4. BioChromes¶

This week was super fun, full of inspiration and a lot about deepening my knowledges about colors, pigments making and natural dyeing. I had already experimented fabric dyeing and botanical printing, but not with the modifiers and pigments making. Unfortunally I couldn't work with the bacterial dyeing, but I'm loking foward to do it someday as I am very much interested in this shared processes.

Inspirations¶

Some of mine inspirations for the week and about color making and discovering in general are:

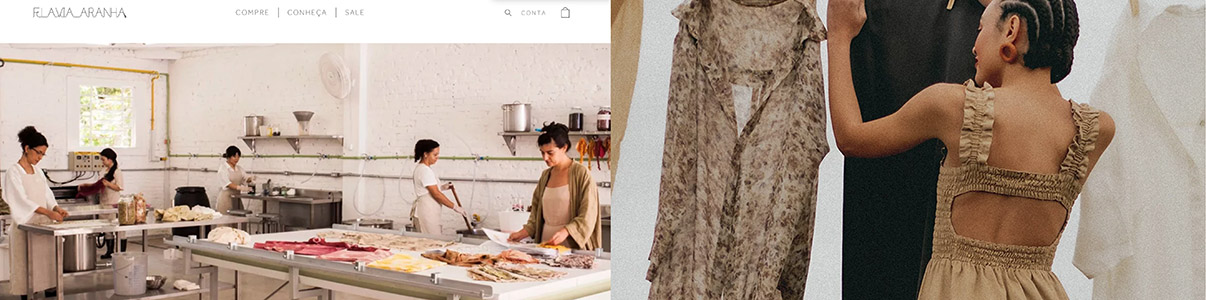

Flávia Aranha - a fashion designer that I had the pleasure of being part of a workshop about botanical printing.

Pictures from Flávia Aranha's website

Pictures from Flávia Aranha's website

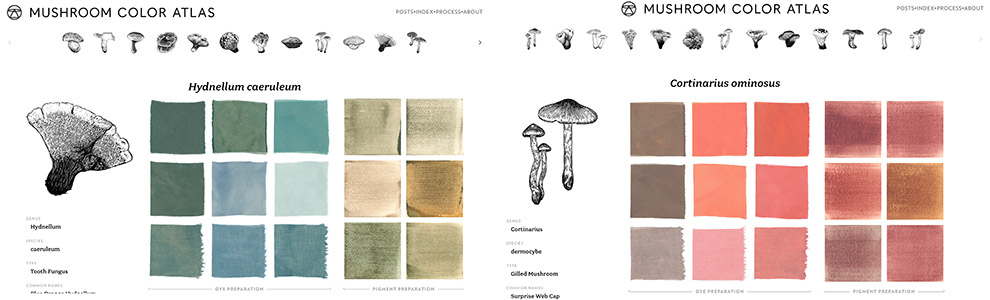

I also got really interested and curious about the mushroom colors and how there might be so much still to be discovered about this pigments from fungi. I felt like going out and mushroom picking for trying fungus colors from the Atlantic Forest. I'll definitely do it.

These are two websites for checking and researching mushroom colors :

Pictures from mushroom color atlas website

Pictures from mushroom color atlas website

The project Air Ink is also a great inspiration for me. They capture and transform air pollution into ink.

