12. Soft robotics¶

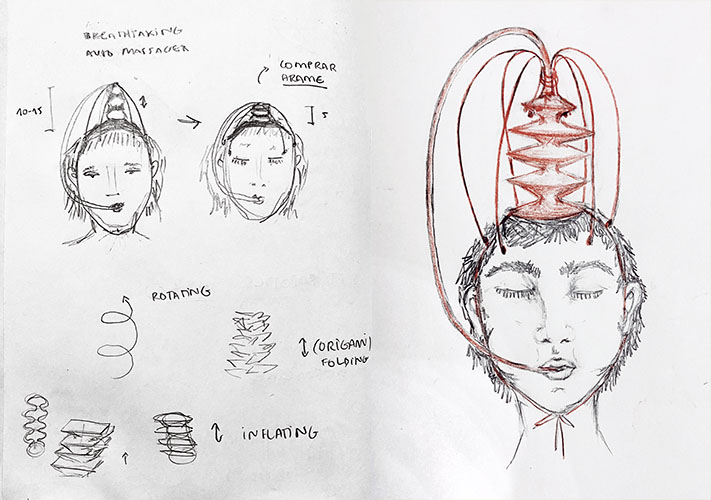

For this week’s assignments I decided to experiment with the inflatables and soft robots possibilities in a joyful way. I remembered this gadget to massage the head that is really amazing and decided to change it a little bit. Normally you massage yourself with one hand or someone can do it for you. My propose is to make it move (up and down) without using the hands. It could be for accessibility or used while your hands are busy with other things. From that I had two options. Make it automatic, with motors and air pumps or make it inflatable through blowing air from the lungs. I chose the 2nd option because of the time I had to do it and also because its interesting that it moves through breathing. Expire and Inspire. It makes sense conceptually if we’re talking about a selfcaring, selfpleasurable, and selfcalming gadget. Breathe deeply and get massaged in return. I named it Breathtaking automassager.

Pictures by amazon and shopee websites

Pictures by amazon and shopee websites

Drawings by Clara Acioli

Drawings by Clara Acioli

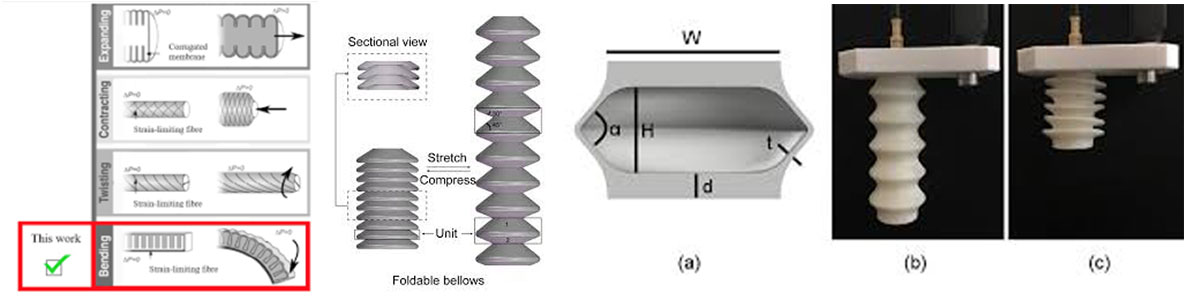

My references for this week were the presentations and tutorials. I loved the work from Lily Chambers that is thinking in a 100% biodegradable soft robots, experimenting materials. Also the work from Joo Young Park that is proposing the aproximação with robots and machines through the soft robots in the woman’s health context. The references that I searched outside the classes were more technical, on how to make a extendable actuator in linear direction. These were some images I found that helped me think about what I should do to make mine work.

