10. Open source hardware¶

This week we worked on building an open source hardware spinning machine: Hilo.

Research¶

Open Source Hardware, (OSH) replicates the principles of copyleft in the physical world, elicits research interest as it relates to the triumph of Open Design and Digital Commons, a novel paradigm of production and consumption patterns. Digital Commons applied to manufacture, are believed to be the most radical, theoretical and organizational innovation to have emerged from the Internet.

Open Source Hardware Innovation is defined as a collaborative, product development process, in which building plan designs, assembly instructions and bills of material are made publicly available online for anyone to study, replicate, modify, distribute, and sell, including hardware based on those designs (Raasch et al., 2009; Bonvoisin et al., 2016; Bonvoisin et al., 2017). Thus, Open source hardware is characterized by knowledge sharing and decentralization enabled by modern information and communication technologies (ICT) (Moritz et al., 2016). Ideally, OSH uses readily-available components, materials and standard processes, maximizing the possibility for others to make and use the hardware.

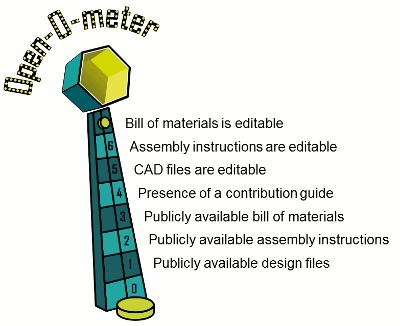

The OPEN! project initiated the Open Source Hardware Observatory as a means to showcase global OSH initiatives. They also developped the open-o-meter which assesses the openness level of a given innovation. This tool has been enhanced by the Danish Design Center to help companies build innovative business models.

- Danish Design Center Remodel Open Business Models

- Danish Design Center Remodel Open Business Models

Current open source projects in the textile sector. - Open Source Hardware Textile production It appears that there are already a numbered of looms, and knitting machines referenced on the Open Source Hardware Observatory.

Hilo¶

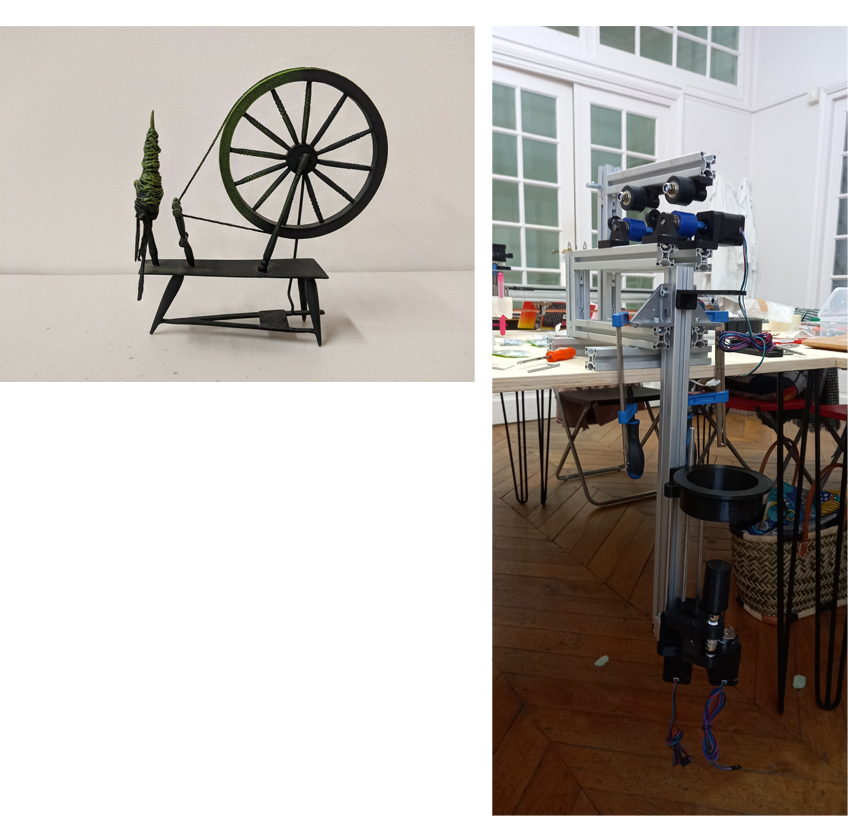

In our group in Oullins, we worked on building this incredible machine, a modern spinning wheel developped by Natalija Krasnoperova and Sara Diaz Rodriguez. - Hilo website

The open-source HILO Spinning Machine allows you to produce your own customized yarn. The open-source HILO Software helps you to design the yarn properties. You choose your raw fibres.