Pictures from Air ink website

Pictures from Air ink website

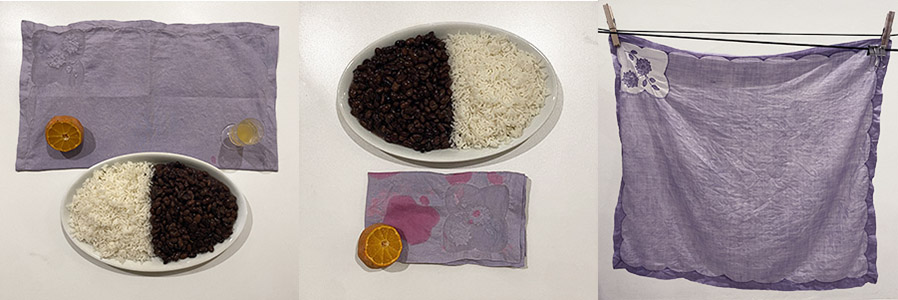

Grandma's beans¶

The idea of this project was to put together some cultural practices and familiar intimacies and discover together with the materials choosen some new colors and alchemical paterns. The fibers choosen was linnen - my grandparents wedding napkings - and cotton. And the color source was from the typical (almost) everyday brazilian dish: black beans - the leftover water from the soaked beans.

Process - dyeing bath¶

The first thing I did was to put the beans to soak. The longer it stays in the water, the stronger (more concentrated) will be the tint. 24H is enouth. Then you can separate the beans from the water. Cook the beans and use the black-blueich water to dye fabrics and make pigments.

Black beans recipe

- 500g of beans

- Cook the beans with water (enought for covering the beans plus 2 fingers), salt and 5 bayleafs on a pressure cooker for 25-30min (after pressurized)

- Fry some of the cooked beans with garlic (a lot! like 8 cloves) and a bit of the water from the pan, smash it until it's creamy

- Add this creamy smashed beans to the rest of the beans in the pan and stir it up

- Ready to eat! You can add pepper and experiment with other spices too

Ok, back to the Biochromes!

The next step was to prepare the fibers. For this, I first cleaned it in a Sodium Carbonate (Na2CO3) boiling bath for more or less 1h. The amount was +-2 tbsp. of Sodium Carbonate for 4,5 liters of water. If you don't have Sodium Carbonate, you can transform Sodium Bicarbonate that is easyest to find into Sodium carbonate by boiling it until there is no water.

Then you added 10-15% of the weight of the fibers of Alum (Potassium alum) in warm water, dissolve the Alum and then add the dryed and rinsed fabrics from the previous bath. This step gives brightness to the colour in the fabric. Always remember to weight everything. Is very easy to forget when you're involved in the process.

In between the Na2CO3 and the Alum, there is the Tanin bath, that helps to fix the colors, I couldn't find tanin around so I skipped that step.

The next step was to let it dry and cut it into the pieces I wanted to experiment with.

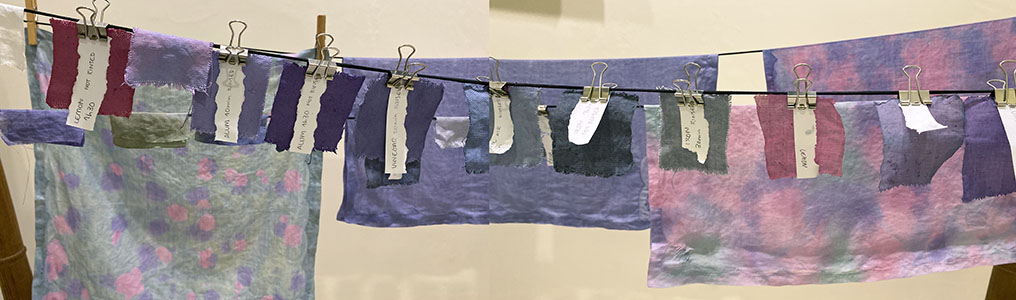

For me the most amazing part was the experimentations with the modifiers and to observe the colours changing in accordance to the ph, time, airflow, etc. I got realy impressed by the amount of colours you can get from only one pigment source. At that moment, before I started with the modifiers, I was planning to experiment with other things such as onion peels, clay and mushrooms, but as soon as I realized the colorfullness of the beans I decided to focus in that and play with the possibilities that it offers.