Pictures by articles in the internet: 1; 2; 3

Pictures by articles in the internet: 1; 2; 3

Processes with silicon¶

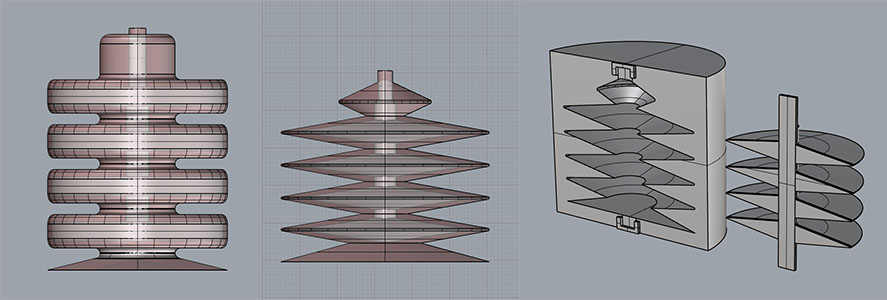

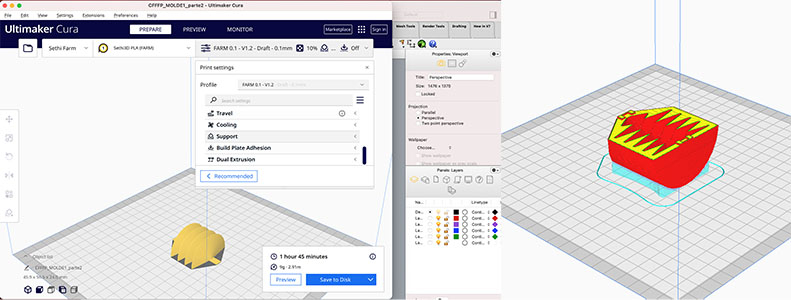

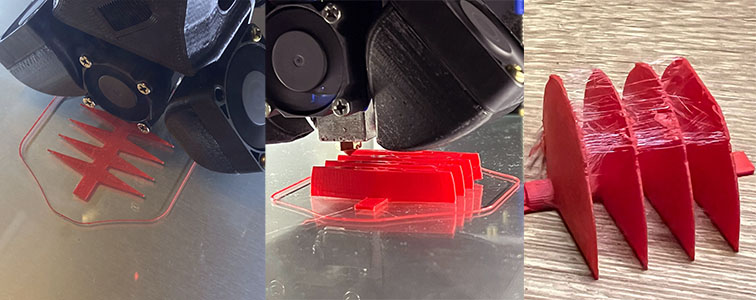

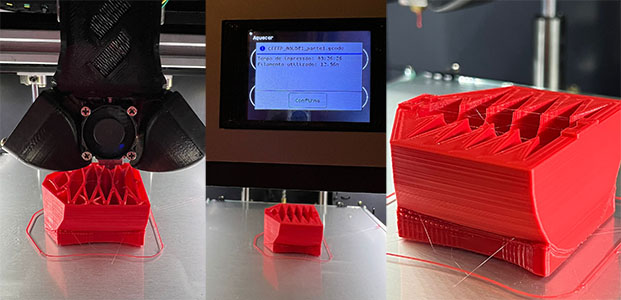

I wanted to experiment with the silicon that Angela have in the lab (semicristal…) and also with the thermoadhesive vinil, that I could buy for the tutorial. (Also with the biomaterials but I knew I had no time fro that..). I started with the silicon because it takes a long time to dry and I knew I needed some stages of doing and drying. The first step was to think about the design and 3d model it so I could make the mold. I modeled the mold on Rhino and 3D printed it with PLA. It took 2h to print it in the SETHI3D printer. We used Ultimaker cura software for doing the G-code.

Screenshots by Clara Acioli

Screenshots by Clara Acioli

Screenshots by Clara Acioli

Screenshots by Clara Acioli

Pictures by Ângela Babour

Pictures by Ângela Babour

Pictures by Ângela Babour

Pictures by Ângela Babour

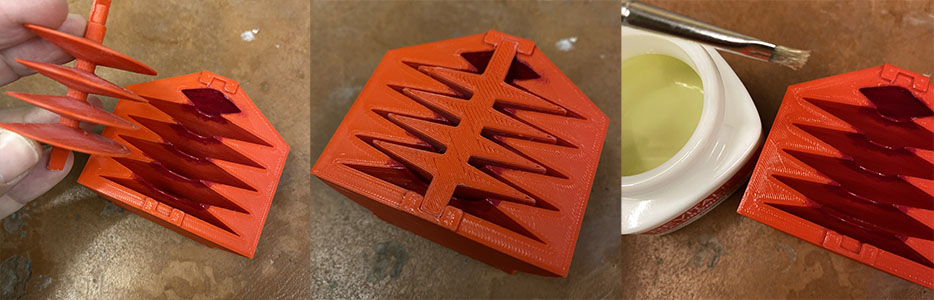

The printing was a success but for casting silicone, that is very delicate and marks all the details, I had to finish it with sandpaper and nail polish.

Pictures by Clara Acioli and Ângela Babour

Pictures by Clara Acioli and Ângela Babour

For using the silicon, we have to mix part A with part B (catalizator?) in equal amounts taking a lot of care for not contaminating one with the other. One important step is isolating the mold from the silicone and for that we used oil (soy oil).

