W10. OPEN SOURCE HARDWARE¶

=>From Fibers to Fabric

After 10 weeks of Hardwork, let's jump into the infinite world of OpEN SOuRCEe HaRDWaRE.

CHECK LIST

-

->Research and document existing fabrication methods, machines and industries, add references, tutorials and sketches of the hardware you will make

-

->Document the process of designing the files for your machine/machine-hack/tool and its fabrication including the assembly process

-

->Document the schematic and the software source code

-

->Document the parts and how to make your tool or machine

-

->Document your BOM (Bill of materials): electronics, materials, their amount, etcetera (with references of the components)

-

->Upload your 3D model and CAM files (if any) Design, create and document a final outcome, a sample project of your process

-

->Make a small video of the machine

PIONEERS/OPEN SOURCE¶

1.KNITTING

Neuroknitting by Varvarag - VARVARAG

Open source digital knitting

Ecal low take factory

2.WEAVING

3.SPINNING MACHINE

4.EMBROIDERY

5.FIBER SPRAY

INSPIRATIONS¶

HELPFUL ALUMNI

MAKING WITH JULIE OUR OWN FIBER GUN¶

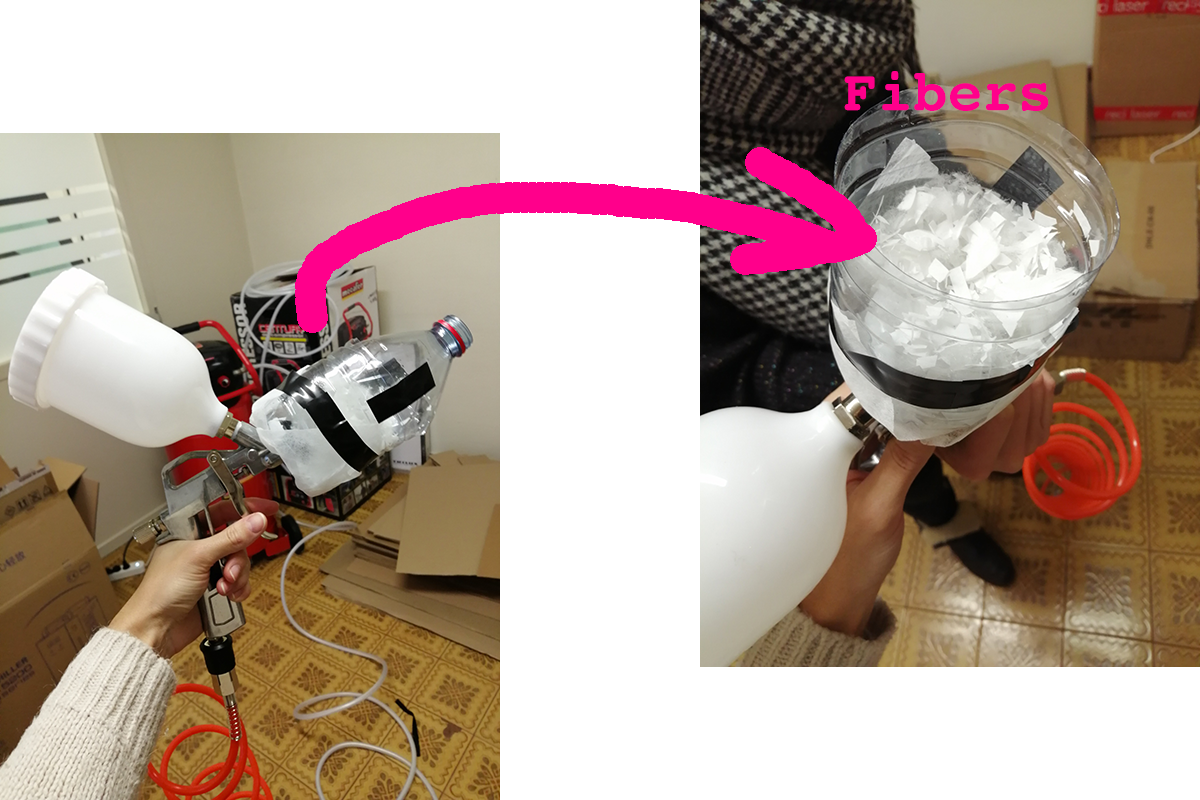

To start with, we tried to hybrid a compressed air gun with a plastic bottle. We added the plastic bottle to the air gun in order to spread fibers into textiles.