You can use the HILO Spinning Machine with software to spin small amounts of new fibres, such as recycled or regional materials. Existing yarns can be twisted into new designs and integrate new functions, such as elasticity through overtwist. Moreover, you can develop yarn samples and rapidly test different qualities for new business opportunities.

Assembly¶

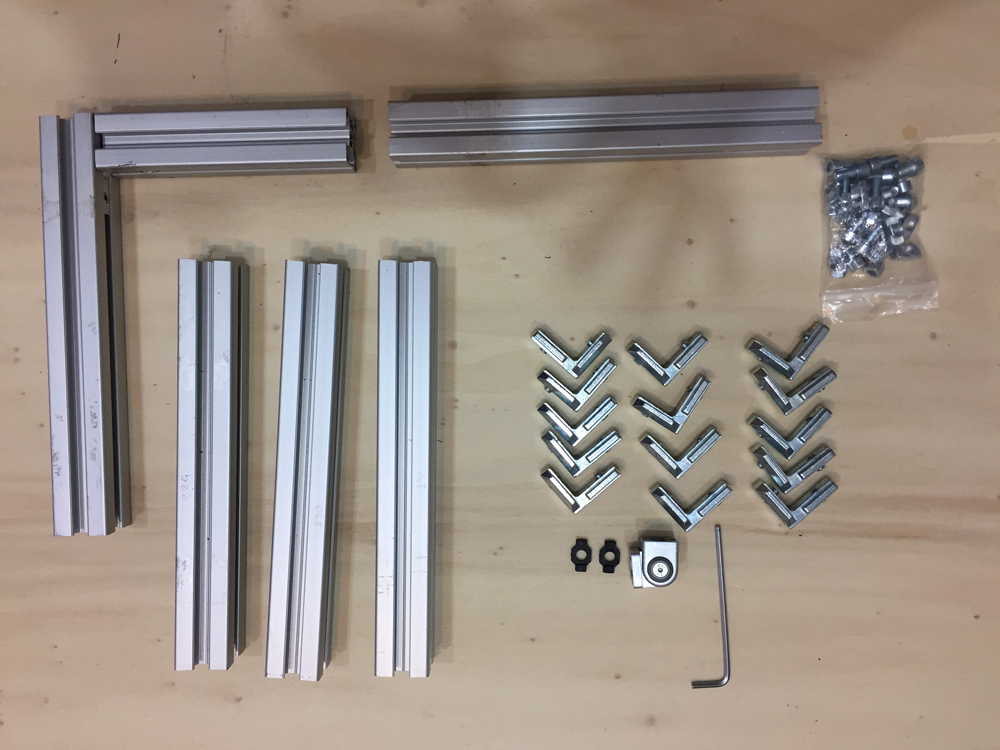

In true open source hardware form, the bill of materials, assembly instructions and schematics are documented. The process felt like working on a modern adaptation of Sleeping Beauty's spinning wheel.

