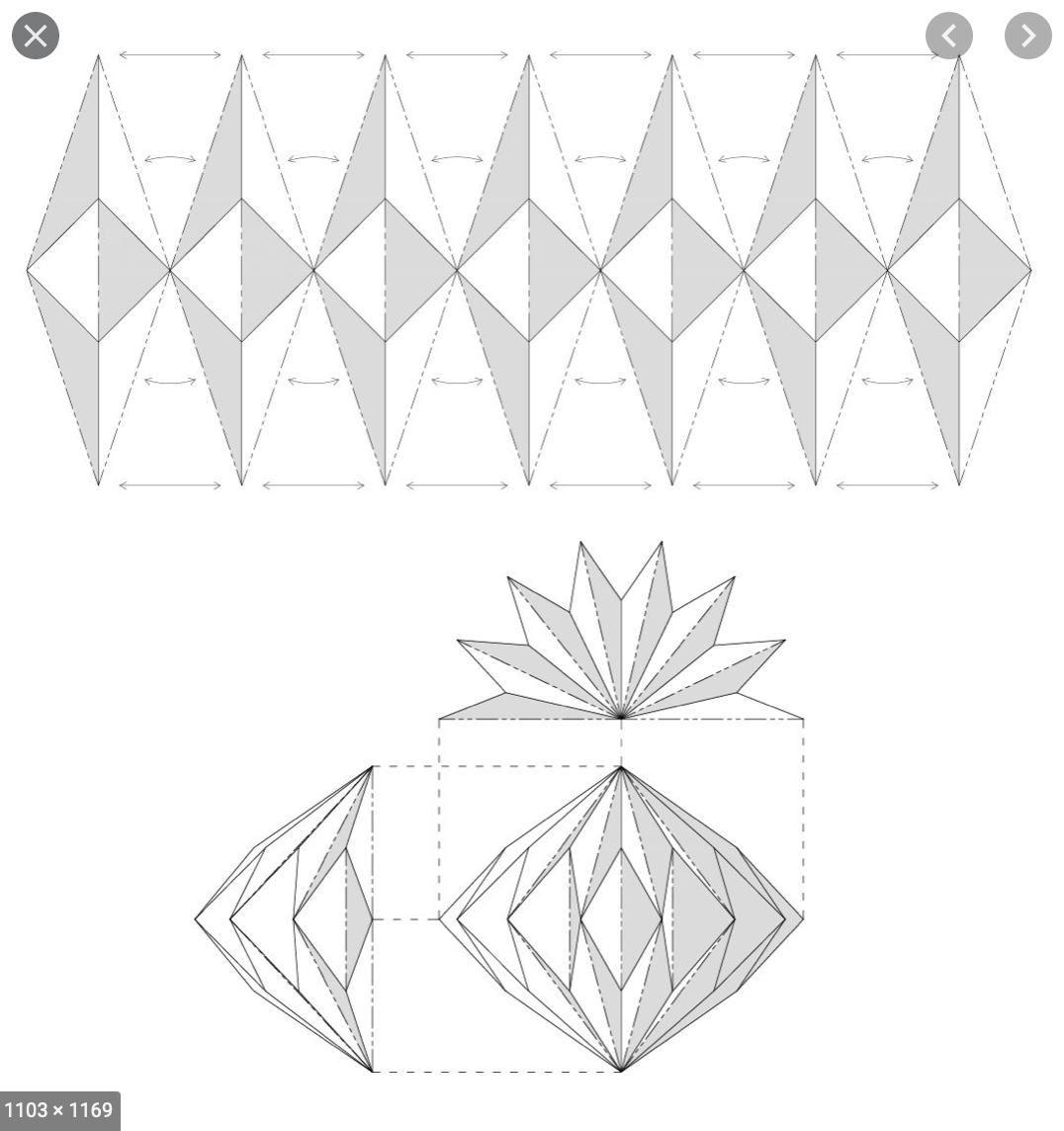

PLASTER ORIGAMI FABRIC

IMPORTANT INFORMATION ABOUT THE ASSIGNMENT

LINKS

Tutors

- Adriana Cabrera General Tutor

PERSONAL NOTES

- --- -----

NECESSARY MATERIALS FOR THIS ASSIGNMENT

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 0 | ---- | 00.00 $ | ----------- | USD |