AIR TOOL MACHINE¶

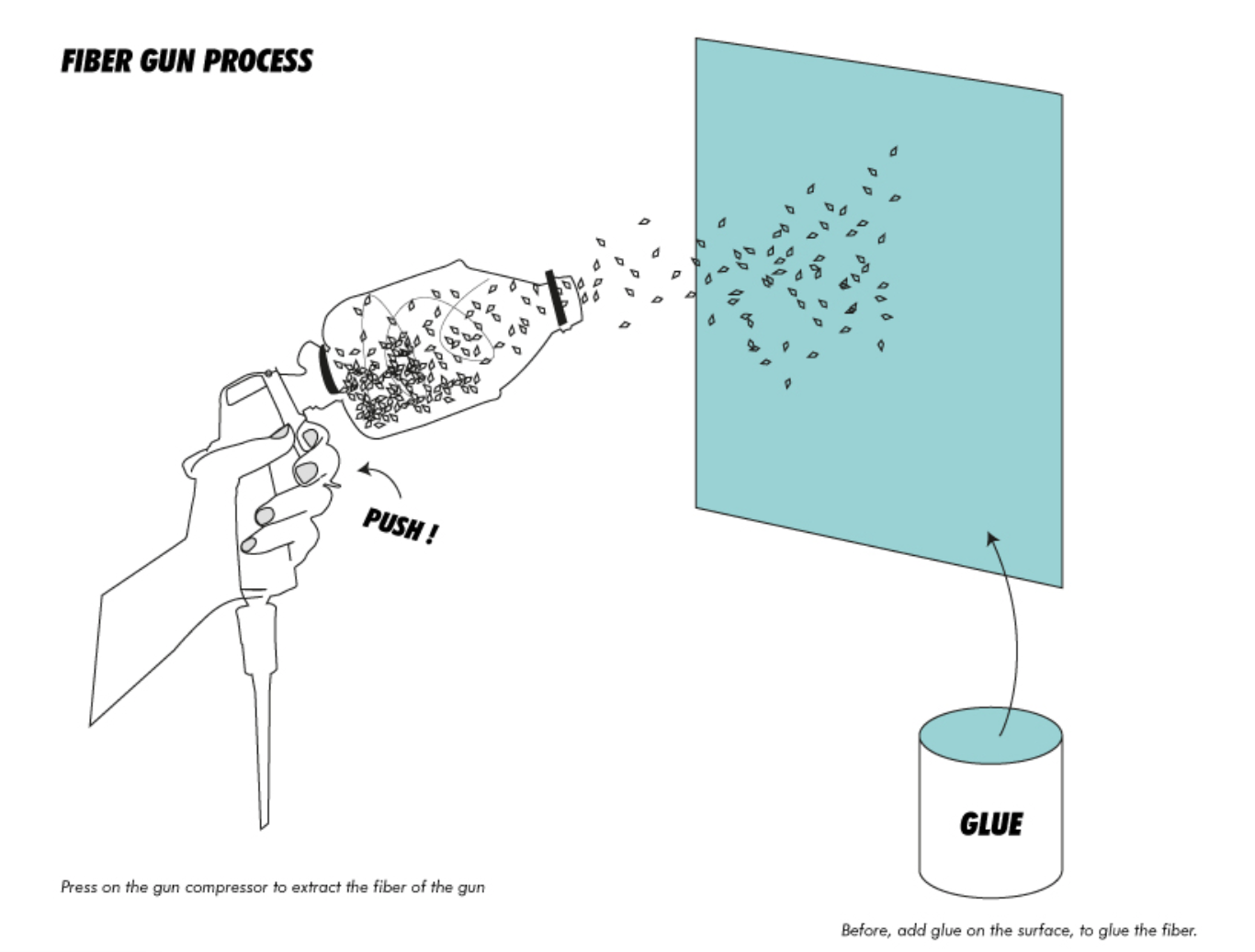

HOW TO TURN IT INTO A FIBER GUN?

Construction process

- Take a plastic bottle of 1,5L

- Cut it into 3 parts

- Only keep the head and bottom part of the bottle

- Make a hole into the bottom part of the bottle in order to connect with the air gun

- Stick it with a strong adhesive

- Put fibers

- Combine this part with the head of the bottle

- Stick it, you have your fiber gun ready :)

First, the compressed air gun + the dirty prototype allowed us to spread fibers: It worked, the hybridation operated.