- Hilo assembly instructions and parts

- Hilo assembly instructions and parts

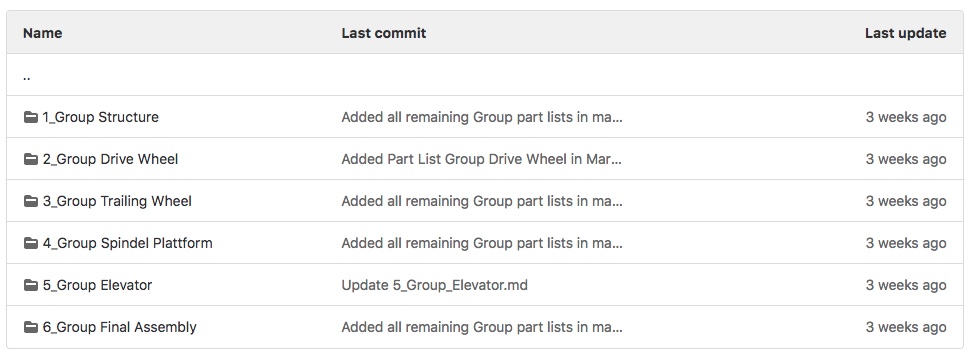

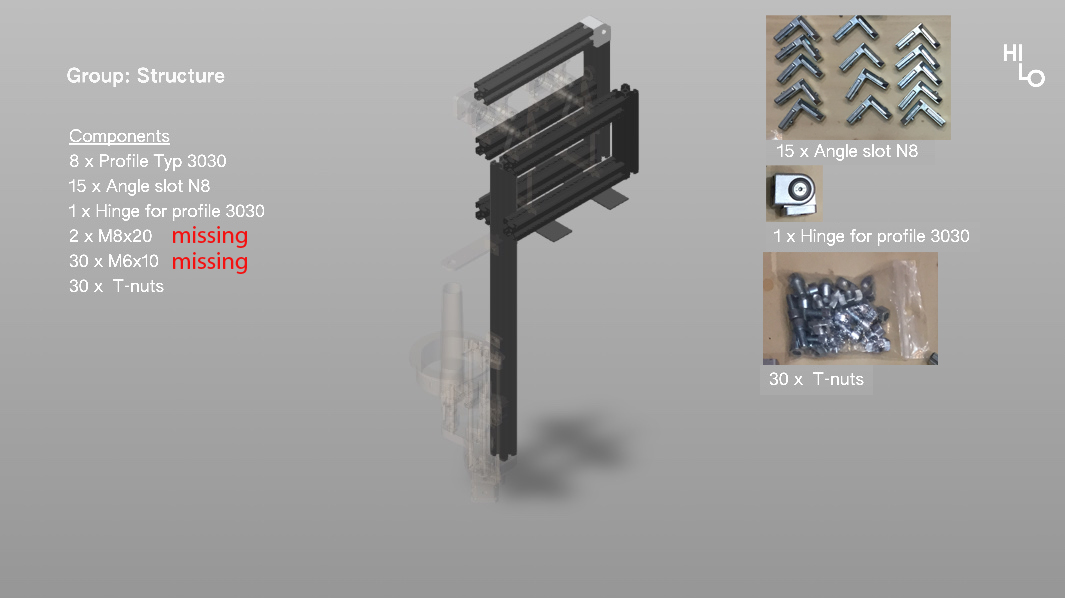

Although an elaborate list of parts exists, for each of the 6 stages, or groups, we still had missing parts for each stage. We were also utter beginners, therefore lego-like instructions with the drawings of each part and tool needed would have been useful.

Group 1: Structure¶

notes¶

on the documentation, it's written 4 profiles of 230mm but we actually needed 6 of them

on the 3D drawing, it looks like the structure holds on 2 metal plates but we fixed it on 2 profiles

