9. Textile as scaffold¶

ASSIGNMENT WEEK8¶

- Document the concept, 3D model of the piece and document the design process

- Make two samples with 2 out of the 5 techniques to make a prototype of a textile form: fabric formwork with casting crystalization wood-textile resin-textile leather molding or other

- Document the process from CAD to CAMM, document how to use the CNC mill and prototype your textile composite Upload your 3D model and CAMM file

- Document the 2 processes you have followed step by side from design to machine and hands-on making, materials you used, your mistakes, failures and achievements

- Use 3D modeling software to simulate your fabric deformation

- For this assignment you will require to build up your tools (container for molding, vacuum bag set up, frames, matrix, recipients) and process for your workflow.

Christalization¶

The process to grow up a cristal is simple. you mix your material into water, you wait it creates cristals and die. You can make your cristals grow more by dipping them into the same die solution.

Some elements to make sure of : 1. Make sure that the bath temperature is at minimum 60 °C 2. dissolve the basic ingredients once 3. take your time 4. reuse the cristals with fabrics or tools to dip them and grow them more.

Alum christals¶

- H2O 75ML

- Alum 75G

- Temperature 60 degres

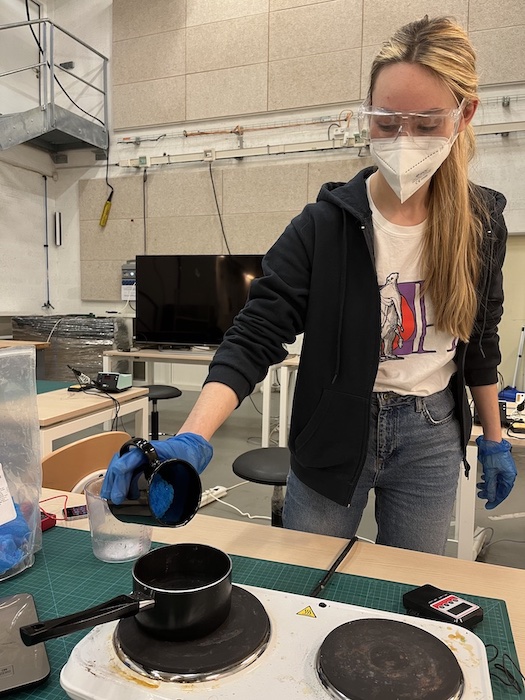

| Preparing the alum cristalization | Results couple days later |

|---|---|

|

|

Copper Cristals¶

- H2O 75ML

- Sulfate of copper pentahydrate 75G

- Temperature 60 degres

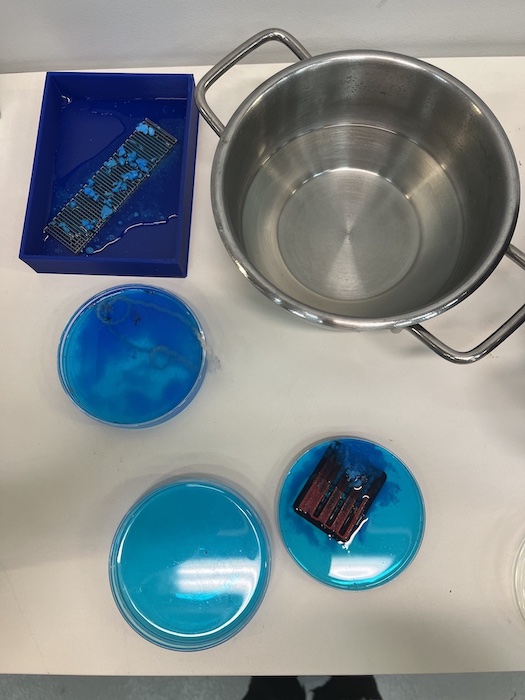

| Preparing the copper cristalization | Result |

|---|---|

|

|

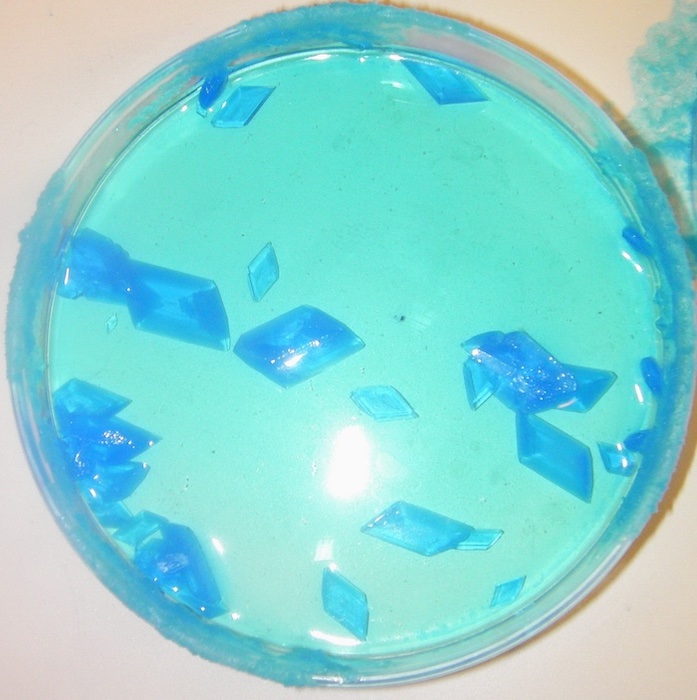

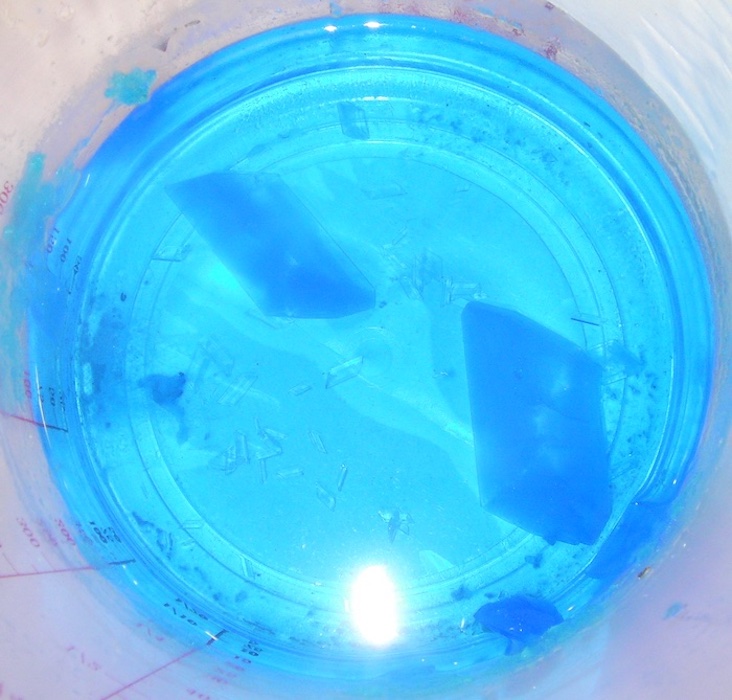

A couple days later the christals formed :

| Cristals of copper | Result |

|---|---|

|

|

3D Model of the piece¶

We are using 3 ideas : a clitoris model, the venus of Milo model and a model of our own body.

Milling the piece¶

Leather molding¶

resin-textile¶

Last update: 2021-12-17