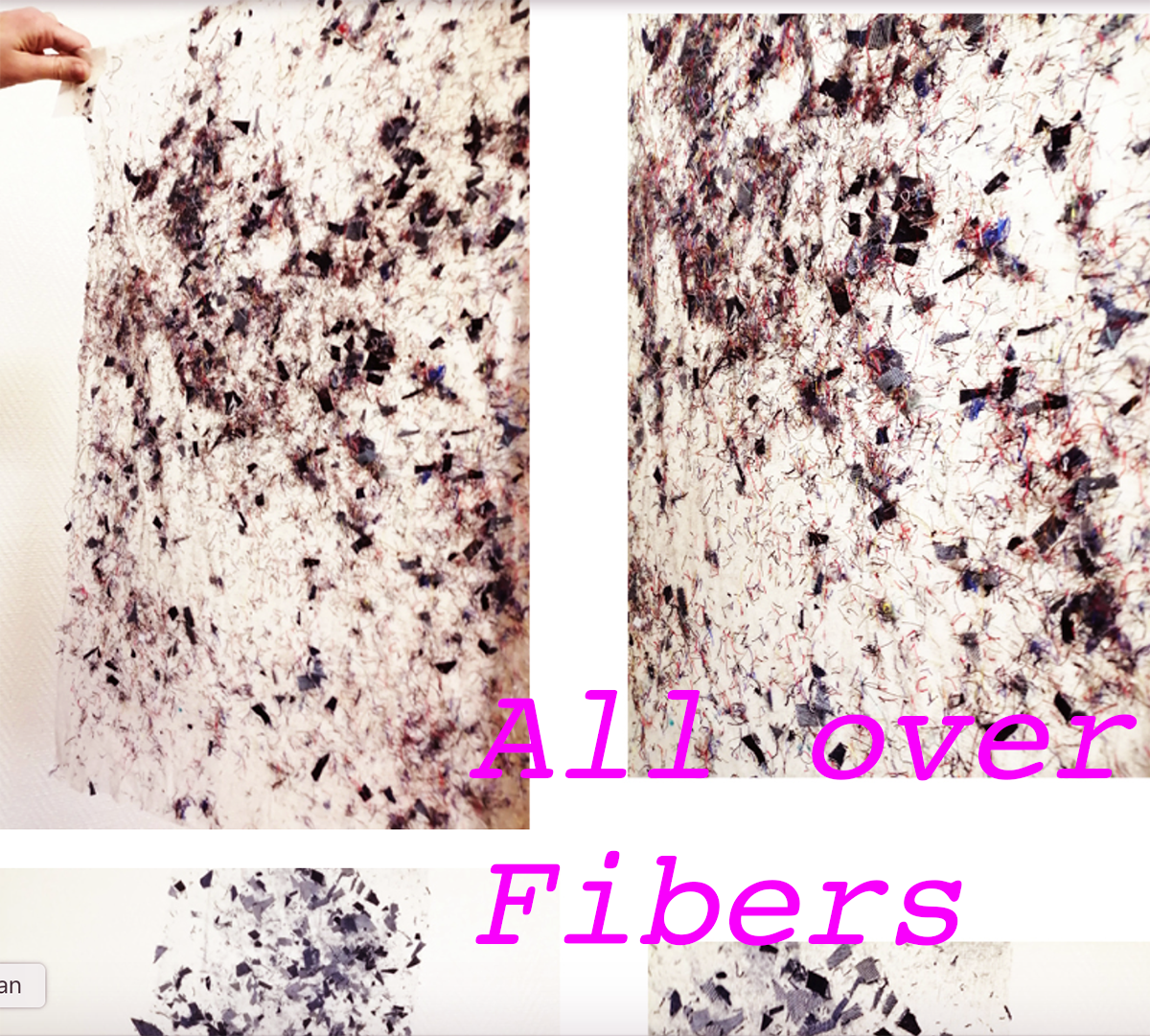

Then, we experimented with different type of fibers and glues to stick the fibers on textiles.

DIRTY PROTOTYPE/ Hybrid air cun compresseur¶

1ST TEST For the fisrt test we tried with synthetic fibers without any glue.

The next step would be to design and 3D print the dirty prototype.

The next step would be to design and 3D print the dirty prototype.

Second TEST¶

For this week we were focused on experimenting the dirty prototype.

For the second test we decided tu use Jeans leftover mixed with a natural glue made from Ethanol and resine.

-

-