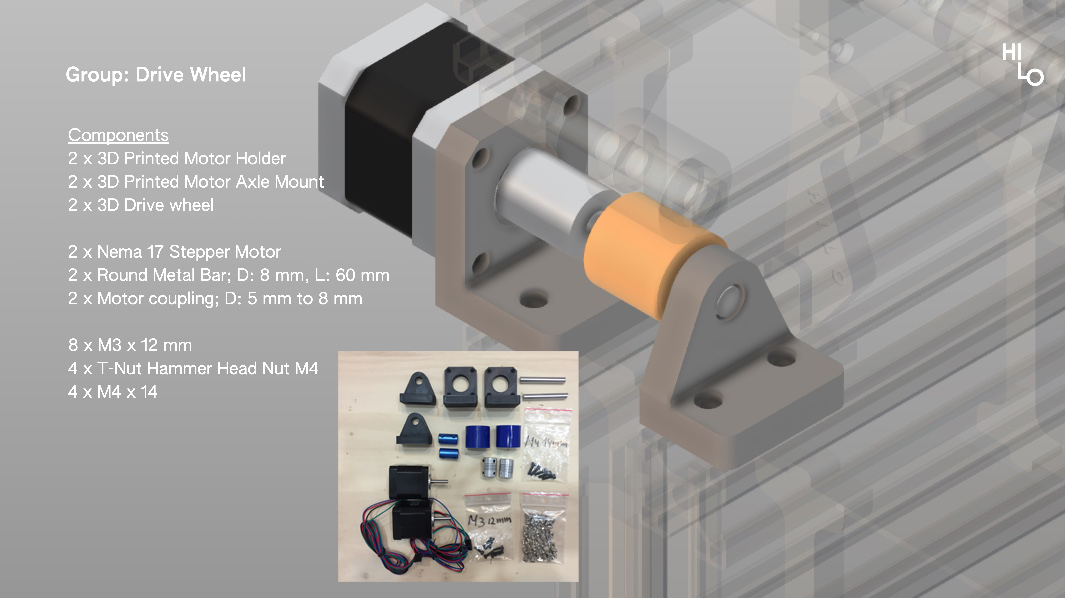

Group 2: Drive wheels (blue)¶

we glued the wheels on the metal bar with a basic liquid glue and it worked

more M3 12 screw needed than what we thought

on the slides, we had the impression that we needed a pierced rod to put in the motor rod. Actually, we used this blue tube (on the picture above) and it worked.

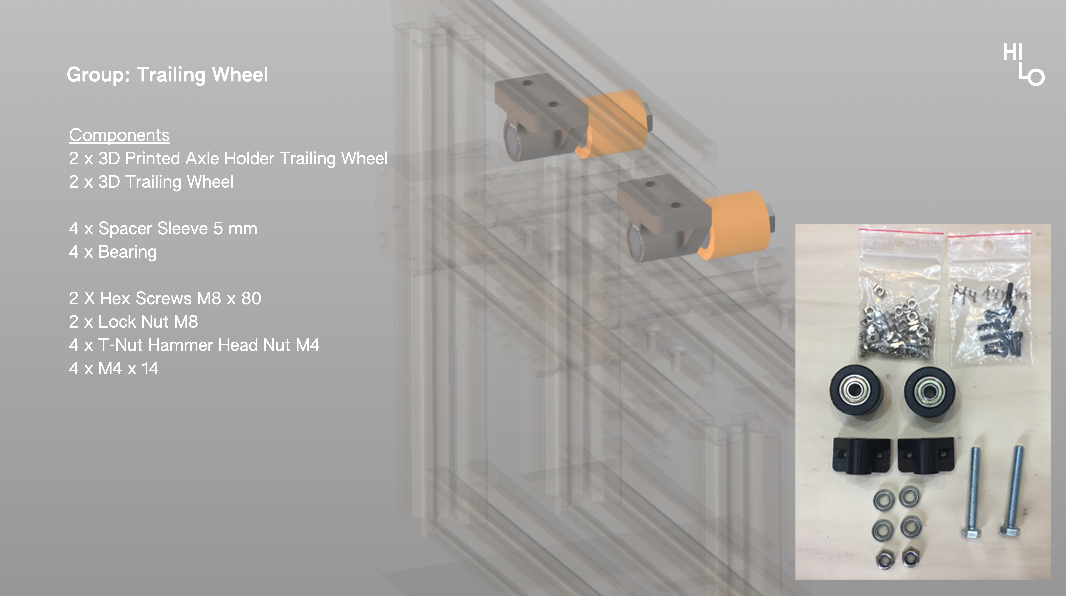

Group 3: Trailing wheels (black)¶

Group 4: Spindel platform¶

we didn't have the trapezoidal swrew but it's not needed to run the machine

we pushed the 9cm rod at the bottom of the hole

our GT2 pulley 20 teeth was to big so we had to put tape in it to fit the motor

the 3D printed holes for the M3 nuts were very very tiny, we had to dig inside with a srewdriver

one M3 30 screw was to big (the one which connect platform A to platform B), M3 20 would be better

on the last slide, we didn't know where to put the M3 10

we had to unbuild the spindel platform and make it again because we forgot the belt pulley, it's not on the documentation slides