| 0 | --- | 00.00 $ | ----------- | USD |

| 0 | ---- | 00.00 $ | ----------- | USD |

| 0 | --- | 00.00 $ | ----------- | USD |

| 0 | ------- | 00.00 $ | ----------- | USD |

| 0 | ----------- | 00.00 $ | ----------- | USD |

CLASS

LEARNING OUTCOMES

- References and Concept development

- Design: Sketch, 3D modeling skills, mould design

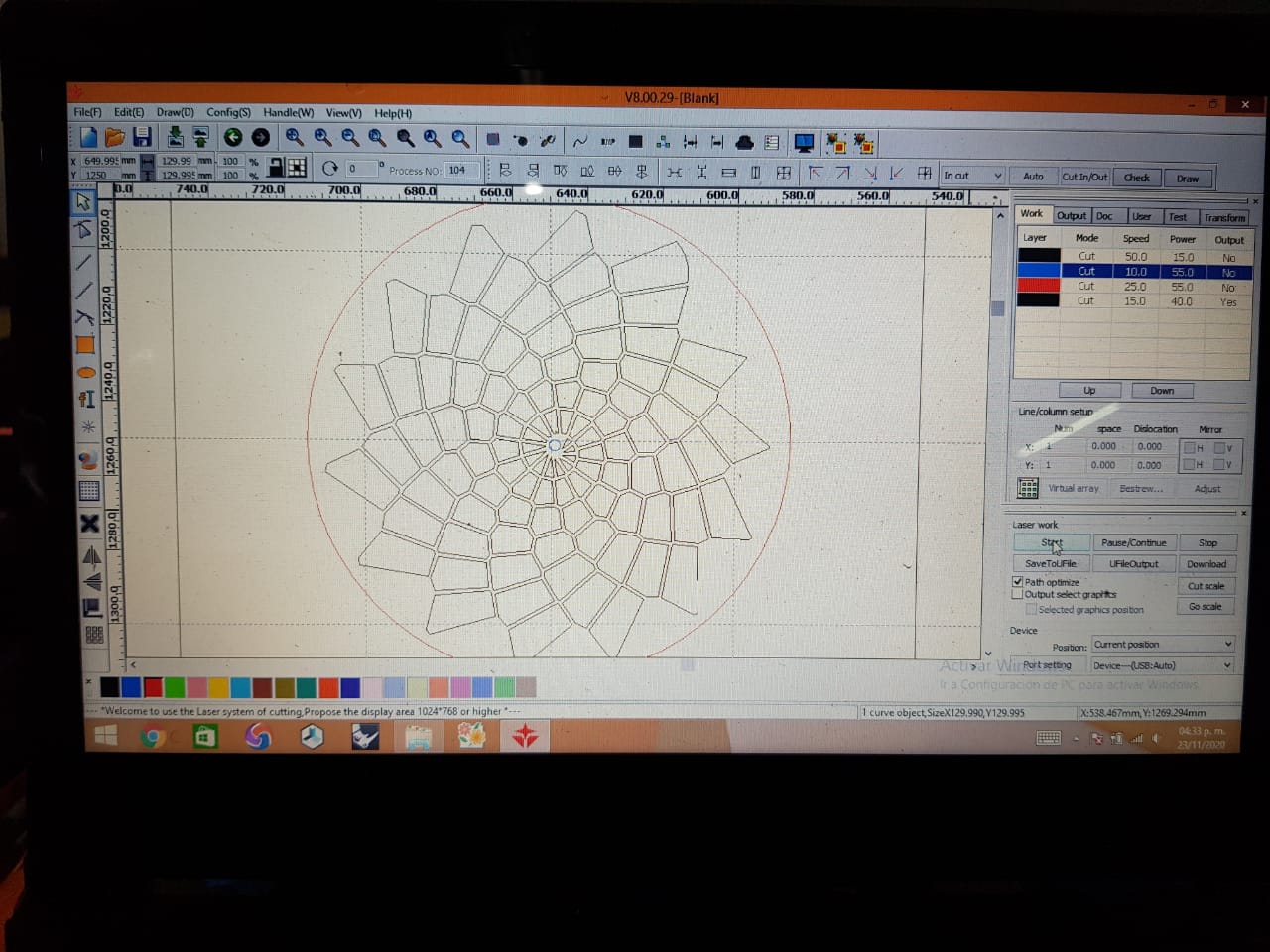

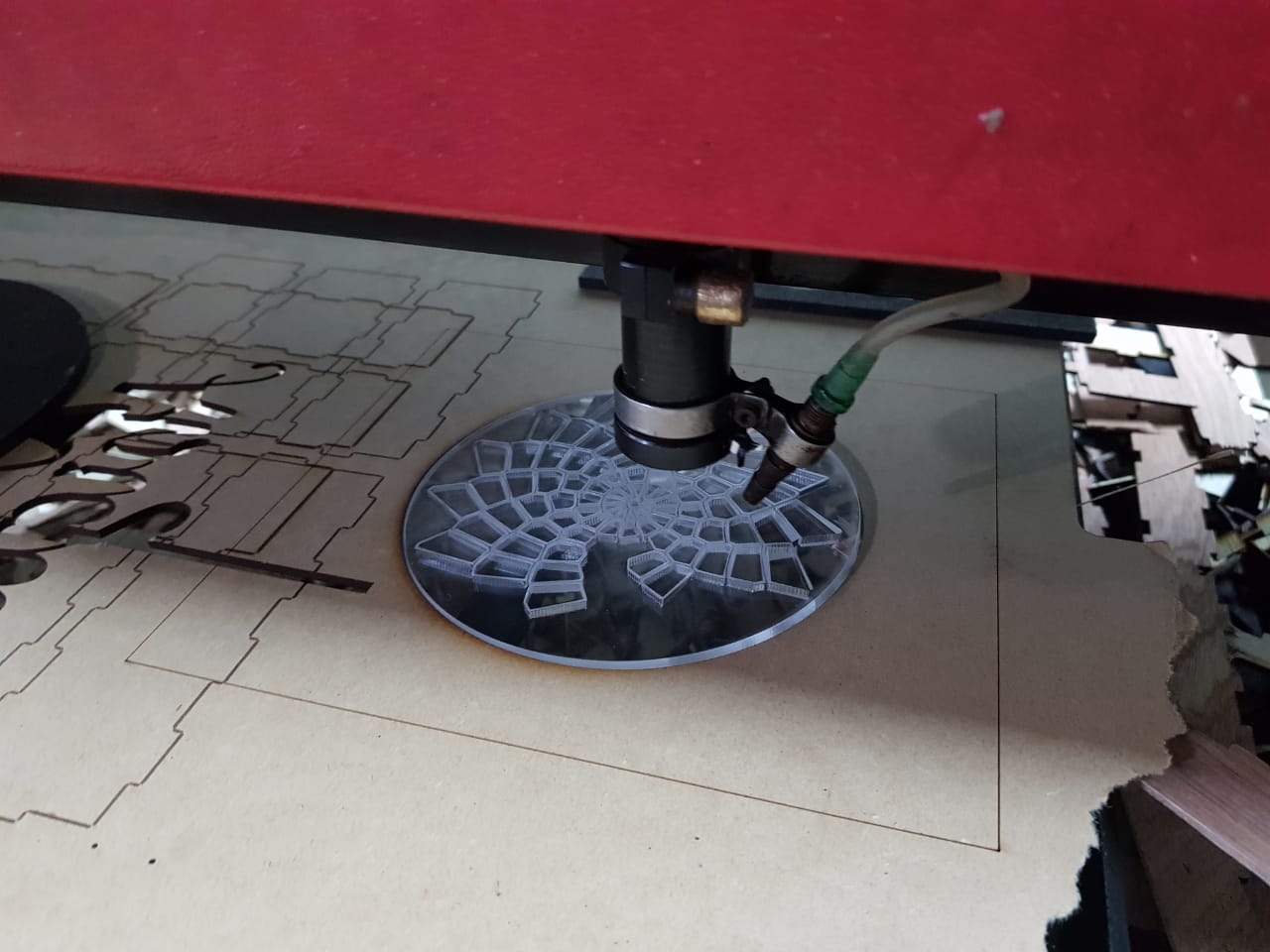

- Fabrication: Capable of executing from file to production workflow, from 3D modelling to 3D milling and composite making, lasercutting, crystal growing, concrete casting

- Documentation: Anyone can go through the process, understand it and reproduce it

- Final outcome: Various samples created using different techniques

- Originality - Aesthetics: Has the design been thought through and elaborated

STUDENT CHECKLIST

- [x] Document the concept, sketches, references also to artistic and scientific publications

- [x] Produce 2 techniques of textile scaffold choosing from the following: 1. fabric formwork with casting 1. crystallization 1. wood-textiles composite 1. resin & bioresin -textiles composite 1. leather molding 1. other

- [x] Document the process from CAD to CAM, the step-by-step instructions for CNC milling, mold making, vaccum forming and textile composites

- [x] Upload your design and fabrication files, including the 3D model and CAM file

- [x] Document at least 2 processes from design to prototyping, fabrication, materials used, document your achievements and unexpected outcomes

- [x] Make a stop motion of your crystal growth or use 3D modeling software to simulate your design (extra credit)