These are some of the modifiers tested: Lemon, Vinegar, Alum, Iron and Soda (Na2CO3):

Alum - Potassium alum

Iron - Irony water solution (with old nails)

Control - beans-water kept in a closed jar

12g fibers (linnen) - 190g 100% concentrated black-bean-water

Lemon

12g fibers (linnen) - 160g 60% concentrated black-bean-water + 40% lemon juice Acidic

Soda - Sodium Carbonate (Na2CO3)

22g fibers (linnen) - 160g concentrated black-bean-water + 4g Soda Alkaline

Modifiers and colors in the Linnen fiber:

Some curiosities along the way:

- The color of the beans-water kept in a closed jar is different from the one that stayed 1h with the jar opened

- mostly every color in the dyeing baths changes after 24h

The different results from the dying bath processes can be seen here:

In Ceci's class we saw that the soy beans are good for post-treatment, softness, shine of the dyed fabric. As rice is the perfect combination for black beans and I was preparing it anyways, I did a quick research about the white rice and fabrics and this was what I found:

"The application of rice starch to fabric smooths and crisps the surface while increasing the fabrics ability to resist wrinkling. The treated fabric feels cool, smooth and has a high sheen on the surface. The rice starch also provides a barrier to stains that might penetrate the cotton fabric thus making it easier to remove any stains that would attract bacteria, fungi and insects."

Quote from Live rice website

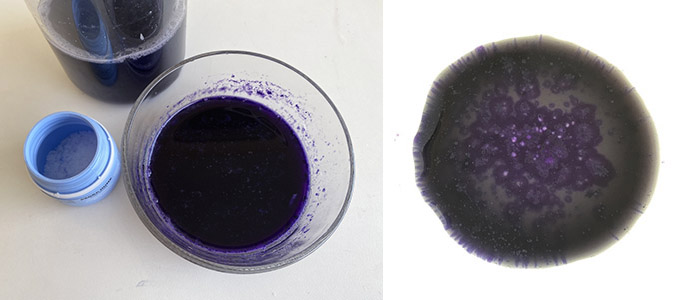

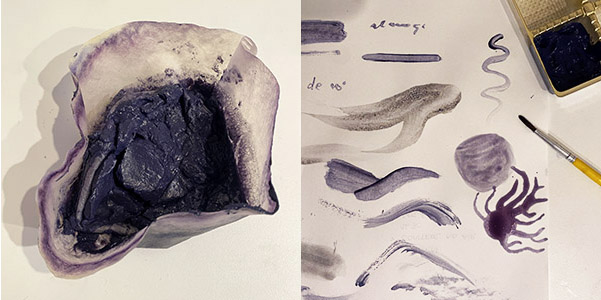

Process - ink / pigment¶

This was the hardest part for me. I first tryed with the leftover from the lemon + beans dyieng bath and it didn't worked. Then I tryed with the control sample - just water from the soaked black beans. It is very important in this step to use the right amount of Na2CO3 and Alum from the class recipes.

2 parts Alum (acidic) - 1 part Na2CO3 (alkaline)

Black bean pigment

* 200ml black-bean-water in a tall jar

* 10g Alum in 120g warm water

* 5g Soda (Na2CO3) in 100g warm water

* Add the Alum to the black-bean-water

* Slowly add the Soda into the mixture

* Let it rest - it will separate the parts

* Leach it with a coffee filter

* Let it dry

* Grind the pigment into a powder

Results¶

For the project presentatios I choosed to make some paterns with the modifiers. Here are the results:

A very interesting thing I observed is that even after dried, the napkins still react with the Ph change and this could be an opportunity for experimenting with the interective material. In the images bellow, I tested the napkin with lemon (acidic) simulating a meal moment where someone cleans the mouth or pours lemon juice in the napkin, creating different paterns and warning that the substance is acidic. When washed while still wet, the color of the napkin goes back to homogeneous (I thing it changes a little bit of the color after, like rebalancing the Ph of the hole napkin color).

Conclusion, wishes, doubts, etc

- wish to experiment more with how modify the pigments

- play with the changing Ph interactiveness

- try clay dyeing and pigments

- try making watercolor palletes

- try to make natural makeup