Pictures by Clara Acioli

Pictures by Clara Acioli

![]() Pictures by Clara Acioli and Ângela Babour

Pictures by Clara Acioli and Ângela Babour

![]() Pictures by Ângela Babour

Pictures by Ângela Babour

![]() Pictures by Clara Acioli

Pictures by Clara Acioli

![]() Pictures by Clara Acioli

Pictures by Clara Acioli

![]() Pictures by Clara Acioli

Pictures by Clara Acioli

Extra mold with the silicon leftovers:

![]() Pictures by Clara Acioli

Pictures by Clara Acioli

![]() Pictures by Clara Acioli

Pictures by Clara Acioli

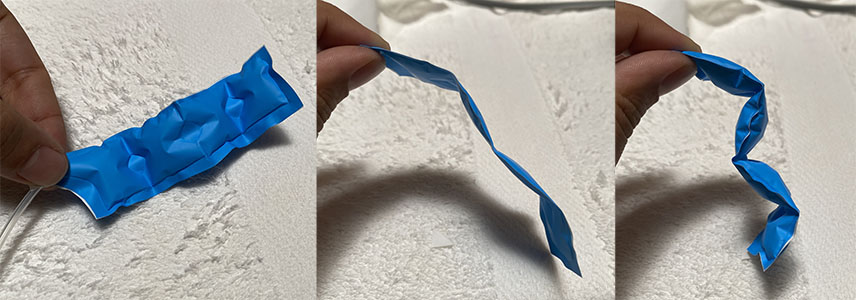

Experiments with the thermoadhesive vinil:¶

1st trial went wrong, I tried with only one layer of butterpaper but it sticked in the vinil. It is important to have 2 layers of butterpaper.

Pictures by Clara Acioli

Pictures by Clara Acioli

Then I decided to make an simpler exercise, to see how the material works, and this was the result:

Pictures by Clara Acioli

Pictures by Clara Acioli

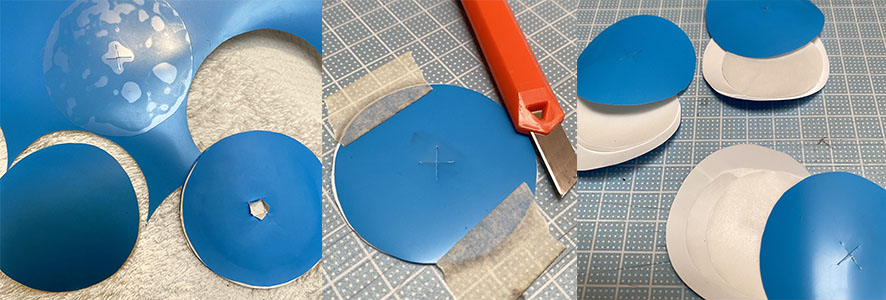

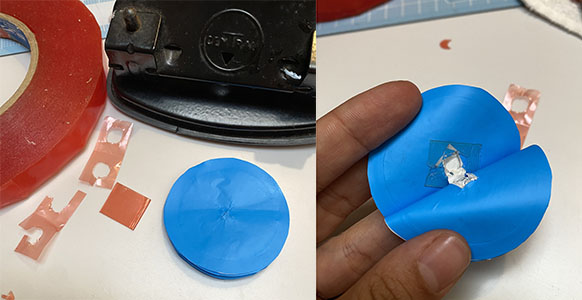

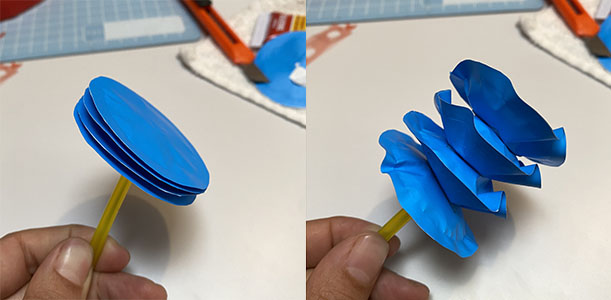

After making the previous one works, I went back to my chalange to make the vinil extend in a linear direction:

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Assembling processes¶

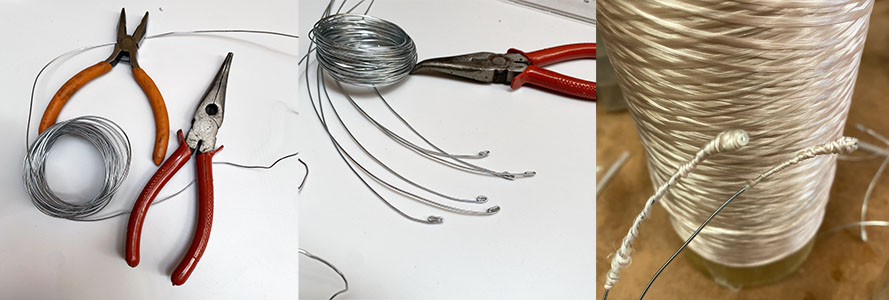

Making the legs of the massager:

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

Pictures by Clara Acioli

conclusions¶

After presenting and receiving feedbacks from Lily and Adriana Cabrera. The silicon is very soft so the shape can be different: It could have a bigger base and grow smaller towards the top, so it would be more stable. Tips from Lily Chambers: look at biomimetics, the bones that gives structure, were the fluids flow in the body? Also for my project look at insects legs. For holding the wires, mix with 3d printed part? Also for stability and resistance.