GRAVITÉ_Final Project¶

Gravité is an Experimental & Artistic concept merging New_Tech & "Savoir-Faire". Material experimentations & technical fab for creating Unexpected Leathercrafts. Co-creation Lucia Javicoli x Sage Folie.

Photo: Sac V Algileather Biocomposite + leather leftovers. Exhibited at Showroom Galerie 7 in Lyon form the 5th to the 28th of may 2022.

VIDEO¶

FINAL PRESENTATION¶

1/CONTRIBUTE¶

-Photo: Leather leftovers with black alginate

Our current global model must be in line with the Zero net Transition. So our agility is challenged in order to change our way of designing, producing, consuming... Thanks to

Local Cooperation

Custom design processes

Waste reduction

Education/community

2/LOCALLY, CO-CREATE¶

I started to work in collaboration with a Leathercrafts atelier called Sage Folie owned by Virginie Bussière and Emeline Lemercier and based in the city center of Lyon. The goal of our co-creation is to combine our skills, expertise, technics, tools, machines, processes & methods in order to create a Handbags collection based on leather leftovers waste coming from local manufacturers.

-Photo: The team working at the atelier

3/CUSTOMED DESIGN & FAB PROCESSES¶

With the mix of New Technologies and Traditional "Savoirs-Faire" in order to reduce waste and create Gravité aesthetic.

-Photo: Focus on Molded leather with its mold

4/LEATHER LEFTOVERS¶

By finding a way of transforming leather waste into a valuable materials.

-Photo: Leather leftovers at the atelier

5/EDUCATE¶

By Showing & Sharing: Exhibit products, materials, processes to build up a community.

-Photo: Leather leftovers with black alginate

6/VIRTUOUS MATERIALS¶

-Photo: Molded leather & Algileather

7/CARRY FOR THE FUTURE¶

Nowadays, users ask for responsible fabrication, long lasting products, ecological impact.

-Photo: Hand playing with Algileather

8/MINDSHIFT¶

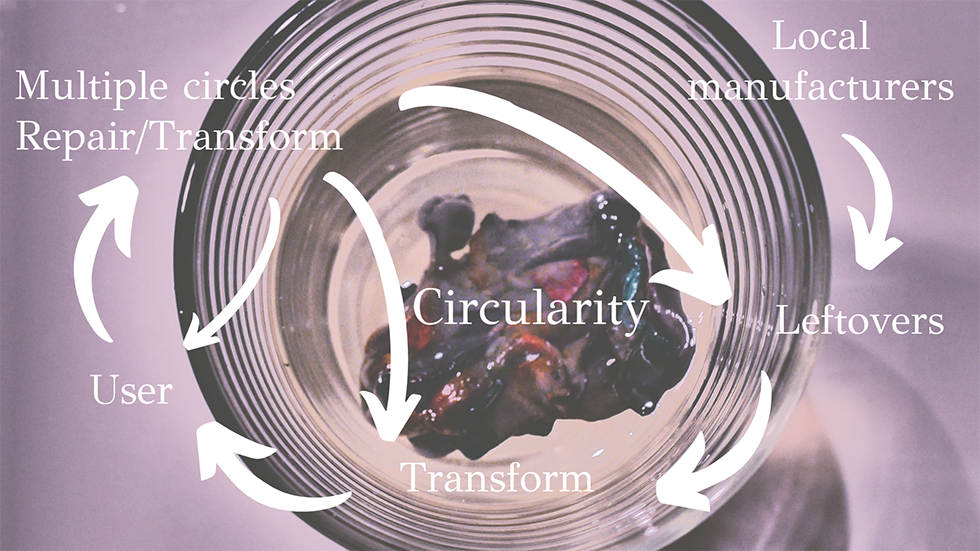

A business model based on Circular Economy means that locally we collect leather leftovers from local manufacturers. We order the pieces by size and nature and transfer it to the transform destination:

-> Leather modeling: pieces in between 25x25cm , thin, vegetal

-> Algileather: pieces less than 25cm

-> Design & Fabrication process: on demand (Library of forms and materials)

-> Reparation & transformation: long lasting product

-Photo: Circularity schema

-Photo: Circularity schema

9/DESIGN & PROTOTYPE¶

Leather Modeling: The first phase was the Digital fabrication for creating patterns. Then the CNC milling for making molds and came the technic of the leather modeling. Finally, the technical developpement for the fabrication of the Black_Box.

-Photo:Rhino 3D pattern/3Dprint/CNCmilling

-Photo:Vaccum box and samples drying

Algileather: The first phase was to trim the small pieces of leather, mix it with the Alginate in order to make samples of leather Biocomposite. The idea is to extend the technical researches with local technical center of leather.

-Photo:Detail of Algileather biocomposite

-Photo: Samples of Algileather: molded or not

-Photo: V_Bag exhibited at Showroom Galerie 7, LYON

JUST A START¶

Thanks to Fabricademy, I had the opportunity to explore new fields and extand my knowledge and my competencies. Now, I want to contribute locally for the future of Textile with values of mutualism, altruism, care, circularity, local synergy & creativity.

-Photo:Focus on working table

-Photo:Focus on working table